The Influence of A Cross-Channel Extrusion Process on The Microstructure and Properties of Copper

Abstract

:1. Introduction

2. Experimental

3. Results and Discussions

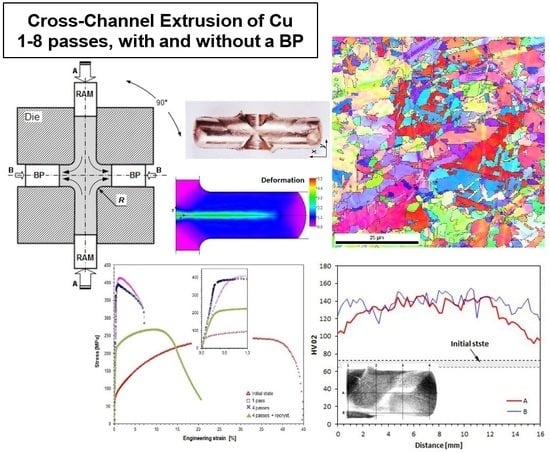

3.1. Deformation Behavior

3.2. Macro- and Microstructure

3.2.1. EBSD Analyze

3.2.2. Microhardness

3.2.3. DSC

3.2.4. Resistivity

3.2.5. Static Tensile Test

4. Conclusions

- The CCE process has been shown to be an effective method that can produce flaw-free billets. This promising technique requires relatively little pressure. In addition, the introduction of a BP improves the uniformity of the billets and allows for their cohesion.

- Processing a material by CCE, due to the large unit deformation values, results in the formation of a lamellar structure along the extruded axis, resulting from triaxial compression (zone A) and the fine-grained structure that results from the impact of the shear stress in the remaining volume of the material (zone B).

- The severely deformed material exhibited the initiation of dynamic recrystallization, which results in the formation of 0.5 to 2 μm grains after a single pass and 2- to 8-μm grains after four passes.

- An increase in the copper microhardness from 70 to 130 HV02 after one CCE pass indicates that all of the material undergoes deformation with considerable diversity. While the microhardness decrease (even to 70 HV02) and the increase in the number of passes may result in progressive recrystallization. This agrees with the exothermic peak that was observed during the DSC testing the CCE-treated copper billets. The temperature in which this exothermic peak was observed (158.5 °C) and the amount of accumulated energy (53 ± 2.1 J/mol) suggest that in such a deformed material, secondary recrystallization, and selective grain growth may also occur.

- The grain refinement caused an improvement in the YS and UTS of approximately 50%, and the elongation to failure decreased to a satisfactory value of 9.7%.

- The resistivity of the once deformed copper significantly decreases, while further processing the copper specimens causes the resistivity to increase.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Valiev, R.Z.; Islamgaliev, R.K.; Alexandrov, I.V. Bulk nanostructured materials from severe plastic deformation. Prog. Mater. Sci. 2000, 45, 103–183. [Google Scholar] [CrossRef]

- Korznikov, A.V.; Tram, G.; Dimitrov, O.; Korznikova, G.; Idrisova, S.R.; Pakiela, Z. Mechanism of nanocrystalline structure formation in Ni3Al during SPD. Acta Mater. 2001, 49, 663–671. [Google Scholar] [CrossRef]

- Azushima, A.; Kopp, R.; Korhonen, A.; Yang, D.Y.; Micari, F.; Lahoti, G.D.; Groche, P. Severe plastic deformation (SPD) processes for metals. CIRP Ann. Manuf. Technol. 2008, 57, 716–736. [Google Scholar] [CrossRef]

- Vinogradov, A. Fatigue and crack in ultra-fine grain metals produced by severe plastic deformation. J. Mater. Sci. 2007, 42, 1797–1809. [Google Scholar] [CrossRef]

- Valiev, R.Z.; Estrin, Y.; Horita, Z.; Langdon, T.G.; Zehetbauer, M.J.; Zhu, Y.T. Producing bulk ultrafine-grained materials by severe plastic deformation. JOM 2006, 58, 33–39. [Google Scholar] [CrossRef]

- Langdon, T.G. Twenty-five years of ultrafine-grained materials, pp. achieving exceptional properties through grain refinement. Acta Mater. 2013, 61, 7035–7060. [Google Scholar]

- Siemiaszko, D.; Kuzia, J. The influence of large particles of iron powder on the microstructure and properties of FeAl intermetallic phase. Intermetallics 2019, 104, 16–23. [Google Scholar] [CrossRef]

- Łazińska, M.; Durejko, T.; Zasada, D.; Bojar, Z. Microstructure and mechanical properties of a Fe-28%Al- 5%Cr-1%Nb-2%B alloy fabricated by Laser Engineered Net Shaping. Mater. Lett. 2017, 196, 87–90. [Google Scholar] [CrossRef]

- Rodak, K.; Urbańczyk-Gucwa, A.; Jabłońska, M.B.; Mizera, J. Influence of heat treatment on the formation of ultrafine-grained structure of Al–Li alloys processed by SPD. Arch. Civ. Mech. Eng. 2018, 18, 331–337. [Google Scholar] [CrossRef]

- Lee, B.S.; Kim, M.H.; Hwang, S.K.; Kwun, S.I.; Chae, S.W. Grain refinement of commercially pure zirconium by ECAP and subsequent intermediate heat treatment. Mater. Sci. Eng. A 2007, 449–451, 1087–1089. [Google Scholar] [CrossRef]

- Lee, S.W.; Chen, Y.L.; Wang, H.Y.; Yang, C.F.; Yeh, J.W. On mechanical properties and superplasticity of Mg–15Al–1Zn alloys processed by reciprocating extrusion. Mater. Sci. Eng. A 2007, 464, 76–84. [Google Scholar] [CrossRef]

- Ma, A.; Nishida, Y.; Suzuki, K.; Shigematsu, I.; Saito, N. Characteristics of plastic deformation by rotary-die equal-channel angular pressing. Scr. Mater. 2005, 52, 433–437. [Google Scholar] [CrossRef]

- Bagherpour, E.; Pardis, N.; Reihanian, M.; Ebrahimi, R. An overview on severe plastic deformation: Research status, techniques classification, microstructure evolution, and applications. Int. J. Adv. Manuf. Technol. 2018, 100, 1647–1694. [Google Scholar] [CrossRef]

- Sabirov, I.; Enikeev, N.A.; Murashkin, M.Y.; Valiev, R.Z. Bulk Nanostructured Metals for Innovative Applications. In Bulk Nanostructured Materials with Multifunctional Properties; Springer Briefs in Materials; Springer: Cham, Switzerland, 2015; pp. 101–113. [Google Scholar] [CrossRef]

- Sakai, G.; Nakamura, K.; Horita, Z.; Langdon, T.G. Developing high-pressure torsion for use with bulk samples. Mater. Sci. Eng. A 2005, 406, 268–273. [Google Scholar] [CrossRef]

- Valiev, R.Z.; Langdon, T.G. Principles of equal-channel angular pressing as a processing tool for grain refinement. Prog. Mater. Sci. 2006, 51, 881–981. [Google Scholar] [CrossRef]

- Polkowski, W.; Jóźwik, P.; Łyszkowski, R.; Bojar, Z. Differential speed rolling of Ni3Al-based intermetallic alloy—Electron Backscatter Diffraction and X-Ray Diffraction study on structure and texture evolution. Adv. Eng. Mater. 2016, 19, 1–7. [Google Scholar] [CrossRef]

- Urbańczyk-Gucwa, A.; Bednarczyk, I.; Jabłońska, M.B.; Rodak, K. Deformation microstructures in metallic materials after severe plastic deformation by rolling with cyclic movement of rolls. Acta Phys. Pol. A 2016, 130, 975. [Google Scholar] [CrossRef]

- Chou, C.Y.; Lee, S.L.; Lin, J.C.; Hsu, C.M. Effects of cross-channel extrusion on the microstructures and superplasticity of a Zn–22 wt.% Al eutectoid alloy. Scr. Mater. 2007, 57, 972–976. [Google Scholar] [CrossRef]

- Chou, C.Y.; Lee, S.L.; Lin, J.C. Effects and deformation characteristics of cross-channel extrusion process on pure Sn and Al–7Si–0.3Mg alloy. Mater. Chem. Phys. 2008, 107, 193–200. [Google Scholar] [CrossRef]

- Lapovok, R. The role of back-pressure in equal channel angular extrusion. J. Mater. Sci. 2005, 40, 341–347. [Google Scholar] [CrossRef]

- Yoon, S.C.; Jeong, H.G.; Lee, S.; Kim, H.S. Analysis of plastic deformation behavior during back pressure ECAP by the FEM. Comp. Mater. Sci. 2013, 77, 202–207. [Google Scholar] [CrossRef]

- Zangiabadi, A.; Kazeminezhad, M. Computation on new deformation routes of tube channel pressing considering back pressure and friction effects. Comp. Mater. Sci. 2012, 59, 174–181. [Google Scholar] [CrossRef]

- Łyszkowski, R.; Czujko, T.; Varin, R.A. Multi-axial forging of Fe3Al-base intermetallic alloy and its mechanical properties. J. Mater. Sci. 2017, 52, 2902–2914. [Google Scholar] [CrossRef]

- Łyszkowski, R.; Polkowski, W.; Czujko, T. Severe plastic deformation of Fe-22Al-5Cr alloy by Cross-Channel Extrusion with Back Pressure. Materials 2018, 11, 2214. [Google Scholar] [CrossRef]

- Ghazani, M.S.; Eghbali, B. Finite element simulation of cross equal channel angular pressing. Comp. Mater. Sci. 2013, 74, 124–129. [Google Scholar] [CrossRef]

- Nagasekhar, A.V.; Kim, H.S. Plastic deformation characteristics of cross-equal channel angular pressing. Comp. Mater. Sci. 2008, 43, 1069–1074. [Google Scholar] [CrossRef]

- Qi, Y.; Kosinova, A.; Lakin, E.; Popov, V.V., Jr.; Rabkin, E.; Lapovok, R. Effect of SPD processing on the strength and conductivity of AA6061 alloy. Adv. Eng. Mater. 2019, 21, 1801370. [Google Scholar] [CrossRef]

- Krishna, S.C.; Karthick, N.K.; Rao, G.S.; Jha, A.K.; Pant, B.; Cherian, R.M. High strength, utilizable ductility and electrical conductivity in cold rolled sheets of Cu-Cr-Zr-Ti alloy. J. Mater. Eng. Perform. 2017, 27, 787–793. [Google Scholar] [CrossRef]

- Rodak, K.; Urbańczyk-Gucwa, A.; Jabłońska, M.B. Microstructure and properties of CuCr0.6 and CuFe2 alloys after rolling with the cyclic movement of rolls. Arch. Civ. Mech. Eng. 2018, 18, 500–507. [Google Scholar] [CrossRef]

- Schwartz, A.J.; Kumar, M.; Adams, B.L.; Field, D.P. Electron Backscatter Diffraction in Materials Science, 2nd ed.; Springer: New York, NY, USA, 2009. [Google Scholar]

- Polkowski, W.; Pęczek, E.; Zasada, D.; Komorek, Z. Differential speed rolling of Ni3Al based intermetallic alloy—Effect of applied processing on structure and mechanical properties an isotropy. Mater. Sci. Eng. A 2015, 647, 170–183. [Google Scholar] [CrossRef]

- Polkowski, W.; Jóźwik, P.; Bojar, Z. EBSD and X-ray diffraction study on the recrystallization of cold rolled Ni3Al based intermetallic alloy. J. Alloys Compd. 2014, 614, 226–233. [Google Scholar] [CrossRef]

- SETARAM Instrumentation. Available online: https://www.setaram.com/application-notes (accessed on 30 September 2019).

- Smits, F.M. Measurement of sheet resistivities with the four-point probe. Bell Syst. Tech. J. 1958, 37, 711–718. [Google Scholar]

- Lide, D.R. CRC Handbook of Chemistry and Physics, 90th ed.; CRC Press: London, UK, 2009; ISBN 978-1-4200-9084-0. [Google Scholar]

- Djavanroodi, F.; Ebrahimi, M. Effect of die channel angle, friction and back pressure in ECAP using 3D FEM simulation. Mater. Sci. Eng. A 2010, 527, 1230–1236. [Google Scholar] [CrossRef]

- Luis-Pérez, C.J.; Luri-Irigoyen, R.; Gastón-Ochoa, D. Finite element modelling of an Al–Mn alloy by equal channel angular extrusion (ECAE). J. Mater. Process. Technol. 2004, 153–154, 846–853. [Google Scholar] [CrossRef]

- Suo, T.; Li, Y.; Guo, Y.; Liu, Y. The simulation of deformation distribution during ECAP using 3D finite element method. Mater. Sci. Eng. A 2006, 432, 269–275. [Google Scholar] [CrossRef]

- Rosochowski, A.; Olejnik, L.; Richert, J.; Rosochowska, M.; Richert, M. Equal channel angular pressing with converging billets—Experiment. Mater. Sci. Eng. A 2013, 560, 358–365. [Google Scholar] [CrossRef]

- Mogucheva, A.; Babich, E.; Ovsyannikov, B.; Kaibyshev, R. Microstructural evolution in a 5024 Al alloy processed by ECAP with and without BP. Mater. Sci. Eng. A 2013, 560, 178–193. [Google Scholar] [CrossRef]

- Dieter, G.E.; Kuhn, H.A.; Semiatin, S.L. Handbook of Workability and Process Design; ASM International: Materials Park, OH, USA, 2003; ISBN 0-87170-778-0. [Google Scholar]

- Estrin, Y.; Beygelzimer, Y.; Kulagin, R. Design of architectured materials based on mechanically driven structural and compositional patterning. Adv. Eng. Mater. 2019, 21, 1–12. [Google Scholar] [CrossRef]

- Cao, Y.; Wang, Y.B.; Figueiredo, R.B.; Chang, L.; Liao, X.Z.; Kawasaki, M.; Zheng, W.L.; Ringer, S.P.; Langdon, T.G.; Zhu, Y.T. Three-dimensional shear-strain patterns induced by high-pressure torsion and their impact on hardness evolution. Acta Mater. 2011, 59, 3903–3915. [Google Scholar] [CrossRef]

- Hodowany, J.; Ravichandran, G.; Rosakis, A.J.; Rosakis, P. Partition of plastic work into heat and stored energy in metals. Exp. Mech. 2000, 40, 113–123. [Google Scholar] [CrossRef]

- Wang, Y.L.; Lapovok, R.; Wang, J.T.; Qi, Y.S.; Estrin, Y. Thermal behavior of copper processed by ECAP with and without back pressure. Mater. Sci. Eng. A 2015, 628, 21–30. [Google Scholar] [CrossRef]

- Sakai, T.; Belyakov, A.; Kaibyshev, R.; Miura, H.; Jonas, J.J. Dynamic and post-dynamic recrystallization under hot, cold and severe plastic deformation conditions. Prog. Mater. Sci. 2014, 60, 130–207. [Google Scholar] [CrossRef] [Green Version]

- Vinogradov, A.; Estrin, Y. Analytical and numerical approaches to modelling SPD. Prog. Mater. Sci. 2018, 95, 172–243. [Google Scholar] [CrossRef]

- Ponge, D.; Gottstein, G. Necklace formation during dynamic recrystallization: Mechanisms and impact on flow behavior. Acta Mater. 1998, 46, 69–80. [Google Scholar] [CrossRef]

- Tao, N.; Lu, K. Nanoscale structural refinement via deformation twinning in face-centered cubic metals. Scr. Mater. 2009, 60, 1039–1043. [Google Scholar] [CrossRef]

- Lu, K.; Hansen, N. Structural refinement and deformation mechanisms in nanostructured metals. Scr. Mater. 2009, 60, 1033–1038. [Google Scholar] [CrossRef]

- Van Swygenhoven, H.; Derlet, P.M.; Frøseth, A.G. Stacking fault energies and slip in nanocrystalline metals. Nat. Mater. 2004, 3, 399–403. [Google Scholar] [CrossRef]

- Han, W.; Zhang, Z.; Wu, S.; Li, S. Combined effects of crystallographic orientation, stacking fault energy and grain size on deformation twinning in fcc crystals. Philos. Mag. 2008, 88, 3011–3029. [Google Scholar] [CrossRef]

- Xue, Q.; Beyerlein, I.; Alexander, D.; Iii, G.G. Mechanisms for initial grain refinement in OFHC copper during equal channel angular pressing. Acta Mater. 2007, 55, 655–668. [Google Scholar] [CrossRef]

- Zhilyaev, A.P.; Langdon, T.G. Using high-pressure torsion for metal processing: Fundamentals and applications. Prog. Mater. Sci. 2008, 53, 893–979. [Google Scholar] [CrossRef]

- Bagherpour, E.; Qods, F.; Ebrahimi, R.; Miyamoto, H. Microstructure evolution of pure copper during a single pass of simple shear extrusion (SSE): Role of shear reversal. Mat. Sci. Eng. A 2016, 666, 324–338. [Google Scholar] [CrossRef]

- Richert, M.; Richert, J.; Zasadziński, J.; Hawryłkiewicz, S.; Długopolski, J. Effect of large deformations on the microstructure of aluminium alloys. Mater. Chem. Phys. 2003, 81, 528–530. [Google Scholar] [CrossRef]

- Cherukuri, B.; Nedkova, T.S.; Srinivasan, R. A comparison of the properties of SPD-processed AA-6061 by ECAP, MAC/forgings and ARB. Mat. Sci. Eng. A 2005, 410–411, 394–398. [Google Scholar] [CrossRef]

- Lachhab, R.; Rekik, M.A.; Azzeddine, H.; Baudin, T.; Helbert, A.L.; Brisset, F.; Khitouni, M. Study of the microstructure and texture heterogeneities of Fe-48wt%Ni alloy severely deformed by equal channel angular pressing. J. Mater. Sci. 2019, 54, 4354–4365. [Google Scholar] [CrossRef]

- Benchabane, G.; Boumerzoug, Z.; Thibon, I.; Gloriant, T. Recrystallization of pure copper investigated by calorimetry and microhardness. Mater. Charact. 2008, 59, 1425–1428. [Google Scholar] [CrossRef]

- Cao, W.Q.; Gu, C.F.; Pereloma, E.V.; Davies, C.H.J. Stored energy, vacancies and thermal stability of ultra-fine grained copper. Mat. Sci. Eng. A 2008, 492, 74–79. [Google Scholar] [CrossRef]

- Higuera-Cobos, O.F.; Cabrera, J.M. Mechanical, microstructural and electrical evolution of commercially pure copper processed by equal channel angular extrusion. Mat. Sci. Eng. A 2013, 571, 103. [Google Scholar] [CrossRef]

- Marković, I.; Nestorović, S.; Markoli, B.; Premović, M.; Mladenović, S. Study of anneal hardening in cold worked Cu–Au alloy. J. Alloys Compd. 2016, 658, 414–421. [Google Scholar] [CrossRef]

- Molodova, X.; Gottstein, G.; Winning, M.; Hellmig, R.J. Thermal stability of ECAP processed pure copper. Mater. Sci. Eng. A 2007, 460–461, 204–213. [Google Scholar] [CrossRef]

- Liang, N.; Zhao, Y.; Li, Y.; Topping, T.; Zhu, Y.; Valiev, R.Z.; Lavernia, E.J. Influence of microstructure on thermal stability of ultrafine-grained Cu processed by equal channel angular pressing. J. Mater. Sci. 2018, 53, 13173–13185. [Google Scholar] [CrossRef]

- Lipińska, M.; Olejnik, L.; Lewandowska, M. The influence of an ECAP-based deformation process on the microstructure and properties of electrolytic tough pitch copper. J. Mater. Sci. 2018, 53, 3862–3875. [Google Scholar] [CrossRef] [Green Version]

- Murashkin, M.Y.; Medvedev, A.E.; Kazykhanov, V.U.; Raab, G.I.; Ovid’ko, I.A.; Valiev, R.Z. Microstructure, strength, electrical conductivity and heat resistance of an Al-Mg-Zr alloy after ECAP-conform and cold drawing. Rev. Adv. Mater. Sci. 2016, 47, 16–25. [Google Scholar]

- Torre, F.D.; Lapovok, R.; Sandlin, J.; Thomson, P.F.; Davies, C.H.J.; Pereloma, E.V. Microstructures and properties of Cu processed by ECAP for 1–16 passes. Acta Mater. 2004, 52, 4819–4832. [Google Scholar] [CrossRef]

- Chinh, N.Q.; Horvath, G.; Horita, Z.; Langdon, T.G. A new constitutive relationship for the homogeneous deformation of metals over a wide range of strain. Acta Mater. 2004, 52, 3555–3563. [Google Scholar] [CrossRef]

- Stepanov, N.D.; Kuznetsov, A.V.; Salishchev, G.A.; Raab, G.I.; Valiev, R.Z. Effect of cold rolling on microstructure and mechanical properties of copper subjected to ECAP with various numbers of passes. Mater. Sci. Eng. A 2012, 554, 105–115. [Google Scholar] [CrossRef]

- Ebrahimi, M.; Gode, C. Severely deformed copper by equal channel angular pressing. Prog. Nat. Sci. Mater. Int. 2017, 27, 244–250. [Google Scholar] [CrossRef]

| Initial (Recrystallized) | 1x CCE | 4x CCE | 4x CCE + Recrystallization |

|---|---|---|---|

| 19.8 | 5.7 | 7.9 | 11.9 |

| Number of Passes | YS (MPa) | UTS (MPa) | A (%) | RA (%) |

|---|---|---|---|---|

| annealed | 75 | 241 | 42.4 | 89 |

| 1 | 390 | 396 | 11.8 | 49 |

| 4 | 403 | 415 | 9.7 | 44 |

| 4 + recrystallization | 218 | 269 | 20.8 | 92 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Łyszkowski, R.; Łazińska, M.; Zasada, D. The Influence of A Cross-Channel Extrusion Process on The Microstructure and Properties of Copper. Materials 2019, 12, 3995. https://doi.org/10.3390/ma12233995

Łyszkowski R, Łazińska M, Zasada D. The Influence of A Cross-Channel Extrusion Process on The Microstructure and Properties of Copper. Materials. 2019; 12(23):3995. https://doi.org/10.3390/ma12233995

Chicago/Turabian StyleŁyszkowski, Radosław, Magdalena Łazińska, and Dariusz Zasada. 2019. "The Influence of A Cross-Channel Extrusion Process on The Microstructure and Properties of Copper" Materials 12, no. 23: 3995. https://doi.org/10.3390/ma12233995

APA StyleŁyszkowski, R., Łazińska, M., & Zasada, D. (2019). The Influence of A Cross-Channel Extrusion Process on The Microstructure and Properties of Copper. Materials, 12(23), 3995. https://doi.org/10.3390/ma12233995