Effect of Processing Route on Microstructure and Mechanical Properties in Single-Roll Angular-Rolling

Abstract

:1. Introduction

2. Materials and Methods

2.1. Single-Roll Angular-Rolling

2.2. Microstructural Characterization

2.3. Mechanical Testing

2.4. Finite Element Analysis

3. Results and Discussion

3.1. Microstructural Characteristics in the Core Region

3.2. Mechanical Properties

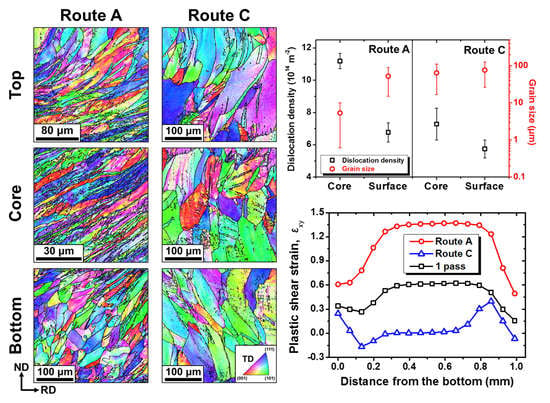

3.3. Microstructural Heterogeneities in Routes A and C

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Zhu, Y.T.; Lowe, T.C.; Langdon, T.G. Performance and applications of nanostructured materials produced by severe plastic deformation. Scr. Mater. 2004, 51, 825–830. [Google Scholar] [CrossRef]

- Valiev, R. Nanostructuring of metals by severe plastic deformation for advanced properties. Nat. Mater. 2004, 3, 511–516. [Google Scholar] [CrossRef] [PubMed]

- Edalati, K.; Horita, Z. Continuous high-pressure torsion. J. Mater. Sci. 2010, 45, 4578–4582. [Google Scholar] [CrossRef]

- Raab, G.J.; Valiev, R.Z.; Lowe, T.C.; Zhu, Y.T. Continuous processing of ultrafine grained Al by ECAP-Conform. Mater. Sci. Eng. A 2004, 382, 30–34. [Google Scholar] [CrossRef]

- Bagherpour, E.; Pardis, N.; Reihanian, M.; Ebrahimi, R. An overview on severe plastic deformation: Research status, techniques classification, microstructure evolution, and applications. Int. J. Adv. Manuf. Technol. 2019, 100, 1647–1694. [Google Scholar] [CrossRef] [Green Version]

- Semenova, I.P.; Polyakov, A.V.; Raab, G.I.; Lowe, T.C.; Valiev, R.Z. Enhanced fatigue properties of ultrafine-grained Ti rods processed by ECAP-Conform. J. Mater. Sci. 2012, 47, 7777–7781. [Google Scholar] [CrossRef]

- Lipinska, M.; Chrominski, W.; Olejnik, L.; Golinski, J.; Rosochowski, A.; Lewandowska, M. Ultrafine-grained plates of Al-Mg-Si alloy obtained by incremental equal channel angular pressing: Microstructure and mechanical properties. Metall. Mater. Trans. A 2017, 48, 4871–4882. [Google Scholar] [CrossRef]

- Dutkiewicz, J.; Bobrowski, P.; Rusz, S.; Hilser, O.; Tański, T.A.; Borek, W.; Łagoda, M.; Ostachowski, P.; Pałka, P.; Boczkal, G.; et al. Effect of various SPD techniques on structure and superplastic deformation of two phase MgLiAl alloy. Met. Mater. Int. 2018, 24, 1077–1089. [Google Scholar] [CrossRef]

- Wu, X.; Zhu, Y. Heterogeneous materials: A new class of materials with unprecedented mechanical properties. Mater. Res. Lett. 2017, 5, 527–532. [Google Scholar] [CrossRef]

- Ovid’ko, I.A.; Valiev, R.Z.; Zhu, Y.T. Review on superior strength and enhanced ductility of metallic nanomaterials. Prog. Mater. Sci. 2018, 94, 462–540. [Google Scholar] [CrossRef]

- Vu, V.Q.; Beygelzimer, Y.; Toth, L.S.; Fundenberger, J.-J.; Kulagin, R.K.; Chen, C. The plastic flow machining: A new SPD process for producing metal sheets with gradient structures. Mater. Charact. 2018, 138, 208–214. [Google Scholar] [CrossRef]

- Kim, K.T.; Kim, Y.S. The effect of the static load in the UNSM process on the corrosion properties of alloy 600. Materials 2019, 12, 3165. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Park, H.; Kim, J.; Pyun, Y.; Auezhan, A.; Choi, Y.S. Numerical and experimental studies on subscale behaviors of ultrasonic surface peening. Met. Mater. Int. 2019, 25, 606–616. [Google Scholar] [CrossRef]

- Lee, H.H.; Yoon, J.I.; Kim, H.S. Single-roll angular-rolling: A new continuous severe plastic deformation process for metal sheets. Scr. Mater. 2018, 146, 204–207. [Google Scholar] [CrossRef]

- Lee, H.H.; Yoon, J.I.; Park, H.K.; Kim, H.S. Unique microstructure and simultaneous enhancements of strength and ductility in gradient-microstructured Cu sheet produced by single-roll angular-rolling. Acta Mater. 2019, 166, 638–649. [Google Scholar] [CrossRef]

- Lee, H.H.; Park, H.K.; Jung, J.; Hwang, K.J.; Kim, H.S. Microstructural tailoring in reverse gradient-structured copper sheet using single-roll angular-rolling and subsequent annealing. Mater. Sci. Eng. A 2019, 764, 138258. [Google Scholar] [CrossRef]

- Furukawa, M.; Horita, Z.; Nemoto, M.; Langdon, T.G. Review: Processing of metals by equal-channel angular pressing. J. Mater. Sci. 2001, 36, 2835–2843. [Google Scholar] [CrossRef]

- Krajňák, T.; Minárik, P.; Gubicza, J.; Máthis, K.; Kužel, R.; Janeček, M. Influence of equal channel angular pressing routes on texture, microstructure and mechanical properties of extruded AX41 magnesium alloy. Mater. Charact. 2017, 123, 282–293. [Google Scholar] [CrossRef]

- Langdon, T.G. The principles of grain refinement in equal-channel angular pressing. Mater. Sci. Eng. A 2007, 462, 3–11. [Google Scholar] [CrossRef]

- Suo, T.; Li, Y.; Deng, Q.; Liu, Y. Optimal pressing route for continued equal channel angular pressing by finite element analysis. Mater. Sci. Eng. A 2007, 466, 166–171. [Google Scholar] [CrossRef]

- Ribárik, G.; Gubicza, J.; Ungár, T. Correlation between strength and microstructure of ball-milled Al-Mg alloys determined by X-ray diffraction. Mater. Sci. Eng. A 2004, 343–347, 387–389. [Google Scholar]

- Ribárik, G.; Ungár, T.; Gubicza, J. MWP-fit: A program for multiple whole-profile fitting of diffraction peak profiles by ab initio theoretical functions. J. Appl. Cryst. 2001, 34, 669–676. [Google Scholar] [CrossRef] [Green Version]

- Jandrlić, I.; Rešković, S.; Brlić, T. Distribution of stress in deformation zone of niobium microalloyed steel. Met. Mater. Int. 2018, 24, 746–751. [Google Scholar] [CrossRef]

- Wei, P.T.; Lu, C.; Tieu, K.; Deng, G.Y. A study of plastic deformation behavior during high pressure torsion process by crystal plasticity finite element simulation. IOP Conf. Ser.: Mater. Sci. Eng. 2014, 63, 012045–012055. [Google Scholar] [CrossRef] [Green Version]

- Lee, H.H.; Kim, W.; Jung, K.C.; Seo, S.; Lee, J.K.; Park, H.L.; Park, K.-T.; Kim, H.S. Circumferential twisting during route B equal-channel angular pressing. J. Mater. Process. Tech. 2018, 259, 305–311. [Google Scholar] [CrossRef]

- Furukawa, M.; Horita, Z.; Langdon, T.G. Factors influencing the shearing patterns in equal-channel angular pressing. Mater. Sci. Eng. A 2002, 332, 97–109. [Google Scholar] [CrossRef]

- Kamachi, M.; Furukawa, M.; Horita, Z.; Langdon, T.G. A model investigation of the shearing characteristics in equal-channel angular pressing. Mater. Sci. Eng. A 2003, 347, 223–230. [Google Scholar] [CrossRef]

- Zhu, Y.T.; Lowe, T.C. Observations and issues on mechanisms of grain refinement during ECAP process. Mater. Sci. Eng. A 2000, 291, 46–53. [Google Scholar] [CrossRef]

- Xue, Q.; Beyerlein, I.J.; Alexander, D.J.; Gray III, G.T. Mechanisms for initial grain refinement in OFHC copper during equal channel angular pressing. Acta Mater. 2007, 55, 655–668. [Google Scholar] [CrossRef]

- Mishra, A.; Kad, B.K.; Gregori, F.; Meyers, M.A. Microstructural evolution in copper subjected to severe plastic deformation: Experiments and analysis. Acta Mater. 2007, 55, 13–28. [Google Scholar] [CrossRef]

- Pinheiro, P.; Monteiro, W.A.; Barbosa, R.; Cetlin, P.R. The effect of strain path on the mechanical behavior and dislocation arrangements in the hot working of copper. Mater. Sci. Eng. A 2004, 368, 280–285. [Google Scholar] [CrossRef]

- Davenport, S.B.; Higginson, R.L.; Sellars, C.M. The effect of strain path on material behavior during hot rolling of FCC metals. Philos. Trans. R. Soc. Lond. 1999, 357, 1645–1661. [Google Scholar] [CrossRef]

- Prangnell, P.B.; Gholinia, A.; Markushev, V.M.; Lowe, T.C.; Valiev, R.Z. (Eds.) Investigations and Applications of Severe Plastic Deformation; Kluwer Academic Publishers: Dordrecht, The Netherlands, 2000; pp. 65–71. [Google Scholar]

- Iwahashi, Y.; Wang, J.; Horita, Z.; Nemoto, M.; Langdon, T.G. Principle of equal-channel angular pressing for the processing of ultra-fine grained materials. Scr. Mater. 1996, 35, 143–146. [Google Scholar] [CrossRef]

- Torre, F.D.; Lapovok, R.; Sandlin, J.; Thomson, P.F.; Davies, C.H.J.; Pereloma, E.V. Microstructures and properties of copper processed by equal channel angular extrusion for 1-16 passes. Acta Mater. 2004, 52, 4819–4832. [Google Scholar] [CrossRef]

- Howeyze, M.; Eivani, A.R.; Arabi, H.; Jafarian, H.R. Effects of deformation routes on the evolution of microstructure, texture and tensile properties of AA5052 aluminum alloy. Mater. Sci. Eng. A 2018, 732, 120–128. [Google Scholar] [CrossRef]

- Park, J.-W.; Suh, J.-Y. Effect of die shape on the deformation behavior in equal-channel angular pressing. Metall. Mater. Trans. 2001, 32, 3007–3014. [Google Scholar] [CrossRef]

- Yang, X.; Ma, X.; Moering, J.; Zhou, H.; Wang, W.; Gong, Y.; Tao, J.; Zhu, Y.; Zhu, X. Influence of gradient structure volume fraction on the mechanical properties. Mater. Sci. Eng. A 2015, 645, 280–285. [Google Scholar] [CrossRef]

- Fang, T.H.; Li, W.L.; Tao, N.R.; Lu, K. Revealing extraordinary intrinsic tensile plasticity in gradient nano-grained copper. Science 2011, 331, 1587–1590. [Google Scholar] [CrossRef] [Green Version]

- Kim, J.G.; Jang, M.J.; Park, H.K.; Chin, K.-G.; Lee, S.; Kim, H.S. Back-stress effect on the mechanical strength of TWIP-IF steels layered sheet. Met. Mater. Int. 2019, 25, 912–917. [Google Scholar] [CrossRef]

- Song, X.; Rettenmayr, M.; Müller, C.; Exner, H.E. Modeling of recrystallization after inhomogeneous deformation. Metall. Mater. Trans. A 2001, 32, 2199–2206. [Google Scholar] [CrossRef]

| Samples | YS, MPa | UTS, MPa | U.E., % | T.E., % |

|---|---|---|---|---|

| 0p | 58.0 ± 1.9 | 217.6 ± 7.1 | 34.7 ± 0.3 | 54.7 ± 1.8 |

| 1p | 268.9 ± 7.3 | 284.9 ± 8.3 | 1.3 ± 0.1 | 22.2 ± 1.3 |

| 2pA | 315.0 ± 0.8 | 327.8 ± 1.5 | 1.2 ± 0.1 | 20.1 ± 0.2 |

| 2pC | 311.3 ± 1.6 | 325.6 ± 0.7 | 0.9 ± 0.1 | 20.9 ± 1.4 |

| 6pA | 352.1 ± 3.0 | 389.9 ± 3.8 | 1.5 ± 0.2 | 16.6 ± 0.5 |

| 6pC | 336.6 ± 1.6 | 366.6 ± 2.5 | 1.1 ± 0.1 | 17.6 ± 1.0 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lee, H.H.; Hwang, K.J.; Park, H.K.; Kim, H.S. Effect of Processing Route on Microstructure and Mechanical Properties in Single-Roll Angular-Rolling. Materials 2020, 13, 2471. https://doi.org/10.3390/ma13112471

Lee HH, Hwang KJ, Park HK, Kim HS. Effect of Processing Route on Microstructure and Mechanical Properties in Single-Roll Angular-Rolling. Materials. 2020; 13(11):2471. https://doi.org/10.3390/ma13112471

Chicago/Turabian StyleLee, Hak Hyeon, Kyo Jun Hwang, Hyung Keun Park, and Hyoung Seop Kim. 2020. "Effect of Processing Route on Microstructure and Mechanical Properties in Single-Roll Angular-Rolling" Materials 13, no. 11: 2471. https://doi.org/10.3390/ma13112471

APA StyleLee, H. H., Hwang, K. J., Park, H. K., & Kim, H. S. (2020). Effect of Processing Route on Microstructure and Mechanical Properties in Single-Roll Angular-Rolling. Materials, 13(11), 2471. https://doi.org/10.3390/ma13112471