The AC Soft Magnetic Properties of FeCoNixCuAl (1.0 ≤ x ≤ 1.75) High-Entropy Alloys

Abstract

:1. Introduction

2. Experimental

3. Results

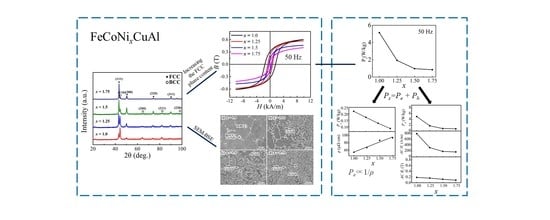

3.1. XRD

3.2. SEM Images

3.3. Magnetic Properties at H = 10 kA/m and f = 50 Hz

3.4. Magnetic Properties at AC Bm = 300 mT

4. Discussions

5. Conclusions

- (1)

- The XRD and SEM results show that the alloys contain two phases, namely a BCC phase and an FCC phase. It is found that increasing the Ni content tends to facilitate the formation of the FCC phase in these alloys due to lattice distortion. When x ≤ 1.25, Cu is enriched in the FCC phase and it is depleted in the BCC phase. When x ≥ 1.5, Cu is depleted in the FCC phase and Al is enriched in the BCC phase. In addition, a Cu-rich phase boundary appears between the FCC and BCC phases.

- (2)

- The formation of the FCC phase would be conducive to a decrease in the values of AC Br, AC Hc and Ps, while it is harmful to AC Bm. The decrease of AC Br, AC Hc and Ps with increasing Ni content might due to a decrease of low angle grain boundary (2–5°), resulting in a release of strain concentration. This provides a direction for improvement of the AC magnetic performance in the future.

- (3)

- With increasing f, the ratio of Ph/Ps decreases. When f ≤ 150 Hz, Ph/Ps is larger than 70%, which means that Ph mainly contributes to Ps. When f ≥ 800 Hz, Ph/Ps is less than 40% (except for the x = 1.0 sample), which means that Pe mainly contributes to Ps.

- (4)

- At the same frequency, the ratio of Ph/Ps decreases gradually with increasing FCC phase content. Pe is inversely proportional to ρ, and Ph is closely related to AC Hc. This provides a direction to reduce Ps.

- (5)

- With increasing Ni content, the value of ρ increases from 54.7 μΩ·cm to 93.3 μΩ·cm, which is larger than that of silicon steel. It indicates that the FeCoNixCuAl (1.0 ≤ x ≤ 1.75) HEAs have potential applications in motors, generators and transformers due to relative low energy loss and high electrical resistivity.

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Sun, B.; Fazeli, F.; Scott, C.; Guo, B.; Aranas, C.; Chu, X.; Jahazi, M.; Yue, S. Microstructural characteristics and tensile behavior of medium manganese steels with different manganese additions. Mater. Sci. Eng. A 2018, 729, 496–507. [Google Scholar] [CrossRef]

- Yang, Q.; Sun, Z.; Wang, Z. Effects of Sn, Si, and Cu addition on the microstructure and properties of hypermonotectic Al92Bi8 alloy. Mater. Sci. Eng. A 2019, 756, 71–81. [Google Scholar] [CrossRef]

- Cantor, B.; Chang, I.T.H.; Knight, P.; Vincent, A.J.B. Microstructural development in equiatomic multicomponent alloys. Mater. Sci. Eng. A 2004, 375–377, 213–218. [Google Scholar] [CrossRef]

- Yeh, J.-W.; Chen, S.-K.; Lin, S.-J.; Gan, J.-Y.; Chin, T.-S.; Shun, T.-T.; Tsau, C.-H.; Chang, S.-Y. Nanostructured high-entropy alloys with multiple principal elements novel alloy design concepts and outcomes. Adv. Eng. Mater. 2004, 6, 299–303. [Google Scholar] [CrossRef]

- Feuerbacher, M.; Lienig, T.; Thomas, C. A single-phase bcc high-entropy alloy in the refractory Zr-Nb-Ti-V-Hf system. Scripta Mater. 2018, 152, 40–43. [Google Scholar] [CrossRef] [Green Version]

- Yang, T.; Zhao, Y.L.; Tong, Y.; Jiao, Z.B.; Wei, J.; Cai, J.X.; Han, X.D.; Chen, D.; Hu, A.; Kai, J.J.; et al. Multicomponent intermetallic nanoparticles and superb mechanical behaviors of complex alloys. Science 2018, 362, 933–937. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Luo, H.; Li, Z.; Lu, W.; Ponge, D.; Raabe, D. Hydrogen embrittlement of an interstitial equimolar high-entropy alloy. Corros. Sci. 2018, 136, 403–408. [Google Scholar] [CrossRef]

- Basu, S.; Li, Z.; Pradeep, K.G.; Raabe, D. Strain Rate Sensitivity of a TRIP-Assisted Dual-Phase High-Entropy Alloy. Front. Mater. 2018, 5, 1–10. [Google Scholar] [CrossRef]

- Gu, J.; Song, M. Annealing-induced abnormal hardening in a cold rolled CrMnFeCoNi high entropy alloy. Scripta Mater. 2019, 162, 345–349. [Google Scholar] [CrossRef]

- Zhao, Y.J.; Qiao, J.W.; Ma, S.G.; Gao, M.C.; Yang, H.J.; Chen, M.W.; Zhang, Y. A hexagonal close-packed high-entropy alloy: The effect of entropy. Mater. Des. 2016, 96, 10–15. [Google Scholar] [CrossRef]

- Gao, M.C.; Zhang, B.; Guo, S.M.; Qiao, J.W.; Hawk, J.A. High-Entropy Alloys in Hexagonal Close-Packed Structure. Metall. Mater. Trans. A 2016, 47, 3322–3332. [Google Scholar] [CrossRef]

- Rao, J.C.; Ocelík, V.; Vainchtein, D.; Tang, Z.; Liaw, P.K.; De Hosson, J.T.M. The fcc-bcc crystallographic orientation relationship in AlxCoCrFeNi high-entropy alloys. Mater. Lett. 2016, 176, 29–32. [Google Scholar] [CrossRef] [Green Version]

- Nagase, T.; Takeuchi, A.; Amiya, K.; Egami, T. Solid state amorphization of metastable Al0.5TiZrPdCuNi high entropy alloy investigated by high voltage electron microscopy. Mater. Chem. Phys. 2018, 210, 291–300. [Google Scholar]

- Huang, H.; Wu, Y.; He, J.; Wang, H.; Liu, X.; An, K.; Wu, W.; Lu, Z. Phase-Transformation Ductilization of Brittle High-Entropy Alloys via Metastability Engineering. Adv. Mater. 2017, 29, 1–7. [Google Scholar] [CrossRef] [PubMed]

- Shivam, V.; Basu, J.; Shadangi, Y.; Singh, M.K.; Mukhopadhyay, N.K. Mechano-chemical synthesis, thermal stability and phase evolution in AlCoCrFeNiMn high entropy alloy. J. Alloys Compd. 2018, 757, 87–97. [Google Scholar] [CrossRef]

- Chen, L.; Zhou, Z.; Tan, Z.; He, D.; Bobzin, K.; Zhao, L.; Öte, M.; Königstein, T. High temperature oxidation behavior of Al0.6CrFeCoNi and Al0.6CrFeCoNiSi0.3 high entropy alloys. J. Alloys Compd. 2018, 764, 845–852. [Google Scholar] [CrossRef]

- Shi, Y.; Collins, L.; Feng, R.; Zhang, C.; Balke, N.; Liaw, P.K.; Yang, B. Homogenization of AlxCoCrFeNi high-entropy alloys with improved corrosion resistance. Corros. Sci. 2018, 133, 120–131. [Google Scholar] [CrossRef]

- Joseph, J.; Haghdadi, N.; Shamlaye, K.; Hodgson, P.; Barnett, M.; Fabijanic, D. The sliding wear behaviour of CoCrFeMnNi and AlxCoCrFeNi high entropy alloys at elevated temperatures. Wear 2019, 428–429, 32–44. [Google Scholar] [CrossRef]

- Amar, A.; Li, J.; Xiang, S.; Liu, X.; Zhou, Y.; Le, G.; Wang, X.; Qu, F.; Ma, S.; Dong, W.; et al. Additive manufacturing of high-strength CrMnFeCoNi-based High Entropy Alloys with TiC addition. Intermetallics 2019, 109, 162–166. [Google Scholar] [CrossRef]

- Chen, Y.; Zhu, S.; Wang, X.; Yang, B.; Ren, Z.; Han, G.; Wen, S. The strength-ductility balance of Al0.4CoCu0.6NiTix (x ≤ 1.0) and Al0.4CoCu0.6NiSi0.2Tix (x ≤ 0.5) high entropy alloys by regulating the proportion of Ti and improving the cooling rate. Vacuum 2018, 155, 270–279. [Google Scholar] [CrossRef]

- Gao, M.C.; Miracle, D.B.; Maurice, D.; Yan, X.; Zhang, Y.; Hawk, J.A. High-entropy functional materials. J. Mater. Res. 2018, 33, 3138–3155. [Google Scholar] [CrossRef] [Green Version]

- Li, P.; Wang, A.; Liu, C.T. A ductile high entropy alloy with attractive magnetic properties. J. Alloys Compd. 2017, 694, 55–60. [Google Scholar] [CrossRef]

- Zhu, X.; Zhou, X.; Yu, S.; Wei, C.; Xu, J.; Wang, Y. Effects of annealing on the microstructure and magnetic property of the mechanically alloyed FeSiBAlNiM (M = Co, Cu, Ag) amorphous high entropy alloys. J. Magn. Magn. Mater. 2017, 430, 59–64. [Google Scholar] [CrossRef]

- Alijani, F.; Reihanian, M.; Gheisari, K. Study on phase formation in magnetic FeCoNiMnV high entropy alloy produced by mechanical alloying. J. Alloys Compd. 2019, 773, 623–630. [Google Scholar] [CrossRef]

- Jung, C.; Kang, K.; Marshal, A.; Pradeep, K.G.; Seol, J.-B.; Lee, H.M.; Choi, P.-P. Effects of phase composition and elemental partitioning on soft magnetic properties of AlFeCoCrMn high entropy alloys. Acta Mater. 2019, 171, 31–39. [Google Scholar] [CrossRef]

- Zuo, T.; Zhang, M.; Liaw, P.K.; Zhang, Y. Novel high entropy alloys of FexCo1-xNiMnGa with excellent soft magnetic properties. Intermetallics 2018, 100, 1–8. [Google Scholar] [CrossRef]

- Liu, C.; Peng, W.; Jiang, C.S.; Guo, H.; Tao, J.; Deng, X.; Chen, Z. Composition and phase structure dependence of mechanical and magnetic properties for AlCoCuFeNix high entropy alloys. J. Mater. Sci. Technol. 2019, 35, 1175–1183. [Google Scholar] [CrossRef]

- Li, Z.; Gu, Y.; Pan, M.; Wang, C.; Wu, Z.; Hou, X.; Tan, X.; Xu, H. Tailoring AC magnetic properties of FeCoNi(MnSi)x (0 ≤ x ≤ 0.4) high-entropy alloys by the addition of Mn and Si elements. J. Alloys Compd. 2019, 792, 215–221. [Google Scholar] [CrossRef]

- Zhang, B.; Duan, Y.; Cui, Y.; Ma, G.; Wang, T.; Dong, X. Improving electromagnetic properties of FeCoNiSi0.4Al0.4 high entropy alloy powders via their tunable aspect ratio and elemental uniformity. Mater. Des. 2018, 149, 173–183. [Google Scholar] [CrossRef]

- Zhang, B.; Duan, Y.; Wen, X.; Ma, G.; Wang, T.; Dong, X.; Zhang, H.; Jia, N.; Zeng, Y. FeCoNiSixAl0.4 high entropy alloy powders with dual-phase microstructure: Improving microwave absorbing properties via controlling phase transition. J. Alloys Compd. 2019, 790, 179–188. [Google Scholar] [CrossRef]

- Duan, Y.; Cui, Y.; Zhang, B.; Ma, G.; Tongmin, W. A novel microwave absorber of FeCoNiCuAl high-entropy alloy powders: Adjusting electromagnetic performance by ball milling time and annealing. J. Alloys Compd. 2019, 773, 194–201. [Google Scholar] [CrossRef]

- Zhong, L. Magnetic Properties and Microstructure of FeCoNiMx (M = AlCu, AlMn, AlSi and MnSi) High-Entropy Alloys; Shanghai University: Shanghai, China, 2019. [Google Scholar]

- Koželj, P.; Vrtnik, S.; Jelen, A.; Krnel, M.; Gačnik, D.; Dražić, G.; Meden, A.; Wencka, M.; Jezeršek, D.; Leskovec, J.; et al. Discovery of a FeCoNiPdCu High-Entropy Alloy with Excellent Magnetic Softness. Adv. Eng. Mater. 2019, 21, 1801055. [Google Scholar] [CrossRef]

- Dean, J.A. Lange’s Chemistry Handbook Version 15th; Advanced Manufacturing Processes: New York, NY, USA, 2003. [Google Scholar]

- Li, Z.; Gu, Y.; Wang, C.; Pan, M.; Zhang, H.; Wu, Z.; Hou, X.; Tan, X.; Xu, H. Microstructure and magnetic properties of the FeCoNi(CuAl)0.8Ga0.06 high-entropy alloy during the phase transition. J. Alloys Compd. 2019, 779, 293–300. [Google Scholar] [CrossRef]

- Chang, L.; Xie, L.; Liu, M.; Li, Q.; Dong, Y.-Q.; Chang, C.-T.; Wang, X.-M.; Inoue, A. Novel Fe-based nanocrystalline powder cores with excellent magnetic properties produced using gas-atomized powder. J. Magn. Magn. Mater. 2018, 452, 442–446. [Google Scholar] [CrossRef]

- Li, Z.-C.; Dong, Y.-Q.; Pauly, S.; Chang, C.-T.; Wei, R.; Li, F.-S.; Wang, X.-M. Enhanced soft magnetic properties of Fe-based amorphous powder cores by longitude magnetic field annealing. J. Alloys Compd. 2017, 706, 1–6. [Google Scholar] [CrossRef]

- Jo Sunday, K.; Hanejko, F.G.; Taheri, M.L. Magnetic and microstructural properties of Fe3O4-coated Fe powder soft magnetic composites. J. Magn. Magn. Mater. 2017, 423, 164–170. [Google Scholar] [CrossRef]

- Zhong, W. Ferromagnetics (2); Science Press: Beijing, China, 2017. [Google Scholar]

- Starodubtsev, Y.N.; Kataev, V.A.; Bessonova, K.O.; Tsepelev, V.S. Hysteresis losses in nanocrystalline alloys with magnetic-field-induced anisotropy. J. Magn. Magn. Mater. 2019, 479, 19–26. [Google Scholar] [CrossRef]

- Deng, Q.; Tang, Y.; Tan, Y.; Tan, X.; Yang, Y.; Xu, H. Effect of grain boundary character distribution on soft magnetic property of face-centered cubic FeCoNiAl0.2 medium-entropy alloy. Mater. Charact. 2019. [Google Scholar] [CrossRef]

- Coey, J.M.D. Magnetism and Magnetic Materials; Cambridge University Press: England, UK; Peking Univeristy Press: Beijing, China, 2014. [Google Scholar]

| x | I(111)F/I(110)B | A ± 0.0002 (nm) | |

|---|---|---|---|

| FCC | BCC | ||

| 1.0 | 0.447 | 0.3618 | 0.2877 |

| 1.25 | 1.374 | 0.3614 | 0.2876 |

| 1.5 | 4.016 | 0.3610 | 0.2872 |

| 1.75 | 11.364 | 0.3608 | - |

| x | VEC | ΔR | ΔX | ΔS (J/K·mol) | ΔH (kJ/mol) | Ω (kJ/mol) |

|---|---|---|---|---|---|---|

| 1.0 | 8.20 | 5.404 | 0.1115 | 1.609R | −5.28 | 3.8477 |

| 1.25 | 8.29 | 5.341 | 0.1102 | 1.605R | −5.51 | 3.6980 |

| 1.5 | 8.36 | 5.278 | 0.1090 | 1.594R | −5.69 | 3.5831 |

| 1.75 | 8.43 | 5.216 | 0.1077 | 1.579R | −5.81 | 3.4932 |

| x | Regions | Fe | Co | Ni | Cu | Al |

|---|---|---|---|---|---|---|

| 1.0 | Nominal | 20.00 | 20.00 | 20.00 | 20.00 | 20.00 |

| A | 19.74 | 20.00 | 20.06 | 18.98 | 21.23 | |

| B | 15.54 | 15.12 | 17.27 | 37.01 | 15.07 | |

| 1.25 | Nominal | 19.05 | 19.05 | 23.80 | 19.05 | 19.05 |

| A | 21.31 | 21.69 | 23.92 | 12.34 | 20.74 | |

| B | 15.77 | 15.05 | 21.61 | 32.39 | 15.18 | |

| 1.5 | Nominal | 18.18 | 18.18 | 27.28 | 18.18 | 18.18 |

| A | 13.56 | 15.50 | 28.33 | 18.56 | 24.05 | |

| B | 21.93 | 22.20 | 26.96 | 13.01 | 15.90 | |

| PB | 13.21 | 13.69 | 24.21 | 32.72 | 16.17 | |

| 1.75 | Nominal | 17.39 | 17.39 | 30.44 | 17.39 | 17.39 |

| A | 12.37 | 13.68 | 31.71 | 17.75 | 24.49 | |

| B | 20.93 | 20.58 | 30.04 | 13.4 | 15.07 | |

| PB | 13.13 | 13.52 | 29.95 | 28.10 | 15.29 |

| x | AC Bm (mT) | AC Br (mT) | AC Hc (A/m) | Ps (W/kg) |

|---|---|---|---|---|

| 1.0 | 608.3 | 320.0 | 1582.0 | 19.79 |

| 1.25 | 577.3 | 244.9 | 705.3 | 8.02 |

| 1.5 | 468.2 | 148.2 | 424.7 | 3.24 |

| 1.75 | 410.6 | 98.2 | 306.3 | 1.89 |

| x | F (Hz) | Ps (W/kg) | Ph (W/kg) | Pe (W/kg) | Ph/Ps (%) | AC Hc (A/m) | AC Br (mT) | Ρ (μΩ·cm) |

|---|---|---|---|---|---|---|---|---|

| 1.0 | 50 | 5.13 | 4.91 | 0.22 | 95.7 | 806.7 | 184.4 | 54.7 |

| 1.25 | 1.93 | 1.76 | 0.17 | 91.2 | 322.2 | 159.8 | 67.1 | |

| 1.5 | 0.97 | 0.85 | 0.12 | 87.6 | 190.5 | 119.9 | 86.7 | |

| 1.75 | 0.85 | 0.77 | 0.08 | 90.6 | 172.7 | 90.1 | 93.3 | |

| 1.0 | 100 | 10.78 | 9.91 | 0.87 | 91.9 | 850.2 | 187.4 | 54.7 |

| 1.25 | 4.25 | 3.56 | 0.69 | 83.8 | 353.3 | 165.5 | 67.1 | |

| 1.5 | 2.21 | 1.71 | 0.50 | 77.4 | 214.7 | 126.7 | 86.7 | |

| 1.75 | 1.86 | 1.52 | 0.34 | 81.7 | 189.0 | 94.0 | 93.3 | |

| 1.0 | 150 | 16.91 | 14.94 | 1.97 | 88.4 | 891.9 | 189.9 | 54.7 |

| 1.25 | 6.94 | 5.39 | 1.55 | 77.7 | 381.6 | 170.5 | 67.1 | |

| 1.5 | 3.68 | 2.56 | 1.12 | 69.5 | 235.4 | 131.8 | 86.7 | |

| 1.75 | 3.02 | 2.26 | 0.76 | 74.9 | 203.5 | 97.4 | 93.3 | |

| 1.0 | 250 | 30.71 | 25.25 | 5.46 | 82.2 | 966.5 | 194.6 | 54.7 |

| 1.25 | 13.49 | 9.19 | 4.30 | 68.1 | 434.3 | 179.1 | 67.1 | |

| 1.5 | 7.40 | 4.28 | 3.12 | 57.9 | 273.1 | 140.9 | 86.7 | |

| 1.75 | 5.92 | 3.82 | 2.10 | 64.5 | 231.5 | 103.4 | 93.3 | |

| 1.0 | 350 | 46.49 | 35.78 | 10.71 | 77.0 | 1039 | 198.9 | 54.7 |

| 1.25 | 21.40 | 12.97 | 8.43 | 60.6 | 481.5 | 185.9 | 67.1 | |

| 1.5 | 12.11 | 5.99 | 6.12 | 49.5 | 308.7 | 148.5 | 86.7 | |

| 1.75 | 9.63 | 5.52 | 4.11 | 57.3 | 258.6 | 109.6 | 93.3 | |

| 1.0 | 450 | 64.18 | 46.48 | 17.70 | 72.4 | 1106 | 202.8 | 54.7 |

| 1.25 | 30.89 | 16.96 | 13.93 | 54.9 | 531.3 | 192.4 | 67.1 | |

| 1.5 | 18.05 | 7.94 | 10.11 | 44.0 | 345.7 | 155.9 | 86.7 | |

| 1.75 | 13.67 | 6.87 | 6.80 | 50.3 | 281.2 | 112.6 | 93.3 | |

| 1.0 | 550 | 82.32 | 55.88 | 26.44 | 67.9 | 1147 | 205.0 | 54.7 |

| 1.25 | 41.35 | 20.55 | 20.80 | 49.7 | 569.1 | 197.6 | 67.1 | |

| 1.5 | 24.63 | 9.52 | 15.11 | 38.7 | 372.2 | 161.1 | 86.7 | |

| 1.75 | 18.55 | 8.39 | 10.16 | 45.2 | 305.0 | 116.8 | 93.3 | |

| 1.0 | 650 | 103.00 | 66.08 | 36.92 | 64.2 | 1202 | 208.6 | 54.7 |

| 1.25 | 52.79 | 23.73 | 29.06 | 45.0 | 607.5 | 201.5 | 67.1 | |

| 1.5 | 32.10 | 11.00 | 21.10 | 34.3 | 402.8 | 165.9 | 86.7 | |

| 1.75 | 23.87 | 9.68 | 14.19 | 40.6 | 330.8 | 119.5 | 93.3 | |

| 1.0 | 750 | 124.30 | 75.14 | 49.16 | 60.5 | 1249 | 210.7 | 54.7 |

| 1.25 | 66.04 | 27.35 | 38.69 | 41.4 | 650.9 | 207.3 | 67.1 | |

| 1.5 | 40.93 | 12.84 | 28.09 | 31.4 | 436.4 | 170.8 | 86.7 | |

| 1.75 | 29.61 | 10.72 | 18.89 | 36.2 | 350.7 | 122.8 | 93.3 | |

| 1.0 | 850 | 147.50 | 84.36 | 63.14 | 57.2 | 1296 | 213.1 | 54.7 |

| 1.25 | 80.00 | 30.31 | 49.69 | 37.9 | 690.5 | 209.9 | 67.1 | |

| 1.5 | 50.54 | 14.46 | 36.08 | 28.6 | 470.4 | 175.9 | 86.7 | |

| 1.75 | 37.63 | 13.37 | 24.26 | 35.5 | 375.0 | 127.5 | 93.3 | |

| 1.0 | 950 | 172.20 | 93.33 | 78.87 | 54.2 | 1346 | 214.8 | 54.7 |

| 1.25 | 95.37 | 33.30 | 62.07 | 34.9 | 729.4 | 214.2 | 67.1 | |

| 1.5 | 61.25 | 16.18 | 45.07 | 26.4 | 501.5 | 179.8 | 86.7 | |

| 1.75 | 45.13 | 14.83 | 30.30 | 32.9 | 395.5 | 129.0 | 93.3 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wu, Z.; Wang, C.; Zhang, Y.; Feng, X.; Gu, Y.; Li, Z.; Jiao, H.; Tan, X.; Xu, H. The AC Soft Magnetic Properties of FeCoNixCuAl (1.0 ≤ x ≤ 1.75) High-Entropy Alloys. Materials 2019, 12, 4222. https://doi.org/10.3390/ma12244222

Wu Z, Wang C, Zhang Y, Feng X, Gu Y, Li Z, Jiao H, Tan X, Xu H. The AC Soft Magnetic Properties of FeCoNixCuAl (1.0 ≤ x ≤ 1.75) High-Entropy Alloys. Materials. 2019; 12(24):4222. https://doi.org/10.3390/ma12244222

Chicago/Turabian StyleWu, Zhongyuan, Chenxu Wang, Yin Zhang, Xiaomeng Feng, Yong Gu, Zhong Li, Huisheng Jiao, Xiaohua Tan, and Hui Xu. 2019. "The AC Soft Magnetic Properties of FeCoNixCuAl (1.0 ≤ x ≤ 1.75) High-Entropy Alloys" Materials 12, no. 24: 4222. https://doi.org/10.3390/ma12244222

APA StyleWu, Z., Wang, C., Zhang, Y., Feng, X., Gu, Y., Li, Z., Jiao, H., Tan, X., & Xu, H. (2019). The AC Soft Magnetic Properties of FeCoNixCuAl (1.0 ≤ x ≤ 1.75) High-Entropy Alloys. Materials, 12(24), 4222. https://doi.org/10.3390/ma12244222