Development of Thermal Resistant FDM Printed Blends. The Preparation of GPET/PC Blends and Evaluation of Material Performance

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Sample Preparation

2.3. Measurements and Characterization

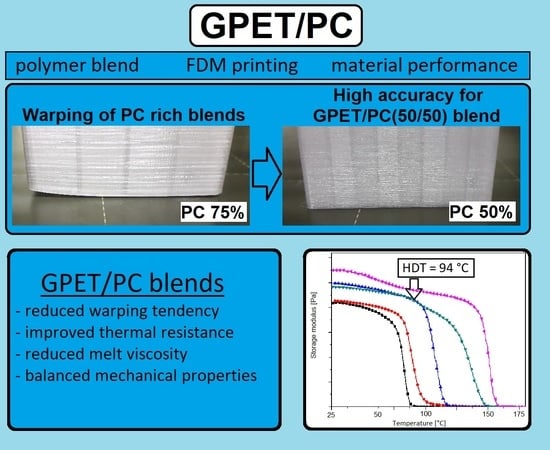

3. Results and Discussion

3.1. Mechanical Performance—Tensile/Flexural Measurements, Notched Izod Impact Tests

3.2. Thermomechanical Ealuation—DMTA Measurements, HDT/VST Tests

3.3. Rheological Analysis—Rotational Rheometer Measurements

3.4. Structure Analysis—SEM Observations

3.5. Geometry Deviations Analysis—Optical Scanning (Structured Light Method)

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Bärwinkel, S.; Seidel, A.; Hobeika, S.; Hufen, R.; Mörl, M.; Altstädt, V. Morphology formation in PC/ABS blends during thermal processing and the effect of the viscosity ratio of blend partners. Materials 2016, 9, 659. [Google Scholar] [CrossRef] [Green Version]

- Chiu, H.T.; Huang, J.K.; Kuo, M.T.; Huang, J.H. Characterisation of PC/ABS blend during 20 reprocessing cycles and subsequent functionality recovery by virgin additives. J. Polym. Res. 2018, 25, 124. [Google Scholar] [CrossRef]

- Balart, R.; López, J.; García, D.; Dolores Salvador, M. Recycling of ABS and PC from electrical and electronic waste. Effect of miscibility and previous degradation on final performance of industrial blends. Eur. Polym. J. 2005, 41, 2150–2160. [Google Scholar] [CrossRef]

- Seelig, T.; Giessen, E. Effects of microstructure on crack tip fields and fracture toughness in PC/ABS polymer blends. Int. J. Fract. 2007, 145, 205–222. [Google Scholar] [CrossRef] [Green Version]

- Öztürk, S.; Ertürk, S.; Yılmazoğlu, G.; Haliloğlu, B.; Okar, H.İ. The weathering study of PC/ASA alloy for automotive exterior applications. J. Turk. Chem. Soc. Sect. A Chem. 2018, 5, 61–72. [Google Scholar] [CrossRef] [Green Version]

- Kang, M.S.; Kim, C.K.; Lee, J.W. PC/ASA blends having enhanced interfacial and mechanical properties. Korea Aust. Rheol. J. 2006, 18, 1–8. [Google Scholar]

- Carrot, C.; Mbarek, S.; Jaziri, M.; Chalamet, Y.; Raveyre, C.; Prochazka, F. Immiscible blends of PC and PET, current knowledge and new results: Rheological properties. Macromol. Mater. Eng. 2007, 292, 693–706. [Google Scholar] [CrossRef]

- Mendes, L.C.; Pereira, P.S.C. Solid State Polymerization: Its action on thermal and rheological properties of PET/PC reactive blends. Polímeros Ciência e Tecnol. 2013, 23, 298–304. [Google Scholar] [CrossRef] [Green Version]

- Pesetski, S.S.; Filimonov, O.V.; Koval, V.N.; Golubovich, V.V. Structural features and relaxation properties of PET/PC blends containing impact strength modifier and chain extender. Express Polym. Lett. 2009, 3, 606–614. [Google Scholar] [CrossRef]

- Marchese, P.; Celli, A.; Fiorini, M.; Gabaldi, M. Effects of annealing on crystallinity and phase behaviour of PET/PC block copolymers. Eur. Polym. J. 2003, 39, 1081–1089. [Google Scholar] [CrossRef]

- Santos, J.M.R.C.A.; Guthrie, J.T. Polymer blends: The PC-PBT case. J. Mater. Chem. 2006, 16, 237–245. [Google Scholar] [CrossRef]

- Lin, G.-P.; Lin, L.; Wang, X.-L.; Chen, L.; Wang, Y.-Z. PBT/PC Blends Compatibilized and Toughened via Copolymers in Situ Formed by MgO-Catalyzed Transesterification. Ind. Eng. Chem. Res. 2015, 54, 1282–1291. [Google Scholar] [CrossRef]

- Guo, Y.; Sun, S.; Zhang, H. Modification of the core-shell ratio to prepare PB-g-(MMA-co-St-co-GMA) particle-toughened poly(butylene terephthalate) and polycarbonate blends with balanced stiffness and toughness. RSC Adv. 2014, 4, 58880–58887. [Google Scholar] [CrossRef]

- Song, Q.; Wen, H.; de Claville Christiansen, J.; Yu, D.; Chen, C.; Jiang, S. Analysis of structure transition and compatibility of PTT/PC blend without transesterification. Chin. J. Polym. Sci. 2016, 34, 1172–1182. [Google Scholar] [CrossRef]

- Na, S.K.; Kong, B.G.; Choi, C.; Jang, M.K.; Nah, J.W.; Kim, J.G.; Jo, B.W. Transesterification and compatibilization in the blends of bisphenol-A polycarbonate and poly(trimethylene terephthalate). Macromol. Res. 2005, 13, 88–95. [Google Scholar] [CrossRef]

- Diederichs, E.V.; Picard, M.C.; Chang, B.P.; Misra, M.; Mielewski, D.F.; Mohanty, A.K. Strategy to improve printability of renewable resource-based engineering plastic tailored for fdm applications. ACS Omega 2019, 4, 20297–20307. [Google Scholar] [CrossRef]

- Yuryev, Y.; Mohanty, A.K.; Misra, M. Novel biocomposites from biobased PC/PLA blend matrix system for durable applications. Compos. Part B Eng. 2017, 130, 158–166. [Google Scholar] [CrossRef]

- Zhou, Y.; Luo, L.; Liu, W.; Zeng, G.; Chen, Y. Preparation and Characteristic of PC/PLA/TPU Blends by Reactive Extrusion. Adv. Mater. Sci. Eng. 2015, 2015, 393582. [Google Scholar] [CrossRef] [Green Version]

- Lin, L.; Deng, C.; Wang, Y. Improving the impact property and heat-resistance of PLA/PC blends through coupling molecular chains at the interface. Polym. Adv. Technol. 2015, 26, 1247–1258. [Google Scholar] [CrossRef]

- Yuryev, Y.; Mohanty, A.K.; Misra, M. Novel super-toughened bio-based blend from polycarbonate and poly(lactic acid) for durable applications. RSC Adv. 2016, 6, 105094–105104. [Google Scholar] [CrossRef]

- Lin, L.; Deng, C.; Lin, G.-P.; Wang, Y.-Z. Super Toughened and High Heat-Resistant Poly(Lactic Acid) (PLA)-Based Blends by Enhancing Interfacial Bonding and PLA Phase Crystallization. Ind. Eng. Chem. Res. 2015, 54, 5643–5655. [Google Scholar] [CrossRef]

- Sako, T.; Date, J.; Hagi, M.; Hiraoka, T.; Matsuoka, S.; Yamaguchi, M. Anomalous viscosity decrease of polycarbonate by addition of polystyrene. Polymer 2019, 170, 135–141. [Google Scholar] [CrossRef]

- Motong, N.; Thongyai, S.; Clarke, N. Melt viscosity reduction of polycarbonate with low molar mass liquid crystals. J. Appl. Polym. Sci. 2008, 107, 1108–1115. [Google Scholar] [CrossRef]

- Khunprasert, S.; Thongyai, S.; Chinsirikul, W.; Wacharawichanant, S. Effect of low-molar-mass liquid crystal on the melt processing conditions of polycarbonate using single screw extruder. J. Appl. Polym. Sci. 2009, 113, 752–756. [Google Scholar] [CrossRef]

- Grzelka, M.; Budzik, G.; Wieczorowski, M.; Jakubowicz, M.; Marciniak-Podsadna, L.; Gapiński, B.; Śremski, K. Reconstruction of a human skeleton using Reverse Engineering and Rapid Prototyping. Mechanik 2015, 974/084–974/090. [Google Scholar] [CrossRef]

- Grzelka, M.; Jakubowicz, M.; Gaca, M. Reconstruction of spine geometry using computed tomography and optical 3D scanner. Mechanik 2015, 974/091–974/096. [Google Scholar] [CrossRef] [Green Version]

- Gapinski, B.; Janicki, P.; Marciniak-Podsadna, L.; Jakubowicz, M. Application of the computed tomography to control parts made on additive manufacturing process. Procedia Eng. 2016, 149, 105–121. [Google Scholar] [CrossRef] [Green Version]

- Grzelka, M.; Jakubowicz, M.; Marciniak-Podsadna, L.; Śremski, K. Analysis of 3D geometry reconstruction accuracy of human skeleton elements on the basis of measurement on medical CT and optical 3D scanner. Mechanik 2015, 974/097–974/102. [Google Scholar] [CrossRef] [Green Version]

- Maszybrocka, J.; Gapiński, B.; Stwora, A.; Skrabalak, G. NDT Porosity Evaluation of AlSi10Mg Samples Fabricated by Selective Laser Sintering Method. Lect. Notes Mech. Eng. 2019, 5, 270–284. [Google Scholar]

- Maszybrocka, J.; Gapiński, B.; Dworak, M.; Skrabalak, G.; Stwora, A. The manufacturability and compression properties of the Schwarz Diamond type Ti6Al4V cellular lattice fabricated by selective laser melting. Int. J. Adv. Manuf. Technol. 2019, 105, 3411–3425. [Google Scholar] [CrossRef] [Green Version]

- Maszybrocka, J.; Stwora, A.; Gapiński, B.; Skrabalak, G.; Karolus, M. Morphology and surface topography of Ti6Al4V lattice structure fabricated by selective laser sintering. Bull. Pol. Acad. Sci. Tech. Sci. 2017, 65, 85–92. [Google Scholar] [CrossRef] [Green Version]

- Lam, K.L.; Bakar, A.A.; Mohd Ishak, Z.A.; Karger-Kocsis, J. Amorphous Copolyester/Polyoxymethylene Blends: Thermal, Mechanical and Morphological Properties. Elastom. und Kunststoffe 2004, 57, 570–578. [Google Scholar]

- Chen, T.; Zhang, J. Surface hydrophilic modification of acrylonitrile-butadiene-styrene terpolymer by poly(ethylene glycol-co-1,4-cyclohexanedimethanol terephthalate): Preparation, characterization, and properties studies. Appl. Surf. Sci. 2016, 388, 133–140. [Google Scholar] [CrossRef]

- Cicala, G.; Ognibene, G.; Portuesi, S.; Blanco, I.; Rapisarda, M.; Pergolizzi, E.; Recca, G. Comparison of Ultem 9085 used in fused deposition modelling (FDM) with polytherimide blends. Materials 2018, 11, 285. [Google Scholar] [CrossRef] [Green Version]

- Yu, Z.Z.; Lei, M.; Ou, Y.; Yang, G. Toughening of polyethylene terephthalate/amorphous copolyester blends with a maleated thermoplastic elastomer. J. Appl. Polym. Sci. 2003, 89, 797–805. [Google Scholar] [CrossRef]

- Papadopoulou, C.P.; Kalfoglou, N.K. Compatibility behaviour of blends of poly(ethylene terephthalate) with an amorphous copolyester. Polymer 1997, 38, 631–637. [Google Scholar] [CrossRef]

- Franciszczak, P.; Piesowicz, E.; Kalniņš, K. Manufacturing and properties of r-PETG/PET fibre composite—Novel approach for recycling of PETG plastic scrap into engineering compound for injection moulding. Compos. Part B Eng. 2018, 154, 430–438. [Google Scholar] [CrossRef]

- Szostak, M. Mechanical Properties of PETG/rPETG Blends Prepared by Injection Moulding Method with TMR Dynamic Mixer. Mech. Czas. Tech. 2009, 3, 331–336. [Google Scholar]

- Latko-Durałek, P.; Dydek, K.; Boczkowska, A. Thermal, Rheological and Mechanical Properties of PETG/rPETG Blends. J. Polym. Environ. 2019, 27, 2600–2606. [Google Scholar] [CrossRef] [Green Version]

- Chen, L.; Zhang, X.; Li, H.; Li, B.; Wang, K.; Zhang, Q.; Fu, Q. Superior tensile extensibility of PETG/PC amorphous blends induced via uniaxial stretching. Chin. J. Polym. Sci. 2011, 29, 125–132. [Google Scholar] [CrossRef]

- Zhang, X.; Wang, K.; Li, B.; Chen, F.; Fu, Q. Brittle-ductile transition in the PETG/PC blends by adding PTW elastomer. Polym. Adv. Technol. 2009, 21, 401–407. [Google Scholar] [CrossRef]

- Andrzejewski, J.; Przyszczypkowski, P.; Szostak, M. Development and characterization of poly(ethylene terephthalate) based injection molded self-reinforced composites. Direct reinforcement by overmolding the composite inserts. Mater. Des. 2018, 153, 273–286. [Google Scholar] [CrossRef]

- Mbarek, S.; Jaziri, M.; Carrot, C. Recycling poly(ethylene terephtalate) wastes: Properties of poly(ethylene terephtalate)/polycarbonate blends and the effect of a transesterification catalyst. Polym. Eng. Sci. 2006, 46, 1378–1386. [Google Scholar] [CrossRef]

- Takemori, M.T. Towards an understanding of the heat distortion temperature of thermoplastics. Polym. Eng. Sci. 1979, 19, 1104–1109. [Google Scholar] [CrossRef]

- Gonzalez-Garzon, M.; Shahbikian, S.; Huneault, M.A. Properties of mineral filled poly(lactic acid)/poly(methyl methacrylate) blend. J. Appl. Polym. Sci. 2019, 136, 1–11. [Google Scholar] [CrossRef]

- Jain, S.; Reddy, M.M.; Mohanty, A.K.; Misra, M.; Ghosh, A.K. A new biodegradable flexible composite sheet from poly(lactic acid)/poly(e-caprolactone) blends and micro-talc. Macromol. Mater. Eng. 2010, 295, 750–762. [Google Scholar] [CrossRef]

- Hao, X.; Kaschta, J.; Pan, Y.; Liu, X.; Schubert, D.W. Intermolecular cooperativity and entanglement network in a miscible PLA/PMMA blend in the presence of nanosilica. Polymer 2016, 82, 57–65. [Google Scholar] [CrossRef]

- Jang, K.S. Mineral filler effect on the mechanics and flame retardancy of polycarbonate composites: Talc and kaolin. E-Polymers 2016, 16, 379–386. [Google Scholar] [CrossRef]

- Barczewski, M.; Mysiukiewicz, O.; Matykiewicz, D.; Skórczewska, K.; Lewandowski, K.; Andrzejewski, J.; Piasecki, A. Development of polylactide composites with improved thermomechanical properties by simultaneous use of basalt powder and a nucleating agent. Polym. Compos. 2020, 1–11. [Google Scholar] [CrossRef]

- Nagarajan, V.; Zhang, K.; Misra, M.; Mohanty, A.K. Overcoming the Fundamental Challenges in Improving the Impact Strength and Crystallinity of PLA Biocomposites: Influence of Nucleating Agent and Mold Temperature. ACS Appl. Mater. Interfaces 2015, 7, 11203–11214. [Google Scholar] [CrossRef]

- Balint, T.; Chang, B.P.; Mohanty, A.K.; Misra, M. Underutilized Agricultural Co-Product as a Sustainable Biofiller for Polyamide 6,6: Effect of Carbonization Temperature. Molecules 2020, 25, 1455. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Nagarajan, V.; Mohanty, A.K.; Misra, M. Biocomposites with Size-Fractionated Biocarbon: Influence of the Microstructure on Macroscopic Properties. ACS Omega 2016, 1, 636–647. [Google Scholar] [CrossRef] [PubMed]

- Qahtani, M.; Wu, F.; Misra, M.; Gregori, S.; Mielewski, D.F.; Mohanty, A.K. Experimental Design of Sustainable 3D Printed Poly(Lactic Acid) (PLA)/Biobased Poly(Butylene Succinate) (BioPBS) Blends via Fused Deposition Modelling. ACS Sustain. Chem. Eng. 2019, 7, 14460–14470. [Google Scholar] [CrossRef] [Green Version]

- Andrzejewski, J.; Skórczewska, K.; Klozinski, A. Improving the toughness and thermal resistance of polyoxymethylene/poly(lactic acid) blends: Evaluation of structure-properties correlation for reactive processing. Polymers 2020, 12, 307. [Google Scholar] [CrossRef] [Green Version]

- Codou, A.; Anstey, A.; Misra, M.; Mohanty, A.K. Novel compatibilized nylon-based ternary blends with polypropylene and poly(lactic acid): Morphology evolution and rheological behaviour. RSC Adv. 2018, 8, 15709–15724. [Google Scholar] [CrossRef] [Green Version]

- Andrzejewski, J.; Cheng, J.; Anstey, A.; Mohanty, A.K.; Misra, M. Development of Toughened Blends of Poly(lactic acid) (PLA) and Poly(butylene adipate-co-terephthalate) (PBAT) for 3D Printing Applications: Compatibilization Methods and Material Performance Evaluation. ACS Sustain. Chem. Eng. 2020. [Google Scholar] [CrossRef]

- Koslow, T. The Best Carbon Fiber 3D Printers & Filaments. Available online: https://all3dp.com/1/best-carbon-fiber-3d-printer-price/ (accessed on 20 March 2020).

- Wieczorowski, M.; Gapiński, B.; Grzelka, M.; Szostak, M.; Szymański, M. The use of photogrammetry in improving quality of workpieces after an injection molding process. Polimery/Polymers 2018, 63, 134–144. [Google Scholar] [CrossRef]

- Santana, L.; Lino Alves, J.; da Costa Sabino Netto, A. A study of parametric calibration for low cost 3D printing: Seeking improvement in dimensional quality. Mater. Des. 2017, 135, 159–172. [Google Scholar] [CrossRef]

- Fitzharris, E.R.; Watanabe, N.; Rosen, D.W.; Shofner, M.L. Effects of material properties on warpage in fused deposition modeling parts. Int. J. Adv. Manuf. Technol. 2018, 95, 2059–2070. [Google Scholar] [CrossRef]

- Panda, B.N.; Shankhwar, K.; Garg, A.; Jian, Z. Performance evaluation of warping characteristic of fused deposition modelling process. Int. J. Adv. Manuf. Technol. 2017, 88, 1799–1811. [Google Scholar] [CrossRef]

- Armillotta, A.; Bellotti, M.; Cavallaro, M. Warpage of FDM parts: Experimental tests and analytic model. Robot. Comput. Integr. Manuf. 2018, 50, 140–152. [Google Scholar] [CrossRef]

- Guerrero-De-Mier, A.; Espinosa, M.M.; Domínguez, M. Bricking: A New Slicing Method to Reduce Warping. Procedia Eng. 2015, 132, 126–131. [Google Scholar] [CrossRef] [Green Version]

- Shahrain, M.; Didier, T.; Lim, G.K.; Qureshi, A.J. Fast Deviation Simulation for “Fused Deposition Modeling” Process. Procedia CIRP 2016, 43, 327–332. [Google Scholar] [CrossRef] [Green Version]

| Sample | Tensile Test | Flexural Test | Izod Test | |||

|---|---|---|---|---|---|---|

| Modulus [MPa] | Strength [MPa] | Elongation at Break [%] | Modulus [MPa] | Strength [MPa] | Impact Strength kJ/m2 | |

| Unmodified blends | ||||||

| GPET | 1490 ± 49 | 31.4 ± 2.1 | 3.0 ± 0.3 | 1720 ± 128 | 53.4 ± 5.2 | 1.0 ± 0.2 (1.7 ± 0.9) * |

| GPET/PC(75/25) | 1610 ± 29 | 28.8 ± 5.0 | 2.2 ± 0.6 | 1730 ± 49 | 52.5 ± 1.2 | 2.8 ± 0.9 (1.1 ± 0.2) |

| GPET/PC(50/50) | 1900 ± 177 | 40.3 ± 3.5 | 2.8 ± 0.2 | 2150 ± 28 | 64.0 ± 2.8 | 2.5 ± 0.5 (1.8 ± 0.5) |

| GPET/PC(25/75) | 1990 ± 159 | 41.2 ± 7.3 | 2.7 ± 0.2 | 2230 ± 230 | 67.1 ± 4.7 | 4.5 ± 0.8 (4.2 ± 0.1) |

| PC-injection molded | 2385 ± 41 | 58.5 ± 0.6 | 37.8 ± 8.0 | 2350 ± 57 | 72.3 ± 1.7 | 35.0 ± 4.7 |

| PET/PC(50/50)-ref. | 2320 ± 103 | 51.3 ± 2.9 | 2.7 ± 0.3 | 2460 ± 85 | 73.0 ± 2.7 | 4.1 ± 0.3 (1.8 ± 0.5) |

| Talc composites (10%) | ||||||

| GPET/PC(50/50)-T10 | 2660 ± 183 | 27.0 ± 3.7 | 1.1 ± 0.1 | 3090 ± 43 | 34.1 ± 0.8 | 1.4 ± 1.1 (1.0 ± 0.5) |

| PET/PC(50/50)-T10 | 2340 ± 71 | 40.6 ± 1.2 | 2.7 ± 0.3 | 2390 ± 74 | 63.8 ± 2.7 | 2.3 ± 0.1 (1.5 ± 0.3) |

| Sample | HDT (1.8 MPa) [°C] | VST (10 N) [°C] |

|---|---|---|

| Unmodified blends | ||

| GPET | 73.3 ± 0.4 | 79.6 ± 0.9 |

| GPET/PC(75/25) | 75.0 ± 1.3 | 99.3 ± 0.6 |

| GPET/PC(50/50) | 94.5 ± 0.7 | 109.0 ± 0.8 |

| GPET/PC(25/75) | 116.5 ± 0.5 | 136.9 ± 0.4 |

| PC-injection molded | 120.3 ± 0.9 | 148.3 ± 0.6 |

| PET/PC(50/50)-ref. | 101.6 ± 4.2 | 140.5 ± 0.6 |

| Talc composites (10%) | ||

| GPET/PC(50/50)-T10 | 88.6 ± 0.3 | 109.9 ± 0.4 |

| PET/PC(50/50)-T10 | 104.5 ± 1.8 | 143.6 ± 0.6 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Andrzejewski, J.; Marciniak-Podsadna, L. Development of Thermal Resistant FDM Printed Blends. The Preparation of GPET/PC Blends and Evaluation of Material Performance. Materials 2020, 13, 2057. https://doi.org/10.3390/ma13092057

Andrzejewski J, Marciniak-Podsadna L. Development of Thermal Resistant FDM Printed Blends. The Preparation of GPET/PC Blends and Evaluation of Material Performance. Materials. 2020; 13(9):2057. https://doi.org/10.3390/ma13092057

Chicago/Turabian StyleAndrzejewski, Jacek, and Lidia Marciniak-Podsadna. 2020. "Development of Thermal Resistant FDM Printed Blends. The Preparation of GPET/PC Blends and Evaluation of Material Performance" Materials 13, no. 9: 2057. https://doi.org/10.3390/ma13092057

APA StyleAndrzejewski, J., & Marciniak-Podsadna, L. (2020). Development of Thermal Resistant FDM Printed Blends. The Preparation of GPET/PC Blends and Evaluation of Material Performance. Materials, 13(9), 2057. https://doi.org/10.3390/ma13092057