Single-Pot Synthesis of Biodiesel using Efficient Sulfonated-Derived Tea Waste-Heterogeneous Catalyst

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Washing and Cleaning of the Waste Tea Sample

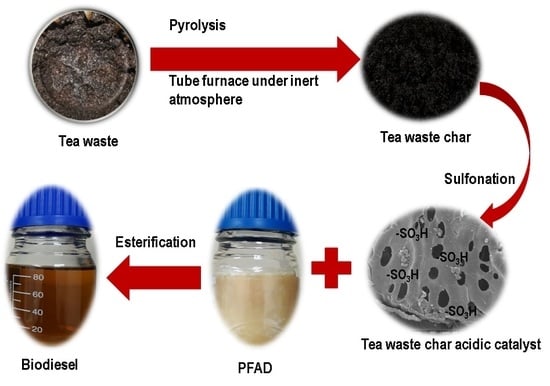

2.3. Chemical Activation of Tea Waste and Char Synthesis

2.4. Synthesis of Sulfonated Tea Waste (TW) Catalyst

2.5. Physical and Chemical Characterization of Sulfonated Tea Waste (STW) Catalyst

2.6. Catalytic Conversion Study

2.7. Reusability of The STW Catalyst

2.8. Statistical Analysis

3. Results and Discussion

3.1. Acid Density Analysis

3.2. Surface Analysis

3.3. Functional Group Analysis

3.4. Morphological Analysis

3.5. Elemental Composition

3.6. XRD Analysis

3.7. Thermal Stability Analysis

3.8. Factors Affecting Esterification Conversion

3.8.1. Effect of Methanol:PFAD Molar Ratio on FFA Conversion

3.8.2. Effect of Catalyst Loading

3.8.3. Effect of Reaction Temperature

3.8.4. Effect of Reaction Time on FFA Conversion

3.9. Regeneration and Reusability of STW Catalyst

3.10. Comparison of Catalytic Activity of Different Residues Valorized as Sulfonated Char Catalysts for Esterification

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Mahmudul, H.M.; Hagos, F.Y.; Mamat, R.; Adam, A.A.; Ishak, W.F.W.; Alenezi, R. Production, characterization and performance of biodiesel as an alternative fuel in diesel engines—A review. Renew. Sust. Energ. Rev. 2017, 72, 497–509. [Google Scholar] [CrossRef]

- Taufiq-Yap, Y.H.; Teo, S.H.; Rashid, U.; Islam, A.; Hussien, M.Z.; Lee, K.T. Transesterification of Jatropha curcas crude oil to biodiesel on calcium lanthanum mixed oxide catalyst: Effect of stoichiometric composition. Energ. Convers. Manage. 2014, 88, 1290–1296. [Google Scholar] [CrossRef]

- Munoz, R.A.A.; Fernandes, D.M.; Santos, D.Q.; Barbosa, T.G.G.; Sousa, R.M.F. Biodiesel: Production, characterization, metallic corrosion and analytical methods for contaminants. In Biodiesel-Feedstocks, Production and Applications; Fang, Z., Ed.; InTech: London, UK, 2012; pp. 129–176. [Google Scholar]

- Mardhiah, H.H.; Ong, H.C.; Masjuki, H.H.; Lim, S.; Pang, Y.L. Investigation of carbon-based solid acid catalyst from Jatropha curcas biomass in biodiesel production. Energ. Convers. Manage. 2017, 144, 10–17. [Google Scholar] [CrossRef]

- López, D.E.; Goodwin, J.G.; Bruce, D.A.; Lotero, E. Transesterification of triacetin with methanol on solid acid and base catalysts. Appl. Catal. A-Gen. 2005, 295, 97–105. [Google Scholar] [CrossRef]

- Kligerman, D.C.; Bouwer, E.J. Prospects for biodiesel production from algae-based wastewater treatment in Brazil: A review. Renew. Sust. Energ. Rev. 2015, 52, 1834–1846. [Google Scholar] [CrossRef]

- Tao, L.; Aden, A. The economics of current and future biofuels. In Biofuels: Global Impact on Renewable Energy, Production Agriculture and Technological Advancement; Tomes, D., Lakshmanan, P., Songstad, D., Eds.; Springer: New York, NY, USA, 2011; pp. 37–70. [Google Scholar]

- Rashid, U.; Ahmad, J.; Yunus, R.; Ibrahim, M.; Masood, H.; Syam, A.M. Momordica charantia seed oil methyl esters: A kinetic study and fuel properties. Int. J. Green Energy 2014, 11, 727–740. [Google Scholar] [CrossRef]

- Demirbas, A. Progress and recent trends in biodiesel fuels. Energ. Convers. Manage. 2009, 50, 14–34. [Google Scholar] [CrossRef]

- Malaysian Palm Oil Board (MPOB). Refinery: Monthly Production of Selected Processed Palm Oil for the Month of December 2018. Available online: http://bepi.mpob.gov.my/index.php/en/statistics/production/186-production-2018/846-production-of-processed-palm-oil-2018.html (accessed on 26 April 2019).

- Metre, A.V.; Nath, K. Super phosphoric acid catalyzed esterification of palm fatty acid distillate for biodiesel production: Physicochemical parameters and kinetics. Pol. J. Chem. Technol. 2015, 17, 88–96. [Google Scholar] [CrossRef]

- Malaysian Palm Oil Board (MPOB). Overview of Malaysian Palm Oil Industry 2018. Available online: http://bepi.mpob.gov.my/images/overview/Overview_of_Industry_2018.pdf (accessed on 25 April 2019).

- Dejean, A.; Ouédraogo, I.W.K.; Mouras, S.; Valette, J.; Blin, J. Shea nut shell based catalysts for the production of ethanolic biodiesel. Energy Sustain. Dev. 2017, 40, 103–111. [Google Scholar] [CrossRef]

- Devi, B.L.A.P.; Gangadhar, K.N.; Prasad, P.S.S.; Jagannadh, B.; Prasad, R.B.N. A glycerol-based carbon catalyst for the preparation of biodiesel. ChemSusChem 2009, 2, 617–620. [Google Scholar] [CrossRef]

- Pukale, D.-D.; Maddikeri, G.-L.; Gogate, P.-R.; Pandit, A.-B.; Pratap, A.-P. Ultrasound assisted transesterification of waste cooking oil using heterogeneous solid catalyst. Ultrason. Sonochem. 2015, 22, 278–286. [Google Scholar] [CrossRef] [PubMed]

- Essamlali, Y.; Amadine, O.; Fihri, A.; Zahouily, M. Sodium modified fluorapatite as a sustainable solid bi-functional catalyst for biodiesel production from rapeseed oil. Renew. Energ. 2019, 133, 1295–1307. [Google Scholar] [CrossRef]

- Alhassan, F.H.; Rashid, U.; Taufiq-Yap, Y.H. Synthesis of waste cooking oil-based biodiesel via effectual recyclable bi-functional Fe2O3MnOSO42−/ZrO2 nanoparticle solid catalyst. Fuel 2015, 142, 38–45. [Google Scholar] [CrossRef]

- Soltani, S.; Rashid, U.; Nehdi, I.A.; Al-Resayes, S.I. Esterification of palm fatty acid distillate using a sulfonated mesoporous CuO-ZnO mixed metal oxide catalyst. Chem. Eng. Technol. 2017, 40, 1931–1939. [Google Scholar] [CrossRef]

- Dal Pozzo, D.M.; Azevedo Dos Santos, J.A.; Júnior, E.S.; Santos, R.F.; Feiden, A.; Melegari De Souza, S.N.; Burgardt, I. Free fatty acids esterification catalyzed by acid Faujasite type zeolite. RSC Adv. 2019, 9, 4900–4907. [Google Scholar] [CrossRef] [Green Version]

- Konwar, L.J.; Boro, J.; Deka, D. Review on latest developments in biodiesel production using carbon-based catalysts. Renew. Sust. Energ. Rev. 2014, 29, 546–564. [Google Scholar] [CrossRef]

- Mansir, N.; Taufiq-Yap, Y.H.; Rashid, U.; Lokman, I.M. Investigation of heterogeneous solid acid catalyst performance on low grade feedstocks for biodiesel production: A review. Energ. Convers. Manage. 2017, 141, 171–182. [Google Scholar] [CrossRef]

- Sharma, A.; Pareek, V.; Zhang, D. Biomass pyrolysis—A review of modelling, process parameters and catalytic studies. Renew. Sust. Energ. Rev. 2015, 50, 1081–1096. [Google Scholar] [CrossRef]

- Konwar, L.J. Biochar supported Cao as heterogeneous catalyst for biodiesel production. Int. J. Innov. Res. Dev. 2012, 1, 186–195. [Google Scholar]

- Mahmood, T.; Hussain, S.T. Nanobiotechnology for the production of biofuels from spent tea. Afr. J. Biotechnol. 2010, 9, 858–868. [Google Scholar] [Green Version]

- Ayas, N.; Esen, T. Hydrogen production from tea waste. Int. J. Hydrogen Energ. 2016, 41, 8067–8072. [Google Scholar] [CrossRef]

- Fadhil, A.B.; Dheyab, M.M. Purification of biodiesel using activated carbons produced from spent tea waste. J. Assn. Arab Univ. Basic Appl. Sci. 2012, 11, 45–49. [Google Scholar] [CrossRef] [Green Version]

- Malakahmad, A.; Tan, S.; Yavari, S. Valorization of wasted black tea as a low-cost adsorbent for nickel and zinc removal from aqueous solution. J. Chem. 2016, 5680983. [Google Scholar] [CrossRef]

- Ormsby, R.; Kastner, J.R.; Miller, J. Hemicellulose hydrolysis using solid acid catalysts generated from biochar. Catal. Today 2012, 190, 89–97. [Google Scholar] [CrossRef]

- Mar, W.W.; Somsook, E. Sulfonic-functionalized carbon catalyst for esterification of high free fatty acid. Procedia Eng. 2012, 32, 212–218. [Google Scholar] [CrossRef]

- Lokman, I.M.; Rashid, U.; Taufiq-Yap, Y.H.; Yunus, R. Methyl ester production from palm fatty acid distillate using sulfonated glucose-derived acid catalyst. Renew. Energ. 2015, 81, 347–354. [Google Scholar] [CrossRef]

- Konwar, L.J.; Das, R.; Thakur, A.J.; Salminen, E.; Mäki-Arvela, P.; Kumar, N. Biodiesel production from acid oils using sulfonated carbon catalyst derived from oil-cake waste. J. Mol. Catal. A-Chem. 2014, 388–389, 167–176. [Google Scholar] [CrossRef]

- Doroodmand, M.M.; Sobhani, S.; Ashoori, A. Sulfonated multiwalled carbon nanotubes (MWCNTs) as a new, efficient, and recyclable heterogeneous nanocatalyst for the synthesis of amines. Can. J. Chem. 2012, 90, 701–707. [Google Scholar] [CrossRef]

- Yu, J.T.; Dehkhoda, A.M.; Ellis, N. Development of Biochar-based Catalyst for Transesterification of Canola Oil. Energ. Fuel. 2011, 25, 337–344. [Google Scholar] [CrossRef]

- Shu, Q.; Gao, J.; Nawaz, Z.; Liao, Y.; Wang, D.; Wang, J. Synthesis of biodiesel from waste vegetable oil with large amounts of free fatty acids using a carbon-based solid acid catalyst. Appl. Energ. 2010, 87, 2589–2596. [Google Scholar] [CrossRef]

- Abu-Jrai, A.M.; Jamil, F.; Al-Muhtaseb, A.H.; Baawain, M.; Al-Haj, L.; Al-Hinai, M. Valorization of waste Date pits biomass for biodiesel production in presence of green carbon catalyst. Energ. Convers. Manage. 2017, 135, 236–243. [Google Scholar] [CrossRef]

- Rao, B.V.S.K.; Chandra Mouli, K.; Rambabu, N.; Dalai, A.K.; Prasad, R.B.N. Carbon-based solid acid catalyst from de-oiled canola meal for biodiesel production. Catal. Commun. 2011, 14, 20–26. [Google Scholar] [CrossRef]

- Akinfalabi, S.-I.; Rashid, U.; Yunus, R.; Taufiq-Yap, Y.H. Synthesis of biodiesel from palm fatty acid distillate using sulfonated palm seed cake catalyst. Renew. Energ. 2017, 111, 611–919. [Google Scholar] [CrossRef]

- Amani, H.; Ahmad, Z.; Hameed, B.H. Highly active alumina-supported Cs-Zr mixed oxide catalysts for low-temperature transesterification of waste cooking oil. Appl. Catal. A-Gen. 2014, 487, 16–25. [Google Scholar] [CrossRef]

- Ezebor, F.; Khairuddean, M.; Abdullah, A.Z.; Boey, P.L. Oil palm trunk and sugarcane bagasse derived solid acid catalysts for rapid esterification of fatty acids and moisture-assisted transesterification of oils under pseudo-infinite methanol. Bioresour. Technol. 2014, 157, 254–262. [Google Scholar] [CrossRef]

- Yu, H.; Niu, S.; Lu, C.; Li, J.; Yang, Y. Preparation and esterification performance of sulfonated coal-based heterogeneous acid catalyst for methyl oleate production. Energ. Convers. Manage. 2016, 126, 488–496. [Google Scholar] [CrossRef]

- Tao, M.-L.; Guan, H.-Y.; Wang, X.-H.; Liu, Y.-C.; Louh, R.-F. Fabrication of sulfonated carbon catalyst from biomass waste and its use for glycerol esterification. Fuel Process. Technol. 2015, 138, 355–360. [Google Scholar] [CrossRef]

- Thushari, I.; Babel, S. Sustainable utilization of waste palm oil and sulfonated carbon catalyst derived from coconut meal residue for biodiesel production. Bioresour. Technol. 2018, 248, 199–203. [Google Scholar] [CrossRef]

- Chen, G.; Fang, B. Preparation of solid acid catalyst from glucose-starch mixture for biodiesel production. Bioresour. Technol. 2011, 102, 2635–2640. [Google Scholar] [CrossRef]

- Chin, L.H.; Abdullah, A.Z.; Hameed, B.H. Sugar cane bagasse as solid catalyst for synthesis of methyl esters from palm fatty acid distillate. Chem. Eng. J. 2012, 183, 104–107. [Google Scholar] [CrossRef]

- Shuit, S.H.; Tan, S.H. Biodiesel production via esterification of palm fatty acid distillate using sulphonated multi-walled carbon nanotubes as a solid acid catalyst: Process study, catalyst reusability and kinetic study. Bioenerg. Res. 2015, 8, 605–617. [Google Scholar] [CrossRef]

- Wang, Y.-T.; Yang, X.-X.; Xu, J.; Wang, H.-L.; Wang, Z.-B.; Zhang, L.; Wang, S.-L.; Liang, J.-L. Biodiesel production from esterification of oleic acid by a sulfonated magnetic solid acid catalyst. Renew. Energ. 2019, 139, 688–695. [Google Scholar] [CrossRef]

- Bureros, G.M.A.; Tanjay, A.A.; Cuizon, D.E.S.; Go, A.W.; Cabatingan, L.K.; Agapay, R.C.; Ju, Y.-H. Cacao shell-derived solid acid catalyst for esterification of oleic acid with methanol. Renew. Energ. 2019, 138, 489–501. [Google Scholar] [CrossRef]

- Liu, T.; Li, Z.; Li, W.; Shi, C.; Wang, Y. Preparation and characterization of biomass carbon-based solid acid catalyst for the esterification of oleic acid with methanol. Bioresour. Technol. 2013, 133, 618–621. [Google Scholar] [CrossRef] [PubMed]

| Sample | NH3-TPD Analysis | Surface Characteristics | ||

|---|---|---|---|---|

| Acid Sites Density (μmol g−1) | Average Surface Area (m2 g−1) | Average Pore Volume (cm3 g−1) | Average Pore Size (nm) | |

| Tea waste char | 16.8 ± 0.48 | 59 ± 0.98 | 0.02 ± 0.002 | 4.8 ± 0.20 |

| Sulfonated tea waste catalyst | 31 ± 1.21 | 122 ± 1.60 | 0.11 ± 0.015 | 3.6 ± 0.31 |

| Samples | C | H | N | S | O* |

|---|---|---|---|---|---|

| Tea waste char | 64.65 ± 2.15 | 3.94 ± 0.10 | 2.69 ± 0.11 | 0.28 ± 0.12 | 28.19 ± 1.25 |

| Sulfonated tea waste catalyst | 58.55 ± 1.68 | 0.77 ± 0.07 | 2.71 ± 0.09 | 2.67 ± 0.10 | 35.3 ± 0.90 |

| Catalysts | Feedstock | Reaction Parameters | Reusability | References | |||

|---|---|---|---|---|---|---|---|

| Methanol/Oil or PFAD Ratio | Catalyst Loading (%) | Temperature (°C) | Time (h) | ||||

| Sulfonated sugarcane bagasse | PFAD | 20:1 | 11.5 | 170 | 0.5 | 1 run | [44] |

| Sulfonated multiwalled carbon nanotubes | PFAD | 20:1 | 3 | 170 | 2 | 5 runs | [45] |

| Sulfonated magnetic solid acid catalysts | Oleic acid | 12:1 | 9 | 90 | 5 | 4 runs | [46] |

| Cacao shell-derived solid acid catalyst | Oleic acid | 7:1 | 5 | 42 | 4 | 4 runs | [47] |

| Sulfonating carbonized corn straw | Oleic acid | 7:1 | 7 | 60 | 4 | - | [48] |

| Sulfonated tea waste | PFAD | 9:1 | 4 | 65 | 1.5 | 5 runs | This study |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rashid, U.; Ahmad, J.; Ibrahim, M.L.; Nisar, J.; Hanif, M.A.; Shean, T.Y.C. Single-Pot Synthesis of Biodiesel using Efficient Sulfonated-Derived Tea Waste-Heterogeneous Catalyst. Materials 2019, 12, 2293. https://doi.org/10.3390/ma12142293

Rashid U, Ahmad J, Ibrahim ML, Nisar J, Hanif MA, Shean TYC. Single-Pot Synthesis of Biodiesel using Efficient Sulfonated-Derived Tea Waste-Heterogeneous Catalyst. Materials. 2019; 12(14):2293. https://doi.org/10.3390/ma12142293

Chicago/Turabian StyleRashid, Umer, Junaid Ahmad, Mohd Lokman Ibrahim, Jan Nisar, Muhammad Asif Hanif, and Thomas Yaw Choong Shean. 2019. "Single-Pot Synthesis of Biodiesel using Efficient Sulfonated-Derived Tea Waste-Heterogeneous Catalyst" Materials 12, no. 14: 2293. https://doi.org/10.3390/ma12142293

APA StyleRashid, U., Ahmad, J., Ibrahim, M. L., Nisar, J., Hanif, M. A., & Shean, T. Y. C. (2019). Single-Pot Synthesis of Biodiesel using Efficient Sulfonated-Derived Tea Waste-Heterogeneous Catalyst. Materials, 12(14), 2293. https://doi.org/10.3390/ma12142293