New Aluminum Alloys Specifically Designed for Laser Powder Bed Fusion: A Review

Abstract

:1. Introduction

2. Methodologies

- the dimension of the laser scan in a real part might be slightly larger with respect to the SSTs due to the heat accumulated during the scanning of the previous layers;

- the microstructure of a SST might be slightly different from the real part one because it does not undergo the intrinsic heat treatment due to the melting and solidification of the following layers.

3. Rapid Solidification

- the extension of the solid solubility;

- the formation of non-equilibrium and metastable phases;

- the reduction of number and size of segregated phases;

- the changes in grain morphology such as grain refinement, location and distribution of the phases;

- the reduced phase crystallinity.

4. Aluminum Alloys for LPBF

4.1. Processability of High Strength Aluminum Alloys

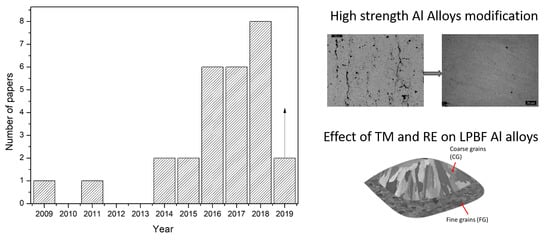

4.2. High Strength Aluminum Alloys Modification

- Control of the solidification process by the formation of nucleant phases (e.g., Al3Zr);

- Modification of the solidification processes by the reduction of the solidification range;

- Reduction of the thermal gradient by preheating the building platform.

4.3. Effect of Transition Metals and Rare Earth Elements to Aluminum Alloys

4.4. Metallic Glasses and Nanocrystalline Materials

5. Mechanical Properties

6. Conclusions

- The reduction of the solidification cracking mechanism of commercial high strength aluminum alloys (e.g., 7075, 2024, and 6061) thanks to the modification of the melting behavior. This effect was obtained mainly by the introduction of Si which increases the fluidity of the molten phase and reduces the alloy melting range, its coefficient of thermal expansion and its solidification shrinkage. The decisive effect of Si was demonstrated on the 7075 and 2024 compositions.

- The reduction of the solidification cracking obtained thanks to the reduction of the grain size of commercial high strength aluminum alloys achieved as a result of the precipitation of strongly coherent phases. Zr was mainly employed in order to obtain fine coherent Al3Zr particles which act as nucleant during the solidification process. This method demonstrated to be promising for the processability of 7075, 2024, and 6061 alloys.

- The reduction of the solidification cracking by the increase in the building platform temperature. This method implies a reduction of the thermal stresses and therefore of the cracking density. The high temperature of the building platform causes however a reduction in the cooling rate and precludes the solidification of fine microstructures. This method was however successfully applied to the 6061 composition which could achieve high mechanical properties in the T6 condition.

- The introduction of rare earth and transition metallic elements to standard Al alloys compositions, which implied a strong increase in the mechanical properties of LPBF samples. The most promising composition was undoubtedly produced by the introduction of Sc and Zr to an Al-Mg alloy leading to the patented Scalmalloy® composition. The high mechanical properties of this alloy are mainly due to the precipitation of coherent Al3(Sc,Zr) particles and to the Mg solid solution strengthening effect. Furthermore, this composition resulted to be stable up to high temperatures thanks to the Al3(ScZr) poor tendency to grow. On the basis of the success of this composition, many authors focused on the study of similar compositions containing Sc, Er, and Zr and obtained promising results. The introduction of less expensive TM elements seems to be also a promising approach for the production of high strength LPBF Al alloys. The rapid solidification achieved during the laser scanning allows the precipitation of extremely fine strengthening phases and therefore high mechanical properties.

- The production of metallic glass and nanocrystalline materials. Thanks to the rapid solidification that arises as a consequence of the laser scanning, it seems that the LPBF process might be a promising production technology for these materials. However, because of the peculiar thermal history to which the material undergoes, different microstructures can be obtained. This aspect has to be carefully taken into account if complex parts have to be built.

Author Contributions

Funding

Conflicts of Interest

References

- Frazier, W.E. Metal Additive Manufacturing: A Review. J. Mater. Eng. Perform. 2014, 23, 1917–1928. [Google Scholar] [CrossRef] [Green Version]

- Adam, G.A.O.; Zimmer, D. Design for Additive Manufacturing—Element transitions and aggregated structures. CIRP J. Manuf. Sci. Technol. 2014, 7, 20–28. [Google Scholar] [CrossRef]

- Chu, C.; Graf, G.; Rosen, D.W. Design for additive manufacturing of cellular structures. Comput. Aided. Des. Appl. 2008, 5, 686–696. [Google Scholar] [CrossRef]

- Wang, P.; Gammer, C.; Brenne, F.; Prashanth, K.G.; Mendes, R.G.; Rümmeli, M.H.; Gemming, T.; Eckert, J.; Scudino, S. Microstructure and mechanical properties of a heat-treatable Al-3.5Cu-1.5Mg-1Si alloy produced by selective laser melting. Mater. Sci. Eng. A 2018, 711, 562–570. [Google Scholar] [CrossRef]

- Aboulkhair, N.T.; Everitt, N.M.; Maskery, I.; Ashcroft, I.; Tuck, C. Selective laser melting of aluminum alloys. MRS Bull. 2017, 42, 311–319. [Google Scholar] [CrossRef] [Green Version]

- Li, X.P.; Ji, G.; Chen, Z.; Addad, A.; Wu, Y.; Wang, H.W.; Vleugels, J.; van Humbeeck, J.; Kruth, J.P. Selective laser melting of nano-TiB2 decorated AlSi10Mg alloy with high fracture strength and ductility. Acta Mater. 2017, 129, 183–193. [Google Scholar] [CrossRef]

- Tang, M.; Pistorius, P.C. Oxides, porosity and fatigue performance of AlSi10Mg parts produced by selective laser melting. Int. J. Fatigue 2016, 94, 192–201. [Google Scholar] [CrossRef]

- Olakanmi, E.O.; Cochrane, R.F.; Dalgarno, K.W. A review on selective laser sintering/melting (SLS/SLM) of aluminium alloy powders: Processing, microstructure, and properties. Prog. Mater. Sci. 2015, 74, 401–477. [Google Scholar] [CrossRef] [Green Version]

- Gu, D.D.; Meiners, W.; Wissenbach, K.; Poprawe, R. Laser additive manufacturing of metallic components: Materials, processes and mechanisms. Int. Mater. Rev. 2012, 57, 133–164. [Google Scholar] [CrossRef]

- Vreeling, J.A.; Ocelik, V.; Pei, Y.T.; Agterveld, V.D.T.L.; de Hosson, J.T.M. Laser Melt Injection in Aluminum Alloys: On the Role of the Oxidaton Skin. Acta Mater. 2000, 48, 4225–4233. [Google Scholar] [CrossRef]

- Uslan, I.; Saritas, S.; Davies, T.J. Effects of variables on size and characteristics of gas atomised aluminium powders. Powder Metall. 2013, 42, 157–163. [Google Scholar] [CrossRef]

- Trevisan, F.; Calignano, F.; Lorusso, M.; Pakkanen, J.; Aversa, A.; Ambrosio, E.P.; Lombardi, M.; Fino, P.; Manfredi, D. On the Selective Laser Melting (SLM) of the AlSi10Mg Alloy: Process, Microstructure, and Mechanical Properties. Materials 2017, 10, 76. [Google Scholar] [CrossRef] [PubMed]

- Aversa, A.; Lorusso, M.; Trevisan, F.; Ambrosio, E.; Calignano, F.; Manfredi, D.; Biamino, S.; Fino, P.; Lombardi, M.; Pavese, M. Effect of Process and Post-Process Conditions on the Mechanical Properties of an A357 Alloy Produced via Laser Powder Bed Fusion. Metals 2017, 7, 68. [Google Scholar] [CrossRef]

- Vora, P.; Mumtaz, K.; Todd, I.; Hopkinson, N. AlSi12 in-situ alloy formation and residual stress reduction using anchorless selective laser melting. Addit. Manuf. 2015, 7, 12–19. [Google Scholar] [CrossRef] [Green Version]

- Kempen, K.; Thijs, L.; van Humbeeck, J.; Kruth, J.-P. Mechanical Properties of AlSi10Mg Produced by Selective Laser Melting. Phys. Procedia 2012, 39, 439–446. [Google Scholar] [CrossRef] [Green Version]

- Rao, J.H.; Zhang, Y.; Zhang, K.; Huang, A.; Davies, C.H.J.; Wu, X. Multiple precipitation pathways in an Al-7Si-0.6Mg alloy fabricated by selective laser melting. Scr. Mater. 2019, 160, 66–69. [Google Scholar] [CrossRef]

- Olabode, M. Weldability of High Strength Aluminium Alloys. Ph.D. Thesis, Lappeenranta University of Technology, Lappeenranta, Finland, 2015. [Google Scholar]

- Tang, M.; Pistorius, P.C.; Narra, S.; Beuth, J.L. Rapid Solidification: Selective Laser Melting of AlSi10Mg. J. Miner. Met. Mater. Soc. 2016, 68, 960–966. [Google Scholar] [CrossRef]

- Guo, H.; Yang, X. Preparation of semi-solid slurry containing fine and globular particles for wrought aluminum alloy 2024. Trans. Nonferrous Met. Soc. China 2007, 17, 799–804. [Google Scholar] [CrossRef]

- Sercombe, T.B.; Li, X. Selective laser melting of aluminium and aluminium metal matrix composites: Review. Mater. Technol. 2016, 31, 77–85. [Google Scholar] [CrossRef]

- Manfredi, D.; Ambrosio, E.P.; Calignano, F.; Krishnan, M.; Canali, R.; Biamino, S.; Pavese, M.; Atzeni, E.; Iuliano, L.; Fino, P.; et al. Direct Metal Laser Sintering: An additive manufacturing technology ready to produce lightweight structural parts for robotic applications Memorie. La Metall. Ital. 2013, 10, 15–24. [Google Scholar]

- Kim, D.-K.; Woo, W.; Hwang, J.-H.; An, K.; Choi, S.-H. Stress partitioning behavior of an AlSi10Mg alloy produced by selective laser melting during tensile deformation using in situ neutron diffraction. J. Alloys Compd. 2016, 686, 281–286. [Google Scholar] [CrossRef]

- Tradowsky, U.; White, J.; Ward, R.M.; Read, N.; Reimers, W.; Attallah, M.M. Selective laser melting of AlSi10Mg: Influence of post-processing on the microstructural and tensile properties development. Mater. Des. 2016, 105, 212–222. [Google Scholar] [CrossRef]

- Hadadzadeh, A.; Baxter, C.; Shalchi, B.; Mohammadi, M. Strengthening mechanisms in direct metal laser sintered AlSi10Mg: Comparison between virgin and recycled powders. Addit. Manuf. J. 2018, 23, 108–120. [Google Scholar] [CrossRef]

- Hadadzadeh, A.; Amirkhiz, B.S.; Mohammadi, M. Contribution of Mg2Si precipitates to the strength of direct metal laser sintered AlSi10Mg. Mater. Sci. Eng. A 2019, 739, 295–300. [Google Scholar] [CrossRef]

- Li, W.; Li, S.; Liu, J.; Zhang, A.; Zhou, Y.; Wei, Q.; Yan, C.; Shi, Y. Effect of heat treatment on AlSi10Mg alloy fabricated by selective laser melting: Microstructure evolution, mechanical properties and fracture mechanism. Mater. Sci. Eng. A 2016, 663, 116–125. [Google Scholar] [CrossRef]

- Brandl, E.; Heckenberger, U.; Holzinger, V.; Buchbinder, D. Additive manufactured AlSi10Mg samples using Selective Laser Melting (SLM): Microstructure, high cycle fatigue, and fracture behavior. Mater. Des. 2012, 34, 159–169. [Google Scholar] [CrossRef]

- Cabrini, M.; Lorenzi, S.; Pastore, T.; Pellegrini, S.; Ambrosio, E.P.; Calignano, F.; Manfredi, D.; Pavese, M.; Fino, P. Effect of heat treatment on corrosion resistance of DMLS AlSi10Mg alloy. Electrochim. Acta 2016, 206, 346–355. [Google Scholar] [CrossRef]

- Salmi, A.; Atzeni, E.; Iuliano, L.; Galati, M. Experimental analysis of residual stresses on AlSi10Mg parts produced by means of Selective Laser Melting (SLM). Procedia CIRP 2017, 62, 458–463. [Google Scholar] [CrossRef]

- Mauduit, A. Study of the suitability of aluminum alloys for additive manufacturing by laser powder bed fusion. Sci. Bull. 2017, 79, 219–238. [Google Scholar]

- Wu, J.; Wang, X.Q.; Wang, W.; Attallah, M.M.; Loretto, M.H. Microstructure and strength of selectively laser melted AlSi10Mg. Acta Mater. 2016, 117, 311–320. [Google Scholar] [CrossRef]

- Martin, J.H.; Yahata, B.D.; Hundley, J.M.; Mayer, J.A.; Schaedler, T.A.; Pollock, T.M. 3D printing of high-strength aluminium alloys. Nature 2017, 549, 365–369. [Google Scholar] [CrossRef] [PubMed]

- Aversa, A.; Lorusso, M.; Cattano, G.; Manfredi, D.; Calignano, F.; Ambrosio, E.P.; Biamino, S.; Fino, P.; Lombardi, M.; Pavese, M. A study of the microstructure and the mechanical properties of an AlSiNi alloy produced via selective laser melting. J. Alloys Compd. 2017, 695, 1470–1478. [Google Scholar] [CrossRef]

- Zhang, H.; Zhu, H.; Nie, X.; Yin, J.; Hu, Z.; Zeng, X. Effect of Zirconium addition on crack, microstructure and mechanical behavior of selective laser melted Al-Cu-Mg alloy. Scr. Mater. 2017, 134, 6–10. [Google Scholar] [CrossRef]

- Nie, X.; Zhang, H.; Zhu, H.; Hu, Z.; Ke, L.; Zeng, X. Effect of Zr content on formability, microstructure and mechanical properties of selective laser melted Zr modified Al-4.24Cu-1.97Mg-0.56Mn alloys. J. Alloys Compd. 2018, 764, 977–986. [Google Scholar] [CrossRef]

- Montero-Sistiaga, M.L.; Mertens, R.; Vrancken, B.; Wang, X.; Van Hooreweder, B.; Kruth, J.P.; Van Humbeeck, J. Changing the alloy composition of Al7075 for better processability by selective laser melting. J. Mater. Process. Technol. 2016, 238, 437–445. [Google Scholar] [CrossRef]

- Aversa, A.; Marchese, G.; Manfredi, D.; Lorusso, M.; Calignano, F.; Biamino, S.; Lombardi, M.; Fino, P.; Pavese, M. Laser Powder Bed Fusion of a High Strength Al-Si-Zn-Mg-Cu Alloy. Metals 2018, 8, 300. [Google Scholar] [CrossRef]

- Wang, P.; Deng, L.; Prashanth, K.G.; Pauly, S.; Eckert, J.; Scudino, S. Microstructure and mechanical properties of Al-Cu alloys fabricated by selective laser melting of powder mixtures. J. Alloys Compd. 2018, 735, 2263–2266. [Google Scholar] [CrossRef]

- Zhou, J.; Tsai, H.-L.; Wang, P.-C. Transport Phenomena and Keyhole Dynamics during Pulsed Laser Welding. Trans. Am. Soc. Mech. Eng. 2006, 128, 680–690. [Google Scholar] [CrossRef]

- Aversa, A.; Moshiri, M.; Librera, E.; Hadi, M.; Marchese, G.; Manfredi, D.; Lorusso, M.; Calignano, F.; Biamino, S.; Lombardi, M.; et al. Single scan track analyses on aluminium based powders. J. Mater. Process. Technol. 2018, 255, 17–25. [Google Scholar] [CrossRef]

- Nie, X.; Zhang, H.; Zhu, H.; Hu, Z.; Ke, L.; Zeng, X. Analysis of processing parameters and characteristics of selective laser melted high strength Al-Cu-Mg alloys: From single tracks to cubic samples. J. Mater. Process. Technol. 2018, 256, 69–77. [Google Scholar] [CrossRef]

- Li, X.P.; Kang, C.W.; Huang, H.; Zhang, L.C.; Sercombe, T.B. Selective laser melting of an Al86Ni6Y4.5Co2La1.5 metallic glass: Processing, microstructure evolution and mechanical properties. Mater. Sci. Eng. A 2014, 606, 370–379. [Google Scholar] [CrossRef]

- Boley, C.D.; Khairallah, S.A.; Rubenchik, A.M. Calculation of laser absorption by metal powders in additive manufacturing. Appl. Opt. 2015, 54, 2477–2482. [Google Scholar] [CrossRef]

- Bartkowiak, K.; Ullrich, S.; Frick, T.; Schmidt, M. New Developments of Laser Processing Aluminium Alloys via Additive Manufacturing Technique. Phys. Procedia 2011, 12, 393–401. [Google Scholar] [CrossRef] [Green Version]

- King, W.E.; Barth, H.D.; Castillo, V.M.; Gallegos, G.F.; Gibbs, J.W.; Hahn, D.E.; Kamath, C.; Rubenchik, A.M. Observation of keyhole-mode laser melting in laser powder-bed fusion additive manufacturing. J. Mater. Process. Technol. 2014, 214, 2915–2925. [Google Scholar] [CrossRef]

- Gu, D.; Shen, Y. Balling phenomena during direct laser sintering of multi-component Cu-based metal powder. J. Alloys Compd. 2007, 432, 163–166. [Google Scholar] [CrossRef]

- Aboulkhair, N.T.; Maskery, I.; Tuck, C.; Ashcroft, I.; Everitt, N.M. On the formation of AlSi10Mg single tracks and layers in selective laser melting: Microstructure and nano-mechanical properties. J. Mater. Process. Technol. 2016, 230, 88–98. [Google Scholar] [CrossRef] [Green Version]

- Jia, Q.; Rometsch, P.; Cao, S.; Zhang, K.; Huang, A.; Wu, X. Characterisation of AlScZr and AlErZr alloys processed by rapid laser melting. Scr. Mater. 2018, 151, 42–46. [Google Scholar] [CrossRef]

- Li, Y.; Gu, D. Parametric analysis of thermal behavior during selective laser melting additive manufacturing of aluminum alloy powder. Mater. Des. 2014, 63, 856–867. [Google Scholar] [CrossRef]

- Scipioni, U.; Guss, G.; Wu, S.; Matthews, M.J.; Schoenung, J.M. In-situ characterization of laser-powder interaction and cooling rates through high-speed imaging of powder bed fusion additive manufacturing. Mater. Des. 2017, 135, 385–396. [Google Scholar] [CrossRef]

- Masoomi, M.; Thompson, S.M.; Shamsaei, N. Laser powder bed fusion of Ti-6Al-4V parts: Thermal modeling and mechanical implications. Int. J. Mach. Tools Manuf. 2017, 119, 73–90. [Google Scholar] [CrossRef]

- Srivastava, V.K. A Reviev on Advances in Rapid Prototype 3D Printing of Multi-Functional Applications. Sci. Technol. 2017, 7, 4–24. [Google Scholar]

- Tawfik, N.L. Mechanical properties of rapidly solidified ribbons of some Al–Si based alloys. J. Mater. Sci. 1997, 32, 2997–3000. [Google Scholar] [CrossRef]

- Ovecoglu, M.L.; Necip, U.; Niyazi, E.; Eruslu, N.; Genc, A. Characterization investigations of a melt-spun ternary Al–8Si–5.1Cu (in wt.%) alloy. Mater. Lett. 2003, 57, 3296–3301. [Google Scholar] [CrossRef]

- Marola, S.; Manfredi, D.; Fiore, G.; Poletti, M.G.; Lombardi, M.; Fino, P.; Battezzati, L. A comparison of Selective Laser Melting with bulk rapid solidification of AlSi10Mg alloy. J. Alloys Compd. 2018, 742, 271–279. [Google Scholar] [CrossRef]

- Ghaini, F.M.; Sheikhi, M.; Torkamany, M.J.; Sabbaghzadeh, J. The relation between liquation and solidification cracks in pulsed laser welding of 2024 aluminium alloy. Mater. Sci. Eng. A 2009, 519, 167–171. [Google Scholar] [CrossRef]

- Zhang, H.; Zhu, H.; Qi, T.; Hu, Z.; Zeng, X. Materials Science & Engineering A Selective laser melting of high strength Al–Cu–Mg alloys: Processing, microstructure and mechanical properties. Mater. Sci. Eng. A 2016, 656, 47–54. [Google Scholar]

- Kaufmann, F.; Imran, N.; Wischeropp, M.; Emmelmann, T.; Siddique, C.; Walther, S. Influence of process parameters on the quality of aluminium alloy EN AW 7075 using selective laser melting (SLM). Phys. Procedia 2016, 83, 918–926. [Google Scholar] [CrossRef]

- Qi, T.; Zhu, H.; Zhang, H.; Yin, J.; Ke, L.; Zeng, X. Selective laser melting of Al7050 powder: Melting mode transition and comparison of the characteristics between the keyhole and conduction mode. Mater. Des. 2017, 135, 257–266. [Google Scholar] [CrossRef]

- Rajan, K.; Wallace, W.; Beddoes, J.C. Microstructural study of a high-strength stress-corrosion resistant 7075 aluminium alloy. J. Mater. Sci. 1982, 17, 2817–2824. [Google Scholar] [CrossRef]

- Zhou, L.; Pan, H.; Hyer, H.; Park, S.; Bai, Y.; McWilliams, B.; Cho, K.; Sohn, Y. Scripta Materialia Microstructure and tensile property of a novel AlZnMgScZr alloy additively manufactured by gas atomization and laser powder bed fusion. Scr. Mater. 2019, 158, 24–28. [Google Scholar] [CrossRef]

- Uddin, S.Z.; Murr, L.E.; Terrazas, C.A.; Morton, P.; Roberson, D.A.; Wicker, R.B. Processing and characterization of crack-free aluminum 6061 using high-temperature heating in laser powder bed fusion additive manufacturing. Addit. Manuf. J. 2018, 22, 405–415. [Google Scholar] [CrossRef]

- Maamoun, A.H.; Xue, J.; Elbestawi, M.; Veldhuis, S.C. The Effect of Selective Laser Melting Process Parameters on the Microstructure and Mechanical Properties of Al6061 and AlSi10Mg Alloys. Materials 2019, 12, 12. [Google Scholar] [CrossRef] [PubMed]

- Loh, L.E.; Liu, Z.H.; Zhang, D.Q.; Mapar, M.; Sing, S.L.; Chua, C.K.; Yeong, W.Y. Selective Laser Melting of aluminium alloy using a uniform beam profile Selective Laser Melting of aluminium alloy using a uniform beam profile. Virtual Phys. Prototyp. 2014, 9, 11–16. [Google Scholar] [CrossRef]

- Louvis, E.; Fox, P.; Sutcliffe, C.J. Selective laser melting of aluminium components. J. Mater. Process. Technol. 2011, 211, 275–284. [Google Scholar] [CrossRef]

- Fulcher, B.A.; Leigh, D.K.; Watt, T.J. Comparison of AlSi10Mg and Al 6061 processes trough DMLS. In Proceedings of the Solid Freeform Fabrication (SFF) Symposium, Austin, TX, USA, 4–6 August 2014; pp. 404–419. [Google Scholar]

- Lee, T.H.; Hong, S.J. Microstructure and mechanical properties of Al–Si–X alloys fabricated by gas atomization and extrusion process. J. Alloys Compd. 2009, 487, 218–224. [Google Scholar] [CrossRef]

- Ma, P.; Jia, Y.; Gokuldoss, K.; Scudino, S.; Yu, Z. Microstructure and phase formation in Al–20Si–5Fe–3Cu–1Mg synthesized by selective laser melting. J. Alloys Compd. 2016, 657, 430–435. [Google Scholar] [CrossRef]

- Rajabi, M.; Vahidi, M.; Simchi, A.; Davami, P. Effect of rapid solidification on the microstructure and mechanical properties of hot-pressed Al-20Si-5Fe alloys. Mater. Charact. 2009, 60, 1370–1381. [Google Scholar] [CrossRef]

- Schmidtke, K.; Palm, F.; Hawkins, A.; Emmelmann, C. Process and Mechanical Properties: Applicability of a Scandium modified Al-alloy for Laser Additive Manufacturing. Phys. Procedia 2011, 12, 369–374. [Google Scholar] [CrossRef] [Green Version]

- Kendig, K.L.; Miracle, D.B. Strengthening mechanisms of an Al-Mg-Sc-Zr alloy. Acta Mater. 2002, 50, 4165–4175. [Google Scholar] [CrossRef]

- Spierings, A.B.; Dawson, K.; Voegtlin, M.; Palm, F.; Uggowitzer, P.J. Microstructure and mechanical properties of as-processed scandium-modified aluminium using selective laser melting. CIRP Ann. Manuf. Technol. 2016, 65, 213–216. [Google Scholar] [CrossRef]

- Spierings, A.B.; Dawson, K.; Heeling, T.; Uggowitzer, P.J.; Schäublin, R.; Palm, F.; Wegener, K. Microstructural features of Sc- and Zr-modified Al-Mg alloys processed by selective laser melting. Mater. Des. 2017, 115, 52–63. [Google Scholar] [CrossRef]

- Spierings, A.B.; Dawson, K.; Uggowitzer, P.J.; Wegener, K. Influence of SLM scan-speed on microstructure, precipitation of Al3Sc particles and mechanical properties in Sc- and Zr-modified Al-Mg alloys. Mater. Des. 2018, 140, 134–143. [Google Scholar] [CrossRef]

- Li, R.; Wang, M.; Yuan, T.; Song, B.; Chen, C.; Zhou, K.; Cao, P. Selective laser melting of a novel Sc and Zr modified Al-6.2 Mg alloy: Processing, microstructure, and properties. Powder Technol. 2017, 319, 117–128. [Google Scholar] [CrossRef]

- Shi, Y.; Rometsch, P.; Yang, K.; Palm, F.; Wu, X. Characterisation of a novel Sc and Zr modified Al–Mg alloy fabricated by selective laser melting. Mater. Lett. 2017, 196, 347–350. [Google Scholar] [CrossRef]

- Griffiths, S.; Rossell, M.D.; Croteau, J.; Vo, N.Q.; Dunand, D.C.; Leinenbach, C. Effect of laser rescanning on the grain microstructure of a selective laser melted Al-Mg-Zr alloy. Mater. Charact. 2018, 143, 34–42. [Google Scholar] [CrossRef]

- Croteau, J.R.; Griffiths, S.; Rossell, M.D.; Leinenbach, C.; Kenel, C.; Jansen, V.; Seidman, D.N.; Dunand, D.C.; Vo, N.Q. Microstructure and mechanical properties of Al-Mg-Zr alloys processed by selective laser melting. Acta Mater. 2018, 153, 35–44. [Google Scholar] [CrossRef]

- Zheng, L.; Liu, Y.; Sun, S.; Zhang, H. Selective laser melting of Al-8.5Fe-1.3V-1.7Si alloy: Investigation on the resultant microstructure and hardness. Chin. J. Aeronaut. 2015, 28, 564–569. [Google Scholar] [CrossRef]

- Leng, Y.; Porr, W.C.; Gangloff, R.P. Tensile Ddeformation of 2618 and Al-Fe-Si-V Aluminium Alloys at Elevated Temperatures. Scr. Metall. Mater. 1990, 24, 2163–2168. [Google Scholar] [CrossRef]

- Pickens, J.R.; Marietta, M. High-Strength Aluminum P/M Alloys. Adv. Mater. Process. 1999, 155, 200–215. [Google Scholar]

- Sun, S.; Zheng, L.; Liu, Y. Characterization of Al-Fe-V-Si heat-resistant aluminum alloy components fabricated by selective laser melting. J. Mater. Res. 2015, 30, 1661–1669. [Google Scholar] [CrossRef]

- Manca, D.R.; Churyumov, A.Y.; Pozdniakov, A.V.; Ryabov, D.K.; Korolev, V.A.; Daubarayte, D.K. Novel heat-resistant Al-Si-Ni-Fe alloy manufactured by selective laser melting. Mater. Lett. 2019, 236, 676–679. [Google Scholar] [CrossRef]

- Inoue, A. Amorphous, nanoquasicrystalline and nanocrystalline alloys in Al-based systems. Prog. Mater. Sci. 1998, 43, 365–520. [Google Scholar] [CrossRef]

- Prashanth, K.G.; Shahabi, H.S.; Attar, H.; Srivastava, V.C.; Ellendt, N.; Uhlenwinkel, V.; Eckertae, J.; Scudino, S. Production of high strength Al85Nd8Ni5Co2 alloy by selective laser melting. Addit. Manuf. 2015, 6, 1–5. [Google Scholar] [CrossRef]

- Li, X.P.; Kang, C.W.; Huang, H.; Sercombe, T.B. The role of a low-energy-density re-scan in fabricating crack-free Al85Ni5Y6Co2Fe2 bulk metallic glass composites via selective laser melting. Mater. Des. 2014, 63, 407–411. [Google Scholar] [CrossRef]

- Cornelius, M.; Karg, H.; Ahuja, B.; Wiesenmayer, S.; Kuryntsev, S.V.; Schmidt, M. Effects of Process Conditions on the Mechanical Behavior of Aluminium Wrought Alloy EN AW-2219 (AlCu6Mn) Additively Manufactured by Laser Beam Melting in Powder Bed. Micromachines 2017, 2219, 1–11. [Google Scholar]

| Composition | Heat Treatment | HV | HB | YS [MPa] | UTS [MPa] | ε (%) | Reference |

|---|---|---|---|---|---|---|---|

| AlSi10Mg H | 135.0 ± 0.9 | 128.6 ± 1.9 | 270 ± 10 | 460 ± 20 | 9 ± 2 | [33] | |

| AlSi10Mg H | S.R. | ~95 | 93 ± 3 | 230 ± 15 | 345 ± 50 | 12 ± 2 | [12] |

| Scalmalloy® | - | - | 100–115 | 276–287 | 403–427 | 14–17 | [74] |

| Scalmalloy® | 325 °C 4 h | ~180 | - | 520 | 530 | 14 | [70] |

| AlScZr L.R. | 5 h 300 °C | 113 HV0.5 | - | - | - | - | [48] |

| AlErZr L.R. | 2 h 300 °C | 91 HV0.5 | - | - | - | - | [48] |

| AlCuMgMn | - | - | 276.2 ± 41 | 402.4 ± 9.5 | 6 ± 1.4 | [57] | |

| Zr/AlCuMgMn | - | - | 446 ± 4.3 | 451 ± 3.6 | 2.7 ± 1.1 | [34] | |

| Zr/AlCuMgMn | - | 153.6 | 464.06 ± 2 | 493.30 ± 10 | 4.76 ± 1 | [35] | |

| 2219 | - | 94 ± 6.6 | [87] | ||||

| 2219 | T6 | 147 ± 2.3 | [87] | ||||

| Al-3.5Cu-1.5Mg-1Si | - | 223 ± 4 | 366 ± 7 | 5.3 ± 0.3 | [4] | ||

| Al-3.5Cu-1.5Mg-1Si | T6 | 368 ± 6 | 455 ± 10 | 6.2 ± 1.8 | [4] | ||

| 7075+Zr | T6 | 130–140 | - | 32–373 | 383–417 | 3.8–5.4 | [32] |

| Si mod. 7075 | 6 h 150 °C | ~170 | - | - | - | - | [36] |

| Si mod. 7075 | 6 h 160 °C | 140–150 | 350 | 415 | - | [37] | |

| Al-8.5Fe-1.3V-1.7Si | - | 135–175 | - | - | - | - | [79] |

| AlSiNi | - | 158.7 ± 3.0 | 179.5 ± 3.0 | - | - | - | [33] |

| Al-3.60Mg-1.18Zr | 400 °C 8 h | - | - | 353 ± 5 | 386 ± 3 | 18.6 ± 0.9 | [78] |

| Al-3.66Mg-1.57Zr | 400 °C 8 h | - | - | 365 ± 11 | 389 ± 4 | 23.9 ± 4.4 | [78] |

| 6061 | - | 67–84 | 246.7 | 392 | [63] | ||

| 6061 500 °C platform | - | 54 ± 2.5 | 66–75 | 133–141 | 11–15 | [62] | |

| 6061 500 °C platform | T6 | 119 ± 6 | 282–290 | 308–318 | 3.5–5.4 | [62] |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Aversa, A.; Marchese, G.; Saboori, A.; Bassini, E.; Manfredi, D.; Biamino, S.; Ugues, D.; Fino, P.; Lombardi, M. New Aluminum Alloys Specifically Designed for Laser Powder Bed Fusion: A Review. Materials 2019, 12, 1007. https://doi.org/10.3390/ma12071007

Aversa A, Marchese G, Saboori A, Bassini E, Manfredi D, Biamino S, Ugues D, Fino P, Lombardi M. New Aluminum Alloys Specifically Designed for Laser Powder Bed Fusion: A Review. Materials. 2019; 12(7):1007. https://doi.org/10.3390/ma12071007

Chicago/Turabian StyleAversa, Alberta, Giulio Marchese, Abdollah Saboori, Emilio Bassini, Diego Manfredi, Sara Biamino, Daniele Ugues, Paolo Fino, and Mariangela Lombardi. 2019. "New Aluminum Alloys Specifically Designed for Laser Powder Bed Fusion: A Review" Materials 12, no. 7: 1007. https://doi.org/10.3390/ma12071007

APA StyleAversa, A., Marchese, G., Saboori, A., Bassini, E., Manfredi, D., Biamino, S., Ugues, D., Fino, P., & Lombardi, M. (2019). New Aluminum Alloys Specifically Designed for Laser Powder Bed Fusion: A Review. Materials, 12(7), 1007. https://doi.org/10.3390/ma12071007