1. Introduction

Analogue modelling represents one of the most useful tools to test hypotheses on the evolution and controlling factors of geological processes at different length and time scales. One of the fundamental steps is to identify the proper analogue material to replicate natural rocks and model the natural process under investigation.

Although the behaviour of natural rock is complex (i.e., experimentally deformed rocks are characterized by an elastic/frictional plastic behaviour with strain hardening prior to failure, and strain softening after failure; e.g., [

1] and references therein), the simple Coulomb rheology may be successfully used to describe the mechanical behavior of upper brittle crust on a regional scale [

2]. This can be justified from the observation that rocks are affected by faults and fractures of any dimensions and orientation, coupled with mechanical heterogeneities of different origins that cause failure by reactivation to occur before the peak strength (undeformed rock strength) is reached.

The most common type of failure at the upper brittle crustal condition (low pressure up to a few hundred MPa) is thus frictional shear failure, governed by the Mohr-Coulomb criterion of failure (Equation (1)) describing the linear increase in the strength of rocks with depth:

where

τ and

σ are the shear and normal stress acting on the fracture plane,

C and

μ are respectively the cohesion and friction coefficient [

3,

4], and

λ is the pore fluid factor, given by the ratio between the fluid pressure and the lithostatic load [

5]. On the basis of experimental tests, Byerlee [

6] proposed that in pre-fractured rocks the shear stress required to slide rock surfaces over one another decreases linearly as a function of the normal stress according to the relationship

τ = 0.85

σ for normal stresses ≤200 MPa, and

τ = 0.6

σ + 0.5 for normal stresses >200 MPa.

Following the above concepts, analogue modellers commonly use different dry granular materials (i.e., sand and powders of different composition and granulometry, flour, rice powder, plaster) to simulate upper crustal deformation. Their behaviour is generally assumed to follow the Coulomb failure criterion, with constant frictional properties and is strain-rate independent (e.g., [

7]), thereby implying that these materials can properly simulate the brittle rock behaviour. However, laboratory experiments on granular materials show that they exhibit a more complex behavior [

8,

9,

10,

11]. For example, the friction coefficient of granular materials is not constant, but strain dependent, showing different values at peak strength (i.e., at fault initiation), stable dynamic strength (fault sliding), and stable static strength (fault reactivation; [

8,

9]). In addition, Ritter et al. [

12] found that strain weakening at normal loads <1 kPa is due to the partial loss of cohesion. Furthermore, for very low stresses (<400 Pa) the failure envelope of granular material is not linear, and thus it is not strictly following the Coulomb criterion [

10,

13]. Additionally, the main material parameters (density, cohesion, internal friction coefficient μ = tanΦ, where Φ is the angle of internal friction) depend primarily on grain shape, dimensions, and grain size distribution (e.g., [

9,

10,

14,

15,

16,

17,

18]), and, secondly, material properties are strongly dependent on the handling technique, i.e., the way they are used in the model building procedure, as this influences the grain packing and the degree of grain compaction (e.g., [

9,

19,

20,

21]). For example, the angle of internal friction may vary approximately up to 3°–4° [

21]. Nevertheless, the granular material behaviour is very similar to the experimentally deformed rock (e.g., [

1,

22,

23]).

The main material parameters that are necessary to be known for characterizing a granular material for analogue modelling purposes are: (1) the frictional parameters (internal friction coefficient μ or the angle of internal friction Φ, and the cohesion C) and (2) the bulk density.

The internal friction coefficient reflects the way that single grains slide against each other [

24]. The internal friction coefficient of crustal rock, obtained from laboratory strength tests, varies between 0.5 and 1.0 (angle of internal friction from 26.5° to 45°; [

3,

25]). The scaling procedure requires its value to be identical—or close—in both the analogue granular material and nature [

26]. Consequently, granular materials used in the laboratory usually possess an internal friction angle included in this range (e.g., [

9,

10,

11,

17]). Higher or lower values are found only for materials employed to simulate specific conditions, such as for microbeads showing an angle of internal friction as low as 20°. The coefficient of friction is lower for spherical particles, more suitable in modelling brittle behavior in analogue experiments [

10], and higher for angular grains [

10,

14].

Cohesion describes the amount of shear stress that a material can resist in a zero normal stress condition [

24]. In non-cohesive granular materials, the interaction between the grains is mainly related to the steric repulsion and to the friction forces. Therefore, the macroscopic properties of the assembly are governed by the geometry of the grains (shape and size distribution) and by the surface properties of the grains [

27]. In nature, cohesion is generally in the range of 10

7 Pa for intact rocks (e.g., [

3]); this value may decrease one or two orders of magnitude in strongly fractured rocks ([

7] and references therein). Cohesion has the dimension of stress, and thus it must be scaled down by the stress scaling factor, which is the ratio between stress in the model and in nature

σ* =

ρ*

g*

h*, where the asterisk denotes the model to nature ratios. Common stress ratios are around 10

−5–10

−6 (e.g., [

7,

28]), and thus it follows that analogue materials should have very low cohesion, on the order of a few to few hundreds of Pa. This requirement is met by many granular materials used in analogue models. More cohesive analogue materials have cohesion of some hundreds of Pa (e.g., gypsum in [

20]), but most common values are in the range of 20 Pa to 80 Pa (e.g., [

9,

10,

16,

29,

30]). However, the measurement of cohesion in granular material is a controversial subject and different contradictory solutions have been proposed. Usually, cohesion of granular materials is inferred from the interception with the shear axis (in the

τ −

σ plot) of the straight line obtained by a linear regression of shear test results. However, this method may give values that are not fully realistic since it contradicts the common observation that dry granular materials are virtually cohesionless [

29]. Furthermore, if the test is made under very low normal stresses (<400 Pa), the Coulomb failure envelope is not linear but instead it shows a convex-outward shape [

10] suggesting that the linearly extrapolated values of cohesion at normal stresses below 400 Pa are overestimated.

Similarly to the angle of internal friction, cohesion shows a lower value for spherical and/or finer particles and higher values for angular and/or coarser material [

10,

14,

16,

19,

27,

31].

The bulk density

ρ is simpler to be analyzed, nevertheless it is central in the analogue modelling scaling procedure (i.e.,

σ =

ρgh); if one of the principal stress directions is vertical, the stress system is Andersonian [

32] and the failure criterion can be written, in terms of principal stresses, as

σ1 −

σ3 =

αρgh, where

α is a parameter dependent on the frictional properties of the material and on the orientation of the stress field [

4]. Despite the easiness of the measure, the bulk density is strongly influenced by the handling techniques: differences in density due to the handling techniques range between 5% and 20% depending on the materials [

9,

19]. Common bulk density values for granular analogue material range between ~400 kg/m

3 for lighter materials (e.g., diatomite powder; [

28]) and ~1900 kg/m

3 for heavier materials like corundum sand (e.g., [

9]).

Generally, the above described analogue material parameters are measured using different apparatuses (i.e., Hubbert-type apparatus [

33] and ring shear test [

34]) which allow for investigating the response of the tested material to a wide range of applied stresses. However, as stated before, the main parameters are dependent on the handling technique. For this reason, in this paper we apply empirical methods to determine the parameters of granular materials under conditions commonly occurring in experimentral analogue modelling. To test the empirical approach, some measurements have been carried out through the ring-shear tester at the Engineering Geology Laboratory of the University of Florence. Empirical methods have the great advantage of measuring the properties of a given analogue material in the same conditions that the material is utilized in during an experiment.

2. Brittle Materials Used in Analogue Modelling

To reproduce in their experiments the brittle crustal rocks, analogue modelers use a wide range of different materials. Each granular material has its own characteristics in terms of the angle of internal friction, cohesion, and density, as well as its grain characteristic that may influence the structural details and the sharpness of the structures. Each material is thus suitable to reproduce a specific geological setting depending on its properties.

Generally, granular materials used in analogue modelling can be divided into two main categories: cohesive and non-cohesive or low cohesion granular materials (e.g., [

11,

27]). Low cohesion materials are mainly used to model weak materials. The most used low cohesion materials are dry quartz sand (i.e., [

9,

11,

16] and references therein) and glass microbeads (high-quality vaporized glass sphere; [

9]). Compared to the other classical granular materials (i.e., quartz sand), glass microbeads are characterized by a lower frictional angle varying between 20° and 29°, [

9,

35,

36,

37]. Given their Moho-Coulomb behaviour, microbeads are mainly used to simulate shale and claystone décollement layers and weakness zones within the model (e.g., [

9,

36,

37,

38]).

Cohesive granular materials are generally silica powder [

39,

40], fine-grained ignimbrite powder [

41], diatomite powder [

28], and gypsum [

20]. These materials fail both by tension (open fractures) and shear at low differential stresses, and are widely employed in reproducing volcanic systems and shallow magma intrusion at different scales ([

11] and references therein), or for modelling peculiar environments with highly cohesive rocks and predominant open fractures (e.g., [

20]).

3. Materials and Methods

To obtain new analogue granular materials that would combine the advantages of quartz sand and cohesive materials, we mixed quartz sand and K-feldspar powder in different proportions. Our aim is to obtain a material characterized by a proper internal friction angle able to simulate crustal rocks, with moderate cohesion, as well as a suitable grain size allowing the development of numerous and detailed structures for a complete fracture/fault (statistical) analysis.

We tested quartz sand (Fontainebleau quartz sand, hereinafter simply called Q-sand) and K-feldspar fine sand (Kaolinwerke-AKW feldspar SF 900 SF sand; hereinafter referred as K-feldspar sand) and different mixtures between these two materials (

Table 1). The use of this sand mixture should produce in the models a high number of brittle structures with very definite details (see also [

13]). This mixture enables the desired analysis without significantly altering the frictional properties and the material density. Sand quantities were weighted with a precision balance and the different mixtures were prepared by mixing the two components in a planetary mixer for at least 5 min to obtain a granulometrically homogenous material.

Fontainebleau Q-sand (

Figure 1a and

Figure 2) is a well sorted sand (average grain diameter ~200 μm), primarily composed of siliceous and sub-rounded grains. K-feldspar SF 900 SF (

Figure 1b and

Figure 2) is a poorly sorted sand (grain diameter mostly (90%) in the range of 20–100 μm, with a significant (50%) finer fraction, <30 μm).

The grains have mostly an angular shape, and are mainly composed of potassium feldspar (83%), with subordinate sodium feldspar (6%), quartz (10%), and a smaller part of kaolinite (1%).

As mentioned earlier, granular material properties are strongly sensitive to the handling techniques [

8,

9,

19]: pouring or sifting the same sand results in a change in its frictional properties as well as of its density, because of the different grain packing. For this reason, we handled and prepared the analyzed materials in the same way that we prepare the experiments; particularly, the granular material was carefully poured from a fixed height (i.e., ~10 cm). After the material reaches the desired height (usually a few centimeters), the top surface is scraped off to level the sand and obtain a flat and smooth (initial) surface. This procedure has been demonstrated to not significantly alter the frictional properties of the granular materials [

21,

42].

3.1. Angle of Internal Friction

The angle of internal friction was determined by the means of two different empirical methods widely used in the literature: (1) by measuring the angle of repose [

27,

43,

44,

45]; and (2) by measuring the dip angle of faults developed during simple set-up analogue extensional models [

9,

19], following the principle that the angle θ between the maximum principal stress

σ1 and the new fault plane is given as θ = 45° − Φ/2.

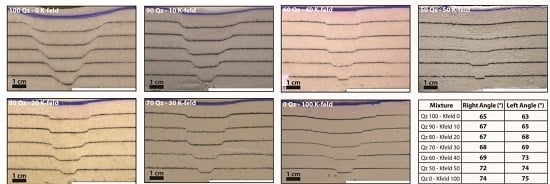

The experiments were built with a simple set-up (here we are interested only in measuring the materials properties, thus no scaling procedure was adopted): a 6 cm-thick layer of sand mixture with a thin colored layer (made of the same sand mixture) every 1 cm of thickness to help recognizing the faults. The sand is colored with Indian ink and naturally dried, over a period of days. Coloring sand is a very common practice in analogue modeling, and it is recognized to not significantly influence the mechanical properties of sand. The sand pack was 20 cm long and rested on the base of a deforming pure/simple shear apparatus (referred to as the ‘Tosi machine’, at the Tectonic Modelling Laboratory of the Institute of Geosciences and Earth Resources at the Earth Science Department of the University of Florence,

Figure 3). Extension was applied by moving a sidewall driven by a stepper motor controlled by a central unit (

Figure 3). Half of the model is placed above a thin rigid metal sheet that is connected to the mobile wall, thereby producing a velocity discontinuity (VD) at the metal sheet edge.

Models were slowly stretched (at 2.5 cm/h) and model deformation invariably consisted of a couple of conjugate faults developed above the velocity discontinuity. Extension was applied until the first extensional faults were clearly observable on the mode surface. The deformation distribution at grain size level is sensitive to the material properties, implying that the amount of extension needed for the first faults to develop may slightly vary depending on the model. In any case, the bulk extension was of the order of a few millimeters (2–4 mm). This however does not influence the model results. Once the experiment was stopped, the model was wetted to allow for cutting model cross sections in the model central part. The fault dip was measured directly above the velocity discontinuity, at the model base, where the conjugate faults initiate and have a rectilinear attitude. In this location, the vertical normal stress corresponds to the maximum principal stress

σ1 (e.g., [

9]).

The results of these extensional models are used for determining the angle of internal friction Φ (and consequently the internal friction coefficient μ) of the granular materials. Considering that μ is determined by the angle between a fault plane and the direction of the maximum principal stress (θ) by the relationship μ = tan(90° − 2θ), and in the extensional setting (i.e., normal faults) the main principal stress is vertical, then the angle θ is equal to the complementary angle of the fault dip

α (i.e., θ = 90 −

α). The value of the internal friction coefficient calculated with the above-described method is sensitive to the handling technique; particularly the more densely packed sifted sand exhibits a higher friction coefficient than poured sand [

8,

9,

19]. Likewise, the coefficient of peak friction calculated from fault dips is higher than the coefficient determined with a ring shear test [

9]. We thus paid close attention when preparing the experiments by always following the same procedure: we carefully poured the sand from the same height and, when the desired height was reached, the top surface was shaved to obtain a flat surface.

Alternatively, the angle of internal friction of the tested materials may be derived from the critical angle of repose. The angle of repose Φ of a granular material can be defined as the maximum angle that allows a heap of soil resting on a horizontal surface to remain stable (e.g., [

43]), and it is equal to the angle of internal friction (e.g., [

27,

44]). A non-cohesive granular material or with inter-particles forces negligible compared to gravity (i.e., small cohesion), poured from a single point forms a cone, whose base angle is the angle of repose Φ. Following Coulomb’s criterion, this occurs because the granular media sustain shear stress as in the solid friction (i.e., due to the resistance to movement of one grain over another). The cone is stable until

τ < μ

σ, where

τ and

σ are the shear and normal stress, and μ is the internal friction coefficient. The slope of the cone is thus limited to a certain slope that is the function of the internal friction coefficient μ (μ and Φ are related by the relation μ = tanΦ).

Many methods have been proposed to measure the angle of repose: static methods, among which are the ‘fixed height cone’, ‘fixed base cone’, and ‘scoop deposition’, and ‘dynamic methods’, like the ‘tilting table’ and the ‘rotating cylinder’. The angle of repose obtained from a static method tends to present a slightly smaller value [

47] with the fixed height cone method, as proposed by the American Society for Testing and Materials (ASTM International; [

48]), and the Cornforth method (a variation of the fixed base method [

49]), giving the best results [

43].

We thus measured the angle of repose for the five mixtures and the two pure sands with both the fixed height cone method [

48] and the fixed base method, which are the most common methods used to determine the angle of repose. Hereafter we shortly describe the two methods used to measure the angle of repose:

‘fixed height cone’ method: the powder is carefully poured through a funnel, at a fixed height until the apex of the heap formed by the granular material reaches the bottom of the funnel (

Figure 4); ‘fixed base cone’ method: the granular material flows through a funnel, which is raised vertically until the heap covers a circular base of fixed size. The funnel is slowly raised as the cone grows, maintaining the same distance between the funnel tip and the apex of the cone during the whole procedure.

In both cases, rather than attempt to measure the angle of the resulting cone directly, the angle of repose Φ can be obtained by measuring with a caliper the width of the cone base

D (86 mm in the fixed base cone method,

Figure 4), and the cone height

H (35 mm in the fixed base cone method); the angle of repose is given by the following equation [

47]:

where

d is the internal diameter of the funnel nozzle (10 mm).

The fixed base cone method is considered more accurate since

D is univocally known (while

D can be ambiguous in the fixed height cone method) [

47]. Moreover, in the fixed base cone method, maintaining the same close distance between the tip of the funnel and the top of the growing cone minimizes the impact of falling particles. In both cases, measurements were repeated 10 times and an average value was taken as representative for each mixture.

In relation to grain size, the pure K-feldspar sand is affected by electrostatic effects [

51], and it is not possible to measure its angle of repose by using this method. The high cohesion and the small size of the grains give the pure K-feldspar sand a high angle of repose, and the resulting poor flow properties do not allow the funnel method to be used (the material stagnates inside the funnel and does not freely flow). Also high K-feldspar content mixtures present not optimal flow properties (cfr. [

27]); nevertheless, the dimension of the diameter of the funnel outlet accommodates this less well flowing material [

47]. However, the influence of the dimension of “

d” on the angle of repose value is considered in Equation (2) [

47].

The angle of internal friction measured with the fault dip methods represents the peak value for the experimental conditions and is a function of the vertical normal stress and thickness of the sand layer (note that the fault angle is measured at the base of the model, at the maximum burial conditions; [

9]). Peak values are higher because they are a function of the dilatation that the material should experience before being able to deform and fail (e.g., [

8,

9]) and may be attributed to the initial yield strength of the sample. Conversely, the angles obtained from the angle of repose correspond to the critical state friction angle or stable friction angle (e.g., [

49,

52]) linked to the stable sliding (i.e., the state of failure when the stresses do not change anymore during shearing and the volume is constant) (e.g., [

8,

52]).

3.2. Density

The bulk density of a granular material strongly depends on the grain arrangement (and of course on the density of the grains themselves). Density is a function of the grain size, grain shape, and grain size distribution. For example, Klinkmüller et al. [

16] established that rounded grains arrange in closer packing than angular grains, when sieved; considering equal grain density and size distribution, rounded materials have a higher bulk density, due to the closer packing. This implies that the density is extremely sensitive to compaction, and that again the handling techniques (i.e., the way we built a model) may influence the density of the used granular materials (e.g., [

8,

9,

19,

21]) with a great impact on the whole scaling procedure.

Density was evaluated using an easy and common method: we filled a small container of known volume with the material and we measured its weight with an electronic balance (e.g., [

19]). Following the above considerations, we paid close attention while filling the container with the same technique used in preparing the models, specifically the granular material was poured from a constant height of a few centimeters, and once the container was filled, the surface was leveled by scraping with a straightedge. Moreover, to consider the possible compaction of the granular material under its own weight, the container had a height (5 cm) that is a good average value of the model thickness. The obtained density can thus realistically be a good approximation of the density inside the model. At least five measurements were made for each material and averaged.

Successively we proceeded to evaluate how the material packing may influence the bulk density. To obtain an estimate of the compressibility of the analyzed granular material (i.e., the increase in density due to a compression/decrease in volume) we measured the Hausner ratio [

53] or compressibility index, which is widely used in the granular material characterisation (i.e., [

27,

47]). The Hausner ratio is used to quantify the material flow properties, as packing and flow are closely related bulk properties in granular materials [

47]. The Hausner ratio is an adimensional number calculated as the ratio between the freely settled bulk density of the granular material and the tapped density, which is an increased bulk density attained after mechanically tapping the container containing the sample. It follows that the greater the Hausner ratio, the greater the bulk density variability due to the different handling technique and the different material packing configurations that may arise. Ideally, a granular material having a low Hausner ratio is an easy to use analogue material (

Table 2). To calculate the Hausner ratio we adopted the following common empirical method: 100 g of granular material, weighed with a precision balance, are gently introduced (i.e., with the same method used in building the model) in a graduated cylinder of 250 mL volume, avoiding compaction as much as possible. Knowing the mass (100 g) and the volume V

0 (from the graduate cylinder), the density D

0 is calculated. The container is then tapped 500 times on a flat surface. The volume of the granular material after tapping is measured (V

500), and the tapped density D

500 is calculated.

The obtained values give a clear idea about the macroscopic properties and the behavior of a granular material [

27].

3.3. Cohesion

A first qualitative idea of the cohesive properties of a material may arise from the observation of the heap shape obtained by letting the granular material flow through a funnel [

27]. The heap shape is strongly dependent on the grain properties. Cohesive granular material gives strong deviations from the conical shape [

44]. The isosceles triangle built with the basal angles equal to the angle of repose corresponds to the ideal heap shape (

Figure 5). The more the heap shape deviates from the ideal shape, the higher the cohesion; in addition, the cohesive index

σr can be obtained from the deviation between the heap interface and the ideal heap shape [

27].

A quantitative estimation of the cohesion of a granular material, if cohesion is not negligible, can be made through an empirical method, which is related to the self-sustaining capability of a vertical wall cut in the analyzed material. In this case, Coulomb’s method for wedges [

55] predicts that the height of the vertical wall L is limited to the value given by the following equation [

44]:

where

c is the cohesion, Φ is the angle of internal friction,

g is the gravitational acceleration, and

ρ is the material density. From the above equation, it follows that the material cohesion is given by:

This method has been previously used to calculate the cohesion for granular materials used in analogue models (e.g., [

7,

56,

57]). The material was handled in the same way we prepared the experiment, to obtain realistic cohesion values representative of the experimental conditions. This is very important in that in Equation 4 the cohesion is a function of both the density and the angle of internal friction.

Following this method, a thin layer of material was poured on a flat base, and the surface was scraped at a known height and a vertical cut was made in the material with a blade. This process was repeated up to the point where a vertical slope could self-sustain (

LMAX). We repeated this procedure up to 10 times for each material, and an average

LMAX value was obtained for each analyzed material. Since the measurements of the free wall height give very small values (see

Section 4.3), pictures of the realized tests were not representative.