Self-Healing Property of Ultra-Thin Wearing Courses by Induction Heating

Abstract

:1. Introduction

2. Materials

3. Research Program

3.1. Mixture Design

3.2. Testing and Characterization

4. Result and Discussion

4.1. Marshall Stability and Flow Value

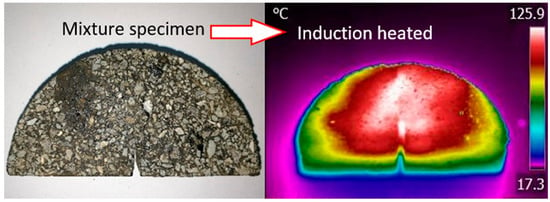

4.2. Induction Heating Property

4.3. Self-Healing Property

- = fracture toughness (MPa × m0.5);

- = the normalized stress intensity factor that is a constant in this study (Dimensionless);

- = the critical load (N);

- = radius of specimens (m);

- = the specimen thickness (m); and,

- = the notch length (m).

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Hunt, L.; Boyle, G. Steel Slag in Hot Mix Asphalt Concrete. Available online: https://rosap.ntl.bts.gov/view/dot/33871 (accessed on 6 August 2018).

- Peshkin, D.G.; Hoerner, T.E.; Zimmerman, K.A. Optimal Timing of Pavement Preventive Maintenance Treatment Applications; Transportation Research Board: Washington, DC, USA, 2004. [Google Scholar]

- Geng, L.; Ma, T.; Zhang, J.; Huang, X.; Hu, P. Research on Performance of a Dense Graded Ultra-Thin Wearing Course Mixture. Appl. Sci. 2017, 7, 800. [Google Scholar] [CrossRef]

- Beyene, M.A.; Meininger, R.C.; Gibson, N.H.; Munoz, J.F.; Youtcheff, J. Forensic investigation of the cause(s) of slippery ultra-thin bonded wearing course of an asphalt pavement: Influence of aggregate mineralogical compositions. Int. J. Pavement Eng. 2016, 17, 887–900. [Google Scholar] [CrossRef]

- Luo, Y.L. Brief Introduction to Application of Maintenance Technology on Ultra-thin Wearing Course for Asphalt Pavement of Expressway. Guangdong Highw. Commun. 2011, 1, 005. [Google Scholar]

- Nan, X.F.; Tian, Z.F. Experimental research on ultra thin friction course interlayer bonding strength. Int. J. Pavement Res. Technol. 2009, 2, 176–180. [Google Scholar]

- Guan, Y.S.; An, F.W.; Han, C.; Zhang, Z.X. Design and Evaluation of Ultra Thin Friction Courses Asphalt Mixture Modified by Polyolefin. Adv. Mater. Res. 2013, 723, 41–49. [Google Scholar] [CrossRef]

- Hefer, A.; Horak, E.; Heathcote, H.; Hess, R.; Jeewan, A. Review of experiences with Ultra-Thin Friction Course Performance on airport runways. Rehabilitation 2008, 204, 758. [Google Scholar]

- Cui, P.; Wu, S.; Xiao, Y.; Wan, M.; Cui, P. Inhibiting effect of Layered Double Hydroxides on the emissions of volatile organic compounds from bituminous materials. J. Clean. Prod. 2015, 108, 987–991. [Google Scholar] [CrossRef]

- Xiao, Y.; Wang, F.; Cui, P.; Lei, L.; Lin, J.; Yi, M. Evaluation of Fine Aggregate Morphology by Image Method and Its Effect on Skid-Resistance of Micro-Surfacing. Materials 2018, 11, 920. [Google Scholar] [CrossRef] [PubMed]

- Chen, Z.; Wu, S.; Xiao, Y.; Zeng, W.; Yi, M.; Wan, J. Effect of hydration and silicone resin on Basic Oxygen Furnace slag and its asphalt mixture. J. Clean. Prod. 2016, 112, 392–400. [Google Scholar] [CrossRef]

- Wu, S.; Xue, Y.; Ye, Q.; Chen, Y. Utilization of steel slag as aggregates for stone mastic asphalt (SMA) mixtures. Build. Environ. 2007, 42, 2580–2585. [Google Scholar] [CrossRef]

- Ahmedzade, P.; Sengoz, B. Evaluation of steel slag coarse aggregate in hot mix asphalt concrete. J. Hazard. Mater. 2009, 165, 300. [Google Scholar] [CrossRef] [PubMed]

- Sun, Y.; Wu, S.; Liu, Q.; Hu, J.; Yuan, Y.; Ye, Q. Snow and Ice Melting Properties of Self-healing Asphalt Mixtures with Induction Heating and Microwave Heating. Appl. Therm. Eng. 2017, 129, 871–883. [Google Scholar] [CrossRef]

- Pan, P.; Wu, S.; Xiao, Y.; Liu, G. A review on hydronic asphalt pavement for energy harvesting and snow melting. Renew. Sustain. Energy Rev. 2015, 48, 624–634. [Google Scholar] [CrossRef]

- Gómez-Meijide, B.; Ajam, H.; Lastra-González, P.; Garcia, A. Effect of air voids content on asphalt self-healing via induction and infrared heating. Constr. Build. Mater. 2016, 126, 957–966. [Google Scholar] [CrossRef]

- Menozzi, A.; Garcia, A.; Partl, M.N.; Tebaldi, G.; Schuetz, P. Induction healing of fatigue damage in asphalt test samples. Constr. Build. Mater. 2015, 74, 162–168. [Google Scholar] [CrossRef]

- Liu, Q.; Wu, S.; Schlangen, E. Induction heating of asphalt mastic for crack control. Constr. Build. Mater. 2013, 41, 345–351. [Google Scholar] [CrossRef]

- Lim, I.L.; Johnston, I.W.; Choi, S.K. Stress intensity factors for semi-circular specimens under three-point bending. Eng. Fract. Mech. 1993, 44, 363–382. [Google Scholar] [CrossRef]

- Li, X.; Marasteanu, M. Evaluation of the low temperature fracture resistance of asphalt mixtures using the semi circular bend test. J. Assoc. Asphalt Paving Technol. 2004, 73, 401–426. [Google Scholar]

| Properties | Apparent Specific Gravity | Bulk Specific Gravity | Water Absorption (%) | Crushing Value (%) | Content of f-CaO (%) |

|---|---|---|---|---|---|

| Basalt | 2.84 | 2.75 | 1.12 | 12.6 | - |

| Steel slag | 3.2 | 2.86 | 2.77 | 14.3 | 1.17 |

| Limestone filler | 2.67 | 2.67 | - | - | - |

| Angularity Range | Basalt | Steel Slag | ||

|---|---|---|---|---|

| Particle Number | Proportion | Particle Number | Proportion | |

| Low (≤2100) | 9 | 4.50% | 18 | 8.87% |

| Moderate (2100–3975) | 143 | 71.50% | 126 | 62.07% |

| High (3975–5400) | 45 | 22.50% | 44 | 21.67% |

| Extreme (5400–10,000) | 3 | 1.50% | 15 | 7.39% |

| Form2D Range | Basalt | Steel Slag | ||

|---|---|---|---|---|

| Particle Number | Proportion | Particle Number | Proportion | |

| Low (≤6.5) | 46 | 23.0% | 81 | 39.9% |

| Moderate (6.5–8) | 64 | 32.0% | 44 | 21.7% |

| High (8–10.75) | 75 | 37.5% | 62 | 30.5% |

| Extreme (10.75–20) | 15 | 7.5% | 16 | 7.9% |

| Description of Mixture | Content of Steel Fiber | ||||

|---|---|---|---|---|---|

| 0% | 1% | 2% | 3% | ||

| Average temperature rising rate (°C/s) | Basalt AC-5 | 0 | 0.31 | 0.61 | 0.99 |

| Basalt SMA-5 | 0 | 0.34 | 0.59 | 1.02 | |

| Basalt-steel slag AC-5 | 0 | 0.37 | 0.70 | 1.11 | |

| Basalt-steel slag SMA-5 | 0 | 0.36 | 0.74 | 1.25 | |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wan, J.; Xiao, Y.; Song, W.; Chen, C.; Pan, P.; Zhang, D. Self-Healing Property of Ultra-Thin Wearing Courses by Induction Heating. Materials 2018, 11, 1392. https://doi.org/10.3390/ma11081392

Wan J, Xiao Y, Song W, Chen C, Pan P, Zhang D. Self-Healing Property of Ultra-Thin Wearing Courses by Induction Heating. Materials. 2018; 11(8):1392. https://doi.org/10.3390/ma11081392

Chicago/Turabian StyleWan, Jiuming, Yue Xiao, Wei Song, Cheng Chen, Pan Pan, and Dong Zhang. 2018. "Self-Healing Property of Ultra-Thin Wearing Courses by Induction Heating" Materials 11, no. 8: 1392. https://doi.org/10.3390/ma11081392

APA StyleWan, J., Xiao, Y., Song, W., Chen, C., Pan, P., & Zhang, D. (2018). Self-Healing Property of Ultra-Thin Wearing Courses by Induction Heating. Materials, 11(8), 1392. https://doi.org/10.3390/ma11081392