Nanosecond-Laser Generation of Nanoparticles in Liquids: From Ablation through Bubble Dynamics to Nanoparticle Yield

Abstract

:1. Introduction

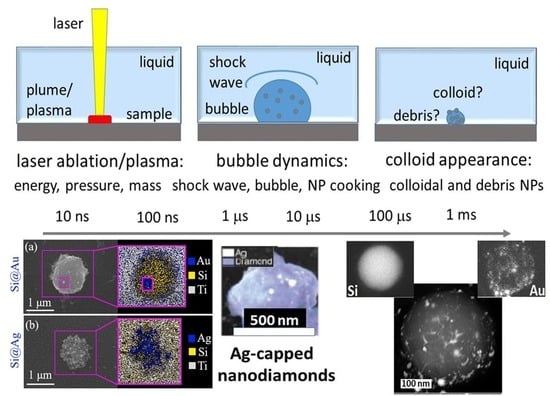

2. Nanosecond-Laser Generation of Nanocolloids: Basic Stages

2.1. Nanosecond Laser Plasma: Energy, Pressure, and Mass Input into Bubble

- Surface vaporization of molten materials along (somewhat lower in vapor pressure) their “melt-vapor” binodes, ending up by short condensation of corresponding low-density atomic or small-cluster vapors, in the characteristic ns-laser intensity range ~0.01–0.1 GW/cm2 (fluence range ~0.1–10 J/cm2 for laser pulse-widths of 10–100 ns) [37,38];

- Surface phase explosion (homogeneous boiling) in the proximity of their “melt-vapor” spinodes, expelling high-density vapor-droplet mixture with its bimodal size distribution, in the characteristic ns-laser intensity range ~0.1–1 GW/cm2 (fluence range ~1–100 J/cm2 for laser pulse-widths of 10–100 ns) [31,32,38,39,40]. This event almost coincides with dense-plume facilitated optical breakdown above the ablated surface, the related onset of sub-critical plasma, and ambient shock-wave emission [38,39];

- The following sub-critical plasma emerges in the characteristic ns-laser intensity range ~1–100 GW/cm2 (fluence range ~10–104 J/cm2 for laser pulse-widths of 10–100 ns), and regulates/mediates “laser–plasma–target” interactions via a number of basic laser–matter interaction parameters [37]—laser energy coupling (fraction) to plasma,plasma pressure and surface pressurization, mechanical coupling efficiency,and ablation rate regulated by screening plasma

- 4

- Finally, deep material melting and superheating by transient bremsstrahlung and recombination plasma emission and its mechanical unloading during plasma adiabatic expansion results in intense, microsecond-delayed expulsion of micro-droplets [39,41,42,43], which is generally not accounted for in Equation (4).

2.2. Insights into Nanoparticle Generation: Looking from the Bubble Side

2.3. Pathways to Colloidal Nanoparticles in Solutions

- Re-assembling (re-condensation) of ultrafine NPs from atomic/cluster plasma species, as seen in Figure 8;

- Plasma-activated chemical interactions with dissolved reagents: gold- and silver-capping of ablated Si NPs via plasma-induced and Si-NP surface reduction of HAuCl4 and AgNO3, as seen in Figure 11. Their plasma-mediated formation mechanism is illustrated in Figure 12, strongly correlating with Figure 3 for bare Si ablation;

2.4. High-Throughput NP Fabrication: Laser, Scanning and Colloid Collection Regimes

- Higher ns-laser intensity provides almost linear wet ablation mass yield ~ng/mJ in the range between the phase explosion and melt ejection thresholds as seen in Figure 3, owing to the intensity-dependent ablation spot size as seen in Figure 7a and justified plasma-mediated mass removal as seen in Equation (4) and Figure 3, resulting in the similar trend for extinction coefficients of the resulting pure silicon, silver- and gold-coated silicon nanoparticles, as seen in Figure 12. The importance of ns-laser plasma in the generation of colloidal nanoparticles was stressed in multiple studies (see, for example, the overview in recent studies [57,58]);

- Laser scanning should be adjusted, to avoid a nanoparticle-initiated breakdown in bulk colloidal solution as seen in Figure 5 and Figure 6 and related laser energy losses (as well as nanoparticle fragmentation) in one pass through the clear water above the fresh surface spots. Otherwise, ablation efficiency can drop by a factor of 10 (see, for example, Figure 3 for comparison of the theoretical prediction and experimental measurements of the mass loss). Furthermore, some advanced scanning trajectories—e.g., spiral-like—could be realized at high scanning velocities (galvoscanners <10 m/s, polygons <1 km/s [59]) and laser repetition rates ~0.1–10 MHz;

- Finally, optimized solvent flow and nanoparticle collection should be chosen for long-term production to avoid the aforementioned colloidal breakdown/screening and laser post-modification of the generated nanoparticles.

- As a result, the advanced semi-industrial milligram per second (~ng × MHz, dry mass) production rates relevant for medicine, pharmacy, material science, and nanophotonics could be scalably achieved [60,61,62], still with sufficient flexibility in laser, scanning, and flow/collection parameters for specific applications.

3. Concluding Remarks

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Kohsakowski, S.; Streubel, R.; Radev, I.; Peinecke, V.; Barcikowski, S.; Marzun, G.; Reichenberger, S. First PEM fuel cell based on ligand-free, laser-generated platinum nanoparticles. Appl. Surf. Sci. 2019, 467, 486–492. [Google Scholar] [CrossRef]

- Barmina, E.V.; Simakin, A.V.; Shafeev, G.A. Hydrogen emission under laser exposure of colloidal solutions of nanoparticles. Chem. Phys. Lett. 2016, 655, 35–38. [Google Scholar] [CrossRef]

- Strohfeldt, N.; Zhao, J.; Tittl, A.; Giessen, H. Sensitivity engineering in direct contact palladium-gold nano-sandwich hydrogen sensors. Opt. Mater. Exp. 2015, 5, 2525–2535. [Google Scholar] [CrossRef]

- Timoshenko, V.Y.; Kudryavtsev, A.A.; Osminkina, L.A.; Vorontsov, A.S.; Ryabchikov, Y.V.; Belogorokhov, I.A.; Kovalev, D.; Kashkarov, P.K. Silicon nanocrystals as photosensitizers of active oxygen for biomedical applications. JETP Lett. 2006, 83, 423–426. [Google Scholar] [CrossRef]

- Xiao, L.; Gu, L.; Howell, S.B.; Sailor, M.J. Porous Silicon Nanoparticle Photosensitizers for Singlet Oxygen and their Phototoxicity against Cancer Cells. ACS Nano 2011, 5, 3651–3659. [Google Scholar] [CrossRef] [PubMed]

- Rioux, D.; Laferrière, M.; Douplik, A.; Shah, D.; Lilge, L.D.; Kabashin, A.V.; Meunier, M. Silicon nanoparticles produced by femtosecond laser ablation in water as novel contamination-free photosensitizers. J. Biomed. Opt. 2009, 14, 021010. [Google Scholar] [CrossRef] [PubMed]

- Fu, P.P.; Xia, Q.; Hwang, H.M.; Ray, P.C.; Yu, H. Mechanisms of nanotoxicity: generation of reactive oxygen species. J. Food Drug Anal. 2014, 22, 64–75. [Google Scholar] [CrossRef] [PubMed]

- Chernousova, S.; Epple, M. Silver as antibacterial agent: Ion, nanoparticle, and metal. Angewandte Chemie Int. Ed. 2013, 52, 1636–1653. [Google Scholar] [CrossRef] [PubMed]

- Nastulyavichus, A.; Kudryashov, S.; Smirnov, N.; Saraeva, I.; Rudenko, A.; Tolordava, E.; Ionin, A.; Romanova, Y.; Zayarny, D. Antibacterial coatings of Se and Si nanoparticles. Appl. Surf. Sci. 2019, 469, 220–225. [Google Scholar] [CrossRef]

- Streubel, R.; Wilms, M.B.; Doñate-Buendía, C.; Weisheit, A.; Barcikowski, S.; Schleifenbaum, J.H.; Gökce, B. Depositing laser-generated nanoparticles on powders for additive manufacturing of oxide dispersed strengthened alloy parts via laser metal deposition. Jpn. J. Appl. Phys. 2018, 57, 040310. [Google Scholar] [CrossRef]

- Zayarny, D.A.; Ivanova, A.K.; Ionin, A.A.; Khmel’nitskii, R.A.; Klevkov, Y.V.; Kudryashov, S.I.; Mel’nik, N.N.; Nastulyavichus, A.A.; Rudenko, A.A.; Saraeva, I.N.; et al. Laser Nanostructuring and Three-Dimensional Ink-Jet Printing of Nanocoatings. Bull. Rus. Acad. Sci. Phys. 2018, 82, 444–447. [Google Scholar] [CrossRef]

- Jendrzej, S.; Gondecki, L.; Debus, J.; Moldenhauer, H.; Tenberge, P.; Barcikowski, S.; Gökce, B. Tribological properties of laser-generated hard ceramic particles in a gear drive contact. Appl. Surf. Sci. 2019, 467, 811–818. [Google Scholar] [CrossRef]

- Shishkovsky, I.V.; Scherbakov, V.I.; Saraeva, I.N.; Ionin, A.A. Thermoelectric properties of gradient polymer composites with nano-inclusions fabricated by laser assisted sintering. Laser Phys. Lett. 2017, 14, 035601. [Google Scholar] [CrossRef]

- Lednev, V.N.; Sdvizhenskii, P.A.; Asyutin, R.D.; Tretyakov, R.S.; Grishin, M.Y.; Stavertiy, A.Y.; Pershin, S.M. In situ multi-elemental analysis by laser induced breakdown spectroscopy in additive manufacturing. Addit. Manuf. 2019, 25, 64–70. [Google Scholar] [CrossRef]

- Ci, X.; Wu, B.; Liu, Y.; Chen, G.; Wu, E.; Zeng, H. Magnetic-based Fano resonance of hybrid silicon-gold nanocavities in the near-infrared region. Opt. Expr. 2014, 22, 23749–23758. [Google Scholar] [CrossRef]

- Makarov, S.V.; Sinev, I.S.; Milichko, V.A.; Komissarenko, F.E.; Zuev, D.A.; Ushakova, E.V.; Mukhin, I.S.; Yu, Y.F.; Kuznetsov, A.I.; Belov, P.A.; et al. Nanoscale generation of white light for ultrabroadband nanospectroscopy. Nano Lett. 2017, 18, 535–539. [Google Scholar] [CrossRef]

- Baranov, A.N.; Butsen, A.V.; Ionin, A.A.; Ivanova, A.K.; Kuchmizhak, A.A.; Kudryashov, S.I.; Kudryavtseva, A.D.; Levchenko, A.O.; Rudenko, A.A.; Saraeva, I.N.; et al. The double-resonance enhancement of stimulated low-frequency Raman scattering in silver-capped nanodiamonds. Proceedings of International Conference on Metamaterials and Nanophotonics (METANANO-2017), Vladivostok, Russia, 18–22 September 2017; AIP Publishing: New York, NY, USA, 1874; p. 03010. [Google Scholar] [CrossRef]

- Simakin, A.V.; Shafeev, G.A. Initiation of nuclear reactions under laser irradiation of Au nanoparticles in the aqueous solution of Uranium salt. Appl. Phys. A 2010, 101, 199–203. [Google Scholar] [CrossRef]

- Semaltianos, N.G. Nanoparticles by laser ablation. Critical Rev. Solid State Mater. Sci. 2010, 35, 105–124. [Google Scholar] [CrossRef]

- Yan, Z.; Chrisey, D.B. Pulsed laser ablation in liquid for micro-/nanostructure generation. J. Photochem. Photobiol. C Photochem. Rev. 2012, 13, 204–223. [Google Scholar] [CrossRef]

- Zeng, H.; Du, X.W.; Singh, S.C.; Kulinich, S.A.; Yang, S.; He, J.; Cai, W. Nanomaterials via laser ablation/irradiation in liquid: A review. Adv. Funct. Mater. 2012, 22, 1333–1353. [Google Scholar] [CrossRef]

- Wang, H.; Kawaguchi, K.; Pyatenko, A.; Li, X.; Swiatkowska-Warkocka, Z.; Katou, Y.; Koshizaki, N. General Bottom-Up Construction of Spherical Particles by Pulsed Laser Irradiation of Colloidal Nanoparticles: A Case Study on CuO. Chem. A Euro. J. 2012, 18, 163–169. [Google Scholar] [CrossRef] [PubMed]

- Zhang, D.; Gökce, B.; Barcikowski, S. Laser synthesis and processing of colloids: fundamentals and applications. Chem. Rev. 2017, 117, 3990–4103. [Google Scholar] [CrossRef] [PubMed]

- Tamura, A.; Matsumoto, A.; Fukami, K.; Nishi, N.; Sakka, T. Simultaneous observation of nascent plasma and bubble induced by laser ablation in water with various pulse durations. J. Appl. Phys. 2015, 117, 173304. [Google Scholar] [CrossRef]

- Lam, J.; Lombard, J.; Dujardin, C.; Ledoux, G.; Merabia, S.; Amans, D. Dynamical study of bubble expansion following laser ablation in liquids. Appl. Phys. Lett. 2016, 108, 074104. [Google Scholar] [CrossRef]

- Letzel, A.; Gökce, B.; Wagener, P.; Ibrahimkutty, S.; Menzel, A.; Plech, A.; Barcikowski, S. Size Quenching during Laser Synthesis of Colloids Happens Already in the Vapor Phase of the Cavitation Bubble. J. Phys. Chem. C. 2017, 121, 5356–5365. [Google Scholar] [CrossRef]

- Letzel, A.; Santoro, M.; Frohleiks, J.; Ziefuß, A.R.; Reich, S.; Plech, A.; Gökce, B. How the re-irradiation of a single ablation spot affects cavitation bubble dynamics and nanoparticles properties in laser ablation in liquids. Appl. Surf. Sci 2018, 473, 828–837. [Google Scholar] [CrossRef]

- Amendola, V.; Meneghetti, M. What controls the composition and the structure of nanomaterials generated by laser ablation in liquid solution? Phys. Chem. Chem. Phys. 2013, 15, 3027–3046. [Google Scholar] [PubMed]

- Dell’Aglio, M.; Mangini, V.; Valenza, G.; De Pascale, O.; De Stradis, A.; Natile, G.; Arnesano, F.; De Giacomo, A. Silver and gold nanoparticles produced by pulsed laser ablation in liquid to investigate their interaction with ubiquitin. Appl. Surf. Sci. 2016, 374, 297–304. [Google Scholar] [CrossRef]

- Reich, S.; Schönfeld, P.; Letzel, A.; Kohsakowski, S.; Olbinado, M.; Gökce, B.; Barcikowski, S.; Plech, A. Fluence Threshold Behaviour on Ablation and Bubble Formation in Pulsed Laser Ablation in Liquids. ChemPhysChem 2017, 18, 1084–1090. [Google Scholar] [CrossRef]

- Kudryashov, S.I.; Nastulyavichus, A.A.; Ivanova, A.K.; Smirnov, N.A.; Khmelnitskiy, R.A.; Rudenko, A.A.; Saraeva, I.N.; Tolordava, E.R.; Kharin, A.Y.; Zavestovskaya, I.N.; et al. High-throughput laser generation of Si-nanoparticle based surface coatings for antibacterial applications. Appl. Surf. Sci. 2019, 470, 825–831. [Google Scholar] [CrossRef]

- Kudryashov, S.I.; Samokhvalov, A.A.; Ageev, E.I.; Petrov, A.A.; Veiko, V.P. Ultrasonic characterization of dry and wet nanosecond laser ablation of solids. J. Heat Mass Transf. 2018, 127, 1095–1100. [Google Scholar] [CrossRef]

- Bauerle, D. Laser Processing and Chemistry; Third, Revised and Enlarged Edition; Springer: Berlin, Germany, 2011. [Google Scholar] [CrossRef]

- Itina, T.E. On nanoparticle formation by laser ablation in liquids. J. Phys. Chem. C 2010, 115, 5044–5048. [Google Scholar] [CrossRef]

- Kalaitzis, A.; Makrygianni, M.; Theodorakos, I.; Hatziapostolou, A.; Melamed, S.; Kabla, A.; Zergioti, I. Jetting dynamics of Newtonian and non-Newtonian fluids via laser-induced forward transfer: Experimental and simulation studies. Appl. Surf. Sci. 2019, 465, 136–142. [Google Scholar] [CrossRef]

- Delaporte, P.; Alloncle, A.P. Laser-induced forward transfer: A high resolution additive manufacturing technology. Opt. Laser Technol. 2016, 78, 33–41. [Google Scholar] [CrossRef]

- Phipps, C.R.; Turner, T.P., Jr.; Harrison, R.F.; York, G.W.; Osborne, W.Z.; Anderson, G.K.; Corlis, X.F.; Haynes, L.C.; Steele, H.S.; Spicochi, K.C.; et al. Impulse coupling to targets in vacuum by KrF, HF, and CO2 single-pulse lasers. J. App. Phys. 1988, 64, 1083–1096. [Google Scholar] [CrossRef]

- Ionin, A.A.; Kudryashov, S.I.; Seleznev, L.V. Near-critical phase explosion promoting breakdown plasma ignition during laser ablation of graphite. Phys. Rev. E 2010, 82, 016404. [Google Scholar] [CrossRef] [PubMed]

- Kudryashov, S.I.; Paul, S.; Lyon, K.; Allen, S.D. Dynamics of laser-induced surface phase explosion in silicon. Appl. Phys. Lett. 2011, 98, 254102. [Google Scholar] [CrossRef]

- Kudryashov, S.I.; Ionov, S.G.; Zorov, N.B. Microscopic model of a charge density distribution for critical and supercritical states of carbon. Mendeleev Commun. 1999, 9, 61–63. [Google Scholar] [CrossRef]

- Kudryashov, S.I. Laser-Induced Surface and Bulk Near-Critical Liquid-Vapor Phase Transformations: Basic Concepts and Recent Advances. In Phase Transitions Induced by Short Laser Pulses; Nova Science Publishers: New York, NY, USA, 2009. [Google Scholar]

- Paul, S.; Kudryashov, S.I.; Lyon, K.; Allen, S.D. Nanosecond laser plasma assisted ultra-deep drilling of optically opaque and transparent solids. J. Appl. Phys. 2007, 101, 043106. [Google Scholar] [CrossRef]

- Bulgakova, N.M.; Evtushenko, A.B.; Shukhov, Y.G.; Kudryashov, S.I.; Bulgakov, A.V. Role of laser-induced plasma in ultradeep drilling of materials by nanosecond laser pulses. Appl. Surf. Sci. 2011, 257, 10876–10882. [Google Scholar] [CrossRef]

- Berthe, L.; Fabbro, R.; Peyre, P.; Tollier, L.; Bartnicki, E. Shock waves from a water-confined laser-generated plasma. J. Appl. Phys. 1997, 82, 2826–2832. [Google Scholar] [CrossRef]

- Kudryashov, S.I.; Zvorykin, V.D. Micro-scale nanosecond laser-induced optical breakdown in water. Phys. Rev. E 2008, 78, 036404. [Google Scholar] [CrossRef] [PubMed]

- Saraeva, I.N.; Van Luong, N.; Kudryashov, S.I.; Rudenko, A.A.; Khmelnitskiy, R.A.; Shakhmin, A.L.V.; Kharin, A.Y.; Ionin, A.A.; Zayarny, D.A.; Van Duong, P.; et al. Laser synthesis of colloidal Si@ Au and Si@Ag nanoparticles in water via plasma-assisted reduction. J. Photochem. Photobiol. A 2018, 360, 125–131. [Google Scholar] [CrossRef]

- Nastulyavichus, A.A.; Kudryashov, S.I.; Smirnov, N.A.; Rudenko, A.A.; Kharin, A.Y.; Zayarny, D.A.; Ionin, A.A. Nanosecond-laser plasma-mediated generation of colloidal solutions from silver films of variable thickness: Colloidal optical density versus pre-determined ablated mass. Opt. Laser Technol. 2019, 111, 75–80. [Google Scholar] [CrossRef]

- Yoo, J.H.; Jeong, S.H.; Greif, R.; Russo, R.E. Explosive change in crater properties during high power nanosecond laser ablation of silicon. J. Appl. Phys. 2000, 88, 1638–1649. [Google Scholar] [CrossRef]

- Neuenschwander, B.; Jaeggi, B.; Schmid, M.; Hennig, G. Surface structuring with ultra-short laser pulses: Basics, limitations and needs for high throughput. Phys. Procedia 2014, 56, 1047–1058. [Google Scholar] [CrossRef]

- Smirnov, N.A.; Kudryashov, S.I.; Danilov, P.A.; Rudenko, A.A.; Ionin, A.A.; Nastulyavichus, A.A. Silicon Ablation by Single Ultrashort Laser Pulses of Variable Width in Air and Water. JETP Lett. 2018, 108, 368–373. [Google Scholar] [CrossRef]

- Song, W.D.; Hong, M.H.; Lukyanchuk, B.; Chong, T.C. Laser-induced cavitation bubbles for cleaning of solid surfaces. J. Appl. Phys. 2004, 95, 2952–2956. [Google Scholar] [CrossRef]

- Yavas, O.; Leiderer, P.; Park, H.K.; Grigoropoulos, C.P.; Poon, C.C.; Tam, A.C. Enhanced acoustic cavitation following laser-induced bubble formation: Long-term memory effect. Phys. Rev. Lett. 1994, 72, 2021. [Google Scholar] [CrossRef]

- Kudryashov, S.I.; Nguyen, L.V.; Kirilenko, D.A.; Brunkov, P.N.; Rudenko, A.A.; Busleev, N.; Saraeva, I.N.; Nastulyavichus, A.A.; Ionin, A.A.; Tolordava, E.R.; et al. Large-scale Laser Fabrication of Anti-Fouling Si Surface Nanosheet Arrays via Nanoplasmonic Ablative Self-organization in Liquid CS2 Tracked by Sulfur Dopant. ACS Appl. Nano Mater. 2018, 1, 2461–2468. [Google Scholar] [CrossRef]

- Grigor’ev, I.S.; Meylikhov, E.Z. Physical Quantities; Energoatomizdat: Moscow, Russia, 1991. [Google Scholar]

- Serkov, A.A.; Barmina, E.V.; Simakin, A.V.; Kuzmin, P.G.; Voronov, V.V.; Shafeev, G.A. Generation of core–shell nanoparticles Al@Ti by laser ablation in liquid for hydrogen storage. Appl. Surf. Sci. 2015, 348, 71–74. [Google Scholar] [CrossRef]

- Ivanova, A.K.; Saraeva, I.N.; Nastulyavichus, A.A.; Rudenko, A.A.; Kirilenko, D.A.; Brunkov, P.N.; Kudryashov, S.I.; Ionin, A.A. Production of novel hybrid metal-semiconductor nanoparticles silicon-gold by nanosecond laser ablation in water. Commun. Phys. (accepted, in press).

- Lam, J.; Amans, D.; Chaput, F.; Diouf, M.; Ledoux, G.; Mary, N.; Masenelli-Varlot, K.; Motto-Ros, V.; Dujardin, C. γ-Al2O3 nanoparticles synthesized by pulsed laser ablation in liquids: A plasma analysis. Phys. Chem. Chem. Phys. 2014, 16, 963–973. [Google Scholar] [PubMed]

- Dell’Aglio, M.; De Giacomo, A.; Kohsakowski, S.; Barcikowski, S.; Wagener, P.; Santagata, A. Pulsed laser ablation of wire-shaped target in a thin water jet: Effects of plasma features and bubble dynamics on the PLAL process. J. Phys. D Appl. Phys. 2017, 50, 185204. [Google Scholar] [CrossRef]

- Loeschner, U.; Schille, J.; Streek, A.; Knebel, T.; Hartwig, L.; Hillmann, R.; Endisch, C. High-rate laser microprocessing using a polygon scanner system. J. Laser Appl. 2015, 27, S29303. [Google Scholar] [CrossRef]

- Sajti, C.L.; Sattari, R.; Chichkov, B.N.; Barcikowski, S. Gram scale synthesis of pure ceramic nanoparticles by laser ablation in liquid. J. Phys. Chem. C 2010, 114, 2421–2427. [Google Scholar] [CrossRef]

- Streubel, R.; Barcikowski, S.; Gökce, B. Continuous multigram nanoparticle synthesis by high-power, high-repetition-rate ultrafast laser ablation in liquids. Opt. Lett. 2016, 41, 1486–1489. [Google Scholar] [CrossRef] [PubMed]

- Ionin, A.; Ivanova, A.; Khmel’nitskii, R.; Klevkov, Yu.; Kudryashov, S.; Mel’nik, N.; Nastulyavichus, A.; Rudenko, A.; Saraeva, I.; Smirnov, N.; et al. Milligram-per-second femtosecond laser production of Se nanoparticle inks and ink-jet printing of nanophotonic 2D-patterns. Appl. Surf. Sci. 2017, 436, 662–669. [Google Scholar] [CrossRef]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kudryashov, S.I.; Samokhvalov, A.A.; Nastulyavichus, A.A.; Saraeva, I.N.; Mikhailovskii, V.Y.; Ionin, A.A.; Veiko, V.P. Nanosecond-Laser Generation of Nanoparticles in Liquids: From Ablation through Bubble Dynamics to Nanoparticle Yield. Materials 2019, 12, 562. https://doi.org/10.3390/ma12040562

Kudryashov SI, Samokhvalov AA, Nastulyavichus AA, Saraeva IN, Mikhailovskii VY, Ionin AA, Veiko VP. Nanosecond-Laser Generation of Nanoparticles in Liquids: From Ablation through Bubble Dynamics to Nanoparticle Yield. Materials. 2019; 12(4):562. https://doi.org/10.3390/ma12040562

Chicago/Turabian StyleKudryashov, Sergey I., Andrey A. Samokhvalov, Alena A. Nastulyavichus, Irina N. Saraeva, Vladimir Y. Mikhailovskii, Andrey A. Ionin, and Vadim P. Veiko. 2019. "Nanosecond-Laser Generation of Nanoparticles in Liquids: From Ablation through Bubble Dynamics to Nanoparticle Yield" Materials 12, no. 4: 562. https://doi.org/10.3390/ma12040562

APA StyleKudryashov, S. I., Samokhvalov, A. A., Nastulyavichus, A. A., Saraeva, I. N., Mikhailovskii, V. Y., Ionin, A. A., & Veiko, V. P. (2019). Nanosecond-Laser Generation of Nanoparticles in Liquids: From Ablation through Bubble Dynamics to Nanoparticle Yield. Materials, 12(4), 562. https://doi.org/10.3390/ma12040562