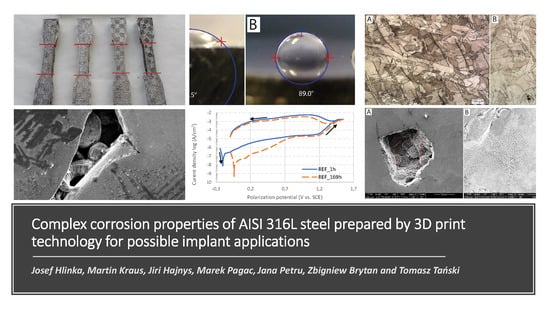

Complex Corrosion Properties of AISI 316L Steel Prepared by 3D Printing Technology for Possible Implant Applications

Abstract

:1. Introduction

2. Material, Heat Treatment and Experimental Techniques

2.1. Material and Processing Parameters

2.2. Heat Treatment

2.3. Chemical Composition, Microstructure and Metallography Observation

2.4. Corrosion Testing Methods

2.5. Wettability and Surface Energy

3. Results

3.1. Porosity

3.2. Chemical Composition

3.3. Microstructure

3.4. Open Circuit Potential and Cyclic Polarization

3.5. Double Loop Electrochemical Potentiokinetic Reactivation

- Initial polarization at −700 mV (SCE) for 120 s to activate the tested surface.

- Potentiokinetic test from –350 mV to +500 mV and back with polarization rate of 4 mV.s−1 in both directions with triple repetition

3.6. Surface Wettability

4. Discussion

5. Conclusions

- ▪

- The porosities of samples were in the 0.0%–0.08% range and were not affected by heat treatment. The pores were in the form of closed holes filled with unmelted powder particles. There were microcrack formations observed near these pores.

- ▪

- Original melt pool reliefs were reduced during 650 °C heat treatment and fully removed at 1050 °C. The microstructure consisted of equiaxial austenitic grains. The structure of the sample heat treated at 1050 °C showed significant grain coarsening. Grains of the non-treated sample treated at 650 °C were shown lying within the melt pools and across melt pool boundaries.

- ▪

- Open circuit potentials of all samples were elevated during 169 h exposition in saline solution. The most significant shift of OCP to more noble values was noted for the sample after 1050 °C heat treatment.

- ▪

- The corrosion rate obtained by potentiodynamic polarization method was deeply under the recommended limit. The reference sample demonstrated the most promising results of corrosion rate, especially after 169 h exposure. The highest values of corrosion rate were measured for the sample after 1050 °C heat treatment and after 1 h exposition in saline solution. The signs of corrosion came in the form of the selective dissolving of microstructural components, leaving cellular-like reliefs on the exposed surfaces rather than in the corrosion pits.

- ▪

- The sample without heat treatment showed very low grain boundary sensitization, which was furthermore reduced by heat treatment. This was due to long holding times and a slow cooling process.

- ▪

- The sample produced by the SLM method indicated nearly doubled surface wettability compared to “standard” ASIS 316L material. This phenomenon is related to higher surface energy and will have a positive effect on biocompatibility.

Author Contributions

Funding

Conflicts of Interest

References

- Frazier, W.E. Metal additive manufacturing: A review. J. Mater. Eng. Perform. 2014, 23, 1917–1928. [Google Scholar] [CrossRef]

- Gao, W.; Zhang, Y.; Ramanujan, D.; Ramani, K.; Chen, Y.; Williams, C.B.; Wang, C.C.L.; Shin, Y.C.; Zhang, S.; Zavattieri, P.D. The status, challenges, and future of additive manufacturing in engineering. Comput. Aided Des. 2015, 69, 65–89. [Google Scholar] [CrossRef]

- Haleem, A.; Javaid, M. 3D printed medical parts with different materials using additive manufacturing. Clin. Epidemiol. Glob. Health 2019. [Google Scholar] [CrossRef] [Green Version]

- Kong, D.; Ni, X.; Dong, C.; Zhang, L.; Man, C.; Yao, J.; Xiao, K.; Li, X. Heat treatment effect on the microstructure and corrosion behavior of 316L stainless steel fabricated by selective laser melting for proton exchange membrane fuel cells. Electrochim. Acta 2018, 276, 293–303. [Google Scholar] [CrossRef]

- Mercelis, P.; Kruth, J.P. Residual stresses in selective laser sintering and selective laser melting. Rapid Prototyp. J. 2006, 12, 254–265. [Google Scholar] [CrossRef]

- ASTM Standard F746. Standard Test Method for Pitting or Crevice Corrosion of Metallic Surgical Implant Materials. ASTM B Stand. 2014. [Google Scholar] [CrossRef]

- Pardo, A.; Merino, M.C.; Coy, A.E.; Viejo, F.; Arrabal, R.; Matykina, E. Pitting corrosion behaviour of austenitic stainless steels—Combining effects of Mn and Mo additions. Corros. Sci. 2008, 50, 1796–1806. [Google Scholar] [CrossRef]

- Blinn, B.; Klein, M.; Gläßner, C.; Smaga, M.; Aurich, J.C.; Beck, T. An investigation of the microstructure and fatigue behavior of additively manufactured AISI 316L stainless steel with regard to the influence of heat treatment. Metals 2018, 8, 220. [Google Scholar] [CrossRef] [Green Version]

- Hlinka, J.; Lasek, S. Influence of Passivation on Wettability of AISI 304 Steel and its Corrosion Properties in Solution of Sodium Hypochlorite. In Key Engineering Materials; Trans Tech Publications Ltd.: Beach, Switzerland, 2019. [Google Scholar]

- Shahryari, A.; Omanovic, S.; Szpunar, J.A. Electrochemical formation of highly pitting resistant passive films on a biomedical grade 316LVM stainless steel surface. Mater. Sci. Eng. C 2008, 28, 94–106. [Google Scholar] [CrossRef]

- Fathi, M.H.; Doostmohammadi, A. Bioactive glass nanopowder and bioglass coating for biocompatibility improvement of metallic implant. J. Mater. Process. Technol. 2009, 209, 1385–1391. [Google Scholar] [CrossRef]

- Aghababaie, E.; Javadinejad, H.R.; Saboktakin Rizi, M.; Ebrahimian, M. Effect of Chlorine Ion on the Corrosion of 316L Austenitic Stainless Steel. In Advanced Engineering Forum; Trans Tech Publications Ltd.: Beach, Switzerland, 2017; Volume 23, pp. 1–12. [Google Scholar]

- Soltis, J. Passivity breakdown, pit initiation and propagation of pits in metallic materials—Review. Corros. Sci. 2015, 90, 5–22. [Google Scholar] [CrossRef]

- Strondl, A.; Lyckfeldt, O.; Brodin, H.; Ackelid, U. Characterization and Control of Powder Properties for Additive Manufacturing. JOM 2015, 67, 549–554. [Google Scholar] [CrossRef]

- Eo, D.R.; Park, S.H.; Cho, J.W. Inclusion evolution in additive manufactured 316L stainless steel by laser metal deposition process. Mater. Des. 2018, 155, 212–219. [Google Scholar] [CrossRef]

- Koutsoukis, T.; Redjaïmia, A.; Fourlaris, G. Phase transformations and mechanical properties in heat treated superaustenitic stainless steels. Mater. Sci. Eng. A 2013, 561, 477–485. [Google Scholar] [CrossRef]

- Kong, D.; Dong, C.; Ni, X.; Zhang, L.; Yao, J.; Man, C.; Cheng, X.; Xiao, K.; Li, X. Mechanical properties and corrosion behavior of selective laser melted 316L stainless steel after different heat treatment processes. J. Mater. Sci. Technol. 2019, 35, 1499–1507. [Google Scholar] [CrossRef]

- Montero-Sistiaga, M.L.; Nardone, S.; Hautfenne, C.; Van Humbeeck, J. Effect of Heat Treatment Of 316L Stainless Steel Produced by Selective Laser Melting (SLM). In Proceedings of the 27th Annual International Solid Freeform Fabrication Symposium—An Additive Manufacturing Conference, Austin, TX, USA, 8–10 August 2016. [Google Scholar]

- Sun, Z.; Tan, X.; Tor, S.B.; Chua, C.K. Simultaneously enhanced strength and ductility for 3D-printed stainless steel 316L by selective laser melting. NPG Asia Mater. 2018, 10, 127–136. [Google Scholar] [CrossRef]

- Yadollahi, A.; Shamsaei, N.; Thompson, S.M.; Seely, D.W. Effects of process time interval and heat treatment on the mechanical and microstructural properties of direct laser deposited 316L stainless steel. Mater. Sci. Eng. A 2015, 644, 171–183. [Google Scholar] [CrossRef]

- Guitar, M.A.; Scheid, A.; Britz, D.; Mücklich, F. Evaluation of the etching process for analysis of secondary carbides in HCCI by optical and confocal laser microscopy. Pract. Metallogr. 2019, 56, 246–261. [Google Scholar] [CrossRef]

- Topoglidis, E.; Cass, A.E.G.; O’Regan, B.; Durrant, J.R. Immobilization and bioelectrochemistry of proteins on nanoporous TiO2 and ZnO films. J. Electroanal. Chem. 2001, 517, 20–27. [Google Scholar] [CrossRef]

- Brabec, C.J.; Cravino, A.; Meissner, D.; Serdar Sariciftci, N.; Fromherz, T.; Rispens, M.T.; Sanchez, L.; Hummelen, J.C. Origin of the open circuit voltage of plastic solar cells. Adv. Funct. Mater. 2001, 11, 374–380. [Google Scholar] [CrossRef]

- Enos, D.G.; Scribner, L.L. The Potentiodynamic Polarization Scan; Technical Report; Solartron Instruments: Hampshire, UK, 1997. [Google Scholar]

- Kam, D.H.; Bhattacharya, S.; Mazumder, J. Control of the wetting properties of an AISI 316L stainless steel surface by femtosecond laser-induced surface modification. J. Micromech. Microeng. 2012, 22, 105019. [Google Scholar] [CrossRef]

- Calvimontes, A. The Measurement of the Surface Energy of Solids by Sessile Drop Accelerometry. Microgravity Sci. Technol. 2018, 30, 277–293. [Google Scholar] [CrossRef]

- Cai, X.; Malcolm, A.A.; Wong, B.S.; Fan, Z. Measurement and characterization of porosity in aluminium selective laser melting parts using X-ray CT. Virtual Phys. Prototyp. 2015, 10, 195–206. [Google Scholar] [CrossRef]

- Mancisidor, A.M.; Garciandia, F.; Sebastian, M.S.; Álvarez, P.; Díaz, J.; Unanue, I. Reduction of the residual porosity in parts manufactured by selective laser melting using skywriting and high focus offset strategies. Phys. Procedia 2016, 83, 864–873. [Google Scholar] [CrossRef] [Green Version]

- Tammas-Williams, S.; Withers, P.J.; Todd, I.; Prangnell, P.B. The Influence of Porosity on Fatigue Crack Initiation in Additively Manufactured Titanium Components. Sci. Rep. 2017, 7, 7308. [Google Scholar] [CrossRef] [PubMed]

- Sola, A.; Nouri, A. Microstructural porosity in additive manufacturing: The formation and detection of pores in metal parts fabricated by powder bed fusion. J. Adv. Manuf. Process. 2019, 1, e10021. [Google Scholar] [CrossRef]

- Andreau, O.; Koutiri, I.; Peyre, P.; Penot, J.D.; Saintier, N.; Pessard, E.; De Terris, T.; Dupuy, C.; Baudin, T. Texture control of 316L parts by modulation of the melt pool morphology in selective laser melting. J. Mater. Process. Technol. 2019, 264, 21–31. [Google Scholar] [CrossRef] [Green Version]

- Li, Y.; Wang, Z.; Wang, L. Surface properties of nitrided layer on AISI 316L austenitic stainless steel produced by high temperature plasma nitriding in short time. Appl. Surf. Sci. 2014, 298, 243–250. [Google Scholar] [CrossRef]

- Licausi, M.P.; Igual Muñoz, A.; Amigó Borrás, V. Influence of the fabrication process and fluoride content on the tribocorrosion behaviour of Ti6Al4V biomedical alloy in artificial saliva. J. Mech. Behav. Biomed. Mater. 2013, 20, 137–148. [Google Scholar] [CrossRef]

- Hlinka, J.; Lasek, S. Structure and Corrosion Properties of Electrochemically Treated Surface of 1.4301 (aisi 304) Steel for Medical Applications. In Proceedings of the METAL 2016 25th Anniversary International Conference on Metallurgy and Materials, Brno, Czech Republic, 25–27 May 2016. [Google Scholar]

- Eliaz, N. Corrosion of metallic biomaterials: A review. Materials 2019, 12, 407. [Google Scholar] [CrossRef] [Green Version]

- Kayali, Y.; Büyüksaǧiş, A.; Güneş, I.; Yalçin, Y. Investigation of corrosion behaviors at different solutions of boronized AISI 316L stainless steel. Prot. Met. Phys. Chem. Surf. 2013, 49, 348–358. [Google Scholar] [CrossRef]

- Kutz, M. Handbook of Environmental Degradation of Materials, 2nd ed.; William Andrew: Norwich, NY, USA, 2012; ISBN 9781437734560. [Google Scholar]

- El-Tahawy, M.; Huang, Y.; Um, T.; Choe, H.; Lábár, J.L.; Langdon, T.G.; Gubicza, J. Stored energy in ultrafine-grained 316L stainless steel processed by high-pressure torsion. J. Mater. Res. Technol. 2017, 6, 339–347. [Google Scholar] [CrossRef] [Green Version]

- Angst, U.; Büchler, M. On the applicability of the Stern-Geary relationship to determine instantaneous corrosion rates in macro-cell corrosion. Mater. Corros. 2015, 66, 1017–1028. [Google Scholar] [CrossRef]

- Wang, Z.; Di-Franco, F.; Seyeux, A.; Zanna, S.; Maurice, V.; Marcus, P. Passivation-induced physicochemical alterations of the native surface oxide film on 316L austenitic stainless steel. J. Electrochem. Soc. 2019, 166, C3376–C3388. [Google Scholar] [CrossRef]

- Cabrini, M.; Lorenzi, S.; Testa, C.; Brevi, F.; Biamino, S.; Fino, P.; Manfredi, D.; Marchese, G.; Calignano, F.; Pastore, T. Microstructure and selective corrosion of alloy 625 obtained by means of laser powder bed fusion. Materials 2019, 12, 1742. [Google Scholar] [CrossRef] [Green Version]

- Rahimi, S.; Engelberg, D.L.; Marrow, T.J.; Centre, M.P.; Road, O. Characterization of the Sensitization Behaviour of Thermo-Mechanically Processed Type 304 Stainless Steel Using DL-EPR Testing and Image Analysis Methods. In Proceedings of the 2nd International Conference Corrosion and Material Protection, Prague, Czech Republic, 19–22 April 2010. [Google Scholar]

- Amadou, T.; Braham, C.; Sidhom, H. Double loop electrochemical potentiokinetic reactivation test optimization in checking of duplex stainless steel intergranular corrosion susceptibility. Metall. Mater. Trans. A Phys. Metall. Mater. Sci. 2004, 35, 3499–3513. [Google Scholar] [CrossRef]

- Kubiak, K.J.; Wilson, M.C.T.; Mathia, T.G.; Carval, P. Wettability versus roughness of engineering surfaces. Wear 2011, 271, 523–528. [Google Scholar] [CrossRef] [Green Version]

- Rabbani, H.S.; Zhao, B.; Juanes, R.; Shokri, N. Pore geometry control of apparent wetting in porous media. Sci. Rep. 2018, 8, 15729. [Google Scholar] [CrossRef]

- Ali, H.; Ghadbeigi, H.; Mumtaz, K. Effect of scanning strategies on residual stress and mechanical properties of Selective Laser Melted Ti6Al4V. Mater. Sci. Eng. A 2018, 712, 175–187. [Google Scholar] [CrossRef]

- Jaskari, M.; Mäkikangas, J.; Järvenpää, A.; Mäntyjärvi, K.; Karjalainen, P. Effect of high porosity on bending fatigue properties of 3D printed AISI 316L steel. Procedia Manuf. 2019, 36, 33–41. [Google Scholar] [CrossRef]

- Fergani, O.; Brotan, V.; Bambach, M.; Pérez-Prado, M.T. Texture evolution in stainless steel processed by selective laser melting and annealing. Mater. Sci. Technol. 2018, 34, 2223–2230. [Google Scholar] [CrossRef]

- Papula, S.; Song, M.; Pateras, A.; Chen, X.B.; Brandt, M.; Easton, M.; Yagodzinskyy, Y.; Virkkunen, I.; Hänninen, H. Selective laser melting of duplex stainless Steel 2205: Effect of post-processing heat treatment on microstructure, mechanical properties, and corrosion resistance. Materials 2019, 12, 2468. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Tillmann, W.; Henning, T.; Wojarski, L. Vacuum Brazing of 316L Stainless Steel Based on Additively Manufactured and Conventional Material Grades. In IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2018. [Google Scholar]

- Cooper, A.J.; Cooper, N.I.; Bell, A.; Dhers, J.; Sherry, A.H. A Microstructural Study on the Observed Differences in Charpy Impact Behavior between Hot Isostatically Pressed and Forged 304L and 316L Austenitic Stainless Steel. Metall. Mater. Trans. A Phys. Metall. Mater. Sci. 2015, 46, 5126–5138. [Google Scholar] [CrossRef] [Green Version]

- Essa, K.; Jamshidi, P.; Zou, J.; Attallah, M.M.; Hassanin, H. Porosity control in 316L stainless steel using cold and hot isostatic pressing. Mater. Des. 2018, 138, 21–29. [Google Scholar] [CrossRef] [Green Version]

- Northcutt, L.A.; Orski, S.V.; Migler, K.B.; Kotula, A.P. Effect of processing conditions on crystallization kinetics during materials extrusion additive manufacturing. Polymer 2018, 154, 182–187. [Google Scholar] [CrossRef]

- Wu, A.S.; Brown, D.W.; Kumar, M.; Gallegos, G.F.; King, W.E. An Experimental Investigation into Additive Manufacturing-Induced Residual Stresses in 316L Stainless Steel. Metall. Mater. Trans. A Phys. Metall. Mater. Sci. 2014, 45, 6260–6270. [Google Scholar] [CrossRef]

- Sing, S.L.; An, J.; Yeong, W.Y.; Wiria, F.E. Laser and electron-beam powder-bed additive manufacturing of metallic implants: A review on processes, materials and designs. J. Orthop. Res. 2016, 34, 369–385. [Google Scholar] [CrossRef]

- Wang, Y.M.; Voisin, T.; McKeown, J.T.; Ye, J.; Calta, N.P.; Li, Z.; Zeng, Z.; Zhang, Y.; Chen, W.; Roehling, T.T.; et al. Additively manufactured hierarchical stainless steels with high strength and ductility. Nat. Mater. 2018, 17, 63–71. [Google Scholar] [CrossRef] [Green Version]

- Verlee, B.; Dormal, T.; Lecomte-Beckers, J. Density and porosity control of sintered 316l stainless steel parts produced by additive manufacturing. Powder Metall. 2012, 55, 260–267. [Google Scholar] [CrossRef]

- Saboori, A.; Toushekhah, M.; Aversa, A.; Lai, M.; Lombardi, M.; Biamino, S.; Fino, P. Critical Features in the Microstructural Analysis of AISI 316L Produced By Metal Additive Manufacturing. Metallogr. Microstruct. Anal. 2020, 9, 92–96. [Google Scholar] [CrossRef] [Green Version]

- Cherry, J.A.; Davies, H.M.; Mehmood, S.; Lavery, N.P.; Brown, S.G.R.; Sienz, J. Investigation into the effect of process parameters on microstructural and physical properties of 316L stainless steel parts by selective laser melting. Int. J. Adv. Manuf. Technol. 2014, 76, 869–879. [Google Scholar] [CrossRef] [Green Version]

- Lavery, N.P.; Cherry, J.; Mehmood, S.; Davies, H.; Girling, B.; Sackett, E.; Brown, S.G.R.; Sienz, J. Effects of hot isostatic pressing on the elastic modulus and tensile properties of 316L parts made by powder bed laser fusion. Mater. Sci. Eng. A 2017, 693, 186–213. [Google Scholar] [CrossRef] [Green Version]

- Espinosa, C.E.; Veleva, L.; López, J.L. Power spectral density analysis of the corrosion potential fluctuation of stainless steel 316L in early stages of exposure to caribbean sea water. ECS Trans. 2015, 66, 3–11. [Google Scholar] [CrossRef]

- Abosrra, L.; Ashour, A.F.; Mitchell, S.C.; Youseffi, M. Corrosion of mild steel and 316L austenitic stainless steel with different surface roughness in sodium chloride saline solutions. WIT Trans. Eng. Sci. 2009, 65, 161–172. [Google Scholar]

- Mameng, S.H.; Pettersson, R.; Jonson, J.Y. Limiting conditions for pitting corrosion of stainless steel EN 1.4404 (316L) in terms of temperature, potential and chloride concentration. Mater. Corros. 2017, 68, 272–283. [Google Scholar] [CrossRef]

- Manivasagam, G.; Dhinasekaran, D.; Rajamanickam, A. Biomedical Implants: Corrosion and its Prevention—A Review. Recent Patents Corros. Sci. 2010, 2, 40–54. [Google Scholar] [CrossRef] [Green Version]

- Cabrini, M.; Lorenzi, S.; Pastore, T.; Pellegrini, S.; Burattini, M.; Miglio, R. Study of the corrosion resistance of austenitic stainless steels during conversion of waste to biofuel. Materials 2017, 10, 325. [Google Scholar] [CrossRef] [Green Version]

- Hadzima, B. Influence of the surface finishing on the corrosion behaviour of AISI 316L stainless steel. Mater. Eng. 2015, 22, 48–53. [Google Scholar]

- Hiromoto, S. Corrosion of Metallic Biomaterials. In Metals for Biomedical Devices; Woodhead Publishing: Sawston, UK, 2010; pp. 131–152. [Google Scholar]

- Baboian, R.; Haynes, G.S. Cyclic Polarization Measurements—Experimental Procedure and Evaluation of Test Data. In Electrochemical Corrosion Testing; ASTM International: West Conshohocken, PE, USA, 1981; pp. 274–282. [Google Scholar]

- Yang, K.; Ren, Y. Nickel-free austenitic stainless steels for medical applications. Sci. Technol. Adv. Mater. 2010, 11, 014105. [Google Scholar] [CrossRef]

- Valente, E.H.; Christiansen, T.L.; Somers, M.A.J. High-Temperature Solution Nitriding and Low-Temperature Surface Nitriding of 3D Printed Stainless Steel. In Proceedings of the 2018 European Conference on Heat Treatment (ECHT), Friedrichshafen, Germany, 12–13 April 2018. [Google Scholar]

- Li, Y.J.; Wang, Y.G.; An, B.; Xu, H.; Liu, Y.; Zhang, L.C.; Ma, H.Y.; Wang, W.M. A practical anodic and cathodic curve intersection model to understand multiple corrosion potentials of Fe-based glassy alloys in OH-contained solutions. PLoS ONE 2016, 11, e0146421. [Google Scholar] [CrossRef] [Green Version]

- Hlinka, J.; Lasek, S.; Siostrzonek, R.; Faisal, N. Characterization of Hydroxyapatite Layer on AISI 316L Stainless Steel. In Proceedings of the 26th International Conference on Metallurgy and Materials (METAL), Brno, Czech Republic, 24–26 May 2017. [Google Scholar]

- Bajaj, P.; Hariharan, A.; Kini, A.; Kürnsteiner, P.; Raabe, D.; Jägle, E.A. Steels in additive manufacturing: A review of their microstructure and properties. Mater. Sci. Eng. A 2020, 772, 138633. [Google Scholar] [CrossRef]

- Matula, M.; Hyspecka, L.; Svoboda, M.; Vodarek, V.; Dagbert, C.; Galland, J.; Stonawska, Z.; Tuma, L. Intergranular corrosion of AISI 316L steel. Mater. Charact. 2001, 46, 203–210. [Google Scholar] [CrossRef]

- Stonawská, Z.; Svoboda, M.; Sozańska, M.; Křístková, M.; Sojka, J.; Dagbert, C.; Hyspecká, L. Structural analysis and intergranular corrosion tests of AISI 316L steel. J. Microsc. 2006, 224, 62–64. [Google Scholar] [CrossRef] [PubMed]

- Terada, M.; Escriba, D.M.; Costa, I.; Materna-Morris, E.; Padilha, A.F. Investigation on the intergranular corrosion resistance of the AISI 316L(N) stainless steel after long time creep testing at 600 °C. Mater. Charact. 2008, 59, 663–668. [Google Scholar] [CrossRef]

- Gellings, P.J.; de Jongh, M.A. Grain boundary oxidation and the chromium-depletion theory of intercrystalline corrosion of austenitic stainless steels. Corros. Sci. 1967, 7, 413–421. [Google Scholar] [CrossRef] [Green Version]

- Wei, J.; Igarashi, T.; Okumori, N.; Igarashi, T.; Maetani, T.; Liu, B.; Yoshinari, M. Influence of surface wettability on com petitive protein adsorption and initial attachment of osteoblasts. Biomed. Mater. 2009, 4, 045002. [Google Scholar] [CrossRef]

- Sahoo, N.K.; Anand, S.C.; Bhardwaj, J.R.; Sachdeva, V.P.; Sapru, B.L. Bone Response to Stainless Steel And Titanium Bone Plates: An Experimental Study On Animals. Med. J. Armed Forces India 1994, 50, 10–14. [Google Scholar] [CrossRef] [Green Version]

- Anil, S.; Anand, P.S.; Alghamdi, H.; Janse, J.A. Dental Implant Surface Enhancement and Osseointegration. In Implant Dentistry—A Rapidly Evolving Practice; Intech Open Ltd.: London, UK, 2011. [Google Scholar]

| Chemical Composition (wt. %) | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| C | Si | Mn | P | S | N | Cr | Mo | Ni | Fe |

| Max. | Max. | Max. | Max. | Max. | Max. | Min.–Max. | Min.–Max. | Min.–Max. | Balance |

| 0.03 | 1.00 | 2.00 | 0.045 | 0.03 | 0.10 | 16.00–18.00 | 2.00–3.00 | 10.00–14.00 | |

| Manufacturing Parameter | Value |

|---|---|

| Laser power (W) | 200 |

| Speed scanning (mm/s) | 650 |

| Exposure time (µs) | 80 |

| Laser beam diameter (µm) | 80 |

| Powder layer thickness (µm) | 50 |

| Hatching pattern | Chessboard |

| Heat Treatment Parameters | HT1 | HT2 | REF (State after SLM) |

|---|---|---|---|

| Temperature | 650 °C | 1050 °C | - |

| Holding time | 30 min | 30 min | - |

| Heating rate | 20 °C min−1 | 20 °C min−1 | - |

| Cooling | Slow-in chamber | Slow-in chamber | - |

| Sample | Average Porosity (%) |

|---|---|

| HT1 | 0.03 |

| HT2 | 0.07 |

| REF | 0.08 |

| Chemical Composition-Content of Each Element in Tested Material AISI 316L (wt.%) | ||||||||

|---|---|---|---|---|---|---|---|---|

| C (%) | Mn (%) | Si (%) | P (%) | S (%) | Cr (%) | Ni (%) | Mo (%) | Cu (%) |

| <0.001 | 1.70 | 0.22 | 0.023 | 0.001 | 17.72 | 14.24 | 2.73 | 0.077 |

| Co (%) | B (%) | Pb (%) | V (%) | W (%) | Al (%) | Nb (%) | Ti (%) | Fe (%) |

| 0.048 | 0.0022 | <0.001 | <0.001 | 0.19 | 0.010 | 0.013 | 0.003 | Balance |

| Sample | Open Circuit Potential vs. SCE (mV) | |||||||

|---|---|---|---|---|---|---|---|---|

| 1 h | 25 h | 49 h | 73 h | 97 h | 121 h | 145 h | 169 h | |

| HT1 | −135 | −130 | −61 | −49 | −22 | 28 | 61 | 50 |

| HT2 | −165 | −86 | −45 | 3 | 11 | 29 | 43 | 86 |

| REF | −129 | −90 | −120 | −45 | −28 | −19 | −25 | −10 |

| Sample | Corrosion Rate Cr (nm year−1) | Corrosion Potential Ecor (mV vs. SCE) | Polarization Resistance Rp (kΩ cm2) | |||

|---|---|---|---|---|---|---|

| 1 h | 169 h | 1 h | 169 h | 1 h | 169 h | |

| HT1 | 675 | 790 | −166 | −181 | 110 | 52 |

| HT2 | 1967 | 1565 | −255 | −190 | 102 | 147 |

| REF | 1234 | 165 | −206 | −47 | 94 | 408 |

| Chemical Composition (wt. %) | ||||||

|---|---|---|---|---|---|---|

| O | Ni | Si | Cl | Cr | Mn | Fe |

| 16.45 | 4.19 | 0.98 | 0.48 | 39.09 | 8.23 | 30.58 |

| Sample | Maximal Value of Current Density for Activation Loop Jp (A.cm−2) | Maximal Value of Current Density for Reactivation Loop Jr (A.cm−2) | Current Density Fraction Jr/Jp (%) | Classification |

|---|---|---|---|---|

| HT1 | 2.31 × 10−2 | 1.38 × 10−4 | 0.60 | <2%, no grain boundary sensitization |

| HT2 | 2.48 × 10−2 | 1.00 × 10−4 | 0.40 | <2%, no grain boundary sensitization |

| REF | 2.89 × 10−2 | 4.94 × 10−4 | 1.7 | <2%, no grain boundary sensitization |

| Sample | Contact Angle (°) | Surface Energy (mJ.m−2) |

|---|---|---|

| REF (SLM) | 43.86 ± 7.26 | 57.23 ± 4.45 |

| Wrought | 88.19 ± 4.99 | 30.37 ± 3.86 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hlinka, J.; Kraus, M.; Hajnys, J.; Pagac, M.; Petrů, J.; Brytan, Z.; Tański, T. Complex Corrosion Properties of AISI 316L Steel Prepared by 3D Printing Technology for Possible Implant Applications. Materials 2020, 13, 1527. https://doi.org/10.3390/ma13071527

Hlinka J, Kraus M, Hajnys J, Pagac M, Petrů J, Brytan Z, Tański T. Complex Corrosion Properties of AISI 316L Steel Prepared by 3D Printing Technology for Possible Implant Applications. Materials. 2020; 13(7):1527. https://doi.org/10.3390/ma13071527

Chicago/Turabian StyleHlinka, Josef, Martin Kraus, Jiri Hajnys, Marek Pagac, Jana Petrů, Zbigniew Brytan, and Tomasz Tański. 2020. "Complex Corrosion Properties of AISI 316L Steel Prepared by 3D Printing Technology for Possible Implant Applications" Materials 13, no. 7: 1527. https://doi.org/10.3390/ma13071527

APA StyleHlinka, J., Kraus, M., Hajnys, J., Pagac, M., Petrů, J., Brytan, Z., & Tański, T. (2020). Complex Corrosion Properties of AISI 316L Steel Prepared by 3D Printing Technology for Possible Implant Applications. Materials, 13(7), 1527. https://doi.org/10.3390/ma13071527