Wear Enhancement of Wheel-Rail Interaction by Ultrasonic Nanocrystalline Surface Modification Technique

Abstract

:1. Introduction

2. Materials and Methods

2.1. Specimen Preparation

2.2. UNSM Treatment Process

2.3. Rolling Contact Wear and Rolling Contact Fatigue Tests

2.4. Specimen Analysis and Measurement Details

3. Results

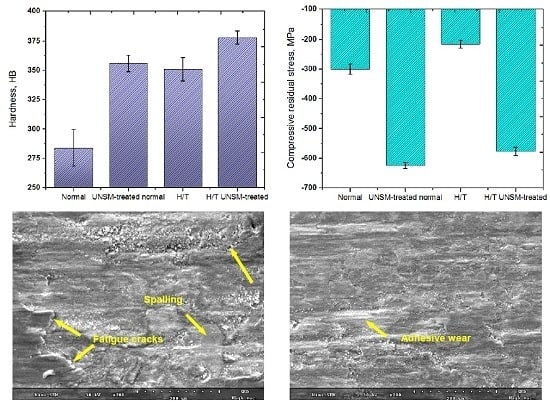

3.1. Hardness and Compressive Residual Stress

3.2. RCW and RCF properties

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Lewis, R.; Olofsson, U. Fatigue of railway wheels. In Wheel-Rail Interface Handbook; Elsevier: Amsterdam, The Netherlands, 2009; pp. 211–244. [Google Scholar]

- SKF Group. Railway Technical Handbook; SKF: Gothenburg, Sweden, 2012; pp. 25–35. [Google Scholar]

- Loubinoux, J.P. Energy consumption and CO2 emission. In Railway Handbook 2015; International Energy Agency: Paris, France, 2015; pp. 27–29. [Google Scholar]

- Iwnicki, S. Wheel-rail contact. In Handbook of Railway Vehicle Dynamics; Taylor & Francis Group: Boca Raton, FL, USA, 2006; pp. 85–121. [Google Scholar]

- Cao, X.; Huang, X.L.; He, G.G.; Peng, J.F.; Guo, J.; Wang, W.J.; Liu, Q.Y.; Zhu, M.H. The effect of alumina particle on improving adhesion and wear damage of wheel/rail under wet conditions. Wear 2016, 348–349, 98–115. [Google Scholar] [CrossRef]

- Gaurdy, M.; Lapeyre, B.; Quinet, E. Infrastructure maintenance, regeneration and service quality economics: A rail example. Transport. Res. Part B Methodol. 2016, 86, 181–210. [Google Scholar]

- Marich, S.; Curcio, P. Development of high strength alloyed rail steels suitable for heavy duty applications. In Rail Steels—Developments, Processing and Use; ASTM International: West Conshohocken, PA, USA, 1978. [Google Scholar]

- Benson, M. Effect of differential hardness on wheel/rail wear literature review. Br. Rail Res. Rep. LR MT 1993, 6, 2–3. [Google Scholar]

- Brunel, J.-F.; Charkaluk, E.; Dufrenoy, P.; Demilly, F. Rolling contact fatigue of railways wheels: Influence of steel grade and sliding conditions. Procedia Eng. 2010, 2, 2161–2169. [Google Scholar] [CrossRef]

- Sharma, S.; Sangal, S.; Mondal, K. Wear behavior of bainitic rail and wheel steels. Mater. Sci. Technol. 2015, 32, 266–274. [Google Scholar] [CrossRef]

- Zeng, D.; Lu, L.; Li, Z.; Zhang, J.; Jin, Z.; Zhu, M. Influence of laser dispersed treatment on rolling contact wear and fatigue behavior of railway wheel steel. Mater. Des. 2014, 54, 137–143. [Google Scholar] [CrossRef]

- Wang, W.J.; Lewis, R.; Yang, B.; Guo, L.C.; Liu, Q.Y.; Zhu, M.H. Wear and damage transitions of wheel and rail materials under various contact conditions. Wear 2016, 362, 146–152. [Google Scholar] [CrossRef]

- Kapoor, A.; Fletcher, D.I.; Schmid, F.; Sawley, K.J.; Ishida, M. Tribology of rail transport. In Modern Tribology Handbook; CRC Press: Boca Raton, FL, USA, 2000; pp. 1271–1325. [Google Scholar]

- Molyneux-Berry, P.; Davis, C.; Bevan, A. The influence of wheel/rail contact conditions on the microstructure and hardness of railway wheels. The Sci. World J. 2014, 2014, 209752. [Google Scholar] [CrossRef]

- Wang, W.J.; Liu, Q.Y.; Zhu, M.H. Hardness matching behavior of wheel/rail materials. Tribology 2013, 33, 65–69. [Google Scholar]

- Information on SAMPYO E&C. Available online: http://www.sampyoenc.com/ (accessed on 25 November 2016).

- Schulze, B.; Bleicher, F.; Groche, P.; Guo, Y.B.; Pyun, Y.S. Surface modification by machine hammer peening and burnishing. CIRP Ann.-Manuf. Technol. 2016, 65, 809–832. [Google Scholar] [CrossRef]

- Amanov, A.; Pyun, Y.S.; Sasaki, S. Effect of ultrasonic nanocrystalline surface modification (UNSM) technique on the tribological behavior of sintered Cu-based alloy. Tribol. Int. 2014, 72, 187–197. [Google Scholar] [CrossRef]

- Amanov, A.; Cho, I.S.; Park, I.G.; Pyun, Y.S. The migration of spheroidal cementite towards the surface in nanostructured AISI 52100 steel. Mater. Lett. 2016, 174, 142–145. [Google Scholar] [CrossRef]

- Chang, S.; Amanov, A.; Pyun, Y.S. Wear and chattering characteristics of rail materials by ultrasonic nanocrystalline surface modification. Int. J. Precis. Eng. Manuf. 2015, 16, 2403–2410. [Google Scholar] [CrossRef]

- Telliskivi, T.; Olofsson, U. Wheel-rail wear simulation. Wear 2004, 257, 1145–1153. [Google Scholar] [CrossRef]

- Taha, A.S.; Hammad, F.H. Application of the Hall-Petch relation to microhardness measurements on Al, Cu, Al-MD 105, and Al-Cu alloys. Appl. Mater. Sci. 1990, 119, 455–462. [Google Scholar] [CrossRef]

- Lewis, R.; Wang, W.J.; Burstow, M.; Lewis, S.R. Investigation of the influence of rail hardness on the wear of rail and wheel materials under dry condtions. In Proceedings of the Third International Conference on Railway Technology: Research, Development and Maintenance, Cagliari, Italy, 5 April 2016.

- Patterson, A.L. The Scherrer formula for X-ray particle size determination. Phys. Rev. 1939, 56, 978–982. [Google Scholar] [CrossRef]

- Lindenmeyer, P.H.; Hosemann, R. Application of theory of paracrystals to the crystal structure analysis of polyacrylonitrile. J. Appl. Phys. 1963, 34, 42–45. [Google Scholar] [CrossRef]

- Amanov, A.; Cho, I.S.; Kim, D.E.; Pyun, Y.S. Fretting wear and friction reduction of CP titanium and Ti-6Al-4V alloy by ultrasonic nanocrystalline surface modification. Surf. Coat. Technol. 2012, 207, 135–142. [Google Scholar] [CrossRef]

- Ahn, D.G.; Amanov, A.; Cho, I.S.; Shin, K.S.; Pyun, Y.S.; Lee, C.S.; Park, I.G. Gigacycle fatigue behavior by ultrasonic nanocrystalline surface modification. J. Nanosci. Nanotechnol. 2012, 12, 5902–5906. [Google Scholar] [CrossRef] [PubMed]

- Amanov, A.; Cho, I.S.; Pyun, Y.S. Microstructural evolution and surface properties of nanostructured Cu-based alloy by ultrasonic nanocrystalline surface modification technique. Appl. Surf. Sci. 2016, 388, 185–195. [Google Scholar] [CrossRef]

- Galas, R.; Omasta, M.; Krupka, I.; Hartl, M. Laboratoty investigation of ability of oil-based friction modifiers to control adhesion at wheel-rail interface. Wear 2016, 368, 230–238. [Google Scholar] [CrossRef]

- Chen, H.; Ishida, M.; Namura, A.; Baek, K.S.; Nakahara, T.; Leban, B.; Pau, M. Estimation of wheel/rail adhesion coefficient under wet condition with measured boundary friction coefficient and real contact area. Wear 2011, 271, 32–39. [Google Scholar] [CrossRef]

- Ding, H.H.; Fu, Z.K.; Wang, W.J.; Guo, J.; Liu, Q.Y.; Zhu, M.H. Investigation on the effect of rotational speed on rolling wear and damage behaviors of wheel/rail materials. Wear 2015, 330, 563–570. [Google Scholar] [CrossRef]

- Nejad, R.M.; Shariati, M.; Farhangdoost, Kh. Effect of wear on rolling contact fatigue crack growth in rails. Tribol. Int. 2016, 94, 118–125. [Google Scholar] [CrossRef]

- Hanaki, T.; Hayashi, Y.; Akebono, H.; Kato, M.; Sugeta, A. Effect of compression residual stress on fatigue properties of stainless cast steel. Procedia Struct. Integr. 2016, 2, 314–3149. [Google Scholar] [CrossRef]

- Sasaki, T.; Takahashi, Sh.; Kanematsu, Y.; Satoh, Y.; Iwafuchi, K.; Ishida, M.; Morii, Y. Measurement of compressive residual stresses in rails by neutron diffraction. Wear 2008, 265, 1402–1407. [Google Scholar] [CrossRef]

- Burstow, M. Wheel/rail hardness and total “system” wear. Vehicle/Track Sys. Interf. Commit. 2012, 1, 1–4. [Google Scholar]

- Lewis, S.R.; Lewis, R.; Fletcher, D.I. Assessment of laser cladding as an option for repairing/enhancing rails. Wear 2015, 330, 581–591. [Google Scholar] [CrossRef]

| Rails | C | Si | Mn | P | S | Fe |

|---|---|---|---|---|---|---|

| Normal | 0.72 | 0.34 | 0.80 | 0.025 | 0.025 | Balance |

| Heat-treated | 0.80 | 0.35 | 1.00 | 0.030 | 0.020 |

| Frequency, kHz | Amplitude, µm | Speed, mm/min | Impact Load, N | Feed-Rate, mm | Ball Diameter, mm | Ball Material |

|---|---|---|---|---|---|---|

| 20 | 30 | 3000 | 40 | 0.07 | 2.38 | WC |

| Load, N | Rolling Speed, rpm | Rolling Time, h | Condition |

|---|---|---|---|

| 50 | 500 | 1 | dry |

| 1000 | |||

| 1500 |

| Contact Stress, GPa | Rolling Time, h | Rolling Speed, rpm | Condition |

|---|---|---|---|

| 2.5 | 12, 24 | 1000 | dry |

| 3.0 |

| Contact Stress, GPa | Cycles to Failure | |

|---|---|---|

| Normal | Normal UNSM-Treated | |

| 2.5 | 478,000 | 669,000 |

| 3.0 | 416,000 | 651,000 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license ( http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chang, S.; Pyun, Y.-S.; Amanov, A. Wear Enhancement of Wheel-Rail Interaction by Ultrasonic Nanocrystalline Surface Modification Technique. Materials 2017, 10, 188. https://doi.org/10.3390/ma10020188

Chang S, Pyun Y-S, Amanov A. Wear Enhancement of Wheel-Rail Interaction by Ultrasonic Nanocrystalline Surface Modification Technique. Materials. 2017; 10(2):188. https://doi.org/10.3390/ma10020188

Chicago/Turabian StyleChang, Seky, Young-Sik Pyun, and Auezhan Amanov. 2017. "Wear Enhancement of Wheel-Rail Interaction by Ultrasonic Nanocrystalline Surface Modification Technique" Materials 10, no. 2: 188. https://doi.org/10.3390/ma10020188

APA StyleChang, S., Pyun, Y. -S., & Amanov, A. (2017). Wear Enhancement of Wheel-Rail Interaction by Ultrasonic Nanocrystalline Surface Modification Technique. Materials, 10(2), 188. https://doi.org/10.3390/ma10020188