An Investigation on the Comprehensive Property Assessment and Future Directions of Single Bamboo Fiber Reinforced Polypropylene Composites Fabricated by a Non-Woven Paving and Advanced Molding Process

Abstract

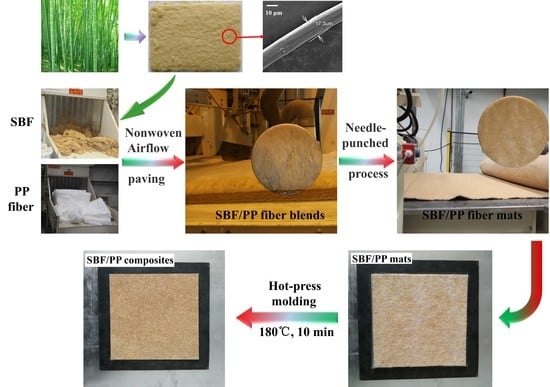

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Fiber Preparation

2.3. Composite Preparation

2.4. Characterization and Measurement

2.4.1. Tests of Mechanical Properties

2.4.2. Scanning Electron Microscopy (SEM)

2.4.3. Thermal Gravimetry (TG)

2.4.4. Differential Scanning Calorimetry (DSC)

2.4.5. Water Absorption (WA) and Thickness Swelling (TS) Properties

3. Results and Discussion

3.1. Impact Strength Analysis

3.2. Bending Properties Analysis

3.3. SEM Analysis

3.4. Analysis of Thermal Properties

3.4.1. TGA

3.4.2. DSC Analysis

3.5. Water Resistance Analysis

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Unterweger, C.; Brüggemann, O.; Fürst, C. Effects of different fibers on the properties of short-fiber-reinforced polypropylene composites. Compos. Sci. Technol. 2014, 103, 49–55. [Google Scholar] [CrossRef]

- Karsli, N.G.; Aytac, A. Effects of maleated polypropylene on the morphology, thermal and mechanical properties of short carbon fiber reinforced polypropylene composites. Mater. Design. 2011, 32, 4069–4073. [Google Scholar] [CrossRef]

- Robert, M.; Roy, R.; Benmokrane, B. Environmental Effects on Glass Fiber Reinforced Polypropylene Thermoplastic Composite Laminate for Structural Applications. Polym. Compos. 2010, 31, 604–611. [Google Scholar] [CrossRef]

- Wang, K.; Guo, M.; Zhao, D.G.; Zhang, Q.; Du, R.N.; Fu, Q.; Dong, X.; Han, C.C. Facilitating transcrystallization of polypropylene/glass fiber composites by imposed shear during injection molding. Polymer 2006, 47, 8374–8379. [Google Scholar] [CrossRef]

- Arroyo, M.; Bell, M. Morphology/behavior relationship and recyclability of composites based of PP/EPDM blends and short aramid fiber. J. Appl. Polym. Sci. 2002, 83, 2474–2484. [Google Scholar] [CrossRef]

- Ramires, E.C.; Megiatto, J.D., Jr.; Gardrat, C.; Castellan, A.; Frollini, E. Biobased composites from glyoxal–phenolic resins and sisal fibers. Bioresour. Technol. 2010, 10, 1998–2006. [Google Scholar] [CrossRef] [PubMed]

- Reddy, N.; Yang, Y.Q. Properties and potential applications of natural cellulose fibers from the bark of cotton stalks. Bioresour. Technol. 2009, 100, 3563–3569. [Google Scholar] [CrossRef] [PubMed]

- Li, X.; Li, Y.H.; Zhong, Z.K.; Wang, D.H.; Ratto, J.A.; Sheng, K.C.; Sun, X.S. Mechanical and water soaking properties of medium density fiberboard with wood fiber and soybean protein adhesive. Bioresour. Technol. 2009, 100, 3556–3562. [Google Scholar] [CrossRef]

- Baley, C. Analysis of the flax fibres tensile behaviour and analysis of the tensile stiffness increase. Compos. Part A Appl. Sci. Manuf. 2002, 33, 939–948. [Google Scholar] [CrossRef]

- Biagiotti, J.; Puglia, D.; Kenny, J.M. A review on natural fibre based composites-part I: Structure, processing and properties of vegetable fibres. J. Nat. Fibers 2004, 1, 37–68. [Google Scholar] [CrossRef]

- Puglia, D.; Biagiotti, J.; Kenny, J.M. A review on natural fibre-based composites-part II: Application of natural reinforcements in composite materials for automotive industry. J. Nat. Fibers 2004, 1, 23–65. [Google Scholar] [CrossRef]

- Tang, Q.H.; Wang, Y.F.; Ren, Y.P.; Zhang, W.; Guo, W.J. A novel strategy for the extraction and preparation of bamboo-fiber-reinforced polypropylene composites. Polym. Compos. 2019, 40, 2178–2186. [Google Scholar] [CrossRef]

- Glória, G.O.; Margema, F.M.; Ribeiroa, C.G.D.; Moraesa, Y.M.D.; Cruzb, R.B.D.; Silvac, F.D.A.; Monteirob, S.N. Charpy impact tests of epoxy composites reinforced with giant bamboo fibers. Mater. Res. 2015, 18, 178–184. [Google Scholar] [CrossRef]

- Moe Moe Thwe, K.L. Environmental effects on bamboo–glass/polypropylene hybrid composites. J. Mater. Sci. 2003, 8, 363–376. [Google Scholar] [CrossRef]

- Ray, A.K.; Das, S.K.; Mondal, S. Microstructural characterization of bamboo. J. Mater. Sci. 2004, 39, 1055–1060. [Google Scholar] [CrossRef]

- Osorio, L.; Trujillo, E.; Vuure, A.W.V.; Verpoest, I. Morphological aspects and mechanical properties of single bamboo fibers and flexural characterization of bamboo/epoxy composites. J. Reinf. Plast. Compos. 2010, 30, 396–408. [Google Scholar] [CrossRef]

- Grosser, D.; Liese, W. On the anatomy of Asian bamboos, with special reference to their vascular bundles. Wood Sci. Technol. 1971, 5, 290–312. [Google Scholar] [CrossRef]

- Fei, P.; Chen, X.; Xiong, H.G.; Din, Z.U.; Chen, L.; Cai, J. Synthesis of H2Ti2O3·H2O nanotubes and their effects on the flame retardancy of bamboo fiber/high-density polyethylene composites. Compos. Part A Appl. Sci. Manuf. 2016, 90, 225–233. [Google Scholar] [CrossRef]

- Bahari, S.A.; Krause, A. Utilizing Malaysian bamboo for use in thermoplastic composites. J. Clean Prod. 2016, 110, 16–24. [Google Scholar] [CrossRef]

- Wang, Y.N.; Weng, Y.X.; Wang, L. Characterization of interfacial compatibility of polylactic acid and bamboo flour (PLA/BF) in biocomposites. Polym. Test. 2014, 36, 119–125. [Google Scholar] [CrossRef]

- Wang, Y.Y.; Shih, Y.F. Flame-retardant recycled bamboo chopstick fiber-reinforced poly(lactic acid) green composites via multifunctional additive system. J. Taiwan Inst. Chem. E. 2016, 65, 452–458. [Google Scholar] [CrossRef]

- Nahar, S.; Khan, R.A.; Dey, K.; Sarker, B.; Anjan, K.; Ghoshal, D.S. Comparative studies of mechanical and interfacial properties between jute and bamboo fiber-reinforced polypropylene-based composites. J. Thermoplast. Compos. 2012, 25, 15–32. [Google Scholar] [CrossRef]

- Sukmawan, R.; Takagi, H.; Nakagaito, A.N. Strength evaluation of cross-ply green composite laminates reinforced by bamboo fiber. Compos. B Eng. 2016, 84, 9–16. [Google Scholar] [CrossRef]

- Li, Y.; Jiang, L.Y.; Xiong, C.D.; Peng, W.J. Effect of different surface treatment for bamboo fiber on the crystallization behavior and mechanical property of bamboo fiber/ nanohydroxyapatite/poly(lactic-co-glycolic) composite. Ind. Eng. Chem. Res. 2015, 54, 12017–12024. [Google Scholar] [CrossRef]

- Liu, W.D.; Xie, T.S.; Qiu, R.H. Bamboo fibers grafted with a soybean-oil-based monomer for its unsaturated polyester composites. Cellulose 2016, 23, 2501–2513. [Google Scholar] [CrossRef]

- Yu, Y.; Wang, H.K.; Fang, L.; Tian, G.L.; Lin, J.G. Bamboo fibers for composite applications: A mechanical and morphological investigation. J. Mater. Sci. 2014, 49, 2559–2566. [Google Scholar] [CrossRef]

- Chen, H.; Wang, G.; Cheng, H.T. Properties of single bamboo fibers isolated by different chemical methods. Wood Fiber Sci. 2011, 43, 111–120. [Google Scholar]

- Shao, Z.P.; Fang, C.H.; Huang, S.X. Tensile properties of Moso bamboo and its components with respect to its fiber-reinforced composite structure. Wood Sci. Technol. 2010, 44, 655–666. [Google Scholar] [CrossRef]

- Pinto, M.; Chalivendra, V.B.; Kim, Y.K.; Lewis, A.F. Improving the strength and service life of jute/epoxy laminar composites for structural applications. Compos. Struct. 2016, 156, 333–337. [Google Scholar] [CrossRef]

- Wood-Based Panels-Determination of Modulus of Elasticity in Bending and of Bending Strength; ISO 16978-2003; International Organization for Standardization: Geneva, Swizerland, 2003.

- Plastics-Determinationofcharpyimpactproperties—Part1:Non-instrumentedimpacttest; GB/T1043.1-2008; Standardization Administration of the People’s Republic of China: Beijing, China, 2009.

- Wood-Based Panels-of Swelling in Thickness after Immersion in Water; International Organization for Standardization 16983: 2003; ISO: Geneva, Swizerland, 2003.

- Ying, S.; Wang, C.; Lin, Q. Effects of heat treatment on the properties of bamboo fiber/polypropylene composites. Fiber Polym. 2013, 14, 1894–1898. [Google Scholar] [CrossRef]

- Boukehili, H.; Nguyen-Tri, P. Helium gas barrier and water absorption behavior of bamboo fiber reinforced recycled polypropylene. J. Reinf. Plast. Comp. 2012, 31, 1638–1651. [Google Scholar] [CrossRef]

- Chen, R.S.; Ghani, M.H.A.; Ahmad, S.; Salleh, M.N.; Tarawneh, M.A. Rice husk flour biocomposites based on recycled high-density polyethylene/polyethylene terephthalate blend: Effect of high filler loading on physical, mechanical and thermal properties. J. Compos. Mater. 2015, 49, 1241–1253. [Google Scholar] [CrossRef]

- Chen, R.S.; Ahmad, S.; Gan, S. Rice husk bio-filler reinforced polymer blends of recycled HDPE/PET: Three-dimensional stability under water immersion and mechanical performance. Polym. Compos. 2018, 39, 2695–2704. [Google Scholar] [CrossRef]

- Ashori, A.; Nourbakhsh, A. Mechanical behavior of agro-residue-reinforced polypropylene composites. J. Appl. Polym. Sci. 2009, 111, 2616–2620. [Google Scholar] [CrossRef]

- Chattopadhyay, S.K.; Khandal, R.K.; Uppaluri, R.; Ghoshal, A.K. Bamboo fiber reinforced polypropylene composites and their mechanical, thermal, and morphological properties. J. Appl. Pplym. Sci. 2011, 119, 1619–1626. [Google Scholar] [CrossRef]

- Rahman, M.R.; Hamdan, S.; Hashim, D.M.A.; Islam, M.S.; Takagi, H. Bamboo fiber polypropylene composites: Effect of fiber treatment and nano clay on mechanical and thermal properties. J. Vinyl. Addit. Techn. 2015, 21, 253–258. [Google Scholar] [CrossRef]

- Hu, L.; Zhou, Y.; Zhang, M.; Liu, R. Characterization and properties of a lignosulfonate-based phenolic foam. BioResources 2012, 7, 554–564. [Google Scholar]

- Kim, U.J.; Eom, S.H.; Wada, M. Thermal decomposition of native cellulose: influence on crystallite size. Polym. Degrad. Stabil. 2010, 95, 778–781. [Google Scholar] [CrossRef]

- Chen, R.S.; Salleh, M.N.; Ghani, M.H.A.; Ahmad, S.; Gan, S. Biocomposites based on rice husk flour and recycled polymer blend: Effects of interfacial modification and high fibre loading. BioResources 2015, 10, 6872–6885. [Google Scholar] [CrossRef]

| Fiber | Tensile Strength (MPa) | Elongation at Break (%) | Young’s Modulus (MPa) | Density (g/cm3) |

|---|---|---|---|---|

| Jute | 187–773 | 1.4–3.1 | 3–55 | 1.30–1.50 |

| Flax | 343–1035 | 2.7–3.2 | 27–80 | 1.40–1.50 |

| Sisal | 507–855 | 2.0–2.9 | 9.0–28.0 | 1.30–1.50 |

| Ramie | 400–938 | 3.6–3.8 | 44–128 | ~1.50 |

| Hemp | 580–1110 | 1.3–4.7 | 3–90 | 1.40–1.50 |

| E-glass | 2000–35,000 | ~2.5 | ~73.0 | 2.50–2.55 |

| Carbon | ~4000 | 5.5–6.9 | 230.0–240.0 | 1.40–1.75 |

| Samples Name | T5% (°C) | Tmaxs1 (°C) | Tmaxs2 (°C) | Char at 600 °C (%) | Tc (°C) | Melting Enthalpy (J/g) |

|---|---|---|---|---|---|---|

| PP | 415.2 | 463.0 | - | 0.04 | 170.3 | 102.5 |

| SBFs | 266.9 | - | 349.7 | 21.7 | - | - |

| 10%-SBF/PP | 371.0 | 349.6 | 464.6 | 1.5 | 167.1 | 79.1 |

| 20%-SBF/PP | 347.3 | 356.3 | 464.2 | 3.6 | 165.2 | 76.9 |

| 40%-SBF/PP | 320.8 | 359.5 | 465.0 | 6.4 | 165.9 | 68.3 |

| 50%-SBF/PP | 312.3 | 360.9 | 465.7 | 8.2 | 165.4 | 58.8 |

| 60%-SBF/PP | 292.3 | 346.2 | 466.1 | 13.4 | 165.8 | 49.3 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tang, Q.; Wang, Y.; Wang, G.; Cheng, H.; Guo, W. An Investigation on the Comprehensive Property Assessment and Future Directions of Single Bamboo Fiber Reinforced Polypropylene Composites Fabricated by a Non-Woven Paving and Advanced Molding Process. Materials 2019, 12, 2641. https://doi.org/10.3390/ma12162641

Tang Q, Wang Y, Wang G, Cheng H, Guo W. An Investigation on the Comprehensive Property Assessment and Future Directions of Single Bamboo Fiber Reinforced Polypropylene Composites Fabricated by a Non-Woven Paving and Advanced Molding Process. Materials. 2019; 12(16):2641. https://doi.org/10.3390/ma12162641

Chicago/Turabian StyleTang, Qiheng, Yunfei Wang, Ge Wang, Haitao Cheng, and Wenjing Guo. 2019. "An Investigation on the Comprehensive Property Assessment and Future Directions of Single Bamboo Fiber Reinforced Polypropylene Composites Fabricated by a Non-Woven Paving and Advanced Molding Process" Materials 12, no. 16: 2641. https://doi.org/10.3390/ma12162641

APA StyleTang, Q., Wang, Y., Wang, G., Cheng, H., & Guo, W. (2019). An Investigation on the Comprehensive Property Assessment and Future Directions of Single Bamboo Fiber Reinforced Polypropylene Composites Fabricated by a Non-Woven Paving and Advanced Molding Process. Materials, 12(16), 2641. https://doi.org/10.3390/ma12162641