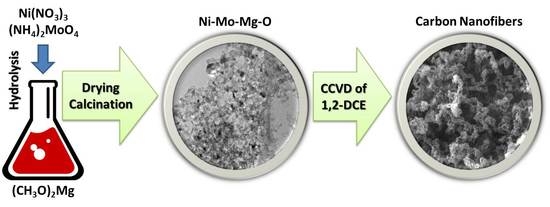

Sol-Gel-Prepared Ni-Mo-Mg-O System for Catalytic Transformation of Chlorinated Organic Wastes into Nanostructured Carbon

Abstract

:1. Introduction

2. Materials and Methods

2.1. Synthesis of the Catalyst’s Samples

2.2. Characterization of the Samples

2.3. Catalytic Cemical Vapor Deposition of 1,2-Dichloroethane

3. Results

3.1. Characterization of the Prepared Samples

3.2. Catalytic Chemical Vapor Deposition of 1,2–Dichloroethane

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Sardhar Basha, S.J.; Sasirekha, N.R.; Maheswari, R.; Shanthi, K. Mesoporous H-AlMCM-41 supported NiO-MoO3 catalysts for hydrodenitrogenation of o-toluidine. Appl. Catal. A Gen. 2006, 308, 91–98. [Google Scholar] [CrossRef]

- Sardhar Basha, S.J.; Vijayan, P.; Suresh, C.; Santhanaraj, D.; Shanthi, K. Effect of Order of Impregnation of Mo and Ni on the Hydrodenitrogenation Activity of NiO-MoO3/AlMCM-41 Catalyst. Ind. Eng. Chem. Res. 2009, 48, 2774–2780. [Google Scholar] [CrossRef]

- Andonova, S.; Vladov, C.; Kunev, B.; Mitov, I.; Tyuliev, G.; Fierro, J.; Damyanova, S.; Petrov, L. Study of the effect of mechanical–chemical activation of Co–Mo/γ-AlO and Ni–Mo/γ-AlO catalysts for hydrodesulfurization. Appl. Catal. A Gen. 2006, 298, 94–102. [Google Scholar] [CrossRef]

- Liu, H.; Yin, C.; Zhang, H.; Liu, C. Sustainable synthesis of ammonium nickel molybdate for hydrodesulfurization of dibenzothiophene. Chinese J. Catal. 2016, 37, 1502–1511. [Google Scholar] [CrossRef]

- Borowiecki, T.; Giecko, G.; Panczyk, M. Effects of small MoO3 additions on the properties of nickel catalysts for the steam reforming of hydrocarbons II. Ni–Mo/Al2O3 catalysts in reforming, hydrogenolysis and cracking of n-butane. Appl. Catal. A Gen. 2002, 230, 85–97. [Google Scholar] [CrossRef]

- Borowiecki, T.; Gac, W.; Denis, A. Effects of small MoO3 additions on the properties of nickel catalysts for the steam reforming of hydrocarbons III. Reduction of Ni-Mo/Al2O3 catalyst. Appl. Catal. A Gen. 2004, 270, 27–36. [Google Scholar] [CrossRef]

- Maluf, S.S.; Assaf, E.M. Ni catalysts with Mo promoter for methane steam reforming. Fuel 2009, 88, 1547–1553. [Google Scholar] [CrossRef]

- Malaibari, Z.O.; Amin, A.; Croiset, E.; Epling, W. Performance characteristics of Mo–Ni/Al2O3 catalysts in LPG oxidative steam reforming for hydrogen production. Int. J. Hydrogen Energ. 2014, 39, 10061–10073. [Google Scholar] [CrossRef]

- Wang, Y.; Weinstock, I.A. Polyoxometalate-decorated nanoparticles. Chem. Soc. Rev. 2012, 41, 7479–7496. [Google Scholar] [CrossRef]

- Tang, S.; Zhong, Z.; Xiong, Z.; Sun, L.; Liu, L.; Lin, J.; Shen, Z.X.; Tan, K.L. Controlled growth of single-walled carbon nanotubes by catalytic decomposition of CH4 over Mo/Co/MgO catalysts. Chem. Phys. Lett. 2001, 350, 19–26. [Google Scholar] [CrossRef]

- Zhou, L.-P.; Ohta, K.; Kuroda, K.; Lei, N.; Matsuishi, K.; Gao, L.; Matsumoto, T.; Nakamura, J. Catalytic Functions of Mo/Ni/MgO in the Synthesis of Thin Carbon Nanotubes. J. Phys. Chem. B 2005, 109, 4439–4447. [Google Scholar] [CrossRef] [PubMed]

- Li, Y.; Zhang, X.B.; Tao, X.Y.; Xu, J.M.; Huang, W.Z.; Luo, J.H.; Luo, Z.Q.; Li, T.; Liu, F.; Bao, Y.; et al. Mass production of high-quality multi-walled carbon nanotube bundles on a Ni/Mo/MgO catalyst. Carbon 2005, 43, 295–301. [Google Scholar] [CrossRef]

- Kennedy, L.J.; Vijaya, J.J.; Sekaran, G.; Joseph, J.; Rani, J.D.; Pragasam, J. Bulk preparation and characterization of mesoporous carbon nanotubes by catalytic decomposition of cyclohexane on sol–gel prepared Ni–Mo–Mg oxide catalyst. Mater. Lett. 2006, 60, 3735–3740. [Google Scholar] [CrossRef]

- Qi, H.; Qian, C.; Liu, J. Synthesis of High-Purity Few-Walled Carbon Nanotubes from Ethanol/Methanol Mixture. Chem. Mater. 2006, 18, 5691–5695. [Google Scholar] [CrossRef]

- Zhang, Q.; Liu, Y.; Hu, L.; Qian, W.-Z.; Luo, G.-H.; Wei, F. Synthesis of thin-walled carbon nanotubes from methane by changing the Ni/Mo ratio in a Ni/Mo/MgO catalyst. New Carbon Mater. 2008, 23, 319–325. [Google Scholar] [CrossRef]

- Song, R.; Ji, Q. Synthesis of Carbon Nanotubes from Polypropylene in the Presence of Ni/Mo/MgO Catalysts via Combustion. Chem. Lett. 2011, 40, 1110–1112. [Google Scholar] [CrossRef]

- Modekwe, H.U.; Mamo, M.; Moothi, K.; Daramola, M.O. Synthesis of bimetallic NiMo/MgO catalyst for catalytic conversion of waste plastics (polypropylene) to carbon nanotubes (CNTs) via chemical vapour deposition method. Mater. Today Proc. 2020. [Google Scholar] [CrossRef]

- Izadi, N.; Rashidi, A.; Borghei, M.; Karimzadeh, R.; Tofigh, A. Synthesis of carbon nanofibres over nanoporous Ni–MgO catalyst: influence of the bimetallic Ni–(Cu, Co, Mo) MgO catalysts. J. Exper. Nanosci. 2011, 7, 160–173. [Google Scholar] [CrossRef]

- Jang, E.; Park, H.-K.; Choi, J.-H.; Lee, C.-S. Synthesis and Characterization of Carbon Nanofibers Grown on Ni and Mo Catalysts by Chemical Vapor Deposition. Bull. Korean Chem. Soc. 2015, 36, 1452–1459. [Google Scholar] [CrossRef]

- Bauman, Y.; Kibis, L.; Mishakov, I.; Rudneva, Y.; Stoyanovskii, V.O.; Vedyagin, A.A. Synthesis and Functionalization of Filamentous Carbon Material via Decomposition of 1,2-Dichlorethane over Self-Organizing Ni-Mo Catalyst. Mater. Sci. Forum 2019, 950, 180–184. [Google Scholar] [CrossRef]

- Bauman, Y.I.; Rudneva, Y.V.; Mishakov, I.V.; Plyusnin, P.E.; Shubin, Y.V.; Korneev, D.V.; Stoyanovskii, V.O.; Vedyagin, A.A.; Buyanov, R.A. Effect of Mo on the catalytic activity of Ni-based self-organizing catalysts for processing of dichloroethane into segmented carbon nanomaterials. Heliyon 2019, 5. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Zibareva, I.V.; Ilina, L.Y.; Vedyagin, A.A. Catalysis by nanoparticles: the main features and trends. Reac. Kinet. Mech. Catal. 2019, 127, 19–24. [Google Scholar] [CrossRef]

- Gutić, S.J.; Jovanović, A.Z.; Dobrota, A.S.; Metarapi, D.; Rafailović, L.D.; Pašti, I.A.; Mentus, S.V. Simple routes for the improvement of hydrogen evolution activity of Ni-Mo catalysts: From sol-gel derived powder catalysts to graphene supported co-electrodeposits. Int. J. Hydrogen Energ. 2018, 43, 16846–16858. [Google Scholar] [CrossRef]

- Umapathy, V.; Neeraja, P.; Manikandan, A.; Ramu, P. Synthesis of NiMoO4 nanoparticles by sol–gel method and their structural, morphological, optical, magnetic and photocatlytic properties. Transac. Nonferrous Metals Soc. China 2017, 27, 1785–1793. [Google Scholar] [CrossRef]

- Baston, E.P.; Urquieta-Gonzalez, E.A. Direct addition of the precursor salts of Mo, Co or Ni oxides during the sol formation of γ-Al2O3 and ZrO2 - The effect on metal dispersion. In Scientific Bases for the Preparation of Heterogeneous Catalysts—Proceedings of the 10th International Symposium, Louvain-la-Neuve, Belgium, 11–15 July 2010. [Google Scholar]

- Baston, E.P.; França, A.B.; Neto, A.V.d.S.; Urquieta-González, E.A. Incorporation of the precursors of Mo and Ni oxides directly into the reaction mixture of sol–gel prepared γ-Al2O3-ZrO2 supports – Evaluation of the sulfided catalysts in the thiophene hydrodesulfurization. Catal. Today 2015, 246, 184–190. [Google Scholar] [CrossRef]

- Ezz, A.A.; Kamel, M.M.; Saad, G.R. Synthesis and characterization of nanocarbon having different morphological structures by chemical vapor deposition over Fe-Ni-Co-Mo/MgO catalyst. J. Saudi Chem. Soc. 2019, 23, 666–677. [Google Scholar] [CrossRef]

- Pudukudy, M.; Yaakob, Z.; Mazuki, M.Z.; Takriff, M.S.; Jahaya, S.S. One-pot sol-gel synthesis of MgO nanoparticles supported nickel and iron catalysts for undiluted methane decomposition into COx free hydrogen and nanocarbon. Appl. Catal. B Environ. 2017, 218, 298–316. [Google Scholar] [CrossRef]

- Ilyina, E.V.; Mishakov, I.V.; Vedyagin, A.A.; Bedilo, A.F. Aerogel method for preparation of nanocrystalline CoOx·MgO and VOx·MgO catalysts. J. Sol Gel Sci. Technol. 2013, 68, 423–428. [Google Scholar] [CrossRef]

- Karnaukhov, T.M.; Vedyagin, A.A.; Cherepanova, S.V.; Rogov, V.A.; Stoyanovskii, V.O.; Mishakov, I.V. Study on reduction behavior of two-component Fe Mg O oxide system prepared via a sol-gel technique. Int. J. Hydrogen Energ. 2017, 42, 30543–30549. [Google Scholar] [CrossRef]

- Vedyagin, A.A.; Mishakov, I.V.; Karnaukhov, T.M.; Krivoshapkina, E.F.; Ilyina, E.V.; Maksimova, T.A.; Cherepanova, S.V.; Krivoshapkin, P.V. Sol–gel synthesis and characterization of two-component systems based on MgO. J. Sol Gel Sci. Technol. 2017, 82, 611–619. [Google Scholar] [CrossRef]

- Karnaukhov, T.M.; Vedyagin, A.A.; Cherepanova, S.V.; Rogov, V.A.; Mishakov, I.V. Sol–gel synthesis and characterization of the binary Ni–Mg–O oxide system. J. Sol Gel Sci. Technol. 2019, 92, 208–214. [Google Scholar] [CrossRef]

- Vedyagin, A.A.; Karnaukhov, T.M.; Cherepanova, S.V.; Stoyanovskii, V.O.; Rogov, V.A.; Mishakov, I.V. Synthesis of binary Co–Mg–O oxide system and study of its behavior in reduction/oxidation cycling. Int. J. Hydrogen Energ. 2019, 44, 20690–20699. [Google Scholar] [CrossRef]

- Bauman, Y.I.; Lysakova, A.S.; Rudnev, A.V.; Mishakov, I.V.; Shubin, Y.V.; Vedyagin, A.A.; Buyanov, R.A. Synthesis of nanostructured carbon fibers from chlorohydrocarbons over Bulk Ni-Cr Alloys. Nanotechnol. Russia 2014, 9, 380–385. [Google Scholar] [CrossRef]

- Bauman, Y.I.; Mishakov, I.V.; Vedyagin, A.A.; Rudnev, A.V.; Plyusnin, P.E.; Shubin, Y.V.; Buyanov, R.A. Promoting Effect of Co, Cu, Cr and Fe on Activity of Ni-Based Alloys in Catalytic Processing of Chlorinated Hydrocarbons. Top. Catal. 2016, 60, 171–177. [Google Scholar] [CrossRef]

- Bauman, Y.I.; Mishakov, I.V.; Korneev, D.V.; Shubin, Y.V.; Vedyagin, A.A.; Buyanov, R.A. Comparative study of 1,2-dichlorethane decomposition over Ni-based catalysts with formation of filamentous carbon. Catal. Today 2018, 301, 147–152. [Google Scholar] [CrossRef]

- Strel’tsov, I.A.; Vinokurova, O.B.; Tokareva, I.V.; Mishakov, I.V.; Isupov, V.P.; Shubin, Y.V.; Vedyagin, A.A. Effect of the nature of a textural promoter on the catalytic properties of a nickel-copper catalyst for hydrocarbon processing in the production of carbon nanofibers. Catal. Ind. 2014, 6, 176–181. [Google Scholar] [CrossRef]

- Ilyina, E.V.; Mishakov, I.V.; Vedyagin, A.A.; Cherepanova, S.V.; Nadeev, A.N.; Bedilo, A.F.; Klabunde, K.J. Synthesis and characterization of mesoporous VOx/MgO aerogels with high surface area. Micropor. Mesopor. Mater. 2012, 160, 32–40. [Google Scholar] [CrossRef]

- Amin, M.H. Relationship Between the Pore Structure of Mesoporous Silica Supports and the Activity of Nickel Nanocatalysts in the CO2 Reforming of Methane. Catalysts 2020, 10, 51. [Google Scholar] [CrossRef] [Green Version]

- Mishakov, I.V.; Buyanov, R.A.; Zaikovskii, V.I.; Strel’tsov, I.A.; Vedyagin, A.A. Catalytic synthesis of nanosized feathery carbon structures via the carbide cycle mechanism. Kinet. Catal. 2008, 49, 868–872. [Google Scholar] [CrossRef]

| Sample | SSA, m2/g | Vp, cm3/g | Dav, Å | Ref. |

|---|---|---|---|---|

| Ni-Mo-Mg-OH | 520 | 0.77 | 53 | This work |

| Ni-Mo-Mg-O | 300 | 0.85 | 111 | This work |

| Mg-OH | 680 | 1.25 | 40 | [31] |

| Mg-O | 243 | 0.97 | 61 | [31] |

| Ni-Mg-OH | 465 | 0.92 | 79 | [31] |

| Ni-Mg-O | 154 | 0.72 | 189 | [31] |

| Mo-Mg-OH | 475 | 1.36 | 114 | [31] |

| Mo-Mg-O | 342 | 1.30 | 153 | [31] |

| Area | Content, % | ||

|---|---|---|---|

| Mg | Ni | Mo | |

| 1 | 67.5 | 20.7 | 11.8 |

| 2 | 71.5 | 19.4 | 9.1 |

| 3 | 88.6 | 4.6 | 6.8 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Veselov, G.B.; Karnaukhov, T.M.; Bauman, Y.I.; Mishakov, I.V.; Vedyagin, A.A. Sol-Gel-Prepared Ni-Mo-Mg-O System for Catalytic Transformation of Chlorinated Organic Wastes into Nanostructured Carbon. Materials 2020, 13, 4404. https://doi.org/10.3390/ma13194404

Veselov GB, Karnaukhov TM, Bauman YI, Mishakov IV, Vedyagin AA. Sol-Gel-Prepared Ni-Mo-Mg-O System for Catalytic Transformation of Chlorinated Organic Wastes into Nanostructured Carbon. Materials. 2020; 13(19):4404. https://doi.org/10.3390/ma13194404

Chicago/Turabian StyleVeselov, Grigory B., Timofey M. Karnaukhov, Yury I. Bauman, Ilya V. Mishakov, and Aleksey A. Vedyagin. 2020. "Sol-Gel-Prepared Ni-Mo-Mg-O System for Catalytic Transformation of Chlorinated Organic Wastes into Nanostructured Carbon" Materials 13, no. 19: 4404. https://doi.org/10.3390/ma13194404

APA StyleVeselov, G. B., Karnaukhov, T. M., Bauman, Y. I., Mishakov, I. V., & Vedyagin, A. A. (2020). Sol-Gel-Prepared Ni-Mo-Mg-O System for Catalytic Transformation of Chlorinated Organic Wastes into Nanostructured Carbon. Materials, 13(19), 4404. https://doi.org/10.3390/ma13194404