Integrated Application of GPR and Ultrasonic Testing in the Diagnostics of a Historical Floor

Abstract

:1. Introduction

2. Materials and Methods

2.1. Object of Investigations

2.2. Data Acquisition and Equipment

2.3. Numerical Simulations of Electomagnetic Wave Propagation

3. Results and Discussion

3.1. Preliminary Investigations for Concrete Slabs

3.2. Numerical Models of the Floor

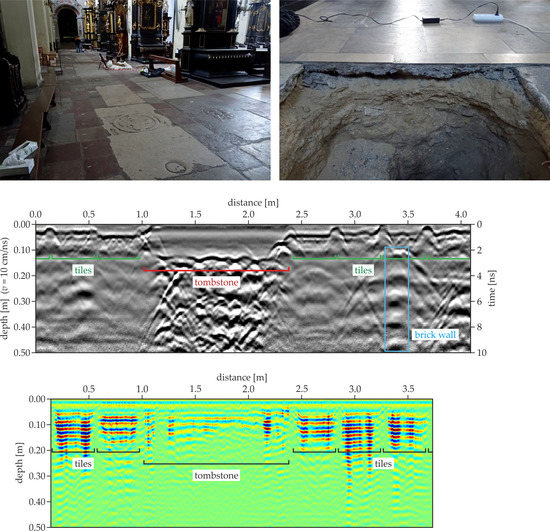

3.3. Experimental Surveys for the Trial Pit

3.4. Experimental Surveys for Floor

3.5. GPR Tomographic Imaging of Floor

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Ziolkowski, P.; Szulwic, J.; Miskiewicz, M. Deformation analysis of a composite bridge during proof loading using point cloud processing. Sensors 2018, 18, 4332. [Google Scholar] [CrossRef] [Green Version]

- Kwiatkowski, J.; Anigacz, W.; Beben, D. Comparison of non-destructive techniques for technological bridge deflection testing. Materials 2020, 13, 1908. [Google Scholar] [CrossRef] [PubMed]

- Miśkiewicz, M.; Pyrzowski, L.; Sobczyk, B. Short and long term measurements in assessment of FRP composite footbridge behavior. Materials 2020, 13, 525. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Binczyk, M.; Kalitowski, P.; Szulwic, J.; Tysiac, P. Nondestructive testing of the miter gates using various measurement methods. Sensors 2020, 20, 1749. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Jonaitis, B.; Antonovič, V.; Šneideris, A.; Boris, R.; Zavalis, R. Analysis of physical and mechanical properties of the mortar in the historic retaining wall of the Gediminas Castle Hill (Vilnius, Lithuania). Materials 2018, 12, 8. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Goodman, D.; Piro, S. GPR Remote Sensing in Archaeology; Springer: Berlin/Heidelberg, Germany, 2013; ISBN 9783642318573. [Google Scholar]

- Neubauer, W.; Eder-Hinterleitner, A.; Seren, S.; Melichar, P. Georadar in the roman civil town carnuntum Austria: An approach for archaeological interpretation of GPR data. Archaeol. Prospect. 2002, 9, 135–156. [Google Scholar] [CrossRef]

- Zhao, W.; Forte, E.; Fontana, F.; Pipan, M.; Tian, G. GPR imaging and characterization of ancient Roman ruins in the Aquileia Archaeological Park, NE Italy. Measurement 2018, 113, 161–171. [Google Scholar] [CrossRef]

- Beben, D.; Ukleja, J.; Maleska, T.; Anigacz, W. Study on the restoration of a masonry arch viaduct: Numerical analysis and lab tests. Materials 2020, 13, 1846. [Google Scholar] [CrossRef] [Green Version]

- Bajno, D.; Bednarz, L.; Matkowski, Z. Monitoring of thermal and moisture processes in various types of external historical walls. Materials 2020, 13, 505. [Google Scholar] [CrossRef] [Green Version]

- Barilaro, D.; Branca, C.; Gresta, S.; Imposa, S.; Leone, A.; Majolino, D. Ground penetrating radar (G.P.R.) surveys applied to the research of crypts in San Sebastiano’s church in Catania (Sicily). J. Cult. Herit. 2007, 8, 73–76. [Google Scholar] [CrossRef]

- Rucka, M.; Wojtczak, E.; Zielińska, M. Interpolation methods in GPR tomographic imaging of linear and volume anomalies for cultural heritage diagnostics. Measurement 2020, 154, 107494. [Google Scholar] [CrossRef]

- Imposa, S.; Mele, G. Ground penetrating radar survey inside the S. Agata cathedral of Catania (eastern Sicily). Int. J. Archit. Herit. 2011, 5, 188–197. [Google Scholar] [CrossRef]

- Yalçıner, C.Ç.; Kurban, Y.C.; Altunel, E. Research using GPR into the cause of cracks and depressions in the floor of the gallery of Hagia Sophia Museum. Constr. Build. Mater. 2017, 139, 458–466. [Google Scholar] [CrossRef]

- Gaber, A.; El-Qady, G.; Khozym, A.; Abdallatif, T.; Kamal, S.A.M. Indirect preservation of egyptian historical sites using 3D GPR survey. Egypt. J. Remote Sens. Space Sci. 2018, 21, S75–S84. [Google Scholar] [CrossRef]

- Imposa, S.; Barone, F.; Gresta, S.; Leone, A. Ground penetrating radar survey finalized to the recovery of the “S. Agata alla Badia” church in Catania (eastern Sicily, Italy). Environ. Geol. 2009, 58, 889–896. [Google Scholar] [CrossRef]

- Pérez-Gracia, V.; Caselles, O.; Clapés, J.; Osorio, R.; Canas, J.A.; Pujades, L.G. Radar exploration applied to historical buildings: A case study of the Marques de Llió palace, in Barcelona (Spain). Eng. Fail. Anal. 2009, 16, 1039–1050. [Google Scholar] [CrossRef]

- Drahor, M.G.; Berge, M.A.; Öztürk, C. Integrated geophysical surveys for the subsurface mapping of buried structures under and surrounding of the Agios Voukolos Church in İzmir, Turkey. J. Archaeol. Sci. 2011, 38, 2231–2242. [Google Scholar] [CrossRef]

- Pérez-Gracia, V.; Caselles, J.O.; Clapes, J.; Osorio, R.; Martínez, G.; Canas, J.A. Integrated near-surface geophysical survey of the Cathedral of Mallorca. J. Archaeol. Sci. 2009, 36, 1289–1299. [Google Scholar] [CrossRef]

- Tapete, D.; Casagli, N.; Luzi, G.; Fanti, R.; Gigli, G.; Leva, D. Integrating radar and laser-based remote sensing techniques for monitoring structural deformation of archaeological monuments. J. Archaeol. Sci. 2013, 40, 176–189. [Google Scholar] [CrossRef] [Green Version]

- Moropoulou, A.; Labropoulos, K.C.; Delegou, E.T.; Karoglou, M.; Bakolas, A. Non-destructive techniques as a tool for the protection of built cultural heritage. Constr. Build. Mater. 2013, 48, 1222–1239. [Google Scholar] [CrossRef]

- Faella, G.; Frunzio, G.; Guadagnuolo, M.; Donadio, A.; Ferri, L. The Church of the Nativity in Bethlehem: Non-destructive tests for the structural knowledge. J. Cult. Herit. 2012, 13, e27–e41. [Google Scholar] [CrossRef]

- Lachowicz, J.; Rucka, M. 3-D finite-difference time-domain modelling of ground penetrating radar for identification of rebars in complex reinforced concrete structures. Arch. Civ. Mech. Eng. 2018, 18, 1228–1240. [Google Scholar] [CrossRef]

- Drobiec, Ł.; Jasiński, R.; Mazur, W. Accuracy of eddy-current and radar methods used in reinforcement detection. Materials 2019, 12, 1168. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Orlando, L.; Slob, E. Using multicomponent GPR to monitor cracks in a historical building. J. Appl. Geophys. 2009, 67, 327–334. [Google Scholar] [CrossRef]

- Jiao, L.; Ye, Q.; Cao, X.; Huston, D.; Xia, T. Identifying concrete structure defects in GPR image. Meas. J. Int. Meas. Confed. 2020, 160, 107839. [Google Scholar] [CrossRef]

- Luo, T.X.H.; Lai, W.W.L. GPR pattern recognition of shallow subsurface air voids. Tunn. Undergr. Space Technol. 2020, 99, 103355. [Google Scholar] [CrossRef]

- Johnston, B.; Ruffell, A.; McKinley, J.; Warke, P. Detecting voids within a historical building façade: A comparative study of three high frequency GPR antenna. J. Cult. Herit. 2018, 32, 117–123. [Google Scholar] [CrossRef] [Green Version]

- Rucka, M.; Lachowicz, J.; Zielińska, M. GPR investigation of the strengthening system of a historic masonry tower. J. Appl. Geophys. 2016, 131, 94–102. [Google Scholar] [CrossRef]

- Lachowicz, J.; Rucka, M. Diagnostics of pillars in St. Mary’s Church (Gdańsk, Poland) using the GPR method. Int. J. Archit. Herit. 2018, 13, 1–11. [Google Scholar] [CrossRef]

- Fu, Q.; Yan, L.; Ning, T.; Wang, B.; Kasal, B. Interfacial bond behavior between wood chip concrete and engineered timber glued by various adhesives. Constr. Build. Mater. 2020, 238, 117743. [Google Scholar] [CrossRef]

- Ryuzono, K.; Yashiro, S.; Nagai, H.; Toyama, N. Topology optimization-based damage identification using visualized ultrasonic wave propagation. Materials 2020, 13, 33. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Mousavi, M.; Holloway, D.; Olivier, J.C.; Alavi, A.H.; Gandomi, A.H. A Shannon entropy approach for structural damage identification based on self-powered sensor data. Eng. Struct. 2019, 200, 109619. [Google Scholar] [CrossRef]

- Rucka, M.; Wilde, K. Ultrasound monitoring for evaluation of damage in reinforced concrete. Bull. Pol. Acad. Sci. Tech. Sci. 2015, 63, 65–75. [Google Scholar] [CrossRef] [Green Version]

- Schabowicz, K. Ultrasonic tomography—The latest nondestructive technique for testing concrete members—Description, test methodology, application example. Arch. Civ. Mech. Eng. 2014, 14, 295–303. [Google Scholar] [CrossRef]

- Hola, J.; Sadowski, Ł.; Schabowicz, K. Nondestructive identification of delaminations in concrete floor toppings with acoustic methods. Autom. Constr. 2011, 20, 799–807. [Google Scholar] [CrossRef]

- Cantero-Chinchilla, S.; Chiachío, J.; Chiachío, M.; Chronopoulos, D.; Jones, A. A robust Bayesian methodology for damage localization in plate-like structures using ultrasonic guided-waves. Mech. Syst. Signal Process. 2019, 122, 192–205. [Google Scholar] [CrossRef] [Green Version]

- Cantero-Chinchilla, S.; Chiachío, J.; Chiachío, M.; Chronopoulos, D.; Jones, A. Optimal sensor configuration for ultrasonic guided-wave inspection based on value of information. Mech. Syst. Signal Process. 2020, 135, 106377. [Google Scholar] [CrossRef]

- Zielińska, M.; Rucka, M. Non-Destructive Assessment of Masonry Pillars using Ultrasonic Tomography. Materials 2018, 11, 2543. [Google Scholar] [CrossRef] [Green Version]

- Rucka, M.; Wojtczak, E.; Lachowicz, J. Damage imaging in Lamb wave-based inspection of adhesive joints. Appl. Sci. 2018, 8, 522. [Google Scholar] [CrossRef] [Green Version]

- Guadagnuolo, M.; Faella, G.; Donadio, A.; Ferri, L. Integrated evaluation of the Church of S. Nicola di Mira: Conservation versus safety. NDT E Int. 2014, 68, 53–65. [Google Scholar] [CrossRef]

- Binda, L.; Saisi, A.; Tiraboschi, C.; Valle, S.; Colla, C.; Forde, M. Application of sonic and radar tests on the piers and walls of the Cathedral of Noto. Constr. Build. Mater. 2003, 17, 613–627. [Google Scholar] [CrossRef]

- Pérez-Gracia, V.; Caselles, J.O.; Clapés, J.; Martinez, G.; Osorio, R. Non-destructive analysis in cultural heritage buildings: Evaluating the Mallorca cathedral supporting structures. NDT E Int. 2013, 59, 40–47. [Google Scholar] [CrossRef]

- Warren, C.; Giannopoulos, A.; Giannakis, I. GprMax: Open source software to simulate electromagnetic wave propagation for Ground Penetrating Radar. Comput. Phys. Commun. 2016, 209, 163–170. [Google Scholar] [CrossRef] [Green Version]

- Sham, J.F.C.; Lai, W.W.-L. Development of a new algorithm for accurate estimation of GPR’s wave propagation velocity by common-offset survey method. NDT E Int. 2016, 83, 104–113. [Google Scholar] [CrossRef]

| Surveys | GPR Traces | UT Traces |

|---|---|---|

| A | A-1 to A-147 | A-121 and A-129 |

| B | B-1 to B-150 | − |

| C | C-1 to C-4 | C-1 to C-4 |

| D | D-1 to D-4 | D-1 to D-4 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rucka, M.; Wojtczak, E.; Zielińska, M. Integrated Application of GPR and Ultrasonic Testing in the Diagnostics of a Historical Floor. Materials 2020, 13, 2547. https://doi.org/10.3390/ma13112547

Rucka M, Wojtczak E, Zielińska M. Integrated Application of GPR and Ultrasonic Testing in the Diagnostics of a Historical Floor. Materials. 2020; 13(11):2547. https://doi.org/10.3390/ma13112547

Chicago/Turabian StyleRucka, Magdalena, Erwin Wojtczak, and Monika Zielińska. 2020. "Integrated Application of GPR and Ultrasonic Testing in the Diagnostics of a Historical Floor" Materials 13, no. 11: 2547. https://doi.org/10.3390/ma13112547

APA StyleRucka, M., Wojtczak, E., & Zielińska, M. (2020). Integrated Application of GPR and Ultrasonic Testing in the Diagnostics of a Historical Floor. Materials, 13(11), 2547. https://doi.org/10.3390/ma13112547