Performance and Durability of Porous Asphalt Mixtures Manufactured Exclusively with Electric Steel Slags

Abstract

:1. Introduction

2. Materials and Methods

2.1. Natural Aggregates, Cement, and Binder

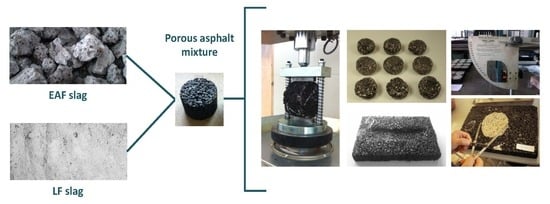

2.2. Ladle Furnace (LF) Slag and Electric Arc Furnace (EAF) Slag

2.3. Specimen Preparation

2.4. Mix Design

2.5. Testing Program

2.5.1. Volumetric and Permeability Properties

2.5.2. Mechanical Behavior

2.5.3. Durability

- In the aged abrasion loss (AAL) test, the aging process as per ASTM D-7064 [71] consisted in conditioning the samples in an oven for seven days at 60 °C.

- Additionally, in the long-term performance (LTP) test, specimens underwent aging in a controlled atmosphere humidity chamber at 23 °C and 96% humidity for six months, to evaluate the result of bitumen aging on the cohesion of the mixes.

- Cold abrasion loss (CAL) was then evaluated through the procedure proposed by Alvarez et al. [69], by conditioning the samples at a near-freezing temperature of 1 °C over 24 h, to evaluate the stiffness of the binder, the potential brittle fracture, and the susceptibility to cracking of the porous asphalt.

2.5.4. Moisture Susceptibility

2.5.5. Skid Resistance

2.5.6. Resistance to Permanent Deformation

3. Results and Discussion

3.1. Volumetric Properties

3.2. Mechanical Behavior

3.3. Durability

3.4. Moisture Susceptibility

3.5. Skid Resistance

3.6. Resistance to Permanent Deformations

4. Conclusions

- Steelmaking slag mixtures were more porous and permeable than the standard mixtures. The high roughness and sharpness of the EAF slag complicated compaction and created mixtures with higher air void contents, even if still meeting the technical specifications.

- In general, abrasion loss results fulfilled the standards for the heaviest loads, but introducing the slags yielded a slightly worse performance than the conventional mixes, which could be due to the increment in porosity of the slag mixes.

- The selected durability indexes were enhanced with the incorporation of slags, making these pavements less susceptible to aging and to thermal cracking.

- The presence of steel slag aggregates, rather than leading to a reduction of the water sensitivity of the mixtures, even improved it. In particular, the mixture prepared with both EAF and LFS showed similar or even improved performance in comparison with the reference mix, in all likelihood due to the rougher texture of the EAFS, which improved adhesion and the affinity with the bitumen, counterbalancing the effects of a higher void content.

- The slag pavements showed excellent skid resistance. Their higher permeability and rougher texture meant that they were very appropriate for rainy regions.

- The specific features of the EAFS as a coarse aggregate enhanced the pavement resistance to permanent deformation.

Author Contributions

Funding

Conflicts of Interest

References

- Craig Heidrich, K.K.; Reiche, T.; Merkel, T. Iron and Steel Slags: Global Perspective on the Circular Economy. In Proceedings of the 9th EUROSLAG Conference, Metz, France, 11–13 October 2017. [Google Scholar]

- Cardoso, C.; Camões, A.; Eires, R.; Mota, A.; Araújo, J.; Castro, F.; Carvalho, J. Using foundry slag of ferrous metals as fine aggregate for concrete. Resour. Conserv. Recycl. 2018, 138, 130–141. [Google Scholar] [CrossRef]

- D’Amore, G.K.O.; Caniato, M.; Travan, A.; Turco, G.; Marsich, L.; Ferluga, A.; Schmid, C. Innovative thermal and acoustic insulation foam from recycled waste glass powder. J. Clean. Prod. 2017, 165, 1306–1315. [Google Scholar] [CrossRef]

- Marques, D.V.; Barcelos, R.L.; Parma, G.O.C.; Girotto, E.; Junior, A.C.; Pereira, N.C.; Magnago, R.F. Recycled polyethylene terephthalate and aluminum anodizing sludge-based boards with flame resistance. Waste Manag. 2019, 92, 1–14. [Google Scholar] [CrossRef] [PubMed]

- EUROSLAG. Position Paper on the Status of Ferrous Slag; The European Slag Association: Duisburg, Germany, 2013. [Google Scholar]

- CEDEX. Catálogo de Residuos Utilizables en Construcción–Escorias de Acería de Horno de Arco Eléctrico. Available online: http://www.cedexmateriales.es/catalogo-de-residuos/25/escorias-de-aceria-de-horno-de-arco-electrico/ (accessed on 1 June 2019).

- Domas, J. Regulatory Framework for Iron and Steel Slags: Towards Major Legal Changes for Slags in France–A New Revolution? In Proceedings of the 9th EUROSLAG Conference, Metz, France, 11–13 October 2017. [Google Scholar]

- Skaf, M.; Manso, J.M.; Aragón, Á.; Fuente-Alonso, J.A.; Ortega-López, V. EAF slag in asphalt mixes: A brief review of its possible re-use. Resour. Conserv. Recycl. 2017, 120, 176–185. [Google Scholar] [CrossRef]

- Pasetto, M.; Baliello, A.; Giacomello, G.; Pasquini, E. Sustainable solutions for road pavements: A multi-scale characterization of warm mix asphalts containing steel slags. J. Clean. Prod. 2017, 166, 835–843. [Google Scholar] [CrossRef]

- Maghool, F.; Arulrajah, A.; Du, Y.-J.; Horpibulsuk, S.; Chinkulkijniwat, A. Environmental impacts of utilizing waste steel slag aggregates as recycled road construction materials. Clean Technol. Environ. Policy 2016, 19, 949–958. [Google Scholar] [CrossRef]

- Sudla, P.; Horpibulsuk, S.; Chinkulkijniwat, A.; Arulrajah, A.; Liu, M.D.; Hoy, M. Marginal lateritic soil/crushed slag blends as an engineering fill material. Soils Found. 2018, 58, 786–795. [Google Scholar] [CrossRef]

- Asi, I.M.; Qasrawi, H.Y.; Shalabi, F.I. Use of steel slag aggregate in asphalt concrete mixes. Can. J. Civ. Eng. 2007, 34, 902–911. [Google Scholar] [CrossRef]

- Pattanaik, M.L.; Choudhary, R.; Kumar, B. Laboratory evaluation of mix design parameters of open-graded friction course mixes with electric arc furnace steel slag. Adv. Civ. Eng. Mater. 2018, 7, 616–632. [Google Scholar] [CrossRef]

- Faleschini, F.; De Marzi, P.; Pellegrino, C. Recycled concrete containing EAF slag: Environmental assessment through LCA. Eur. J. Environ. Civ. Eng. 2014, 18, 1009–1024. [Google Scholar] [CrossRef]

- Fuente-Alonso, J.A.; Ortega-López, V.; Skaf, M.; Aragón, Á.; San-José, J.T. Performance of fiber-reinforced EAF slag concrete for use in pavements. Constr. Build. Mater. 2017, 149, 629–638. [Google Scholar] [CrossRef]

- Santamaría, A.; Orbe, A.; Losañez, M.M.; Skaf, M.; Ortega-Lopez, V.; González, J.J. Self-compacting concrete incorporating electric arc-furnace steelmaking slag as aggregate. Mater. Des. 2017, 115, 179–193. [Google Scholar] [CrossRef]

- Qasrawi, H. Towards sustainable self-compacting concrete: Effect of recycled slag coarse aggregate on the fresh properties of SCC. Adv. Civ. Eng. 2018, 2018, 1–9. [Google Scholar] [CrossRef]

- Ortega-López, V.; Skaf, M.; Santamaría, A. The reuse of ladle furnace basic slags in clayey soil-stabilization applications. In Soil Stabilization: Types, Methods and Applications; Nova Science Publishers, Inc.: Hauppauge, NY, USA, 2017; pp. 231–271. [Google Scholar]

- Moliné, M.N.; Calvo, W.A.; Martinez, A.G.T.; Galliano, P.G. Ambient weathering of steelmaking ladle slags. Ceram. Int. 2018, 44, 18920–18927. [Google Scholar] [CrossRef]

- Adolfsson, D.; Engström, F.; Robinson, R.; Björkman, B. Cementitious phases in ladle slag. Steel Res. Int. 2011, 82, 398–403. [Google Scholar] [CrossRef]

- Papayianni, I.; Anastasiou, E. Effect of granulometry on cementitious properties of ladle furnace slag. Cem. Concr. Compos. 2012, 34, 400–407. [Google Scholar] [CrossRef]

- Herrero, T.; Vegas, I.J.; Santamaría, A.; San-José, J.T.; Skaf, M. Effect of high-alumina ladle furnace slag as cement substitution in masonry mortars. Constr. Build. Mater. 2016, 123, 404–413. [Google Scholar] [CrossRef]

- Sáez-De-Guinoa, A.; Ferreira, V.J.; López-Sabirón, A.M.; Aranda-Usón, A.; Lausín-González, C.; Berganza-Conde, C.; Ferreira, G. Utilization of ladle furnace slag from a steelwork for laboratory scale production of portland cement. Constr. Build. Mater. 2015, 94, 837–843. [Google Scholar] [CrossRef]

- Brand, A.S.; Roesler, J.R. Interfacial transition zone of cement composites with steel furnace slag aggregates. Cem. Concr. Compos. 2018, 86, 117–129. [Google Scholar] [CrossRef]

- García-Cuadrado, J.; Santamaría-Vicario, I.; Rodríguez, A.; Calderón, V.; Gutiérrez-González, S. Lime-cement mortars designed with steelmaking slags as aggregates and validation study of their properties using mathematical models. Constr. Build. Mater. 2018, 188, 210–220. [Google Scholar] [CrossRef]

- Perez-Garcia, F.; Parron-Rubio, M.E.; Garcia-Manrique, J.M.; Rubio-Cintas, M.D. Study of the suitability of different types of slag and its influence on the quality of green grouts obtained by partial replacement of cement. Materials 2019, 12, 1166. [Google Scholar] [CrossRef] [PubMed]

- Alonso, A.; Rodríguez, A.; Gadea, J.; Gutiérrez-González, S.; Calderón, V. Impact of plasterboard with ladle furnace slag on fire reaction and thermal behavior. Fire Technol. 2019, 55, 1733–1751. [Google Scholar] [CrossRef]

- Ortega-López, V.; Manso, J.M.; Cuesta, I.I.; González, J.J. The long-term accelerated expansion of various ladle-furnace basic slags and their soil-stabilization applications. Constr. Build. Mater. 2014, 68, 455–464. [Google Scholar] [CrossRef]

- Frías Rojas, M.; Sánchez, M.I. Chemical assessment of the electric arc furnace slag as construction material: Expansive compounds. Cem. Concr. Res. 2004, 34, 1881–1888. [Google Scholar] [CrossRef]

- Santamaria, A.; Faleschini, F.; Giacomello, G.; Brunelli, K.; San José, J.T.; Pellegrino, C.; Pasetto, M. Dimensional stability of electric arc furnace slag in civil engineering applications. J. Clean. Prod. 2018, 205, 599–609. [Google Scholar] [CrossRef]

- Scheibmeir, E.; Ortiz, J.; Bou, M. Mezclas bituminosas de granulometría continua elaboradas enteramente con árido siderúrgico, communication 47. In VI Jornadas Nacionales; de la Asociación Española de Fabricantes de Mezclas Asfálticas (ASEFMA): Madrid, Spain, 2011. [Google Scholar]

- Xue, Y.; Hou, H.; Zhu, S.; Zha, J. Utilization of municipal solid waste incineration ash in stone mastic asphalt mixture: Pavement performance and environmental impact. Constr. Build. Mater. 2009, 23, 989–996. [Google Scholar] [CrossRef]

- Milačič, R.; Zuliani, T.; Oblak, T.; Mladenovič, A.; Ščančar, J. Environmental impacts of asphalt mixes with electric arc furnace steel slag. J. Environ. Qual. 2011, 40, 1153–1161. [Google Scholar] [CrossRef] [PubMed]

- Sorlini, S.; Sanzeni, A.; Rondi, L. Reuse of steel slag in bituminous paving mixtures. J. Hazard. Mater. 2012, 209, 84–91. [Google Scholar] [CrossRef] [PubMed]

- Alvarez, A.; Martin, A.; Estakhri, C. A review of mix design and evaluation research for permeable friction course mixtures. Constr. Build. Mater. 2011, 25, 1159–1166. [Google Scholar] [CrossRef]

- Tanzadeh, J.; Gamasaei, R.S.; Gilani, F.R. Laboratory evaluation on the performance comparison between OGFC asphalt reinforcement with fibers and modified with nanosilica. J. Test. Eval. 2019, 48. [Google Scholar] [CrossRef]

- Mullaney, J.; Lucke, T. Practical review of pervious pavement designs. Clean Soil Air Water 2014, 42, 111–124. [Google Scholar] [CrossRef]

- Pančić, I.; Ilić, V.; Orešković, M.; Gavran, D. The Use of Porous Asphalt for the Improvement of the Grading Plan Geometry and Drainage of Pavement Surfaces on Urban Roads; Wegman, F., Dell’Acqua, G., Eds.; CRC Press: Boca Raton, FL, USA, 2017; pp. 443–450. [Google Scholar]

- Afonso, M.L.; Dinis-Almeida, M.; Fael, C.S. Characterization of the Skid Resistance and Mean Texture Depth in a Permeable Asphalt Pavement; Segalini, A., Dabija, A.M., Drusa, M., Yilmaz, I., Decky, M., Rybak, J., Marschalko, M., Coisson, E., Eds.; Institute of Physics Publishing: Bristol, UK, 2019. [Google Scholar]

- Ahmad, K.A.; Abdullah, M.E.; Hassan, N.A.; Daura, H.A.; Ambak, K. A review of using porous asphalt pavement as an alternative to conventional pavement in stormwater treatment. World J. Eng. 2017, 14, 355–362. [Google Scholar] [CrossRef]

- Vaitkus, A.; Andriejauskas, T.; Vorobjovas, V.; Jagniatinskis, A.; Fiks, B.; Zofka, E. Asphalt wearing course optimization for road traffic noise reduction. Constr. Build. Mater. 2017, 152, 345–356. [Google Scholar] [CrossRef]

- Knabben, R.M.; Trichês, G.; Gerges, S.N.Y.; Vergara, E.F. Evaluation of sound absorption capacity of asphalt mixtures. Appl. Acoust. 2016, 114, 266–274. [Google Scholar] [CrossRef]

- ANEFA (National Association of Aggregate Manufacturers). El Sector de los Áridos. Available online: http://www.aridos.org/el-sector/ (accessed on 1 June 2019).

- Evangelista, B.L.; Rosado, L.P.; Penteado, C.S.G. Life cycle assessment of concrete paving blocks using electric arc furnace slag as natural coarse aggregate substitute. J. Clean. Prod. 2018, 178, 176–185. [Google Scholar] [CrossRef]

- Hunt, L.; Boyle, G. Steel Slag in Hot Mix Asphalt Concrete; Final Report No. OR-RD-00-09; Oregon Department of Transportation: Salem, OR, USA, 2000.

- Mladenovič, A.; Turk, J.; Kovač, J.; Mauko, A.; Cotič, Z. Environmental evaluation of two scenarios for the selection of materials for asphalt wearing courses. J. Clean. Prod. 2015, 87, 683–691. [Google Scholar] [CrossRef]

- Manso, J.M.; Hernández, D.; Losáñez, M.M.; González, J.J. Design and elaboration of concrete mixtures using steelmaking slags. ACI Mater. J. 2011, 108, 673–681. [Google Scholar]

- Polanco, J.A.; Manso, J.M.; Setién, J.; González, J.J. Strength and durability of concrete made with electric steelmaking slag. ACI Mater. J. 2011, 108, 196–203. [Google Scholar]

- Papayianni, I.; Anastasiou, E. Production of high-strength concrete using high volume of industrial by-products. Constr. Build. Mater. 2010, 24, 1412–1417. [Google Scholar] [CrossRef]

- EN 1097-6, Tests for Mechanical and Physical Properties of Aggregates. Part 6: Determination of Particle Density and Water Absorption; European Committee for Standardization: Brussels, Belgium, 2014.

- EN 933-1, Tests for Geometrical Properties of Aggregates. Part 1: Determination of Particle Size Distribution. Sieving Method; European Committee for Standardization: Brussels, Belgium, 2012.

- EN 933-8, Tests for Geometrical Properties of Aggregates. Part 8: Assessment of Fines. Sand Equivalent Test; European Committee for Standardization: Brussels, Belgium, 2015.

- EN 1097-2, Tests for Mechanical and Physical Properties of Aggregates. Part 2: Methods for the Determination of Resistance to Fragmentation; European Committee for Standardization: Brussels, Belgium, 2010.

- EN 12697-8, Bituminous Mixtures. Test Methods for Hot Mix Asphalt. Part 8: Determination of Void Characteristics of Bituminous Specimens; European Committee for Standardization: Brussels, Belgium, 2003.

- EN 933-3, Tests for Geometrical Properties of Aggregates. Part 3: Determination of Particle Shape. Flakiness Index; European Committee for Standardization: Brussels, Belgium, 2012.

- EN 933-5, Tests for Geometrical Properties of Aggregates. Part 5: Determination of Percentage of Crushed and Broken Surfaces in Coarse Aggregate Particles; European Committee for Standardization: Brussels, Belgium, 2005.

- EN 14023, Bitumen and Bituminous Binders. Specification Framework for Polymer Modified Bitumens; European Committee for Standardization: Brussels, Belgium, 2010.

- PG-3. Pliego de Prescripciones Técnicas Generales para Obras de Carreteras y Puentes, PG-3; General Technical Specifications; Spanish Ministry of Public Works: Madrid, Spain, 2014.

- Ortega-López, V.; Fuente-Alonso, J.A.; Santamaría, A.; San-José, J.T.; Aragón, Á. Durability studies on fiber-reinforced EAF slag concrete for pavements. Constr. Build. Mater. 2018, 163, 471–481. [Google Scholar] [CrossRef]

- Yildirim, I.Z.; Prezzi, M. Experimental evaluation of EAF ladle steel slag as a geo-fill material: Mineralogical, physical & mechanical properties. Constr. Build. Mater. 2017, 154, 23–33. [Google Scholar] [CrossRef]

- Skaf, M.; Ortega-López, V.; Fuente-Alonso, J.A.; Santamaría, A.; Manso, J.M. Ladle furnace slag in asphalt mixes. Constr. Build. Mater. 2016, 122, 488–495. [Google Scholar] [CrossRef] [Green Version]

- EN 12697-35, Bituminous Mixtures. Test Methods. Part 35: Laboratory Mixing; European Committee for Standardization: Brussels, Belgium, 2017.

- EN 12697-30, Bituminous Mixtures. Test Methods for Hot Mix Asphalt. Part 30: Specimen Preparation by Impact Compactor; European Committee for Standardization: Brussels, Belgium, 2013.

- EN 12697-33, Bituminous Mixtures. Test Methods for Hot Mix Asphalt. Part 33: Specimen Prepared by Roller Compactor; European Committee for Standardization: Brussels, Belgium, 2007.

- EN 12697-17, Bituminous Mixtures. Test Methods. Part 17: Particle Loss of Porous Asphalt Specimens; European Committee for Standardization: Brussels, Belgium, 2018.

- EN 12697-18, Bituminous Mixtures. Test Methods. Part 18: Binder Drainage; European Committee for Standardization: Brussels, Belgium, 2018.

- EN 12697-19, Bituminous Mixtures. Test Methods for Hot Mix Asphalt. Part 19: Permeability of Specimen; European Committee for Standardization: Brussels, Belgium, 2013.

- Mallick, R.B.; Cooley, L.A., Jr. Design, construction, and performance of new-generation open-graded friction courses. In Proceedings of the Association of Asphalt Paving Technologists, Reno, NV, USA, 13–15 March 2000; pp. 391–423. [Google Scholar]

- Alvarez, A.E.; Martin, A.E.; Estakhri, C.; Izzo, R. Evaluation of durability tests for permeable friction course mixtures. Int. J. Pavement Eng. 2010, 11, 49–60. [Google Scholar] [CrossRef]

- EN 12697-23, Bituminous Mixtures. Test Methods. Part 23: Determination of the Indirect Tensile Strength of Bituminous Specimens; European Committee for Standardization: Brussels, Belgium, 2018.

- ASTM D-7064, Standard Practice for Open-Graded Friction Course (OGFC) Mix Design; Annual Book of ASTM Standards; American Society for Testing and Materials (ASTM): West Conshohocken, PA, USA, 2013.

- EN 12697-12, Bituminous Mixtures. Test Methods. Part 12: Determination of the Water Sensitivity of Bituminous Specimens; European Committee for Standardization: Brussels, Belgium, 2019.

- Asi, I.M. Evaluating skid resistance of different asphalt concrete mixes. Build. Environ. 2007, 42, 325–329. [Google Scholar] [CrossRef]

- EN 13036-1, Road and Airfield Surface Characteristics. Test Methods. Part 1: Measurement of Pavement Surface Macrotexture Depth Using a Volumetric Patch Technique; European Committee for Standardization: Brussels, Belgium, 2010.

- EN 13036-4, Road and Airfield Surface Characteristics. Test Methods. Part 4: Method for Measurement of Slip/Skid Resistance of a Surface: The Pendulum Test; European Committee for Standardization: Brussels, Belgium, 2012.

- EN 12697-22, Bituminous Mixtures. Test Methods. Part 22: Wheel Tracking; European Committee for Standardization: Brussels, Belgium, 2008.

- Kong, D.; Chen, M.; Xie, J.; Zhao, M.; Yang, C. Geometric characteristics of BOF slag coarse aggregate and its influence on asphalt concrete. Materials 2019, 12, 741. [Google Scholar] [CrossRef]

- Oluwasola, E.A.; Hainin, M.R.; Aziz, M.M.A. Evaluation of asphalt mixtures incorporating electric arc furnace steel slag and copper mine tailings for road construction. Trans. Geotech. 2015, 2, 47–55. [Google Scholar] [CrossRef]

- Pasetto, M.; Baldo, N. Performance comparative analysis of stone mastic asphalts with electric arc furnace steel slag: A laboratory evaluation. Mater. Struct. 2012, 45, 411–424. [Google Scholar] [CrossRef]

- Bagampadde, U.; Wahhab, H.I.A.-A.; Aiban, S.A. Optimization of steel slag aggregates for bituminous mixes in Saudi Arabia. J. Mater. Civ. Eng. 1999, 11, 30–35. [Google Scholar] [CrossRef]

- Tao, G.; Xiao, Y.; Yang, L.; Cui, P.; Kong, D.; Xue, Y. Characteristics of steel slag filler and its influence on rheological properties of asphalt mortar. Constr. Build. Mater. 2019, 201, 439–446. [Google Scholar] [CrossRef]

- Xie, Y.; Li, J.; Lu, Z.; Jiang, J.; Niu, Y. Effects of bentonite slurry on air-void structure and properties of foamed concrete. Constr. Build. Mater. 2018, 179, 207–219. [Google Scholar] [CrossRef]

- Khosravani, M.R.; Weinberg, K. A review on split Hopkinson bar experiments on the dynamic characterisation of concrete. Constr. Build. Mater. 2018, 190, 1264–1283. [Google Scholar] [CrossRef]

- Alvarez, A.; Martin, A.; Estakhri, C. Optimizing the design of permeable friction course mixtures. Transp. Res. Rec. J. Trans. Res. Board 2011, 2209, 26–33. [Google Scholar] [CrossRef]

- Yan, Y.; Zaniewski, J.P.; Hernando, D. Development of a predictive model to estimate permeability of dense-graded asphalt mixture based on volumetrics. Constr. Build. Mater. 2016, 126, 426–433. [Google Scholar] [CrossRef]

- Pattanaik, M.L.; Choudhary, R.; Kumar, B. Clogging evaluation of open graded friction course mixes with EAF steel slag and modified binders. Constr. Build. Mater. 2018, 159, 220–233. [Google Scholar] [CrossRef]

- Alvarez, A.E.; Martin, A.E.; Estakhri, C. Drainability of permeable friction course mixtures. J. Mater. Civ. Eng. 2010, 22, 556–564. [Google Scholar] [CrossRef]

- Kamar, F.H.A.; Sarif, J.N. Design of porous asphalt mixture to performance related criteria. In Proceedings of the 13th Conference of the Road Engineering Association of Asia and Australasia (REAAA), Incheon City, Korea, 23–26 September 2009. [Google Scholar]

- Frigio, F.; Pasquini, E.; Ferrotti, G.; Canestrari, F. Improved durability of recycled porous asphalt. Constr. Build. Mater. 2013, 48, 755–763. [Google Scholar] [CrossRef]

- Yang, B.; Li, H.; Zhang, H.; Xie, N.; Zhou, H. Laboratorial investigation on effects of microscopic void characteristics on properties of porous asphalt mixture. Constr. Build. Mater. 2019, 213, 434–446. [Google Scholar] [CrossRef]

- Wang, Y.; Wang, G. Improvement of Porous Pavement; Final Report to US Green Building Council; East Carolina University: Greenville, NC, USA, 2011. [Google Scholar]

- Ahmedzade, P.; Sengoz, B. Evaluation of steel slag coarse aggregate in hot mix asphalt concrete. J. Hazard. Mater. 2009, 165, 300–305. [Google Scholar] [CrossRef] [PubMed]

- Kanitpong, K.; Pummarin, K. Investigation of industrial wastes in hot mix asphalt for moisture damage resistance. J. Solid Waste Technol. Manag. 2010, 36, 81–90. [Google Scholar] [CrossRef]

- Donbavand, J. Skidding resistance of road surfaces-implications for New Zealand. Publ. Natl. Roads Board N. Z. 1989, 81, 69. [Google Scholar]

- JRA. Guidelines for Porous Asphalt Pavement; Japanese Road Association Publication: Tokyo, Japan, 2005. [Google Scholar]

- CEDEX. Resistencia a la Deformación Plástica de las Mezclas Bituminosas Mediante la Pista de Ensayo de Laboratorio; Fomento, M., Ed.; Centro de Estudios de Carreteras, CEDEX: Madrid, Spain, 1984. [Google Scholar]

- Zhu, H.; Nodes, J.E. Contact based analysis of asphalt pavement with the effect of aggregate angularity. Mech. Mater. 2000, 32, 193–202. [Google Scholar] [CrossRef]

- Hainin, M.R.; Rusbintardjo, G.; Hameed, M.A.S.; Hassan, N.A.; Yusoff, N.I.M. Utilisation of steel slag as an aggregate replacement in porous asphalt mixtures. J. Teknol. 2014, 69, 67–73. [Google Scholar] [CrossRef]

| Characteristic | Test Method | Natural Agg. (0–16 mm) | EAFS (2–16 mm) | LFS (0–2 mm) | Technical Requirements |

|---|---|---|---|---|---|

| Bulk Density | EN 1097-6 [50] | 2.74 g/cm3 | 3.60 g/cm3 | 2.83 g/cm3 | - |

| Water Absorption | EN 1097-6 [50] | 1.5 % | 2.1% | 0.4% | - |

| Fineness modulus | EN 933-1 [51] | 4.2 | - | 2.9 | - |

| Sand Equivalent (SE) | EN 933-8 [52] | 78% | 98% | 50% | >50%* |

| Los Angeles (LA) | EN 1097-2 [53] | 20% | 23% | - | <25–20–15%** |

| Polished Stone Value (PSV) | EN 1097-8 [54] | 52% | 56% | - | >56–50–44%** |

| Flakiness index | EN 933-3 [55] | 18% | 3% | - | <20% |

| Crushability index | EN 933-5 [56] | 100% | 100% | - | 100–90%** |

| Component | CaO | SiO2 | MgO | Al2O3 | Fe2O3 | MnO | CO2 | Others |

|---|---|---|---|---|---|---|---|---|

| EAFS wt% | 27.7 | 19.1 | 2.5 | 13.7 | 26.8 | 5.4 | - | 4.8 |

| LFS wt% | 56.7 | 17.7 | 9.6 | 6.6 | 2.2 | - | 1.3 | 5.9 |

| Size (mm.) | 16 | 11.2 | 8 | 4 | 2 | 0.5 | 0.063 |

| % passing | 100 | 90–100 | 50–70 | 13–27 | 10–17 | 5–12 | 3–6 |

| Element | Size (mm) | PA-SSC | PA-SLL | PA-ELL | |||

|---|---|---|---|---|---|---|---|

| Material | Wt.% | Material | Wt.% | Material | Wt.% | ||

| Coarse aggregate | 16–11.2 | Siliceous | 4.8% | Siliceous | 4.8% | EAFS | 5.0% |

| 11.2–8 | Siliceous | 33.2% | Siliceous | 33.2% | EAFS | 29.7% | |

| 8–4 | Siliceous | 38.0% | Siliceous | 38.0% | EAFS | 37.6% | |

| 4–2 | Siliceous | 6.2% | Siliceous | 6.2% | EAFS | 9.9% | |

| Fine aggregate | 2–0.5 | Siliceous | 4.7% | LFS | 4.7% | LFS | 5.6% |

| 0.5–0.063 | Siliceous | 3.1% | LFS | 3.1% | LFS | 3.8% | |

| Filler | <0.063 | Cement | 5.0% | LFS | 5.0% | LFS | 4.2% |

| Binder | - | PMB 45/80-60 | 5.0% | PMB 45/80-60 | 5.0% | PMB 45/80-60 | 4.2% |

| Feature | Test | PA-SSC | PA-SLL | PA-ELL |

|---|---|---|---|---|

| Bulk density (g/cm3) | EN 12697-6 | 2.00 (0.04) | 1.99 (0.03) | 2.34 (0.04) |

| Maximum density (g/cm3) | EN 12697-5 | 2.54 | 2.57 | 3.09 |

| Air voids (%) | EN 12697-8 | 21.1 (1.3) | 21.7 (1.3) | 24.3 (0.7) |

| CT | 20.5 | 21.1 | 25.2 | |

| Voids in the Mineral Aggregate (%) | EN 12697-8 | 30.9 | 31.4 | 33.9 |

| CT | 30.2 | 31.1 | 34.9 | |

| Permeability (cm/s) | EN 12697-19 | 9.01 × 10−2 | 9.04 × 10−2 | 1.51 × 10−1 |

| Feature | Test | PA-SSC | PA-SLL | PA-ELL |

|---|---|---|---|---|

| Abrasion loss (AL) | Void content (%) | 19.8 | 20.0 | 24.1 |

| Particle loss, PL (%) | 8.06 (1.44) | 10.57 (2.02) | 14.62 (2.38) | |

| Indirect tensile strength (ITS) | Void content (%) | 20.9 | 20.7 | 23.3 |

| Maximum load (N) | 12.96 | 13.53 | 14.66 | |

| ITS (N/mm2) | 1.26 (0.03) | 1.31 (0.09) | 1.41 (0.11) |

| Feature | PA-SSC | PA-SLL | PA-ELL | |

|---|---|---|---|---|

| Microtexture | BPN fresh | 61 | 61 | 77 |

| BPN polished | 54 | 54 | 59 | |

| Macrotexture | Void content (%) | 18.5 | 21.5 | 25.4 |

| MDT (mm) | 1.53 | 1.76 | 1.89 | |

| Feature | PA-SSC | PA-SLL | PA-ELL |

|---|---|---|---|

| Mean void content of the samples | 19.53% | 20.90% | 22.91% |

| Linear slope (mm/103 cycles) | 0.58 | 0.98 | 0.24 |

| Dynamic stability, DS (passes/mm) | 2500 | 2000 | 3500 |

| Deformation rate, v (µm/min) | 16 | 20 | 12 |

| Rut depth at 4000 cycles, d4000 (mm) | 2.6 | 2.8 | 2.4 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Skaf, M.; Pasquini, E.; Revilla-Cuesta, V.; Ortega-López, V. Performance and Durability of Porous Asphalt Mixtures Manufactured Exclusively with Electric Steel Slags. Materials 2019, 12, 3306. https://doi.org/10.3390/ma12203306

Skaf M, Pasquini E, Revilla-Cuesta V, Ortega-López V. Performance and Durability of Porous Asphalt Mixtures Manufactured Exclusively with Electric Steel Slags. Materials. 2019; 12(20):3306. https://doi.org/10.3390/ma12203306

Chicago/Turabian StyleSkaf, Marta, Emiliano Pasquini, Víctor Revilla-Cuesta, and Vanesa Ortega-López. 2019. "Performance and Durability of Porous Asphalt Mixtures Manufactured Exclusively with Electric Steel Slags" Materials 12, no. 20: 3306. https://doi.org/10.3390/ma12203306

APA StyleSkaf, M., Pasquini, E., Revilla-Cuesta, V., & Ortega-López, V. (2019). Performance and Durability of Porous Asphalt Mixtures Manufactured Exclusively with Electric Steel Slags. Materials, 12(20), 3306. https://doi.org/10.3390/ma12203306