Correlating Microstrain and Activated Slip Systems with Mechanical Properties within Rotary Swaged WNiCo Pseudoalloy

Abstract

:1. Introduction

2. Materials and Methods

3. Results

3.1. Phase Identification and Grain Size

3.2. Data for Microstrain Determination

3.3. Electron Microscopy

3.4. Material Properties

4. Data Analysis and Discussion

4.1. Microstrain Determination

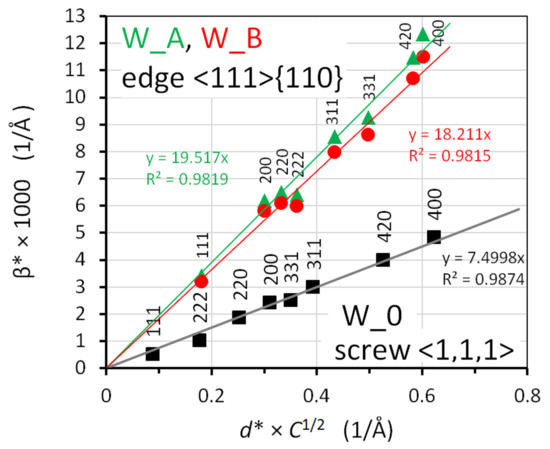

4.2. Dislocation and Slip System Type

4.3. Dislocation Density

- W_0: 1.7 × 1011 cm/cm3 (screw dislocations with <111> slip system);

- W_A: 8.7 × 1011 cm/cm3 (either edge dislocations with <110> {111} slip system or <110> screw dislocations);

- W_B: 7.6 × 1011 cm/cm3 (either edge dislocations with <110> {111} slip system or <110> screw dislocations).

4.4. Mechanical Properties

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Kocich, R.; Kunčická, L.; Dohnalík, D.; Macháčková, A.; Šofer, M. Cold rotary swaging of a tungsten heavy alloy: Numerical and experimental investigations. Int. J. Refract. Met. Hard Mater. 2016, 61, 264–272. [Google Scholar] [CrossRef]

- Durlu, N.; Caliskan, N.K.; Sakir, B. Effect of swaging on microstructure and tensile properties of W-Ni-Fe alloys. Int. J. Refract. Met. Hard Mater. 2014, 42, 126–131. [Google Scholar] [CrossRef]

- Chen, B.; Cao, S.; Xu, H.; Jin, Y.; Li, S.; Xiao, B. Effect of processing parameters on microstructure and mechanical properties of 90W–6Ni–4Mn heavy alloy. Int. J. Refract. Met. Hard Mater. 2015, 48, 293–300. [Google Scholar] [CrossRef]

- Liu, J.; Li, S.; Fan, A.; Sun, H. Effect of fibrous orientation on dynamic mechanical properties and susceptibility to adiabatic shear band of tungsten heavy alloy fabricated through hot-hydrostatic extrusion. Mater. Sci. Eng. A 2008, 487, 235–242. [Google Scholar] [CrossRef]

- Liu, J.; Li, S.; Zhou, X.; Wang, Y.; Yang, J. Dynamic Recrystallization in the Shear Bands of Tungsten Heavy Alloy Processed by Hot-Hydrostatic Extrusion and Hot Torsion. Rare Met. Mater. Eng. 2011, 40, 957–960. [Google Scholar] [CrossRef]

- Kunčická, L.; Kocich, R.; Hervoches, C.; Macháčková, A. Study of structure and residual stresses in cold rotary swaged tungsten heavy alloy. Mater. Sci. Eng. A 2017, 704, 25–31. [Google Scholar] [CrossRef]

- Jinglian, F.; Xing, G.; Meigui, Q.; Tao, L.; Shukui, L.; Jiamin, T. Dynamic Behavior and Adiabatic Shear Bands in Fine-Grained W-Ni-Fe Alloy under High Strain Rate Compression. Rare Met. Mater. Eng. 2009, 38, 2069–2074. [Google Scholar] [CrossRef]

- Zhigang, W.; Shisheng, H.; Yongchi, L.; Cunshan, F. Dynamic Properties and Ballistic Performance of Pre-Torqued Tungsten Heavy Alloys. In Proceedings of the 17th International Symposium on Ballistics, Midrand, South Africa, 23–27 March 1998; pp. 391–398. [Google Scholar]

- Xiaoqing, Z.; Shukui, L.; Jinxu, L.; Yingchun, W.; Xing, W. Self-sharpening behavior during ballistic impact of the tungsten heavy alloy rod penetrators processed by hot-hydrostatic extrusion and hot torsion. Mater. Sci. Eng. A 2010, 527, 4881–4886. [Google Scholar] [CrossRef]

- Kocich, R.; Kunčická, L.; Král, P.; Macháčková, A. Sub-structure and mechanical properties of twist channel angular pressed aluminium. Mater. Charact. 2016, 119, 75–83. [Google Scholar] [CrossRef]

- Kunčická, L.; Kocich, R.; Král, P.; Pohludka, M.; Marek, M. Effect of strain path on severely deformed aluminium. Mater. Lett. 2016, 180, 280–283. [Google Scholar] [CrossRef]

- Yuan, Y.; Ma, A.; Gou, X.; Jiang, J.; Arhin, G.; Song, D.; Liu, H. Effect of heat treatment and deformation temperature on the mechanical properties of ECAP processed ZK60 magnesium alloy. Mater. Sci. Eng. A 2016, 677, 125–132. [Google Scholar] [CrossRef]

- Lukac, P.; Kocich, R.; Greger, M.; Padalka, O.; Szaraz, Z. Microstructure of AZ31 and AZ61 Mg alloys prepared by rolling and ECAP. Kov. Mater. 2007, 45, 115–120. [Google Scholar]

- Hlaváč, L.M.; Kocich, R.; Gembalová, L.; Jonšta, P.; Hlaváčová, I.M. AWJ cutting of copper processed by ECAP. Int. J. Adv. Manuf. Technol. 2016, 86, 885–894. [Google Scholar] [CrossRef]

- Levin, Z.S.; Srivastava, A.; Foley, D.C.; Hartwig, K.T. Fracture in annealed and severely deformed tungsten. Mater. Sci. Eng. A 2018, 734, 244–254. [Google Scholar] [CrossRef]

- Wu, Y.; Hou, Q.; Luo, L.; Zan, X.; Zhu, X.; Li, P.; Xu, Q.; Cheng, J.; Luo, G.; Chen, J. Preparation of ultrafine-grained/nanostructured tungsten materials: An overview. J. Alloys Compd. 2019, 779, 926–941. [Google Scholar] [CrossRef]

- Kocich, R.; Kunčická, L.; Král, P.; Lowe, T.C. Texture, deformation twinning and hardening in a newly developed Mg–Dy–Al–Zn–Zr alloy processed with high pressure torsion. Mater. Des. 2016, 90, 1092–1099. [Google Scholar] [CrossRef]

- Ma, Y.; Zhang, J.; Liu, W.; Yue, P.; Huang, B. Microstructure and dynamic mechanical properties of tungsten-based alloys in the form of extruded rods via microwave heating. Int. J. Refract. Met. Hard Mater. 2014, 42, 71–76. [Google Scholar] [CrossRef]

- Gong, X.; Fan, J.L.; Ding, F.; Song, M.; Huang, B.Y.; Tian, J.M. Microstructure and highly enhanced mechanical properties of fine-grained tungsten heavy alloy after one-pass rapid hot extrusion. Mater. Sci. Eng. A 2011, 528, 3646–3652. [Google Scholar] [CrossRef]

- Fortuna, E.; Zielinski, W.; Sikorski, K.; Kurzydlowski, K.J. TEM characterization of the microstructure of a tungsten heavy alloy. Mater. Chem. Phys. 2003, 81, 469–471. [Google Scholar] [CrossRef]

- Yu, Y.; Zhang, W.; Chen, Y.; Wang, E. Effect of swaging on microstructure and mechanical properties of liquid-phase sintered 93W-4.9(Ni, Co)-2.1Fe alloy. Int. J. Refract. Met. Hard Mater. 2014, 44, 103–108. [Google Scholar] [CrossRef]

- Kocich, R.; Kunčická, L.; Král, P.; Strunz, P. Characterization of innovative rotary swaged Cu-Al clad composite wire conductors. Mater. Des. 2018, 160, 828–835. [Google Scholar] [CrossRef]

- Kiran, U.R.; Panchal, A.; Sankaranarayana, M.; Nandy, T.K. Tensile and impact behavior of swaged tungsten heavy alloys processed by liquid phase sintering. Int. J. Refract. Met. Hard Mater. 2013, 37, 1–11. [Google Scholar] [CrossRef]

- Kunčická, L.; Kocich, R. Deformation behaviour of Cu-Al clad composites produced by rotary swaging. IOP Conf. Ser. Mater. Sci. Eng. 2018, 369, 012029. [Google Scholar]

- Kunčická, L.; Kocich, R.; Strunz, P.; Macháčková, A. Texture and residual stress within rotary swaged Cu/Al clad composites. Mater. Lett. 2018, 230, 88–91. [Google Scholar] [CrossRef]

- Kunčická, L.; Lowe, T.C.; Davis, C.F.; Kocich, R.; Pohludka, M. Synthesis of an Al/Al2O3 composite by severe plastic deformation. Mater. Sci. Eng. A 2015, 646, 234–241. [Google Scholar] [CrossRef]

- Beran, P.; Ivanov, S.A.; Nordblad, P.; Middey, S.; Nag, A.; Sarma, D.D.; Ray, S.; Mathieu, R. Neutron powder diffraction study of Ba3ZnRu2-xIrxO9 (x = 0, 1, 2) with 6H-type perovskite structure. Solid State Sci. 2015, 50, 58–64. [Google Scholar] [CrossRef]

- Davydov, V.; Lukáš, P.; Strunz, P.; Kužel, R. Single-Line Diffraction Profile Analysis Method Used for Evaluation of Microstructural Parameters in the Plain Ferritic Steel upon Tensile Straining. Mater. Sci. Forum 2008, 571, 181–188. [Google Scholar] [CrossRef]

- Beausir, B.; Fundenberger, J.J. Analysis Tools for Electron and X-ray Diffraction, ATEX–Software. Available online: www.atex-software.eu (accessed on 22 May 2019).

- Rodríguez-Carvajal, J. Recent advances in magnetic structure determination by neutron powder diffraction. Phys. B Condens. Matter 1993, 192, 55–69. [Google Scholar] [CrossRef]

- Williamson, G.; Hall, W. X-ray line broadening from filed aluminium and wolfram. Acta Metall. 1953, 1, 22–31. [Google Scholar] [CrossRef]

- Stephens, P.W. Phenomenological model of anisotropic peak broadening in powder diffraction. J. Appl. Crystallogr. 1999, 32, 281–289. [Google Scholar] [CrossRef]

- Rodriguez-Carvajal, J.; Fernandez-Diaz, M.T.; Martinez, J.L. Neutron diffraction study on structural and magnetic properties of La2NiO4. J. Phys. Condens. Matter 1991, 3, 3215–3234. [Google Scholar] [CrossRef]

- Mittemeijer, E.J.; Welzel, U. The “state of the art” of the diffraction analysis of crystallite size and lattice strain. Z. Für Krist. 2008, 223, 552–560. [Google Scholar]

- Kužel, R. Kinematical diffraction by distorted crystals–dislocation X-ray line broadening. Z. Für Krist. Cryst. Mater. 2007, 222, 136–149. [Google Scholar] [CrossRef]

- Borbély, A.; Dragomir-Cernatescu, J.; Ribárik, G.; Ungár, T. Computer program ANIZC for the calculation of diffraction contrast factors of dislocations in elastically anisotropic cubic, hexagonal and trigonal crystals. J. Appl. Crystallogr. 2003, 36, 160–162. [Google Scholar] [CrossRef]

- Ungár, T.; Borbély, A. The effect of dislocation contrast on x-ray line broadening: A new approach to line profile analysis. Appl. Phys. Lett. 1996, 69, 3173–3175. [Google Scholar] [CrossRef]

- Ledbetter, H.; Kim, S. Monocrystal Elastic Constants and Derived Properties of the Cubic and the Hexagonal Elements; Handbook of Elastic Properties of Solids, Fluids, and Gases; Academic Press: Cambridge, MA, USA, 2001; pp. 97–106. [Google Scholar] [CrossRef]

- Leamy, H.J.; Warlimont, H. The Elastic Behaviour of Ni–Co Alloys. Phys. Status Solidi B 1970, 37, 523–534. [Google Scholar] [CrossRef]

- Russell, A.; Lee, K.L. Structure-Property Relations in Nonferrous Metals, 1st ed.; John Wiley & Sons, Inc.: New York, NY, USA, 2005. [Google Scholar]

- Rodney, D.; Ventelon, L.; Clouet, E.; Pizzagalli, L.; Willaime, F. Ab initio modeling of dislocation core properties in metals and semiconductors. Acta Mater. 2017, 124, 633–659. [Google Scholar] [CrossRef]

- Wilkens, M. The determination of density and distribution of dislocations in deformed single crystals from broadened X-ray diffraction profiles. Phys. Status Solidi 1970, 2, 359–370. [Google Scholar] [CrossRef]

- Krivoglaz, M.A.; Martynenko, O.V.; Ryaboshapka, K. Influence of correlation in dislocation arrangement on the X-ray diffraction by deformed crystals. Fiz. Met. Met. 1983, 55, 5–17. [Google Scholar]

- Scardi, P.; Leoni, M.; Dong, Y.H. Whole diffraction pattern-fitting of polycrystalline fcc materials based on microstructure. Eur. Phys. J. B 2000, 18, 23–30. [Google Scholar] [CrossRef]

- Ungár, T.; Gubicza, J.; Ribárik, G.; Borbély, A. Crystallite size distribution and dislocation structure determined by diffraction profile analysis: Principles and practical application to cubic and hexagonal crystals. J. Appl. Cryst. 2001, 34, 298–310. [Google Scholar] [CrossRef] [Green Version]

- Vermeulen, A.C.; Delhez, R.; de Keijser, T.H.; Mittemeijer, E.J. Changes in the densities of dislocations on distinct slip systems during stress relaxation in thin aluminium layers: The interpretation of x-ray diffraction line broadening and line shift. J. Appl. Phys. 1995, 77, 5026–5049. [Google Scholar] [CrossRef]

- Gong, X.; Fan, J.L.; Ding, F.; Song, M.; Huang, B.Y. Effect of tungsten content on microstructure and quasi-static tensile fracture characteristics of rapidly hot-extruded W–Ni–Fe alloys. Int. J. Refract. Met. Hard Mater. 2012, 30, 71–77. [Google Scholar] [CrossRef]

- Katavić, B.; Odanović, Z.; Burzić, M. Investigation of the rotary swaging and heat treatment on the behavior of W- and γ-phases in PM 92.5W-5Ni-2.5Fe-0.26Co heavy alloy. Mater. Sci. Eng. A 2008, 492, 337–345. [Google Scholar] [CrossRef]

- Kiran, U.R.; Khaple, S.K.; Sankaranarayana, M.; Nageswara Rao, G.V.S.; Nandy, T.K. Effect of swaging and aging heat treatment on microstructure and mechanical properties of tungsten heavy alloy. Mater. Today Proc. 2018, 5, 3914–3918. [Google Scholar] [CrossRef]

- Kumari, A.; Sankaranarayana, M.; Nandy, T.K. On structure property correlation in high strength tungsten heavy alloys. Int. J. Refract. Met. Hard Mater. 2017, 67, 18–31. [Google Scholar] [CrossRef]

| Sample | Young’s Modulus (GPa) | Shear Modulus (GPa) | Poisson’s Ratio (-) |

|---|---|---|---|

| W_0 | 340 | 130 | 0.280 |

| W_A | 350 | 137 | 0.278 |

| W_B | 359 | 141 | 0.270 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Strunz, P.; Kunčická, L.; Beran, P.; Kocich, R.; Hervoches, C. Correlating Microstrain and Activated Slip Systems with Mechanical Properties within Rotary Swaged WNiCo Pseudoalloy. Materials 2020, 13, 208. https://doi.org/10.3390/ma13010208

Strunz P, Kunčická L, Beran P, Kocich R, Hervoches C. Correlating Microstrain and Activated Slip Systems with Mechanical Properties within Rotary Swaged WNiCo Pseudoalloy. Materials. 2020; 13(1):208. https://doi.org/10.3390/ma13010208

Chicago/Turabian StyleStrunz, Pavel, Lenka Kunčická, Přemysl Beran, Radim Kocich, and Charles Hervoches. 2020. "Correlating Microstrain and Activated Slip Systems with Mechanical Properties within Rotary Swaged WNiCo Pseudoalloy" Materials 13, no. 1: 208. https://doi.org/10.3390/ma13010208

APA StyleStrunz, P., Kunčická, L., Beran, P., Kocich, R., & Hervoches, C. (2020). Correlating Microstrain and Activated Slip Systems with Mechanical Properties within Rotary Swaged WNiCo Pseudoalloy. Materials, 13(1), 208. https://doi.org/10.3390/ma13010208