Self-Developed Testing System for Determining the Temperature Behavior of Concrete

Abstract

:1. Introduction

1.1. Cracking Frame

1.2. TSTM

1.3. The Development of TSTM

- The deformation measurement method. It is important to determine the value of shrinkage, elastic modulus, and creep. Several methods have been adopted, such as monitoring the displacement of the movable grip [14,15,16,17], however, this method could generate some artifacts by ignoring the interaction between the grip and the sample. Altoubat [18,19] used the linear variable differential transformer (LVDT) attachment method to demonstrate the difference from LVDT on the grip. However, only the displacement of one surface could be measured rather than the whole sample. A method using embedded bars/rods [20,21,22,23] was developed to directly measure the concrete displacement. The embedded bars/rods method has the disadvantage of creating local damage inside the sample, and the strength would be affected. Thus, a deformation measurement method of directly measuring the concrete displacement with little influence on the sample could be developed.

- Temperature control method. Some devices without thermal regulation systems have been designed to meet the purpose of studying the shrinkage property [18,24,25]. For TSTMs, two types of temperature control methods, the fluid-cooled formwork [26] and environmental chamber [27,28], have been employed. Only a single specimen can be tested in the same environment restrained by the present temperature control method. Concrete is an artificial material having discrete properties, so some parallel specimens should be synchronously performed in the same environmental atmosphere to evaluate the material properties more representatively.

- Concrete quality. Concrete is poured into the mold of the TSTM directly and a vibrating rod is used to guarantee the concrete quality. When multi-TSTMs are employed, the homogeneity of all samples is hardly to be guaranteed by vibrating the sample separately with a handheld vibration rod. The representation and applicability of the test results will be influenced.

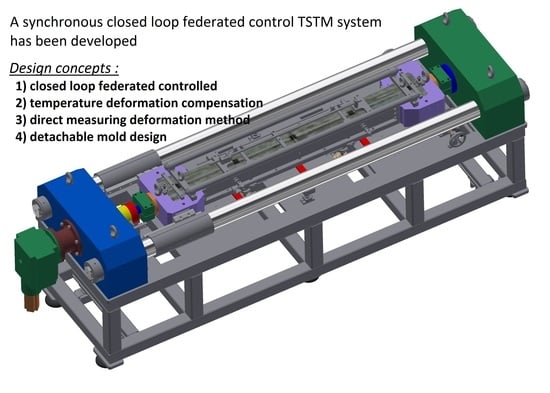

2. The Self-developed Synchronous Closed Loop Federated Control TSTM System

2.1. The Synchronous Closed Loop Federated Control TSTM System

2.2. The Detachable Mold Design of the TSTM

2.3. The Direct Measuring Deformation Method

2.4. The Compensation Method of Temperature Deformation

3. Experimental Program

3.1. The Centricity Assessment of the TSTM

3.2. Temperature Deformation Compensation Verification Experiment

3.3. TSTM Performance Verification Experiment

- Test Start Time

- Multi-TSTM Settings

- Temperature Modes

4. Results and Discussions

4.1. The Deformation Results to Assess Eccentricity Degree of TSTM

4.2. The Results of the Temperature of Deformation Compensation Verification

4.3. The Results of the TSTM Performance Verification Experiment

- Temperature Regulation Results

- Temperature Stress Test Results of Multi-TSTMs

- E Results

5. Conclusions

- It has the comprehensive ability of simulating different restraint degrees, multiple temperature and humidity modes, and closed-loop control of multi-TSTMs during one test period.

- The environment simulation laboratory system, including a walk-in environment simulation laboratory, allow for multi-concrete specimens of temperature stress tests to be conducted synchronously under the same environmental conditions. Additionally, no obvious fluctuation of the concrete temperature appears before or after concrete specimen demolding. The operation is more flexible during the test as the TSTM is no more restrained by the small chamber and fluid-cooled formwork. Finally, all parts of the TSTM are in the same environment, which reduces the disturbance caused by the external temperature.

- The deformation measuring design with embedded cross part can obtain more accurate deformation and restraint degree results with little damage.

- The compensation method of temperature deformation with different considerations of steel materials can eliminate the external temperature deformation’s effects on the concrete specimen.

- Some design concepts, such as the sliding sleeve on the steel shaft, height-adjustable ball supporting points, cross-head positioning fixture, and the mold assembly platform, have been taken into consideration so that the self-developed TSTM has greatly overcome the difficulty of eccentric force and deformation.

- The detachable mold design of TSTM guarantees that the concrete quality of different TSTMs is similar to the greatest extent by being vibrated on the vibrating stand synchronously.

- The active method should be used for determining E on a specific TSTM without any other application, such as restraint testing, because the frequent tension and compression will cause damage which will influence the mechanical properties in tension.

Supplementary Materials

Acknowledgments

Author Contributions

Conflicts of Interest

References

- American Concrete Institute. Report on Thermal and Volume Change Effects on Cracking of Mass Concrete; American Concrete Institute (ACI): Farmington Hills, MI, USA, 2007. [Google Scholar]

- Claisse, P.A. Chapter 23—Creep, shrinkage, and cracking of concrete. In Civil Engineering Materials; Butterworth-Heinemann: Boston, MA, USA, 2016; pp. 241–249. [Google Scholar]

- Bentur, A.; Kovler, K. Evaluation of early age cracking characteristics in cementitious systems. Mater. Struct. 2003, 36, 183–190. [Google Scholar] [CrossRef]

- Chen, B.; Sun, W.; Ding, J. Concrete crack resistance research based on temperature stress test—A short review. J. Chin. Ceramic Soc. 2013, 41, 1124–1133. [Google Scholar]

- Rilem, T.C. Avoidance of Thermal Cracking in Concrete at Early Ages; E&FN Spon: London, UK, 1998; pp. 461–464. [Google Scholar]

- Riding, K.A.; Poole, J.L.; Schindler, A.K.; Juenger, M.C.G.; Folliard, K.J. Quantification of effects of fly ash type on concrete early-age cracking. Aci. Mater. J. 2008, 105, 149–155. [Google Scholar]

- Thermal Cracking in Concrete at Early Ages: Proceedings of the International RILEM Symposium; Springenschmid, R. (Ed.) E&FN Spon: London, UK, 1994. [Google Scholar]

- Prevention of Thermal Cracking in Concrete at Early Ages; Springenschmid, R. (Ed.) E&FN Spon: London, UK, 1998. [Google Scholar]

- Breitenbücher, R. Investigation of thermal cracking with the cracking-frame. Mater. Struct. 1990, 23, 172–177. [Google Scholar] [CrossRef]

- Kim, J.J.; Jeon, S.; Kim, J. Development of new device for measuring thermal stresses. Cem. Concr. Res. 2002, 32, 1645–1651. [Google Scholar] [CrossRef]

- Amin, M.N.; Kim, J.; Lee, Y.; Kim, J. Simulation of the thermal stress in mass concrete using a thermal stress measuring device. Cem. Concr. Res. 2009, 39, 154–164. [Google Scholar] [CrossRef]

- Springenschmid, R.; Breitenbiicher, R. Are low heat cements the most favourable cements for the prevention of cracks due to heat of hydration? Concr. Precasting Plant Technol. 1986, 52, 704–711. [Google Scholar]

- Staquet, S.; Delsaute, B.; Darquennes, A.; Espion, B. Design of a Revisited TSTM System for Testing Concrete Since Setting Time under Free and Restraint Conditions; RILEM Publications SARL: Paris, France, 2012. [Google Scholar]

- Kovler, K. Testing system for determining the mechanical behaviour of early age concrete under restrained and free uniaxial shrinkage. Mater. Struct. 1994, 27, 324–330. [Google Scholar] [CrossRef]

- Bloom, R.; Bentur, A. Free and restrained shrinkage of normal and high-strength concretes. Aci Mater. J. 1995, 92, 211–217. [Google Scholar]

- Zhihai, L. Quantitative Evaluation of the Effectiveness of Expansive Concrete as a Countermeasure for Thermal Cracking and the Development of its Practical Application. Ph.D. Thesis, University of Tokyo, Tokyo, Japan, September 2006. [Google Scholar]

- Zhang, T.; Qin, W. Tensile creep due to restraining stresses in high-strength concrete at early ages. Cem. Concr. Res. 2006, 36, 584–591. [Google Scholar]

- Altoubat, S.A.; Lange, D.A. Creep, shrinkage, and cracking of restrained concrete at early age. Aci. Mater. J. 2001, 98, 323–331. [Google Scholar]

- Altoubat, S.A. Early Age Stresses and Creep-shrinkage Interaction of Restrained Concrete. Ph.D. Thesis, University of Illinois at Urbana-Champaign, Urbana, IL, USA, 2000. [Google Scholar]

- Van Breugel, K.; Lokhorst, S.J.; Kovler, K.; Bentur, A. Stress-based crack criterion as a basis for prevention of through-cracks in concrete structures at early ages. In International RILEM Conference on Early Age Cracking in Cementitious Systems; RILEM Publications SARL: London, UK, 2003. [Google Scholar]

- Bjøntegaard, Ø.; Sellevold, E.J. The temperature-stress testing machine (TSTM): Capabilities and limitations. In First International Rilem Symposium on Advances in Concrete through Science and Engineering; E&FN Spon: London, UK, 2004. [Google Scholar]

- Springenschmid, R.; Breitenbücher, R.; Mangold, M. Development of the cracking frame and the temperature-stress testing machine. In Thermal Cracking in Concrete at Early Ages; E&FN Spon: London, UK, 1994. [Google Scholar]

- Lura, P. Autogenous Deformation and Internal Curing of Concrete. Ph.D. Thesis, Delft University of Technology, Delft, Netherlands, April 2003. [Google Scholar]

- Pigeon, M.; Toma, G.; Delagrave, A.; Bissonnette, B.; Marchand, J.; Prince, J.C. Equipment for the analysis of the behaviour of concrete under restrained shrinkage at early ages. Mag. Concr. Res. 2000, 52, 297–302. [Google Scholar] [CrossRef]

- Cusson, D.; Hoogeveen, T. An experimental approach for the analysis of early-age behaviour of high-performance concrete structures under restrained shrinkage. Cem. Concr. Res. 2007, 37, 200–209. [Google Scholar] [CrossRef]

- Wei, Y.; Hansen, W. Tensile creep behavior of concrete subject to constant restraint at very early ages. J. Mater. Civil. Eng. 2013, 25, 1277–1284. [Google Scholar] [CrossRef]

- Hu, S.; Chen, J. Principle and Equipment for Concrete Temperature Stress Detection; The Defense Industry Publication Agency: Beijing, China, 2008. (In Chinese) [Google Scholar]

- American Concrete Institute. Report on Early-age Cracking: Causes, Measurement, and Mitigation; American Concrete Institute (ACI): Farmington Hills, MI, USA, 2010. [Google Scholar]

- China, Ministry of Water Resources. Test code for hydraulic concrete. In SL 352-2006; China Water Power Press: Beijing, China, 2006. [Google Scholar]

- Riding, K.A.; Poole, J.L.; Schindler, A.K.; Juenger, M.C.; Folliard, K.J. Effects of construction time and coarse aggregate on bridge deck cracking. Aci. Mater. J. 2009, 106, 448–454. [Google Scholar]

- Shen, D.; Jiang, J.; Shen, J.; Yao, P.; Jiang, G. Influence of curing temperature on autogenous shrinkage and cracking resistance of high-performance concrete at an early age. Constr. Build. Mater. 2016, 103, 67–76. [Google Scholar] [CrossRef]

- Klausen, A.E.; Kanstad, T.; Bjøntegaard, Ø.; Kollegger, J.; Hellmich, C.; Pichler, B. Updated temperature-stress testing machine (TSTM): Introductory tests, calculations, verification, and Investigation of variable fly ash content. Proceedings of 10th International Conference on Mechanics and Physics of Creep, Shrinkage, and Durability of Concrete and Concrete Structures, Vienna, Austria, 21–23 September 2015. [Google Scholar]

- Delsaute, B.; Boulay, C.; Granja, J.; Carette, J.; Azenha, M.; Dumoulin, C.; Karaiskos, G.; Deraemaeker, A.; Staquet, S. Testing concrete E-modulus at very early ages through several techniques: An Inter-laboratory comparison. Strain 2016, 52, 91–109. [Google Scholar] [CrossRef]

- Li, Q.; Guan, J.; Wu, Z.; Dong, W.; Zhou, S. Equivalent maturity for ambient temperature effect on fracture parameters of site-casting dam concrete. Constr. Build. Mater. 2016, 120, 293–308. [Google Scholar] [CrossRef]

| TSTM Performance | Capacity |

|---|---|

| Restraint degree | 0%–100% |

| Loading capacity | ±200 kN |

| Temperature control capacity | −20 to +80 °C |

| Humidity control capacity | 0–100% RH |

| The diameter of the steel shaft | 130 mm |

| Specimen dimensions | 150 mm × 150 mm × 2000 mm |

| Water | Cement | Sand | Gravel |

|---|---|---|---|

| 200 | 380 | 900 | 975 |

| Compound | CaO | SiO2 | Al2O3 | MgO | SO3 | Fe2O3 | Na2O | K2O | TiO2 | P2O5 |

|---|---|---|---|---|---|---|---|---|---|---|

| Mass Percent/% | 47.87 | 25.12 | 11.29 | 5.52 | 2.95 | 2.39 | 0.654 | 0.599 | 0.399 | 0.247 |

| TSTM | B | C | D |

|---|---|---|---|

| Tensile Strength (MPa) | 0.93 | 1.02 | 1.35 |

| Failure Strain (με) | 111.1 | 115.75 | 37.6 |

| Cracking Temperature (°C) | - | 20.7 | 25.67 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhu, H.; Li, Q.; Hu, Y. Self-Developed Testing System for Determining the Temperature Behavior of Concrete. Materials 2017, 10, 419. https://doi.org/10.3390/ma10040419

Zhu H, Li Q, Hu Y. Self-Developed Testing System for Determining the Temperature Behavior of Concrete. Materials. 2017; 10(4):419. https://doi.org/10.3390/ma10040419

Chicago/Turabian StyleZhu, He, Qingbin Li, and Yu Hu. 2017. "Self-Developed Testing System for Determining the Temperature Behavior of Concrete" Materials 10, no. 4: 419. https://doi.org/10.3390/ma10040419

APA StyleZhu, H., Li, Q., & Hu, Y. (2017). Self-Developed Testing System for Determining the Temperature Behavior of Concrete. Materials, 10(4), 419. https://doi.org/10.3390/ma10040419