Surface Roughness Characterisation and Analysis of the Electron Beam Melting (EBM) Process

Abstract

:1. Introduction

2. Materials and Methods

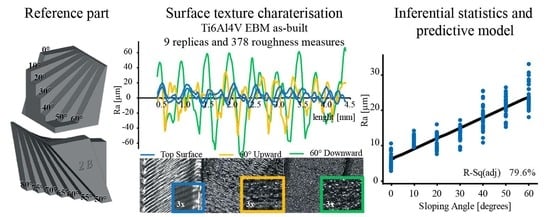

2.1. Design of the Reference Artefact

2.2. Equipment and Material

3. Results and Discussion

3.1. Analysis of the Experimental Validity Using Ra Values

3.2. Upward Surfaces Analysis

3.3. Downward Surfaces Analysis

4. Conclusions

- -

- No evidence of an effect of the arrangement of the replicas on the build plate was found for the upward surfaces.

- -

- The upward surfaces appeared less rough compared to the downward ones that, on the contrary, showed a lower standard deviation.

- -

- The mean roughness value (Ra) for the top surfaces was found to be around 6 µm. Mean Ra values were found to be around 15 and 19 μm for upward and downward surfaces, respectively. These values are in line with those of the literature on the EBM process, meaning that the artefact is an adequate representative of the process.

- -

- The surface roughness of the upwards surfaces was mainly influenced by the staircase effect, and thus by the slope angle. The surface roughness was linearly dependent on the sloping angle.

- -

- The heat distribution affected the surface roughness for the downward surfaces. The surface roughness appeared to be independent of the sloping angle, due to the differences in the heat distribution during the melting of the section of the designed reference.

Author Contributions

Funding

Conflicts of Interest

References

- Biamino, S.; Penna, A.; Ackelid, U.; Sabbadini, S.; Tassa, O.; Fino, P.; Pavese, M.; Gennaro, P.; Badini, C. Electron beam melting of Ti-48Al-2Cr-2Nb alloy: Microstructure and mechanical properties investigation. Intermetallics 2011, 19, 776–781. [Google Scholar] [CrossRef]

- Baudana, G.; Biamino, S.; Ugues, D.; Lombardi, M.; Fino, P.; Pavese, M.; Badini, C. Titanium aluminides for aerospace and automotive applications processed by Electron Beam Melting: Contribution of Politecnico di Torino. Met. Powder Rep. 2016, 71, 193–199. [Google Scholar] [CrossRef]

- Galati, M.; Iuliano, L. A literature review of powder-based electron beam melting focusing on numerical simulations. Addit. Manuf. 2018, 19, 1–20. [Google Scholar] [CrossRef]

- Parthasarathy, J.; Starly, B.; Raman, S.; Christensen, A. Mechanical evaluation of porous titanium (Ti6Al4V) structures with electron beam melting (EBM). J. Mech. Behav. Biomed. Mater. 2010, 3, 249–259. [Google Scholar] [CrossRef] [PubMed]

- Heinl, P.; Körner, C.; Singer, R.F. Selective electron beam melting of cellular titanium: Mechanical properties. Adv. Eng. Mater. 2008, 10, 882–888. [Google Scholar] [CrossRef]

- Harrysson, O.L.; Cansizoglu, O.; Marcellin-Little, D.J.; Cormier, D.R.; West, H.A. Direct metal fabrication of titanium implants with tailored materials and mechanical properties using electron beam melting technology. Mater. Sci. Eng. C 2008, 28, 366–373. [Google Scholar] [CrossRef]

- Fager Franzén, S.; Karlsson, J. Titanium Aluminide Manufactured by Electron Beam Melting. Master’s Thesis, Chalmers University of Technology, Gothenburg, Sweden, 2010. [Google Scholar]

- Gibson, I.; Rosen, D.W.; Stucker, B. Additive Manufacturing Technologies; Springer: New York, NY, USA, 2010. [Google Scholar]

- Murr, L.E.; Martinez, E.; Amato, K.N.; Gaytan, S.M.; Hernandez, J.; Ramirez, D.A.; Shindo, P.W.; Medina, F.; Wicker, R.B. Fabrication of metal and alloy components by additive manufacturing: Examples of 3D materials science. J. Mater. Res. Technol. 2012, 1, 42–54. [Google Scholar] [CrossRef]

- Mahale, T. Electron Beam Melting of Advanced Materials and Structures, Mass Customization, Mass Personalization; Industrial Engineering, North Carolina State University: Raleigh, NC, USA, 2009. [Google Scholar]

- Cheng, B.; Price, S.; Lydon, J.; Cooper, K.; Chou, K. On Process Temperature in Powder-Bed Electron Beam Additive Manufacturing: Model Development and Validation. J. Manuf. Sci. Eng. 2014, 136, 061018. [Google Scholar] [CrossRef]

- Weiwei, H.; Wenpeng, J.; Haiyan, L.; Huiping, T.; Xinting, K.; Yu, H. Research on Preheating of Titanium Alloy Powder in Electron Beam Melting Technology. Rare Met. Mater. Eng. 2011, 40, 2072–2075. [Google Scholar] [CrossRef]

- Froes, F.; Dutta, B. The additive manufacturing (AM) of titanium alloys. Adv. Mater. Res. 2014, 1019, 19–25. [Google Scholar] [CrossRef]

- Sigl, M.; Lutzmann, S.; Zäh, M. Transient physical effects in electron beam sintering. In Proceedings of the 2006 7th Annual Solid Freeform Fabrication Symposium, Austin, TX, USA, 6–8 August 2006; pp. 397–405. [Google Scholar]

- Leach, R.K.; Bourell, D.; Carmignato, S.; Donmez, A.; Senin, N.; Dewulf, W. Geometrical metrology for metal additive manufacturing. CIRP Ann. 2019, in press. [Google Scholar] [CrossRef]

- Brown, C.A.; Hansen, H.N.; Jiang, X.J.; Blateyron, F.; Berglund, J.; Senin, N.; Bartkowiak, T.; Dixon, B.; Le Goïc, G.; Quinsat, Y.; et al. Multiscale analyses and characterizations of surface topographies. CIRP Ann. 2018, 67, 839–862. [Google Scholar] [CrossRef]

- Townsend, A.; Senin, N.; Blunt, L.; Leach, R.; Taylor, J. Surface texture metrology for metal additive manufacturing: A review. Precis. Eng. 2016, 46, 34–47. [Google Scholar] [CrossRef]

- Brajlih, T.; Tasic, T.; Drstvensek, I.; Valentan, B.; Hadzistevic, M.; Pogacar, V.; Balic, J.; Acko, B. Possibilities of using three-dimensional optical scanning in complex geometrical inspection. Strojniški Vestn. J. Mech. Eng. 2011, 57, 826–833. [Google Scholar] [CrossRef]

- Palousek, D.; Omasta, M.; Koutny, D.; Bednar, J.; Koutecky, T.; Dokoupil, F. Effect of matte coating on 3D optical measurement accuracy. Opt. Mater. 2015, 40, 1–9. [Google Scholar] [CrossRef]

- Senin, N.; Thompson, A.; Leach, R.K. Characterisation of the topography of metal additive surface features with different measurement technologies. Meas. Sci. Technol. 2017, 28, 095003. [Google Scholar] [CrossRef]

- Deligianni, D.D.; Katsala, N.; Ladas, S.; Sotiropoulou, D.; Amedee, J.; Missirlis, Y. Effect of surface roughness of the titanium alloy Ti–6Al–4V on human bone marrow cell response and on protein adsorption. Biomaterials 2001, 22, 1241–1251. [Google Scholar] [CrossRef]

- Ponader, S.; Vairaktaris, E.; Heinl, P.; Wilmowsky, C.V.; Rottmair, A.; Körner, C.; Singer, R.F.; Holst, S.; Schlegel, K.A.; Neukam, F.W. Effects of topographical surface modifications of electron beam melted Ti-6Al-4V titanium on human fetal osteoblasts. J. Biomed. Mater. Res. Part A 2008, 84, 1111–1119. [Google Scholar] [CrossRef]

- Zhang, L.-C.; Liu, Y.; Li, S.; Hao, Y. Additive Manufacturing of Titanium Alloys by Electron Beam Melting: A Review. Adv. Eng. Mater. 2018, 20, 1700842. [Google Scholar] [CrossRef]

- Chern, A.H.; Nandwana, P.; Yuan, T.; Kirka, M.M.; Dehoff, R.R.; Liaw, P.K.; Duty, C.E. A review on the fatigue behavior of Ti-6Al-4V fabricated by electron beam melting additive manufacturing. Int. J. Fatigue 2019, 119, 173–184. [Google Scholar] [CrossRef]

- Liu, S.; Shin, Y.C. Additive manufacturing of Ti6Al4V alloy: A review. Mater. Des. 2019, 164, 107552. [Google Scholar] [CrossRef]

- Murr, L.E.; Gaytan, S.M.; Ceylan, A.; Martinez, E.; Martinez, J.L.; Hernandez, D.H.; Machado, B.I.; Ramirez, D.A.; Medina, F.; Collins, S.; et al. Characterization of titanium aluminide alloy components fabricated by additive manufacturing using electron beam melting. Acta Mater. 2010, 58, 1887–1894. [Google Scholar] [CrossRef]

- Koike, M.; Martinez, K.; Guo, L.; Chahine, G.; Kovacevic, R.; Okabe, T. Evaluation of titanium alloy fabricated using electron beam melting system for dental applications. J. Mater. Process. Technol. 2011, 211, 1400–1408. [Google Scholar] [CrossRef]

- Neira Arce, A. Thermal Modeling and Simulation of Electron Beam Melting for Rapid Prototyping on Ti6Al4V Alloys. Ph.D. Thesis, North Carolina State Univerity, Raleigh, NC, USA, 2012. [Google Scholar]

- Karlsson, J.; Snis, A.; Engqvist, H.; Lausmaa, J. Characterization and comparison of materials produced by Electron Beam Melting (EBM) of two different Ti–6Al–4V powder fractions. J. Mater. Process. Technol. 2013, 213, 2109–2118. [Google Scholar] [CrossRef]

- Safdar, A.; He, H.; Wei, L.-Y.; Snis, A.; Chavez de Paz, L.E. Effect of process parameters settings and thickness on surface roughness of EBM produced Ti-6Al-4V. Rapid Prototyp. J. 2012, 18, 401–408. [Google Scholar] [CrossRef]

- Jamshidinia, M.; Kovacevic, R. The influence of heat accumulation on the surface roughness in powder-bed additive manufacturing. Surf. Topogr. Metrol. Prop. 2015, 3, 014003. [Google Scholar] [CrossRef]

- Galati, M.; Snis, A.; Iuliano, L. Experimental validation of a numerical thermal model of the EBM process for Ti6Al4V. Comput. Math. Appl. 2018, in press. [Google Scholar] [CrossRef]

- Klingvall Ek, R.; Rännar, L.-E.; Bäckstöm, M.; Carlsson, P. The effect of EBM process parameters upon surface roughness. Rapid Prototyp. J. 2016, 22, 495–503. [Google Scholar] [CrossRef]

- Wang, P.; Sin, W.; Nai, M.; Wei, J. Effects of processing parameters on surface roughness of additive manufactured Ti-6Al-4V via electron beam melting. Materials 2017, 10, 1121. [Google Scholar] [CrossRef]

- Townsend, A.; Racasan, R.; Blunt, L. Surface-specific additive manufacturing test artefacts. Surf. Topogr. Metrol. Prop. 2018, 6, 024007. [Google Scholar] [CrossRef]

- Reeves, P.; Cobb, R. Surface deviation modeling of LMT processes—A comparative analysis. In Proceedings of the Fifth European Conference on Rapid Prototyping and Manufacturing, Helsinki, Finland, 4–6 June 1996; pp. 59–77. [Google Scholar]

- Kim, G.; Oh, Y. A benchmark study on rapid prototyping processes and machines: Quantitative comparisons of mechanical properties, accuracy, roughness, speed, and material cost. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2008, 222, 201–215. [Google Scholar] [CrossRef]

- Bartkowiak, T.; Lehner, J.T.; Hyde, J.; Wang, Z.; Pedersen, D.B.; Hansen, H.N.; Brown, C. Multi-scale areal curvature analysis of fused deposition surfaces. In Proceedings of the ASPE Spring Topical Meeting on Achieving Precision Tolerances in Additive Manufacturing, At Raleigh, NC, USA, 2015; pp. 77–82. [Google Scholar]

- Strano, G.; Hao, L.; Everson, R.M.; Evans, K.E. Surface roughness analysis, modelling and prediction in selective laser melting. J. Mater. Process. Technol. 2013, 213, 589–597. [Google Scholar] [CrossRef]

- Udroiu, R.; Braga, I.C.; Nedelcu, A. Evaluating the Quality Surface Performance of Additive Manufacturing Systems: Methodology and a Material Jetting Case Study. Materials 2019, 12, 995. [Google Scholar] [CrossRef] [PubMed]

- Zhang, K.; Fu, G.; Zhang, P.; Ma, Z.; Mao, Z.; Zhang, D.Z. Study on the Geometric Design of Supports for Overhanging Structures Fabricated by Selective Laser Melting. Materials 2018, 12, 27. [Google Scholar] [CrossRef] [PubMed]

- Rizza, G.; Galati, M.; Minetola, P. Artefact for Roughness Measurements and Data, Version 3; Mendeley Data: Amsterdam, The Netherlands, 2019. [Google Scholar]

- Petropoulos, G.P.; Pandazaras, C.N.; Davim, J.P. Surface texture characterization and evaluation related to machining. In Surface Integrity in Machining; Springer: London, UK, 2010; pp. 37–66. [Google Scholar]

- Horváth, R.; Czifra, Á.; Drégelyi-Kiss, Á. Effect of conventional and non-conventional tool geometries to skewness and kurtosis of surface roughness in case of fine turning of aluminium alloys with diamond tools. Int. J. Adv. Manuf. Technol. 2015, 78, 297–304. [Google Scholar] [CrossRef]

| Upward Surfaces | ||||||

| 1 | 2 | 3 | 4 | 5 | 6 | 7 |

| 0° | 10° | 20° | 30° | 40° | 50° | 60° |

| Downward Surfaces | ||||||

| 8 | 9 | 10 | 11 | 12 | 13 | 14 |

| 80° | 75° | 70° | 65° | 60° | 55° | 50° |

| Process Parameter for Contour | ||||||

| Melting strategy | Scan speed [mm/s] | Focus Offset [mA] | Beam Current [mA] | Number of spots | Number of contours | Hatch contours [mm] |

| MultiBeam | 850 | 6 | 5 | 70 | 3 | 0.29 |

| Process Parameter for the Hatching | ||||||

| Melting strategy | Speed Function | Focus Offset [mA] | Beam Current Max [mA] | Reference Length [mm] | Reference Current [mA] | Line Offset [mm] |

| Continuous | 45 | 25 | 20 | 45 | 12 | 0.2 |

| Analysis | Null Hypothesis: The position of the replica on the build plate affects the roughness | Degrees of Freedom | Variance | F-ratio | Fmax |

|---|---|---|---|---|---|

| 1 | Examined factor | 8 | 6.89 × 10−3 | 0.22 | 1.96 |

| Casual errors | 369 | 3.14 × 10−2 | |||

| Total | 377 | ||||

| 2 | Examined factor | 13 | 6.64 × 10−1 | 79.96 | 1.75 |

| Casual errors | 364 | 8.31 × 10−1 | |||

| Total | 377 | ||||

| 3 | Examined factor | 1 | 2.08 × 10−1 | 9.98 | 3.93 |

| Casual errors | 106 | 2.08 × 10−2 | |||

| Total | 107 |

| Source | Degrees of Freedom | Sum of Square | Mean Square | F-ratio | P-value |

|---|---|---|---|---|---|

| Slope | 6 | 175 | 29.2 | 4.67 | 0.000 |

| Position | 8 | 300 | 37.6 | 6.01 | 0.000 |

| Interaction | 48 | 520 | 10.8 | 1.17 | 0.008 |

| Error | 126 | 787 | 6.3 | ||

| Total | 188 | 1783 | |||

| S | 2.5 | R-Sq | 34.13% |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Galati, M.; Minetola, P.; Rizza, G. Surface Roughness Characterisation and Analysis of the Electron Beam Melting (EBM) Process. Materials 2019, 12, 2211. https://doi.org/10.3390/ma12132211

Galati M, Minetola P, Rizza G. Surface Roughness Characterisation and Analysis of the Electron Beam Melting (EBM) Process. Materials. 2019; 12(13):2211. https://doi.org/10.3390/ma12132211

Chicago/Turabian StyleGalati, Manuela, Paolo Minetola, and Giovanni Rizza. 2019. "Surface Roughness Characterisation and Analysis of the Electron Beam Melting (EBM) Process" Materials 12, no. 13: 2211. https://doi.org/10.3390/ma12132211

APA StyleGalati, M., Minetola, P., & Rizza, G. (2019). Surface Roughness Characterisation and Analysis of the Electron Beam Melting (EBM) Process. Materials, 12(13), 2211. https://doi.org/10.3390/ma12132211