Ultra-Stretchable and Self-Healing Anti-Freezing Strain Sensors Based on Hydrophobic Associated Polyacrylic Acid Hydrogels

Abstract

:1. Introduction

2. Experimental Section

2.1. Materials

2.2. Synthesis of HAGx Hydrogels

2.3. Characterizations

3. Results and Discussion

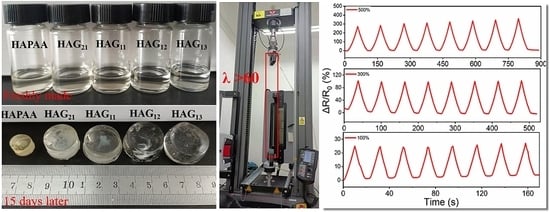

3.1. Anti-Freezing Property and Moisture Stability

3.2. Adhesive Property and Transparency

3.3. Ultra-Stretchable Properties

3.4. Self-Healing Property

3.5. Strain Sensors

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Lei, Z.; Wang, Q.; Sun, S.; Zhu, W.; Wu, P. A Bioinspired Mineral Hydrogel as a Self-Healable, Mechanically Adaptable Ionic Skin for Highly Sensitive Pressure Sensing. Adv. Mater. 2017, 29, 1700321. [Google Scholar] [CrossRef]

- Jian, Y.; Handschuh-Wang, S.; Zhang, J.; Lu, W.; Zhou, X.; Chen, T. Biomimetic Anti-Freezing Polymeric Hydrogels: Keeping Soft-Wet Materials Active in Cold Environments. Mater. Horiz. 2021, 8, 351–369. [Google Scholar] [CrossRef]

- Bao, Z.; Chen, X. Flexible and Stretchable Devices. Adv. Mater. 2016, 28, 4177–4179. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Lee, K.Y.; Mooney, D.J. Alginate: Properties and Biomedical Applications. Prog. Polym. Sci. 2012, 37, 106–126. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Zheng, Y.; Liang, Y.; Zhang, D.; Zhou, Z.; Li, J.; Sun, X.; Liu, Y.N. Fabrication of Injectable Cus Nanocomposite Hydrogels Based on Ucst-Type Polysaccharides for Nir-Triggered Chemo-Photothermal Therapy. Chem. Commun. 2018, 54, 13805–13808. [Google Scholar] [CrossRef]

- Jia, H.; Li, Z.; Wang, X.; Zheng, Z. Facile Functionalization of a Tetrahedron-Like Peg Macromonomer-Based Fluorescent Hydrogel with High Strength and Its Heavy Metal Ion Detection. J. Mater. Chem. A 2015, 3, 1158–1163. [Google Scholar] [CrossRef]

- Guo, Y.; Zhou, X.; Zhao, F.; Bae, J.; Rosenberger, B.; Yu, G. Synergistic Energy Nanoconfinement and Water Activation in Hydrogels for Efficient Solar Water Desalination. ACS Nano 2019, 13, 7913–7919. [Google Scholar] [CrossRef]

- Cipriano, B.H.; Banik, S.J.; Sharma, R.; Rumore, D.; Hwang, W.; Briber, R.M.; Raghavan, S.R. Superabsorbent Hydrogels That Are Robust and Highly Stretchable. Macromolecules 2014, 47, 4445–4452. [Google Scholar] [CrossRef]

- Wan, C.; Chen, G.; Fu, Y.; Wang, M.; Matsuhisa, N.; Pan, S.; Pan, L.; Yang, H.; Wan, Q.; Zhu, L.; et al. An Artificial Sensory Neuron with Tactile Perceptual Learning. Adv. Mater. 2018, 30, 1801291. [Google Scholar] [CrossRef]

- Park, S.; Vosguerichian, M.; Bao, Z. A Review of Fabrication and Applications of Carbon Nanotube Film-Based Flexible Electronics. Nanoscale 2013, 5, 1727–1752. [Google Scholar] [CrossRef]

- Bae, J.; Li, Y.; Zhao, F.; Zhou, X.; Ding, Y.; Yu, G. Designing 3d Nanostructured Garnet Frameworks for Enhancing Ionic Conductivity and Flexibility in Composite Polymer Electrolytes for Lithium Batteries. Energy Storage Mater. 2018, 15, 46–52. [Google Scholar] [CrossRef]

- Liu, B.; Bo, R.; Taheri, M.; Di Bernardo, I.; Motta, N.; Chen, H.; Tsuzuki, T.; Yu, G.; Tricoli, A. Metal-Organic Frameworks/Conducting Polymer Hydrogel Integrated Three-Dimensional Free-Standing Monoliths as Ultrahigh Loading Li-S Battery Electrodes. Nano Lett. 2019, 19, 4391–4399. [Google Scholar] [CrossRef]

- Peng, S.; Zhang, L.; Zhang, C.; Ding, Y.; Guo, X.; He, G.; Yu, G. Gradient-Distributed Metal-Organic Framework-Based Porous Membranes for Nonaqueous Redox Flow Batteries. Adv. Energy Mater. 2018, 8, 1802533. [Google Scholar] [CrossRef]

- Lu, C.; Chen, X. All-Temperature Flexible Supercapacitors Enabled by Antifreezing and Thermally Stable Hydrogel Electrolyte. Nano Lett. 2020, 20, 1907–1914. [Google Scholar] [CrossRef]

- Pan, L.; Chortos, A.; Yu, G.; Wang, Y.; Isaacson, S.; Allen, R.; Shi, Y.; Dauskardt, R.; Bao, Z. An Ultra-Sensitive Resistive Pressure Sensor Based on Hollow-Sphere Microstructure Induced Elasticity in Conducting Polymer Film. Nat. Commun. 2014, 5, 3002. [Google Scholar] [CrossRef] [Green Version]

- Boutry, C.M.; Beker, L.; Kaizawa, Y.; Vassos, C.; Tran, H.; Hinckley, A.C.; Pfattner, R.; Niu, S.; Li, J.; Claverie, J.; et al. Biodegradable and Flexible Arterial-Pulse Sensor for the Wireless Monitoring of Blood Flow. Nat. Biomed. Eng. 2019, 3, 47–57. [Google Scholar] [CrossRef] [PubMed]

- Zhao, F.; Zhou, X.; Liu, Y.; Shi, Y.; Dai, Y.; Yu, G. Super Moisture-Absorbent Gels for All-Weather Atmospheric Water Harvesting. Adv. Mater. 2019, 31, 1806446. [Google Scholar] [CrossRef] [PubMed]

- Zhao, F.; Zhou, X.; Shi, Y.; Qian, X.; Alexander, M.; Zhao, X.; Mendez, S.; Yang, R.; Qu, L.; Yu, G. Highly Efficient Solar Vapour Generation Via Hierarchically Nanostructured Gels. Nat. Nanotechnol. 2018, 13, 489–495. [Google Scholar] [CrossRef]

- Wu, X.; Han, Y.; Zhang, X.; Zhou, Z.; Lu, C. Large-Area Compliant, Low-Cost, and Versatile Pressure-Sensing Platform Based on Microcrack-Designed Carbon Black@Polyurethane Sponge for Human-Machine Interfacing. Adv. Funct. Mater. 2016, 26, 6246–6256. [Google Scholar] [CrossRef]

- Glavin, N.R.; Rao, R.; Varshney, V.; Bianco, E.; Ajayan, P.M. Emerging Applications of Elemental 2D Materials. Adv. Mater. 2020, 32, 1904302. [Google Scholar] [CrossRef]

- Gogurla, N.; Roy, B.; Min, K.; Park, J.Y.; Kim, S. A Skin-Inspired, Interactive, and Flexible Optoelectronic Device with Hydrated Melanin Nanoparticles in a Protein Hydrogel–Elastomer Hybrid. Adv. Mater. Technol. 2020, 5, 1900936. [Google Scholar] [CrossRef]

- Shao, T.; Wu, J.; Zhang, Y.; Cheng, Y. Highly Sensitive Conformal Pressure Sensing Coatings Based on Thermally Expandable Microspheres. Adv. Mater. Technol. 2020, 5, 2000032. [Google Scholar] [CrossRef]

- Lv, J.; Chen, J.; Lee, P.S. Sustainable Wearable Energy Storage Devices Self-Charged by Human-Body Bioenergy. SusMat 2021, 1, 285–302. [Google Scholar] [CrossRef]

- Pandey, P.K.; Ulla, H.; Satyanarayan, M.N.; Rawat, K.; Gaur, A.; Gawali, S.; Hassan, P.A.; Bohidar, H.B. Fluorescent MoS2 Quantum Dot–DNA Nanocomposite Hydrogels for Organic Light-Emitting Diodes. ACS Appl. Nano Mater. 2020, 3, 1289–1297. [Google Scholar] [CrossRef]

- Le, T.H.; Choi, Y.; Kim, S.; Lee, U.; Heo, E.; Lee, H.; Chae, S.; Im, W.B.; Yoon, H. Highly Elastic and >200% Reversibly Stretchable Down-Conversion White Light-Emitting Diodes Based on Quantum Dot Gel Emitters. Adv. Opt. Mater. 2020, 8, 1901972. [Google Scholar] [CrossRef]

- He, Z.; Yuan, W. Adhesive, Stretchable, and Transparent Organohydrogels for Antifreezing, Antidrying, and Sensitive Ionic Skins. ACS Appl. Mater. Inter. 2021, 13, 1474–1485. [Google Scholar] [CrossRef] [PubMed]

- He, P.; Wu, J.; Pan, X.; Chen, L.; Liu, K.; Gao, H.; Wu, H.; Cao, S.; Huang, L.; Ni, Y. Anti-Freezing and Moisturizing Conductive Hydrogels for Strain Sensing and Moist-Electric Generation Applications. J. Mater. Chem. A 2020, 8, 3109–3118. [Google Scholar] [CrossRef]

- Jian, Y.; Wu, B.; Le, X.; Liang, Y.; Zhang, Y.; Zhang, D.; Zhang, L.; Lu, W.; Zhang, J.; Chen, T. Antifreezing and Stretchable Organohydrogels as Soft Actuators. Research 2019, 6, 2384347. [Google Scholar] [CrossRef] [Green Version]

- Fan, X.; Zhou, W.; Chen, Y.; Yan, L.; Fang, Y.; Liu, H. An Antifreezing/Antiheating Hydrogel Containing Catechol Derivative Urushiol for Strong Wet Adhesion to Various Substrates. ACS Appl. Mater. Inter. 2020, 12, 32031–32040. [Google Scholar] [CrossRef]

- Muthukumar, M. Theory of Counter-Ion Condensation on Flexible Polyelectrolytes: Adsorption Mechanism. J. Chem. Phys. 2004, 120, 9343–9350. [Google Scholar] [CrossRef]

- Zhang, X.F.; Ma, X.; Hou, T.; Guo, K.; Yin, J.; Wang, Z.; Shu, L.; He, M.; Yao, J. Inorganic Salts Induce Thermally Reversible and Anti-Freezing Cellulose Hydrogels. Angew Chem. Int. Ed. Engl. 2019, 58, 7366–7370. [Google Scholar] [CrossRef]

- Lou, D.; Wang, C.; He, Z.; Sun, X.; Luo, J.; Li, J. Robust Organohydrogel with Flexibility and Conductivity across the Freezing and Boiling Temperatures of Water. Chem. Commun. 2019, 55, 8422–8425. [Google Scholar] [CrossRef]

- Morelle, X.P.; Illeperuma, W.R.; Tian, K.; Bai, R.; Suo, Z.; Vlassak, J.J. Highly Stretchable and Tough Hydrogels Below Water Freezing Temperature. Adv. Mater. 2018, 30, 1801541. [Google Scholar] [CrossRef] [PubMed]

- Liao, H.; Guo, X.; Wan, P.; Yu, G. Conductive Mxene Nanocomposite Organohydrogel for Flexible, Healable, Low-Temperature Tolerant Strain Sensors. Adv. Funct. Mater. 2019, 29, 1904507. [Google Scholar] [CrossRef]

- Pan, X.; Wang, Q.; Guo, R.; Ni, Y.; Liu, K.; Ouyang, X.; Chen, L.; Huang, L.; Cao, S.; Xie, M. An Integrated Transparent, Uv-Filtering Organohydrogel Sensor Via Molecular-Level Ion Conductive Channels. J. Mater. Chem. A 2019, 7, 4525–4535. [Google Scholar] [CrossRef]

- Han, L.; Liu, K.; Wang, M.; Wang, K.; Fang, L.; Chen, H.; Zhou, J.; Lu, X. Mussel-Inspired Adhesive and Conductive Hydrogel with Long-Lasting Moisture and Extreme Temperature Tolerance. Adv. Funct. Mater. 2018, 28, 1704195. [Google Scholar] [CrossRef]

- Xia, Y.; Wu, Y.; Yu, T.; Xue, S.; Guo, M.; Li, J.; Li, Z. Multifunctional Glycerol-Water Hydrogel for Biomimetic Human Skin with Resistance Memory Function. ACS Appl. Mater. Inter. 2019, 11, 21117–21125. [Google Scholar] [CrossRef]

- Rong, Q.; Lei, W.; Chen, L.; Yin, Y.; Zhou, J.; Liu, M. Anti-Freezing, Conductive Self-Healing Organohydrogels with Stable Strain-Sensitivity at Subzero Temperatures. Angew Chem. Int. Ed. Engl. 2017, 56, 14159–14163. [Google Scholar] [CrossRef]

- Phadke, A.; Zhang, C.; Arman, B.; Hsu, C.C.; Mashelkar, R.A.; Lele, A.K.; Tauber, M.J.; Arya, G.; Varghese, S. Rapid Self-Healing Hydrogels. Proc. Natl. Acad. Sci. USA 2012, 109, 4383–4388. [Google Scholar] [CrossRef] [Green Version]

- Chen, J.; Peng, Q.; Thundat, T.; Zeng, H. Stretchable, Injectable, and Self-Healing Conductive Hydrogel Enabled by Multiple Hydrogen Bonding toward Wearable Electronics. Chem. Mater. 2019, 31, 4553–4563. [Google Scholar] [CrossRef]

- Song, Y.; Liu, Y.; Qi, T.; Li, G.L. Towards Dynamic but Supertough Healable Polymers through Biomimetic Hierarchical Hydrogen-Bonding Interactions. Angew Chem. Int. Ed. Engl. 2018, 57, 13838–13842. [Google Scholar] [CrossRef] [PubMed]

- Gulyuz, U.; Okay, O. Self-Healing Poly (Acrylic Acid) Hydrogels with Shape Memory Behavior of High Mechanical Strength. Macromolecules 2014, 47, 6889–6899. [Google Scholar] [CrossRef]

- Gulyuz, U.; Okay, O. Self-Healing Polyacrylic Acid Hydrogels. Soft Matter 2013, 9, 10287–10293. [Google Scholar] [CrossRef]

- Tuncaboylu, D.C.; Sari, M.; Oppermann, W.; Okay, O. Tough and Self-Healing Hydrogels Formed Via Hydrophobic Interactions. Macromolecules 2011, 44, 4997–5005. [Google Scholar] [CrossRef]

- Rehage, H.; Hoffmann, H. Viscoelastic Surfactant Solutions: Model Systems for Rheological Research. Mol. Phys. 1991, 74, 933–973. [Google Scholar] [CrossRef]

- Hu, D.; Zeng, M.; Sun, Y.; Yuan, J.; Wei, Y. Cellulose-based Hydrogels Regulated by Supramolecularchemistry. SusMat 2021, 1, 266–284. [Google Scholar] [CrossRef]

- Gulyuz, U.; Okay, O. Self-Healing Poly (Acrylic Acid) Hydrogels: Effect of Surfactant. Macromol. Symp. 2015, 358, 232–238. [Google Scholar] [CrossRef]

- Guo, M.; Wu, Y.; Xue, S.; Xia, Y.; Yang, X.; Dzenis, Y.; Li, Z.; Lei, W.; Smith, A.T.; Sun, L. A Highly Stretchable, Ultra-Tough, Remarkably Tolerant, and Robust Self-Healing Glycerol-Hydrogel for a Dual-Responsive Soft Actuator. J. Mater. Chem. A 2019, 7, 25969–25977. [Google Scholar] [CrossRef]

- Su, G.; Cao, J.; Zhang, X.; Zhang, Y.; Yin, S.; Jia, L.; Guo, Q.; Zhang, X.; Zhang, J.; Zhou, T. Human-Tissue-Inspired Anti-Fatigue-Fracture Hydrogel for a Sensitive Wide-Range Human–Machine Interface. J. Mater. Chem. A 2020, 8, 2074–2082. [Google Scholar] [CrossRef]

- Zhang, Z.; Tang, L.; Chen, C.; Yu, H.; Bai, H.; Wang, L.; Qin, M.; Feng, Y.; Feng, W. Liquid Metal-Created Macroporous Composite Hydrogels with Self-Healing Ability and Multiple Sensations as Artificial Flexible Sensors. J. Mater. Chem. A 2021, 9, 875–883. [Google Scholar] [CrossRef]

- Liu, H.; Li, M.; Ouyang, C.; Lu, T.J.; Li, F.; Xu, F. Biofriendly, Stretchable, and Reusable Hydrogel Electronics as Wearable Force Sensors. Small 2018, 14, 1801711. [Google Scholar] [CrossRef]

- Abbott, A.P.; Harris, R.C.; Ryder, K.S.; D’Agostino, C.; Gladden, L.F.; Mantle, M.D. Glycerol Eutectics as Sustainable Solvent Systems. Green Chem. 2011, 13, 82–90. [Google Scholar] [CrossRef]

- Chen, N.-S. Formula for the Viscosity of a Glycerol−Water Mixture. Ind. Eng. Chem. Res. 2008, 47, 3285–3288. [Google Scholar] [CrossRef]

- Jeon, I.; Cui, J.; Illeperuma, W.R.; Aizenberg, J.; Vlassak, J.J. Extremely Stretchable and Fast Self-Healing Hydrogels. Adv. Mater. 2016, 28, 4678–4683. [Google Scholar] [CrossRef] [PubMed]

- Su, G.; Yin, S.; Guo, Y.; Zhao, F.; Guo, Q.; Zhang, X.; Zhou, T.; Yu, G. Balancing the mechanical, electronic, and self-healing properties in conductive self-healing hdyrogel for wearable sensor applications. Mater. Horiz. 2021, 8, 1795–1804. [Google Scholar] [CrossRef]

- Pan, X.; Wang, Q.; Ning, D.; Dai, L.; Liu, K.; Ni, Y.; Chen, L.; Huang, L. Ultraflexible Self-Healing Guar Gum-Glycerol Hydrogel with Injectable, Antifreeze, and Strain-Sensitive Properties. ACS Biomater. Sci. Eng. 2018, 4, 3397–3404. [Google Scholar] [CrossRef]

- Zhang, C.; Li, Y.; Kang, W.; Liu, X.; Wang, Q. Current Advances and Future Perspectives of Additive Manufacturing for Functional Polymeric Materials and Devices. SusMat 2021, 1, 127–147. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yin, S.; Su, G.; Chen, J.; Peng, X.; Zhou, T. Ultra-Stretchable and Self-Healing Anti-Freezing Strain Sensors Based on Hydrophobic Associated Polyacrylic Acid Hydrogels. Materials 2021, 14, 6165. https://doi.org/10.3390/ma14206165

Yin S, Su G, Chen J, Peng X, Zhou T. Ultra-Stretchable and Self-Healing Anti-Freezing Strain Sensors Based on Hydrophobic Associated Polyacrylic Acid Hydrogels. Materials. 2021; 14(20):6165. https://doi.org/10.3390/ma14206165

Chicago/Turabian StyleYin, Shuya, Gehong Su, Jiajun Chen, Xiaoyan Peng, and Tao Zhou. 2021. "Ultra-Stretchable and Self-Healing Anti-Freezing Strain Sensors Based on Hydrophobic Associated Polyacrylic Acid Hydrogels" Materials 14, no. 20: 6165. https://doi.org/10.3390/ma14206165

APA StyleYin, S., Su, G., Chen, J., Peng, X., & Zhou, T. (2021). Ultra-Stretchable and Self-Healing Anti-Freezing Strain Sensors Based on Hydrophobic Associated Polyacrylic Acid Hydrogels. Materials, 14(20), 6165. https://doi.org/10.3390/ma14206165