Towards the Use of Waste Pig Fat as a Novel Potential Bio-Based Rejuvenator for Recycled Asphalt Pavement

Abstract

:1. Introduction

2. Materials and Methods

2.1. Waste Pig Fat (WPF) Preparation

2.2. Preparation of Waste Pig Fat (WPF)-Asphalt Blends

2.3. Fourier-Transform Infrared Spectroscopy (FT-IR)

2.4. Thin-Layer Chromatography–Flame Ionization Detection (TLC-FID)

2.5. Scanning Electron Microscopy (SEM)

2.6. Atomic Force Microscopy (AFM)

2.7. Thermogravimetric Analysis (TGA/DTGA)

2.8. Differential Scanning Calorimetry (DSC)

2.9. Conventional Binder Tests (Penetration, Softening Point, and Viscosity)

2.10. Temperature Susceptibility

2.11. Dynamic Shear Rheometer (DSR) Test

3. Results and Discussion

3.1. Fourier-Transform Infrared Spectroscopy (FT-IR)

3.2. Thin-Layer Chromatography-Flame Ionization Detection (TLC-FID)

3.3. Scanning Electron Microscopy (SEM)

3.4. Atomic Force Microscopy (AFM)

3.5. Conventional Physical Properties (Penetration, Softening Point, and Viscosity)

3.6. Temperature Susceptibility

3.7. Dynamic Shear Rheometer (DSR) Test

3.7.1. Rutting Resistance Factor (G*/sin δ)

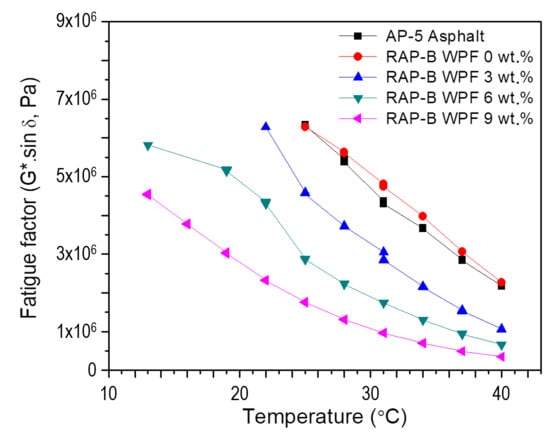

3.7.2. Fatigue Cracking Factor (G*⋅sin δ)

3.8. Performance Grade (PG) Test

3.9. Thermogravimetric Analysis (TGA)

3.10. Differential Scanning Calorimetry (DSC)

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- AbuQtaish, L.; Nazzal, M.D.; Kaya, S.; Kim, S.S.; Abbas, A.; Abu Hassan, Y. AFM-Based Approach to Study Blending between RAP and Virgin Asphalt Binders. J. Mater. Civil. Eng. 2018, 30. [Google Scholar] [CrossRef]

- Petersen, J.C.; Glaser, R. Asphalt Oxidation Mechanisms and the Role of Oxidation Products on Age Hardening Revisited. Road Mater. Pavement 2011, 12, 795–819. [Google Scholar] [CrossRef]

- Sirin, O.; Paul, D.K.; Kassem, E. State of the Art Study on Aging of Asphalt Mixtures and Use of Antioxidant Additives. Adv. Civ. Eng. 2018, 3428961. [Google Scholar] [CrossRef] [Green Version]

- Delgadillo, R.; Bahia, H.U. Effects of Temperature and Pressure on Hot Mixed Asphalt Compaction: Field and Laboratory Study. J. Mater. Civil. Eng. 2008, 20, 440–448. [Google Scholar] [CrossRef]

- Mogawer, W.S.; Austerman, A.; Roque, R.; Underwood, S.; Mohammad, L.; Zou, J. Ageing and rejuvenators: Evaluating their impact on high RAP mixtures fatigue cracking characteristics using advanced mechanistic models and testing methods. Road Mater. Pavement 2015, 16, 1–28. [Google Scholar] [CrossRef]

- McDaniel, R.S.; Shah, A.; Huber, G.A.; Copeland, A. Effects of reclaimed asphalt pavement content and virgin binder grade on properties of plant produced mixtures. Road Mater. Pavement 2012, 13, 161–182. [Google Scholar] [CrossRef]

- Mogawer, W.S.; Booshehrian, A.; Vahidi, S.; Austerman, A.J. Evaluating the effect of rejuvenators on the degree of blending and performance of high RAP, RAS, RAP/RAS mixtures. Road Mater. Pavement 2013, 14, 193–213. [Google Scholar] [CrossRef]

- Zaumanis, M.; Mallick, R.B.; Poulikakos, L.; Frank, R. Influence of six rejuvenators on the performance properties of Reclaimed Asphalt Pavement (RAP) binder and 100% recycled asphalt mixtures. Constr. Build. Mater. 2014, 71, 538–550. [Google Scholar] [CrossRef]

- Tran, N.; Taylor, A.; Turner, P.; Holmes, C.; Porot, L. Effect of rejuvenator on performance characteristics of high RAP mixture. Road Mater. Pavement 2016, 18, 183–208. [Google Scholar] [CrossRef]

- Kuang, D.; Jiao, Y.; Ye, Z.; Lu, Z.; Chen, H.; Yu, J.; Liu, N. Diffusibility Enhancement of Rejuvenator by Epoxidized Soybean Oil and Its influence on the Performance of Recycled Hot Mix Asphalt Mixtures. Materials 2018, 11, 833. [Google Scholar] [CrossRef] [Green Version]

- Lin, J.; Guo, P.; Xie, J.; Wu, S.; Chen, M. Effect of Rejuvenator Sealer Materials on the Properties of Aged Asphalt Binder. J. Mater. Civ. Eng. 2013, 25, 829–835. [Google Scholar] [CrossRef]

- Xie, Z.; Tran, N.; Julian, G.; Taylor, A.; Blackburn, L.D. Performance of Asphalt Mixtures with High Recycled Contents Using Rejuvenators and Warm-Mix Additive: Field and Lab Experiments. J. Mater. Civ. Eng. 2017, 29, 04017190. [Google Scholar] [CrossRef]

- Zaumanis, M.; Mallick, R.B.; Frank, R. Evaluation of Rejuvenator’s Effectiveness with Conventional Mix Testing for 100% Reclaimed Asphalt Pavement Mixtures. Transp. Res. Record 2013, 17–25. [Google Scholar] [CrossRef] [Green Version]

- Mamun, A.A.; Al-Abdul Wahhab, H.I. Evaluation of Waste Engine Oil-Rejuvenated Asphalt Concrete Mixtures with High RAP Content. Adv. Civ. Eng. 2018, 7386256. [Google Scholar] [CrossRef] [Green Version]

- Wallace, T.; Gibbons, D.; O’Dwyer, M.; Curran, T.P. International evolution of fat, oil and grease (FOG) waste management—A review. J. Environ. Manage. 2017, 187, 424–435. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ministry of Environment. 2013 Generation and Disposal of Waste in South Korea; Korea Environment Corporation: Sejong, Korea, 2014.

- El-Adawy, M.; Ibrahim, A.; El-Kassaby, M.M. An Experimental Evaluation of using Waste Cooking Oil Biodiesel in a Diesel Engine. Energy Technol. 2013, 1, 726–734. [Google Scholar] [CrossRef]

- Murayama, T.; Fujiwara, Y.; Noto, T. Evaluating waste vegetable oils as diesel fuel. P. I. Mech. Eng. D. J. Aut. 2000, 214, 141–148. [Google Scholar] [CrossRef]

- Ndiaye, M.; Arhaliass, A.; Legrand, J.; Roelens, G.; Kerihuel, A. Reuse of waste animal fat in biodiesel: Biorefining heavily-degraded contaminant-rich waste animal fat and formulation as diesel fuel additive. Renew. Energ. 2020, 145, 1073–1079. [Google Scholar] [CrossRef]

- Maharaj, R.; Ramjattan-Harry, V.; Mohamed, N. Rutting and Fatigue Cracking Resistance of Waste Cooking Oil Modified Trinidad Asphaltic Materials. Sci. World J. 2015, 385013. [Google Scholar] [CrossRef] [Green Version]

- Zargar, M.; Ahmadinia, E.; Asli, H.; Karim, M.R. Investigation of the possibility of using waste cooking oil as a rejuvenating agent for aged bitumen. J. Hazard. Mater. 2012, 233–234, 254–258. [Google Scholar] [CrossRef]

- Bailey, H.K.; Philips, P. Asphalt Rejuvenation. U.S. Patent 2010/0034586A1, 11 February 2010. [Google Scholar]

- Ji, J.; Yao, H.; Suo, Z.; You, Z.; Li, H.; Xu, S.; Sun, L. Effectiveness of Vegetable Oils as Rejuvenators for Aged Asphalt Binders. J. Mater. Civil. Eng. 2017, 29, D4016003. [Google Scholar] [CrossRef]

- American Society of Testing Materials (ASTM) International. ASTM D946/D946M-15, Standard Specification for Penetration-Graded Asphalt Binder for Use in Pavement Construction; American Society of Testing Materials (ASTM) International: West Conshohocken, PA, USA, 2015. [Google Scholar]

- American Association of State Highway and Transportation Officials. AASHTO T 164, Standard Method of Test for Quantitative Extraction of Asphalt Binder from Hot-Mix Asphalt (HMA); American Association of State Highway and Transportation Officials: Washington, DC, USA, 2014. [Google Scholar]

- American Society of Testing Materials (ASTM) International. ASTM D5404 / D5404M-12, Standard Practice for Recovery of Asphalt from Solution Using the Rotary Evaporator; American Society of Testing Materials (ASTM) International: West Conshohocken, PA, USA, 2012. [Google Scholar]

- American Society of Testing Materials (ASTM) International. ASTM D8272-19, Standard Test Method for Effect of Heat and Air on a Moving Film of Asphalt (Rolling Thin-Film Oven Test); American Society of Testing Materials (ASTM) International: West Conshohocken, PA, USA, 2019. [Google Scholar]

- American Society of Testing Materials (ASTM) International. ASTM D6521-13, Standard Practice for Accelerated Aging of Asphalt Binder Using a Pressurized Aging Vessel (PAV); American Society of Testing Materials (ASTM) International: West Conshohocken, PA, USA, 2013. [Google Scholar]

- American Association of State Highway and Transportation Officials. AASHTO T 30, Standard Method of Test for Mechanical Analysis of Extracted Aggregates; American Association of State Highway and Transportation Officials: Washington, DC, USA, 2015. [Google Scholar]

- Loeber, L.; Sutton, O.; Morel, J.; Valleton, J.M.; Muller, G. New direct observations of asphalts and asphalt binders by scanning electron microscopy and atomic force microscopy. J. Microsc. 1996, 182, 32–39. [Google Scholar] [CrossRef]

- Mazumder, M.; Ahmed, R.; Ali, A.W.; Lee, S.J. SEM and ESEM techniques used for analysis of asphalt binder and mixture: A state of the art review. Constr. Build. Mater. 2018, 186, 313–329. [Google Scholar] [CrossRef]

- Butt, H.-J.; Jaschke, M. Calculation of thermal noise in atomic force microscopy. Nanotechnology 1995, 6, 1–7. [Google Scholar] [CrossRef]

- American Society of Testing Materials (ASTM) International. ASTM D5/D5M-13, Standard Test Method for Penetration of Bituminous Materials; American Society of Testing Materials (ASTM) International: West Conshohocken, PA, USA, 2013. [Google Scholar]

- American Society of Testing Materials (ASTM) International. ASTM D36/D36M-14e1, Standard Test Method for Softening Point of Bitumen (Ring-and-ball Apparatus); American Society of Testing Materials (ASTM) International: West Conshohocken, PA, USA, 2014. [Google Scholar]

- American Society of Testing Materials (ASTM) International. ASTM D4402/D4402M-15, Standard Test Method for Viscosity Determination of Asphalt at Elevated Temperatures Using a Rotational Viscometer; American Society of Testing Materials (ASTM) International: West Conshohocken, PA, USA, 2015. [Google Scholar]

- Roberts, F.L.; Kandhal, P.S.; Brown, E.R.; Lee, D.Y.; Kennedy, T.Y. Hot Mix Asphalt Materials, Mixture Design and Construction; National Asphalt Pavement Association Research and Education Foundation: Lanham, MD, USA, 1991. [Google Scholar]

- American Society of Testing Materials (ASTM) International. ASTM D7175-15, Standard Test Method for Determining the Rheological Properties of Asphalt Binder Using a Dynamic Shear Rheometer; American Society of Testing Materials (ASTM) International: West Conshohocken, PA, USA, 2015. [Google Scholar]

- Cordella, C.; Moussa, I.; Martel, A.C.; Sbirrazzuoli, N.; Lizzani-Cuvelier, L. Recent Developments in Food Characterization and Adulteration Detection: Technique-Oriented Perspectives. J. Agr. Food Chem. 2002, 50, 1751–1764. [Google Scholar] [CrossRef]

- Coates, J. Interpretation of Infrared Spectra, A Practical Approach. In Encyclopedia of Analytical Chemistry, Meyers, R.A., Eds.; John Wiley & Sons Ltd.: Chichester, UK, 2000; pp. 10881–10882. [Google Scholar]

- Masson, J.F.; Leblond, V.; Margeson, J. Bitumen morphologies by phase-detection atomic force microscopy. J. Microsc. Oxf. 2006, 221, 17–29. [Google Scholar] [CrossRef] [Green Version]

- Pauli, A.T.; Grimes, R.W.; Beemer, A.G.; Turner, T.F.; Branthaver, J.F. Morphology of asphalts, asphalt fractions and model wax-doped asphalts studied by atomic force microscopy. Int. J. Pavement Eng. 2011, 12, 291–309. [Google Scholar] [CrossRef]

- Das, P.K.; Kringos, N.; Wallqvist, V.; Birgisson, B. Micromechanical investigation of phase separation in bitumen by combining atomic force microscopy with differential scanning calorimetry results. Road Mater. Pavement 2013, 14, 25–37. [Google Scholar] [CrossRef]

- American Society of Testing Materials (ASTM) International. ASTM D6373-16, Standard Specification for Performance Graded Asphalt Binder; American Society of Testing Materials (ASTM) International: West Conshohocken, PA, USA, 2016. [Google Scholar]

- Jing-Song, G.; Wei-Biao, F.; Bei-Jing, Z. A study on the pyrolysis of asphalt. Fuel 2003, 82, 49–52. [Google Scholar] [CrossRef]

- Nciri, N.; Kim, N.; Cho, N. New insights into the effects of styrene-butadiene-styrene polymer modifier in the structure, properties, and performance of asphalt binder: The case of AP-5 asphalt and solvent deasphalting pitch. Mater. Chem. Phys. 2017, 193, 477–495. [Google Scholar] [CrossRef]

- Elseifi, M.; Mohammad, L.N.; Glover, I.; Negulescu, I.; Daly, W.H.; Abadie, C. Relationship between Molecular Compositions and Rheological Properties of Neat Asphalt Binder at Low and Intermediate Temperatures. J. Mater. Civ. Eng. 2010, 22, 1288–1294. [Google Scholar] [CrossRef]

- Azir, M.; Abbasiliasi, S.; Ibrahim, T.A.T.; Manaf, Y.N.A.; Sazili, A.Q.; Mustafa, S. Detection of Lard in Cocoa Butter—Its Fatty Acid Composition, Triacylglycerol Profiles, and Thermal Characteristics. Foods 2017, 6, 98. [Google Scholar] [CrossRef] [PubMed] [Green Version]

| Property | Value |

|---|---|

| Acid value (mg of KOH/g) | 0.71 |

| Iodine value (g of I2/ 100 g) | 67 |

| Moisture content (wt.%) | 0.03 |

| Fatty acid composition (wt.%) | |

| Saturated fats | 39.20 |

| Unsaturated fats | |

| Total monounsaturated | 45.10 |

| Total polyunsaturated | 11.20 |

| Elemental analysis | Ave | SD |

| C (carbon) | 85.16 wt.% | 0.40 |

| H (hydrogen) | 9.40 wt.% | 0.24 |

| N (nitrogen) | 0.94 wt.% | 0.05 |

| S (sulfur) | 3.80 wt.% | 0.21 |

| O (oxygen) | 0.70 wt.% | 0.08 |

| SARA Generic fractions | Ave | SD |

| Saturates | 5.09 wt.% | 0.41 |

| Aromatics | 12.94 wt.% | 0.71 |

| Resins | 38.53 wt.% | 2.35 |

| Asphaltenes | 43.44 wt.% | 2.24 |

| Physical properties | Ave | SD |

| Penetration at 25 °C, 0.1 mm | 60.00 | 1.0 |

| Softening point | 42.9 °C | 0.5 |

| Viscosity at 135 °C | 309 cP | 11 |

| Sample | TGA/DTGA (°C) | ΔW (wt.%) | |

|---|---|---|---|

| ΔTdec | Tmax | ||

| WPF | 362.6–420.9 | 397.7 | 0 |

| RAP-B WPF 0 wt.% | 376.0–466.0 | 439.8 | 16.7 |

| RAP-B WPF 3 wt.% | 376.7–467.2 | 442.4 | 15.8 |

| RAP-B WPF 6 wt.% | 351.3–458.0 | 432.0 | 14.6 |

| RAP-B WPF 9 wt.% | 345.3–464.6 | 431.3 | 12.9 |

| Sample | Tg1 (°C) | ΔCp1 (J/g⋅°C) | Tg2 (°C) | ΔCp2 (J/g⋅°C) |

|---|---|---|---|---|

| RAP-B WPF 0 wt.% | –25.3 | 0.238 | 8.1 | 0.277 |

| RAP-B WPF 3 wt.% | –29.7 | 0.311 | 3.8 | 0.277 |

| RAP-B WPF 6 wt.% | –33.2 | 0.285 | –3.4 | 0.262 |

| RAP-B WPF 9 wt.% | –33.8 | 0.208 | –6.1 | 0.257 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nciri, N.; Shin, T.; Kim, N.; Caron, A.; Ben Ismail, H.; Cho, N. Towards the Use of Waste Pig Fat as a Novel Potential Bio-Based Rejuvenator for Recycled Asphalt Pavement. Materials 2020, 13, 1002. https://doi.org/10.3390/ma13041002

Nciri N, Shin T, Kim N, Caron A, Ben Ismail H, Cho N. Towards the Use of Waste Pig Fat as a Novel Potential Bio-Based Rejuvenator for Recycled Asphalt Pavement. Materials. 2020; 13(4):1002. https://doi.org/10.3390/ma13041002

Chicago/Turabian StyleNciri, Nader, Taesub Shin, Namho Kim, Arnaud Caron, Hanen Ben Ismail, and Namjun Cho. 2020. "Towards the Use of Waste Pig Fat as a Novel Potential Bio-Based Rejuvenator for Recycled Asphalt Pavement" Materials 13, no. 4: 1002. https://doi.org/10.3390/ma13041002

APA StyleNciri, N., Shin, T., Kim, N., Caron, A., Ben Ismail, H., & Cho, N. (2020). Towards the Use of Waste Pig Fat as a Novel Potential Bio-Based Rejuvenator for Recycled Asphalt Pavement. Materials, 13(4), 1002. https://doi.org/10.3390/ma13041002