Tensile and Flexural Properties of Cement Composites Reinforced with Flax Nonwoven Fabrics

Abstract

:1. Introduction

2. Results and Discussion

2.1. Effect of Nonwoven Thickness on the Cement Penetrability of the Nonwoven Fabrics

2.2. Effect of Number of Layers and Water Treatment of the Nonwovens on the Composite Performance

2.3. Effect of Needle-Punching of the Flax-Fiber Nonwovens in the Composite Properties

3. Materials and Methods

3.1. Materials

3.2. Nonwoven Preparation and Characterization

3.3. Composite Preparation and Characterization

4. Conclusions

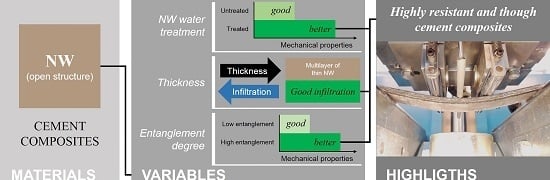

- The use of nonwoven flax fabrics as reinforcement in cement-based composites leads to cement materials with very high ductility.

- Nonwoven structures with low thickness and high entanglement, in the form of multilayer reinforcement, allow a higher infiltration of the cement paste through the nonwoven promoting higher fiber-matrix adherence.

- Increasing the number of nonwoven layers from three to four leads to an increase of the flexural MOR and toughness values of 19.7% and 26.9% respectively. This increase is of 49.1% and 46.7% of the flexural MOR and toughness values respectively for the composites prepared with the water treated nonwovens.

- The composites reinforced with the nonwovens with high entanglement (HNP-NW) presented higher values of flexural LOP (226%), MOE (7%), MOR (7%), and toughness (28%) than the ones prepared with the nonwovens with lower entanglement (MNP-NW). A similar trend was found for the LOP, MOE, MOR, and toughness values determined under tensile configuration with increases of 90%, 8%, 11%, and 20%, respectively.

Supplementary Materials

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Ardanuy, M.; Claramunt, J.; Toledo Filho, R.D. Cellulosic fiber reinforced cement-based composites: A review of recent research. Constr. Build. Mater. 2015, 79, 115–128. [Google Scholar] [CrossRef] [Green Version]

- Mejia Ballesteros, J.E.; Santos, S.F.; Mármol, G.; Savastano, H.; Fiorelli, J. Evaluation of cellulosic pulps treated by hornification as reinforcement of cementitious composites. Constr. Build. Mater. 2015, 100, 83–90. [Google Scholar] [CrossRef]

- Savastano, H.; Warden, P.G.; Coutts, R.S.P. Brazilian waste fibres as reinforcement for cement-based composites. Cem. Concr. Compos. 2000, 22, 379–384. [Google Scholar] [CrossRef]

- Tonoli, G.H.D.; Rodrigues Filho, U.P.; Savastano, H.; Bras, J.; Belgacem, M.N.; Rocco Lahr, F.A. Cellulose modified fibres in cement based composites. Compos. Part A Appl. Sci. Manuf. 2009, 40, 2046–2053. [Google Scholar] [CrossRef]

- Savastano, H.; Warden, P.G.; Coutts, R.S.P. Mechanically pulped sisal as reinforcement in cementitious matrices. Cem. Concr. Compos. 2003, 25, 311–319. [Google Scholar] [CrossRef]

- Toledo Filho, R.D.; England, G.L. Development of vegetable fibre—Mortar composites of improved durability. Cem. Concr. Compos. 2003, 25, 185–196. [Google Scholar] [CrossRef]

- Savastano, H.; Santos, S.F.; Radonjic, M.; Soboyejo, W.O. Fracture and fatigue of natural fiber-reinforced cementitious composites. Cem. Concr. Compos. 2009, 31, 232–243. [Google Scholar] [CrossRef]

- Claramunt, J.; Ardanuy, M.; García-Hortal, J.A.; Filho, R.D.T. The hornification of vegetable fibers to improve the durability of cement mortar composites. Cem. Concr. Compos. 2011, 33, 586–595. [Google Scholar] [CrossRef]

- Bentchikou, M.; Guidoum, A.; Scrivener, K.; Silhadi, K.; Hanini, S. Effect of recycled cellulose fibres on the properties of lightweight cement composite matrix. Constr. Build. Mater. 2012, 34, 451–456. [Google Scholar] [CrossRef]

- Pehanich, J.L.; Blankenhorn, P.R.; Silsbee, M.R. Wood fiber surface treatment level effects on selected mechanical properties of wood fiber-cement composites. Cem. Concr. Res. 2004, 34, 59–65. [Google Scholar] [CrossRef]

- Fidelis, M.E.A.; Toledo Filho, R.D.; de Andrade Silva, F.; Mechtcherine, V.; Butler, M.; Hempel, S. The effect of accelerated aging on the interface of jute textile reinforced concrete. Cem. Concr. Compos. 2016, 74, 183–193. [Google Scholar] [CrossRef]

- Claramunt, J.; Fernández-Carrasco, L.J.; Ventura, H.; Ardanuy, M. Natural fiber nonwoven reinforced cement composites as sustainable materials for building envelopes. Constr. Build. Mater. 2016, 115, 230–239. [Google Scholar] [CrossRef] [Green Version]

- De Andrade Silva, F.; Toledo Filho, R.D.; de Almeida Melo Filho, J.; Fairbairn, E.D.M.R. Physical and mechanical properties of durable sisal fiber–cement composites. Constr. Build. Mater. 2010, 24, 777–785. [Google Scholar] [CrossRef]

- Olivito, R.S.; Cevallos, O.A.; Carrozzini, A. Development of durable cementitious composites using sisal and flax fabrics for reinforcement of masonry structures. Mater. Des. 2014, 57, 258–268. [Google Scholar] [CrossRef]

- Cevallos, O.A.; Olivito, R.S. Effects of fabric parameters on the tensile behaviour of sustainable cementitious composites. Compos. Part B Eng. 2014, 69, 256–266. [Google Scholar] [CrossRef]

- Scardino, F. An introduction to textile structures and their behaviour. In Textile Structural Composites; Chou, T.-W., Ko, F.K., Eds.; Elsevier: Amsterdam, The Netherlands, 1989; pp. 1–24. [Google Scholar]

- Carloni, C.; Bournas, D.A.; Carozzi, F.G.; D’Antino, T.; Fava, G.; Focacci, F.; Giacomin, G.; Mantegazza, G.; Pellegrino, C.; Perinelli, C. Fiber reinforced composites with cementitious (inorganic) matrix. In Design Procedures for the Use of Composites in Strengthening of Reinforced Concrete Structures; Pellegrino, C., Sena-Cruz, J., Eds.; Springer: Amsterdam, The Netherlands, 2015; pp. 349–392. [Google Scholar]

- Carozzi, F.G.; Poggi, C. Mechanical properties and debonding strength of fabric reinforced cementitious matrix (FRCM) systems for masonry strengthening. Compos. Part B Eng. 2015, 70, 215–230. [Google Scholar] [CrossRef]

- D’Ambrisi, A.; Focacci, F. Flexural strengthening of RC beams with cement based composites. J. Compos. Constr. 2011, 15, 707–720. [Google Scholar] [CrossRef]

- De Felice, G.; de Santis, S.; Garmendia, L.; Ghiassi, B.; Larrinaga, P.; Lourenço, P.B.; Oliveira, D.V.; Paolacci, F.; Papanicolau, C.G. Mortar-based systems for externally bonded strengthening of masonryitle. Mater. Struct. 2014, 47, 2021–2037. [Google Scholar] [CrossRef] [Green Version]

- D’Ambrisi, A.; Feo, L.; Focacci, F. Bond-slip relations for PBO-FRCM materials externally bonded to concrete. Compos. Part B Eng. 2012, 43, 2938–2949. [Google Scholar] [CrossRef]

- D’Ambrisi, A.; Feo, L.; Focacci, F. Experimental and analytical investigation on bond between carbon-FRCM materials and masonry. Compos. Part B Eng. 2013, 46, 15–20. [Google Scholar] [CrossRef]

- D’Ambrisi, A.; Feo, L.; Focacci, F. Experimental analysis on bond between PBO-FRCM strengthening materials and concrete. Compos. Part B Eng. 2013, 44, 524–532. [Google Scholar] [CrossRef]

- D’Antino, T.; Carloni, C.; Sneed, L.H.; Pellegrino, C. Matrix–fiber bond behavior in PBO FRCM composites: A fracture mechanics approach. Eng. Fract. Mech. 2014, 117, 94–111. [Google Scholar] [CrossRef]

- Barkoula, N.M.; Garkhail, S.K.; Peijs, T. Biodegradable composites based on flax/polyhydroxybutyrate and its copolymer with hydroxyvalerate. Ind. Crops Prod. 2010, 31, 34–42. [Google Scholar] [CrossRef]

- Bodros, E.; Pillin, I.; Montrelay, N.; Baley, C. Could biopolymers reinforced by randomly scattered flax fibre be used in structural applications? Compos. Sci. Technol. 2007, 67, 462–470. [Google Scholar] [CrossRef]

- Kumar, R.; Yakubu, M.K.; Anandjiwala, R.D. Biodegradation of flax fiber reinforced poly lactic acid. Express Polym. Lett. 2010, 4, 423–430. [Google Scholar] [CrossRef] [Green Version]

- Peijs, T.; Garkhail, S.; Heijenrath, R.; Van Den Oever, M.; Bos, H. Thermoplastic composites based on flax fibres and polypropylene: Influence of fibre length and fibre volume fraction on mechanical properties. Macromol. Symp. 1998, 127, 193–203. [Google Scholar] [CrossRef]

- De Andrade Silva, F.; Mobasher, B.; Toledo Filho, R.D. Cracking mechanisms in durable sisal fiber reinforced cement composites. Cem. Concr. Compos. 2009, 31, 721–730. [Google Scholar] [CrossRef]

- Ferreira, S.R.; Martinelli, E.; Pepe, M.; de Andrade Silva, F.; Toledo Filho, R.D. Inverse identification of the bond behavior for jute fibers in cementitious matrix. Compos. Part B Eng. 2016, 95, 440–452. [Google Scholar] [CrossRef]

- Fernández-Carrasco, L.; Claramunt, J.; Ardanuy, M. Autoclaved cellulose fibre reinforced cement: Effects of silica fume. Constr. Build. Mater. 2014, 66, 138–145. [Google Scholar] [CrossRef]

- Ventura, H.; Ardanuy, M.; Capdevila, X.; Cano, F.; Tornero, J.A. Effects of needling parameters on some structural and physico-mechanical properties of needle-punched nonwovens. J. Text. Inst. 2014, 105, 1065–1075. [Google Scholar] [CrossRef]

- Test for the Determination of Modulus of Rupture and Limit of Proportionality of Thin Libre Reinforced Cement Sections; TFR1; E & FN SPON: London, UK, 1984.

- The Determination of Energy Absorption in Flexure of Thin Libre: Reinforced Cement Sections. Rilem Recommendations for the Testing and Use of Constructions Materials; TFR4; E & FN SPON: London, UK, 1984.

| Sample Reference | Number of Layers | Nonwoven Treatment | Nonwoven: Cement Ratio (wt %) | Final w/c Ratio (after Mold Compression) | Flexural Strength (MPa) | Toughness (kJ/m2) |

|---|---|---|---|---|---|---|

| C-3LNW | 3 layers | Untreated | 6.7 | 0.50 | 13.9 ± 2.22 | 4.9 ± 0.24 |

| C-4LNW | 4 layers | Untreated | 9.1 | 0.48 | 17.3 ± 3.34 | 6.7 ± 0.34 |

| C-4L-NW_T | 4 layers | Water treatment | 9.1 | 0.43 | 27.3 ± 0.59 | 9.2 ± 0.17 |

| Reference | Test Direction | Maximum Tensile Force (N) | Deformation (%) | Weight (g/m2) | Thickness (mm) |

|---|---|---|---|---|---|

| HNP-NW | MD 1 | 40.7 ± 17.1 | 43.3 ± 6.8 | - | - |

| CD 2 | 41.2 ± 15.2 | 52.7 ± 6.7 | - | - | |

| Average | 40.9 ± 16.1 | 48.0 ± 6.7 | 276 | 1.2 ± 0.1 | |

| MNP-NW | MD | 12.8 ± 1.9 | 31.3 ± 5.9 | - | - |

| CD | 22.9 ± 9.3 | 48.4 ± 8.4 | - | - | |

| Average | 17.8 ± 5.6 | 39.8 ± 7.1 | 213 | 1.6 ± 0.1 |

| Parameter | MNP-NW Composite | HNP-NW Composite | Increase for HNP-NW vs. MNP-NW Composite |

|---|---|---|---|

| LOP (MPa) | 5.54 ± 0.99 | 18.05 ± 4.59 | 226% |

| MOR (MPa) | 31.08±1.61 | 33.41 ± 4.35 | 7% |

| Toughness (kJ/m2) | 13.99 ± 1.62 | 16.68 ± 1.59 | 28% |

| EA (GPa) (zone A) | 11.09 ± 3.66 | 15.71 ± 0.65 | 42% |

| EB (GPa) (zone B) | 0.31 ± 0.26 | 0.517 ± 0.06 | 69% |

| EC (GPa) (zone C) | 0.33 ± 0.21 | 0.338 ± 0.18 | 2% |

| Parameter | MNP-NW Composite | HNP-NW Composite | Increase of Property HNP-NW vs. MNP-NW Composite |

|---|---|---|---|

| LOP (MPa) | 2.67 ± 1.43 | 5.06 ± 2.91 | 90% |

| MOR (MPa) | 7.18 ± 0.94 | 7.75 ± 0.34 | 8% |

| Toughness (kJ/m2) | 35.49 ± 3.27 | 39.34 ± 3.51 | 11% |

| EA (GPa) (zone A) | 15.08 ± 0.98 | 18.17 ± 3.47 | 20% |

| EB (GPa) (zone B) | 0.14 ± 0.11 | 0.16 ± 0.15 | 8% |

| EC (GPa) (zone C) | 0.14 ± 0.16 | 0.15 ± 0.12 | 8% |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license ( http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Claramunt, J.; Ventura, H.; Fernández-Carrasco, L.J.; Ardanuy, M. Tensile and Flexural Properties of Cement Composites Reinforced with Flax Nonwoven Fabrics. Materials 2017, 10, 215. https://doi.org/10.3390/ma10020215

Claramunt J, Ventura H, Fernández-Carrasco LJ, Ardanuy M. Tensile and Flexural Properties of Cement Composites Reinforced with Flax Nonwoven Fabrics. Materials. 2017; 10(2):215. https://doi.org/10.3390/ma10020215

Chicago/Turabian StyleClaramunt, Josep, Heura Ventura, Lucía J Fernández-Carrasco, and Mònica Ardanuy. 2017. "Tensile and Flexural Properties of Cement Composites Reinforced with Flax Nonwoven Fabrics" Materials 10, no. 2: 215. https://doi.org/10.3390/ma10020215

APA StyleClaramunt, J., Ventura, H., Fernández-Carrasco, L. J., & Ardanuy, M. (2017). Tensile and Flexural Properties of Cement Composites Reinforced with Flax Nonwoven Fabrics. Materials, 10(2), 215. https://doi.org/10.3390/ma10020215