Role of Wood Fibers in Tuning Dynamic Rheology, Non-Isothermal Crystallization, and Microcellular Structure of Polypropylene Foams

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation of PP/Wood Fiber Composites

2.3. Fabrication of Polypropylene/Wood Fiber Composite Foams

2.4. Rheology Characterization

2.5. Foam Morphology Characterization

2.6. Crystallization Characterization

2.7. X-Ray Diffraction (XRD) Analysis

3. Results and Discussion

3.1. Dynamic Rheological Behavior

3.2. Non-Isothermal Crystallization Behavior

3.3. Apparent Density and Expansion Ratio of Composite Foams

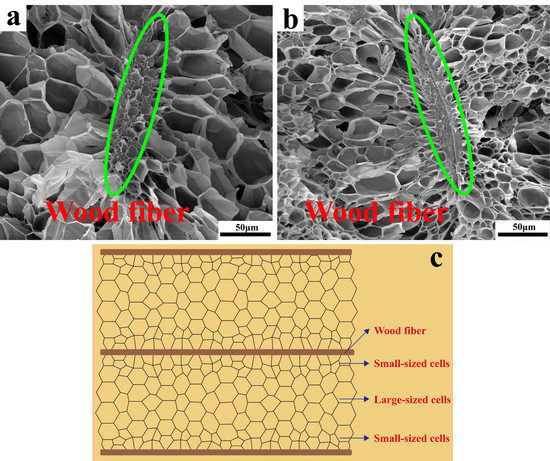

3.4. Cell Morphology

3.5. Crystallinity and Melting Behaviors of Composite Foams

3.6. Crystal Structure of the Composite Foams

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Ou, R.; Xie, Y.; Wolcott, M.P.; Sui, S.; Wang, Q. Morphology, mechanical properties, and dimensional stability of wood particle/high density polyethylene composites: Effect of removal of wood cell wall composition. Mater. Des. 2014, 58, 339–345. [Google Scholar] [CrossRef]

- Zhou, H.; Hao, X.; Wang, H.; Wang, X.; Liu, T.; Xie, Y.; Wang, Q. The reinforcement efficacy of nano- and microscale silica for extruded wood flour/HDPE composites: The effects of dispersion patterns and interfacial modification. J. Mater. Sci. 2017, 53, 1899–1910. [Google Scholar] [CrossRef]

- Dányádi, L.; Móczó, J.; Pukánszky, B. Effect of various surface modifications of wood flour on the properties of PP/wood composites. Compos. Part A 2010, 41, 199–206. [Google Scholar] [CrossRef]

- Sobczak, L.; Lang, R.W.; Haider, A. Polypropylene composites with natural fibers and wood—General mechanical property profiles. Compos. Sci. Technol. 2012, 72, 550–557. [Google Scholar] [CrossRef]

- Mashkour, M.; Ranjbar, Y. Superparamagnetic Fe3O4@ wood flour/polypropylene nanocomposites: Physical and mechanical properties. Ind. Crops Prod. 2018, 111, 47–54. [Google Scholar] [CrossRef]

- Zhang, Z.-X.; Gao, C.; Xin, Z.X.; Kim, J.K. Effects of extruder parameters and silica on physico-mechanical and foaming properties of PP/wood-fiber composites. Compos. Part B 2012, 43, 2047–2057. [Google Scholar] [CrossRef]

- Zhou, X.; Huang, S.; Chen, L. Effect of antiaging agents on the outdoor natural weathering of bamboo powder/polypropylene foamed composites. J. Vinyl Addit. Technol. 2016, 22, 311–319. [Google Scholar] [CrossRef]

- Zhai, W.; Wang, H.; Yu, J.; Dong, J.; He, J. Cell coalescence suppressed by crosslinking structure in polypropylene microcellular foaming. Polym. Eng. Sci. 2008, 48, 1312–1321. [Google Scholar] [CrossRef]

- Shukla, S.; Koelling, K.W. Classical Nucleation Theory Applied to Homogeneous Bubble Nucleation in the Continuous Microcellular Foaming of the Polystyrene-CO2 System. Ind. Eng. Chem. Res. 2009, 48, 7603–7615. [Google Scholar] [CrossRef]

- Hardelin, L.; Strom, A.; Di Maio, E.; Iannace, S.; Larsson, A. Microcellular foaming of arabinoxylan and PEGylated arabinoxylan with supercritical CO2. Carbohydr. Polym. 2018, 181, 442–449. [Google Scholar] [CrossRef]

- Hossieny, N.J. Morphology and Properties of Polymer/Carbon Nanotube Nanocomposite Foams Prepared by Super Critical Carbon Dioxide. Master’s Thesis, Florida State University, Tallahassee, FL, USA, 2009. [Google Scholar]

- Doroudiani, S.; Park, C.B.; Kortschot, M.T. Processing and Characterization of Microcellular Foamsed High-Density olyethylene/lsotactic Polypropylene Blends. Polym. Eng. Sci. 1998, 38, 1205–1215. [Google Scholar] [CrossRef]

- Bao, J.-B.; Liu, T.; Zhao, L.; Hu, G.-H. A two-step depressurization batch process for the formation of bi-modal cell structure polystyrene foams using scCO2. J. Supercrit. Fluids 2011, 55, 1104–1114. [Google Scholar] [CrossRef]

- Diaz-Acosta, C.A. Continuous Microcellular Foamsing of Polylactic Acid/Natural Fiber Composites. Ph.D. Thesis, Michigan State University, East Lansing, MI, USA, 2011. [Google Scholar]

- Yu, P.; Mi, H.-Y.; Huang, A.; Geng, L.-H.; Chen, B.-Y.; Kuang, T.-R.; Mou, W.-J.; Peng, X.-F. Effect of Poly(butylenes succinate) on Poly(lactic acid) Foaming Behavior: Formation of Open Cell Structure. Ind. Eng. Chem. Res. 2015, 54, 6199–6207. [Google Scholar] [CrossRef]

- Zhang, J.; Rizvi, G.M.; Park, C.B.; Hasan, M.M. Study on cell nucleation behavior of HDPE–wood composites/supercritical CO2 solution based on rheological properties. J. Mater. Sci. 2011, 46, 3777–3784. [Google Scholar] [CrossRef]

- Matuana, L.M.; Diaz, C.A. Study of Cell Nucleation in Microcellular Poly(lactic acid) Foamed with Supercritical CO2 through a Continuous-Extrusion Process. J. Mater. Sci. 2010, 49, 2186–2193. [Google Scholar] [CrossRef]

- Guo, G.; Lee, Y.H.; Rizvi, G.M.; Park, C.B. Influence of wood fiber size on extrusion foaming of wood fiber/HDPE composites. J. Appl. Polym. Sci. 2008, 107, 3505–3511. [Google Scholar] [CrossRef]

- Shah, B.L.; Matuana, L.M. Online measurement of rheological properties of PVC/wood-flour composites. J. Vinyl Addit. Technol. 2004, 10, 121–128. [Google Scholar] [CrossRef]

- Matuana, L.M.; Diaz, C.A. Strategy To Produce Microcellular Foamed Poly(lactic acid)/Wood-Flour Composites in a Continuous Extrusion Process. Ind. Eng. Chem. Res. 2013, 52, 12032–12040. [Google Scholar] [CrossRef]

- Matuana, L.M.; Faruk, O. Effect of gas saturation conditions on the expansion ratio of microcellular poly(lactic acid)/wood-flour composites. Express Polym. Lett. 2010, 4, 621–631. [Google Scholar] [CrossRef]

- Ding, W.; Jahani, D.; Chang, E.; Alemdar, A.; Park, C.B.; Sain, M. Development of PLA/cellulosic fiber composite foams using injection molding: Crystallization and foaming behaviors. Compos. Part A 2016, 83, 130–139. [Google Scholar] [CrossRef]

- Wang, Y.; Song, Y.; Du, J.; Xi, Z.; Wang, Q. Preparation of Desirable Porous Cell Structure Polylactide/Wood Flour Composite Foams Assisted by Chain Extender. Materials 2017, 10, 999. [Google Scholar] [CrossRef] [PubMed]

- Bocz, K.; Tabi, T.; Vadas, D.; Sauceau, M.; Fages, J.; Marosi, G. Characterisation of natural fibre reinforced PLA foams prepared by supercritical CO2 assisted extrusion. Express Polym. Lett. 2016, 10, 771–779. [Google Scholar] [CrossRef]

- Neagu, R.C.; Cuénoud, M.; Berthold, F.; Bourban, P.-E.; Gamstedt, E.K.; Lindström, M.; Månson, J.-A.E. The potential of wood fibers as reinforcement in cellular biopolymers. J. Cell. Plast. 2012, 48, 71–103. [Google Scholar] [CrossRef]

- Rodrigue, D.; Souici, S.; Twite-Kabamba, E. Effect of wood powder on polymer foam nucleation. J. Vinyl Addit. Technol. 2006, 12, 19–24. [Google Scholar] [CrossRef]

- Bledzki, A.K.; Faruk, O. Extrusion and Injection Moulded Microcellular Wood Fibre Reinforced Polypropylene Composites. Cell. Polym. 2004, 23, 211–227. [Google Scholar] [CrossRef]

- Zepnik, S.; Kabasci, S.; Kopitzky, R.; Radusch, H.-J.; Wodke, T. Extensional Flow Properties of Externally Plasticized Cellulose Acetate: Influence of Plasticizer Content. Polymers 2013, 5, 873–889. [Google Scholar] [CrossRef] [Green Version]

- Standard Test Method for Melt Flow Rates of Thermoplastics by Extrusion Plasometer; ASTM D 1238-04; ASTM International: West Conshohocken, PA, USA, 2004.

- Liu, S.; Zoetebier, B.; Hulsman, L.; Zhang, Y.; Duvigneau, J.; Vancso, G.J. Nanocellular polymer foams nucleated by core-shell nanoparticles. Polymer 2016, 104, 22–30. [Google Scholar] [CrossRef]

- Yin, J.; Wang, S.; Zhang, Y.; Zhang, Y. Isothermal crystallization kinetics of PP in PP/Mg(OH)2 composites. J. Polym. Sci. Part B 2005, 43, 1914–1923. [Google Scholar] [CrossRef]

- Ahmed, A.K.; Atiqullah, M.; Pradhan, D.R.; Al-Harthi, M.A. Crystallization and melting behavior of i-PP: A perspective from Flory’s thermodynamic equilibrium theory and DSC experiment. RSC. Adv. 2017, 7, 42491–42504. [Google Scholar] [CrossRef]

- Idumah, C.I.; Hassan, A. Hibiscus Cannabinus Fiber/PP based Nano-Biocomposites Reinforced with Graphene Nanoplatelets. J. Nat. Fibers 2017, 14, 691–706. [Google Scholar] [CrossRef]

- Jeziorny, A. Parameters characterizing the kinetics of the non-isothermal crystallization of poly (ethylene terephthalate) determined by DSC. Polymer 1978, 19, 1142–1144. [Google Scholar] [CrossRef]

- Mohanty, S.; Nayak, S.K. Dynamic and steady state viscoelastic behavior and morphology of MAPP treated PP/sisal composites. Mater. Sci. Eng. A 2007, 443, 202–208. [Google Scholar] [CrossRef]

- Azizi, H.; Ghasemi, I. Investigation on the dynamic melt rheological properties of polypropylene/wood flour composites. Polym. Compos. 2009, 30, 429–435. [Google Scholar] [CrossRef]

- Huang, C.-W.; Yang, T.-C.; Hung, K.-C.; Xu, J.-W.; Wu, J.-H. The Effect of Maleated Polypropylene on the Non-Isothermal Crystallization Kinetics of Wood Fiber-Reinforced Polypropylene Composites. Polymers 2018, 10, 382. [Google Scholar] [CrossRef]

- Ebadi-Dehaghani, H.; Barikani, M.; Khonakdar, H.A.; Jafari, S.H. Microstructure and non-isothermal crystallization behavior of PP/PLA/clay hybrid nanocomposites. J. Therm. Anal. Calorim. 2015, 121, 1321–1332. [Google Scholar] [CrossRef]

- Wu, W.; Wu, G.; Zhang, H. Effect of wood flour as nucleating agent on the isothermal crystallization of poly(lactic acid). Polym. Adv. Technol. 2017, 28, 252–260. [Google Scholar] [CrossRef]

- Wang, L.; Ando, M.; Kubota, M.; Ishihara, S.; Hikima, Y.; Ohshima, M.; Sekiguchi, T.; Sato, A.; Yano, H. Effects of hydrophobic-modified cellulose nanofibers (CNFs) on cell morphology and mechanical properties of high void fraction polypropylene nanocomposite foams. Compos. Part A 2017, 98, 166–173. [Google Scholar] [CrossRef]

- Huang, L.; Wang, H.; Wang, W.; Wang, Q.; Song, Y. Non-isothermal crystallization kinetics of wood-flour/polypropylene composites in the presence of β-nucleating agent. J. For. Res. 2016, 27, 949–958. [Google Scholar] [CrossRef]

- Bledzki, A.K.; Faruk, O. Injection moulded microcellular wood fibre–polypropylene composites. Compos. Part A 2006, 37, 1358–1367. [Google Scholar] [CrossRef]

- Moldovan, D.; Fechete, R.; Demco, D.E.; Culea, E.; Blumich, B.; Herrmann, V.; Heinz, M. The heterogeneity of segmental dynamics of filled EPDM by 1H transverse relaxation NMR. J. Magn. Reson. 2011, 208, 156–162. [Google Scholar] [CrossRef]

- Mortazavian, H.; Fennell, C.J.; Blum, F.D. Structure of the Interfacial Region in Adsorbed Poly(vinyl acetate) on Silica. Macromolecules 2015, 49, 298–307. [Google Scholar] [CrossRef]

- Song, Y.; Zheng, Q. Concepts and conflicts in nanoparticles reinforcement to polymers beyond hydrodynamics. Prog. Mater. Sci. 2016, 84, 1–58. [Google Scholar] [CrossRef]

- Nofar, M.; Zhu, W.; Park, C.B. Effect of dissolved CO2 on the crystallization behavior of linear and branched PLA. Polymer 2012, 53, 3341–3353. [Google Scholar] [CrossRef]

- Huang, J.; Xu, C.; Wu, D.; Lv, Q. Transcrystallization of polypropylene in the presence of polyester/cellulose nanocrystal composite fibers. Carbohydr. Polym. 2017, 167, 105–114. [Google Scholar] [CrossRef] [PubMed]

| Samples | Φ (°C/min) | t1/2 (min) | G (min−1) | n | lnkt | lnkc | kc |

|---|---|---|---|---|---|---|---|

| PP/WF0 | 5 | 0.66 | 1.52 | 2.76 | 0.75 | 0.15 | 1.16 |

| 10 | 0.36 | 2.78 | 2.89 | 2.60 | 0.26 | 1.30 | |

| 20 | 0.14 | 7.14 | 2.95 | 5.40 | 0.27 | 1.31 | |

| 30 | 0.07 | 14.29 | 3.02 | 7.50 | 0.25 | 1.28 | |

| PP/WF10 | 5 | 0.74 | 1.35 | 2.93 | 0.50 | 0.10 | 1.11 |

| 10 | 0.38 | 2.63 | 2.89 | 2.40 | 0.24 | 1.27 | |

| 20 | 0.21 | 4.76 | 3.09 | 4.40 | 0.22 | 1.25 | |

| 30 | 0.11 | 9.09 | 3.02 | 6.30 | 0.21 | 1.23 | |

| PP/WF20 | 5 | 0.76 | 1.32 | 2.76 | 0.40 | 0.08 | 1.08 |

| 10 | 0.44 | 2.27 | 2.91 | 2.00 | 0.20 | 1.22 | |

| 20 | 0.26 | 3.85 | 2.95 | 3.60 | 0.18 | 1.20 | |

| 30 | 0.13 | 7.69 | 3.02 | 5.70 | 0.19 | 1.21 | |

| PP/WF30 | 5 | 0.78 | 1.28 | 2.72 | 0.30 | 0.06 | 1.06 |

| 10 | 0.50 | 2.00 | 2.85 | 1.60 | 0.16 | 1.17 | |

| 20 | 0.30 | 3.33 | 2.99 | 3.20 | 0.16 | 1.17 | |

| 30 | 0.17 | 5.88 | 3.09 | 5.20 | 0.14 | 1.15 | |

| PP/WF40 | 5 | 0.81 | 1.23 | 2.75 | 0.20 | 0.04 | 1.04 |

| 10 | 0.52 | 1.92 | 2.87 | 1.50 | 0.15 | 1.16 | |

| 20 | 0.36 | 2.78 | 2.91 | 2.60 | 0.13 | 1.14 | |

| 30 | 0.25 | 4.00 | 2.90 | 3.60 | 0.12 | 1.13 |

| Samples | TL (°C) | TH (°C) | Xc (%) |

|---|---|---|---|

| PP/WF0 | 164.3 | 173.5 | 47.1 |

| PP/WF10 | 165.8 | 174.2 | 43.2 |

| PP/WF20 | 166.6 | 174.3 | 44.6 |

| PP/WF30 | 166.8 | 174.8 | 44.7 |

| PP/WF40 | 166.2 | 173.4 | 44.9 |

| Samples | Crystal Grain Size/nm | Average Size | |||

|---|---|---|---|---|---|

| [110] | [040] | [130] | [111] | ||

| PPWF0 | 12.38 | 10.28 | 9.43 | 5.82 | 9.48 |

| PP/WF10 | 10.52 | 10.16 | 8.48 | 6.81 | 8.99 |

| PP/WF20 | 10.42 | 10.25 | 9.45 | 6.06 | 9.05 |

| PP/WF30 | 11.13 | 7.42 | 9.02 | 6.40 | 8.49 |

| PP/WF40 | 10.50 | 7.43 | 8.46 | 5.09 | 7.87 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Song, Y.; Wang, Y.; Li, H.; Zong, Q.; Xu, A. Role of Wood Fibers in Tuning Dynamic Rheology, Non-Isothermal Crystallization, and Microcellular Structure of Polypropylene Foams. Materials 2019, 12, 106. https://doi.org/10.3390/ma12010106

Song Y, Wang Y, Li H, Zong Q, Xu A. Role of Wood Fibers in Tuning Dynamic Rheology, Non-Isothermal Crystallization, and Microcellular Structure of Polypropylene Foams. Materials. 2019; 12(1):106. https://doi.org/10.3390/ma12010106

Chicago/Turabian StyleSong, Yongming, Youyong Wang, Hao Li, Qiling Zong, and Ailing Xu. 2019. "Role of Wood Fibers in Tuning Dynamic Rheology, Non-Isothermal Crystallization, and Microcellular Structure of Polypropylene Foams" Materials 12, no. 1: 106. https://doi.org/10.3390/ma12010106

APA StyleSong, Y., Wang, Y., Li, H., Zong, Q., & Xu, A. (2019). Role of Wood Fibers in Tuning Dynamic Rheology, Non-Isothermal Crystallization, and Microcellular Structure of Polypropylene Foams. Materials, 12(1), 106. https://doi.org/10.3390/ma12010106