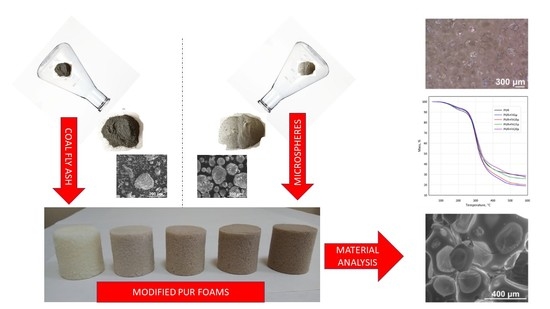

Fly Ash as an Eco-Friendly Filler for Rigid Polyurethane Foams Modification

Abstract

:1. Introduction

2. Materials and Methods

2.1. Characterization of the Fly Ash and Microsphere

2.2. PUR Foams Formulation

2.3. PUR Foams Characteristics

3. Results and Discussion

3.1. Cellular Structure

3.2. Chemical Structure and Mechanical Properties

3.3. Thermal Properties

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

References

- Wang, S.; Yang, X.; Li, Z.; Xu, X.; Liu, H.; Wang, D.; Min, H.; Shang, S. Novel eco-friendly maleopimaric acid based polysiloxane flame retardant and application in rigid polyurethane foam. Compos. Sci. Technol. 2020, 198, 108272. [Google Scholar] [CrossRef]

- Zhou, Y.; Bu, R.; Yi, L.; Sun, J. Heat transfer mechanism of concurrent flame spread over rigid polyurethane foam: Effect of ambient pressure and inclined angle. Int. J. Therm. Sci. 2020, 155, 106403. [Google Scholar] [CrossRef]

- Szycher, M. Szycher’s Handbook of Polyurethanes; CRC Press: Boca Raton, FL, USA, 1999. [Google Scholar]

- Stanzione, M.; Russo, V.; Oliviero, M.; Verdolotti, L.; Sorrentino, A.; Di Serio, M.; Tesser, R.; Iannace, S.; Lavorgna, M. Synthesis and characterization of sustainable polyurethane foams based on polyhydroxyls with different terminal groups. Polymer 2018, 149, 134–145. [Google Scholar] [CrossRef]

- Pagacz, J.; Hebda, E.; Michałowski, S.; Ozimek, J.; Sternik, D.; Pielichowski, K. Polyurethane foams chemically reinforced with POSS—Thermal degradation studies. Thermochim. Acta 2016, 642, 95–104. [Google Scholar] [CrossRef]

- Zhang, L.; Zhang, M.; Zhou, Y.; Hu, L. The study of mechanical behavior and flame retardancy of castor oil phosphate-based rigid polyurethane foam composites containing expanded graphite and triethyl phosphate. Polym. Degrad. Stab. 2013, 98, 2784–2794. [Google Scholar] [CrossRef]

- Członka, S.; Strąkowska, A.; Strzelec, K.; Kairyte, A.; Vaitkus, S. Composites of rigid polyurethane foams and silica powder filler enhanced with ionic liquid. Polym. Test. 2019, 75, 12–25. [Google Scholar] [CrossRef]

- Zatorski, W.; Brzozowski, Z.K.; Kolbrecki, A. New developments in chemical modification of fire-safe rigid polyurethane foams. Polym. Degrad. Stab. 2008, 93, 2071–2076. [Google Scholar] [CrossRef]

- Research, I. Global Rigid Polyurethane Foam (RPUF) Sales Market Report 2021. Available online: https://www.industryresearch.biz/global-rigid-polyurethane-foam-rpuf-sales-market-17401488 (accessed on 19 March 2021).

- Członka, S.; Sienkiewicz, N.; Strąkowska, A.; Strzelec, K. Keratin feathers as a filler for rigid polyurethane foams on the basis of soybean oil polyol. Polym. Test. 2018, 72, 32–45. [Google Scholar] [CrossRef]

- Qian, L.; Li, L.; Chen, Y.; Xu, B.; Qiu, Y. Quickly self-extinguishing flame retardant behavior of rigid polyurethane foams linked with phosphaphenanthrene groups. Compos. Part B Eng. 2019, 175, 107186. [Google Scholar] [CrossRef]

- Zieleniewska, M.; Leszczyński, M.K.; Szczepkowski, L.; Bryśkiewicz, A.; Krzyżowska, M.; Bień, K.; Ryszkowska, J. Development and applicational evaluation of the rigid polyurethane foam composites with egg shell waste. Polym. Degrad. Stab. 2016, 132, 78–86. [Google Scholar] [CrossRef]

- Baek, S.H.; Kim, J.H. Polyurethane composite foams including silicone-acrylic particles for enhanced sound absorption via increased damping and frictions of sound waves. Compos. Sci. Technol. 2020, 198, 108325. [Google Scholar] [CrossRef]

- Leszczyńska, M.; Ryszkowska, J.; Szczepkowski, L.; Kurańska, M.; Prociak, A.; Leszczyński, M.K.; Gloc, M.; Antos-Bielska, M.; Mizera, K. Cooperative effect of rapeseed oil-based polyol and egg shells on the structure and properties of rigid polyurethane foams. Polym. Test. 2020, 90, 106696. [Google Scholar] [CrossRef]

- Zhang, X.; Kim, Y.; Eberhardt, T.L.; Shmulsky, R. Lab-scale structural insulated panels with lignin-incorporated rigid polyurethane foams as core. Ind. Crop. Prod. 2019, 132, 292–300. [Google Scholar] [CrossRef]

- Da Silva, V.R.; Mosiewicki, M.A.; Yoshida, M.I.; Da Silva, M.C.; Stefani, P.M.; Marcovich, N.E. Polyurethane foams based on modified tung oil and reinforced with rice husk ash I: Synthesis and physical chemical characterization. Polym. Test. 2013, 32, 438–445. [Google Scholar] [CrossRef]

- Da Silva, V.R.; Mosiewicki, M.A.; Yoshida, M.I.; Da Silva, M.C.; Stefani, P.M.; Marcovich, N.E. Polyurethane foams based on modified tung oil and reinforced with rice husk ash II: Mechanical characterization. Polym. Test. 2013, 32, 665–672. [Google Scholar] [CrossRef]

- Kuźnia, M.; Magiera, A.; Pielichowska, K.; Ziąbka, M.; Benko, A.; Szatkowski, P.; Jerzak, W. Fluidized bed combustion fly ash as filler in composite polyurethane materials. Waste Manag. 2019, 92, 115–123. [Google Scholar] [CrossRef]

- Choe, H.; Lee, J.H.; Kim, J.H. Polyurethane composite foams including CaCO3 fillers for enhanced sound absorption and compression properties. Compos. Sci. Technol. 2020, 194, 108153. [Google Scholar] [CrossRef]

- Chindaprasirt, P.; Rattanasak, U. Utilization of blended fluidized bed combustion (FBC) ash and pulverized coal combustion (PCC) fly ash in geopolymer. Waste Manag. 2010, 30, 667–672. [Google Scholar] [CrossRef]

- Chindaprasirt, P.; Jenjirapanya, S.; Rattanasak, U. Characterizations of FBC/PCC fly ash geopolymeric composites. Constr. Build. Mater. 2014, 66, 72–78. [Google Scholar] [CrossRef]

- Anthony, E.; Berry, E.; Blondin, J.; Bulewicz, E.; Burwell, S. Advanced ash management technologies for CFBC ash. Waste Manag. 2003, 23, 503–516. [Google Scholar] [CrossRef]

- Hejna, A.; Kopczyńska, M.; Kozłowska, U.; Klein, M.; Kosmela, P.; Piszczyk, Ł. Foamed polyurethane composites with different types of ash–morphological, mechanical and thermal behavior assessments. Cell. Polym. 2016, 35, 287–308. [Google Scholar] [CrossRef]

- Sroka, J.; Rybak, A.; Sekuła, R.; Sitarz, M. An Investigation into the Influence of Filler Silanization Conditions on Mechanical and Thermal Parameters of Epoxy Resin-Fly Ash Composites. J. Polym. Environ. 2016, 24, 298–308. [Google Scholar] [CrossRef]

- Sroka, J.; Rybak, A.; Sekuła, R.; Filipczak, P.; Kozanecki, M.; Sitarz, M. Two-Step Procedure of Fly Ash Modification as an Alternative Method for Creation of Functional Composite. J. Polym. Environ. 2017, 25, 1342–1347. [Google Scholar] [CrossRef]

- Porąbka, A.; Jurkowski, K.; Laska, J. Fly ash used as a reinforcing and flame- retardant filler in low-density polyethylene. Polimery 2015, 60, 251–257. [Google Scholar] [CrossRef]

- Liu, H.; Sun, Q.; Wang, B.; Wang, P.; Zou, J. Morphology and Composition of Microspheres in Fly Ash from the Luohuang Power Plant, Chongqing, Southwestern China. Minerals 2016, 6, 30. [Google Scholar] [CrossRef] [Green Version]

- Nugteren, H.W. Coal fly ash: From waste to industrial product. Part. Part. Syst. Charact. 2007, 24, 49–55. [Google Scholar] [CrossRef]

- Drozhzhin, V.; Shpirt, M.Y.; Danilin, L.; Kuvaev, M.; Pikulin, I.; Potemkin, G.; Redyushev, S. Formation processes and main properties of hollow aluminosilicate microspheres in fly ash from thermal power stations. Solid Fuel Chem. 2008, 42, 107–119. [Google Scholar] [CrossRef]

- Grishin, N.; Belogurova, O.; Belyaevskii, A.; Osipov, Y.P.; Kalinnikov, V. High- temperature heat-insulating materials based on hollow aluminosilicate microspheres from the ash dump of the apatity thermal power plant. Refract. Ind. Ceram. 2000, 41, 50–55. [Google Scholar] [CrossRef]

- Kuźnia, M.; Magiera, A.; Jerzak, W.; Ziąbka, M.; Lach, R. Study on chemical composition of fly ash ram fluidized-bed and conventional coal combustion. Przem. Chem. 2017, 96, 1699–1703. [Google Scholar] [CrossRef]

- Magiera, A.; Kuźnia, M.; Jerzak, W.; Ziąbka, M.; Lach, R.; Handke, B. Microspheres as potential fillers in composite polymeric materials. E3S Web Conf. 2019, 108, 02009. [Google Scholar] [CrossRef]

- Ma, X.F.; Yu, J.G.; Wang, N. Fly ash-reinforced thermoplastic starch composites. Carbohydr. Polym. 2007, 67, 32–39. [Google Scholar] [CrossRef]

- Ramesh, A.; Ramu, K.; Ahmed Ali Baig, M.; Dinesh Guptha, E. Influence of fly ash nano filler on the tensile and flexural properties of novel hybrid epoxy nano-composites. Mater. Today Proc. 2020, 27, 1252–1257. [Google Scholar] [CrossRef]

- Tiwari, S.; Gehlot, C.L.; Srivastava, D. Synergistic influence of CaCO3 nanoparticle on the mechanical and thermal of fly ash reinforced epoxy polymer composites. Mater. Today Proc. 2021, 43, 3375–3385. [Google Scholar] [CrossRef]

- Girge, A.; Goel, V.; Gupta, G.; Fuloria, D.; Ranjan Pati, P.; Sharma, A.; Kumar Mishra, V. Industrial waste filled polymer composites—A review. Mater. Today Proc. 2021, 47, 2852–2863. [Google Scholar] [CrossRef]

- Rozhina, E.; Ishmukhametov, I.; Nigamatzyanova, L.; Akhatova, F.; Batasheva, S.; Taskaev, S.; Montes, C.; Lvov, Y.; Fakhrullin, R. Comparative Toxicity of Fly Ash: An In Vitro Study. Molecules 2021, 26, 1926. [Google Scholar] [CrossRef]

- Prociak, A.; Kurańska, M.; Malewska, E. Porous polyurethane plastics synthetized using bio-polyols from renewable raw materials. Polimery 2017, 62, 353–363. [Google Scholar] [CrossRef]

- Prociak, A. Heat-insulating properties of rigid polyurethane foams synthesized with use of vegetable oils—based polyols. Polimery 2008, 53, 195–200. [Google Scholar] [CrossRef]

- Usta, N. Investigation of fire behavior of rigid polyurethane foams containing fly ash and intumescent flame retardant by using a cone calorimeter. J. Appl. Polym. Sci. 2012, 124, 3372–3382. [Google Scholar] [CrossRef]

- Tarakcılar, A.R. The effects of intumescent flame retardant including ammonium polyphosphate/pentaerythritol and fly ash fillers on the physicomechanical properties of rigid polyurethane foams. J. Appl. Polym. Sci. 2011, 120, 2095–2102. [Google Scholar] [CrossRef]

- Madaleno, L.; Pyrz, R.; Crosky, A.; Jensen, L.R.; Rauhe, J.C.M.; Dolomanova, V.; de Barros, A.M.M.V.; Pinto, J.J.C.; Norman, J. Processing and characterization of polyurethane nanocomposite foam reinforced with montmorillonite–carbon nanotube hybrids. Compos. Part A Appl. Sci. Manuf. 2013, 44, 1–7. [Google Scholar] [CrossRef]

- Asefnejad, A.; Khorasani, M.T.; Behnamghader, A.; Farsadzadeh, B.; Bonakdar, S. Manufacturing of biodegradable polyurethane scaffolds based on polycaprolactone using a phase separation method: Physical properties and in vitro assay. Int. J. Nanomed. 2011, 6, 2375–2384. [Google Scholar] [CrossRef] [Green Version]

- Trovati, G.; Sanches, E.A.; Neto, S.C.; Mascarenhas, Y.P.; Chierice, G.O. Characterization of polyurethane resins by FTIR, TGA and XRD. J. Appl. Polym. Sci. 2010, 115, 263–268. [Google Scholar] [CrossRef]

- Gujral, P.; Varshney, S.; Dhawan, S. Designing of Multiphase Fly Ash/MWCNT/PU Composite Sheet Against Electromagnetic Environmental Pollution. J. Electron. Mater. 2016, 45, 3142–3148. [Google Scholar] [CrossRef]

- Hejna, A.; Kosmela, P.; Mikicka, M.; Danowska, M.; Piszczyk, Ł. Modification of microporous polyurethane elastomers with different types of ash—morphological, mechanical, and thermal studies. Polym. Compos. 2016, 37, 881–889. [Google Scholar] [CrossRef]

- Mozgawa, W.; Król, M.; Dyczek, J.; Deja, J. Investigation of the coal fly ashes using IR spectroscopy. Spectrochim. Acta Part A Mol. Biomol. Spectrosc. 2014, 132, 889–894. [Google Scholar] [CrossRef]

- Fauzi, A.; Nuruddin, M.F.; Malkawi, A.B.; Abdullah, M.M.A.B. Study of fly ash characterization as a cementitious material. Procedia Eng. 2016, 148, 487–493. [Google Scholar] [CrossRef] [Green Version]

- Paciorek-Sadowska, J.; Czupryński, B.; Borowicz, M.; Liszkowska, J. Rigid polyurethane–polyisocyanurate foams modified with grain fraction of fly ashes. J. Cell. Plast. 2020, 56, 53–72. [Google Scholar] [CrossRef]

| Fly Ash | Microspheres | ||||||

|---|---|---|---|---|---|---|---|

| Element | Conc., % | Oxide | Conc., % | Element | Conc., % | Oxide | Conc., % |

| Mg | 0.658 | MgO | 1.464 | O | 49.30 | Na2O | 0.464 |

| Al | 18.10 | Al2O3 | 27.38 | Si | 24.69 | MgO | 0.274 |

| Si | 35.53 | SiO2 | 52.31 | Al | 21.12 | Al2O3 | 39.91 |

| P | 0.748 | P2O5 | 0.880 | Ca | 1.016 | SiO2 | 52.83 |

| S | 1.035 | SO3 | 1.201 | Fe | 0.984 | P2O5 | 1.017 |

| K | 9.383 | Cl | 0.000 | Ti | 0.728 | SO3 | 0.032 |

| Ca | 6.434 | K2O | 4.153 | P | 0.443 | K2O | 0.502 |

| Ti | 2.819 | CaO | 2.954 | K | 0.416 | CaO | 1.421 |

| V | 0.115 | TiO2 | 1.409 | Na | 0.344 | TiO2 | 1.215 |

| Cr | 0.076 | V2O5 | 0.058 | As | 0.246 | Cr2O3 | 0.006 |

| Mn | 0.224 | Cr2O3 | 0.033 | Ba | 0.237 | MnO | 0.033 |

| Fe | 21.29 | MnO | 0.078 | Mg | 0.165 | Fe2O3 | 1.407 |

| Co | 0.094 | Fe2O3 | 7.916 | Sr | 0.101 | CuO | 0.010 |

| Ni | 0.058 | Co3O4 | 0.030 | F | 0.076 | ZnO | 0.004 |

| Cu | 0.042 | NiO | 0.015 | Zr | 0.032 | Ga2O3 | 0.005 |

| Zn | 0.083 | CuO | 0.011 | Cl | 0.029 | As2O3 | 0.325 |

| Ga | 0.011 | ZnO | 0.022 | Mn | 0.026 | Rb2O | 0.002 |

| As | 0.004 | Ga2O3 | 0.003 | S | 0.013 | SrO | 0.119 |

| Br | 0.004 | GeO2 | 0.000 | Cu | 0.008 | Y2O3 | 0.006 |

| Rb | 0.035 | Br | 0.001 | Y | 0.005 | ZrO2 | 0.044 |

| Sr | 0.074 | Rb2O | 0.008 | Cr | 0.004 | BaO | 0.264 |

| Y | 0.006 | SrO | 0.018 | Ga | 0.003 | PbO | 0.002 |

| Zr | 0.032 | Y2O3 | 0.002 | Zn | 0.003 | F | 0.076 |

| Ag | 0.065 | ZrO2 | 0.009 | Pb | 0.002 | Cl | 0.030 |

| Sn | 0.003 | Nb2O5 | 0.001 | Rb | 0.002 | - | - |

| Ba | 0.021 | Ag2O | 0.015 | - | - | - | - |

| Pb | 0.043 | SnO2 | 0.001 | - | - | - | - |

| - | - | BaO | 0.006 | - | - | - | - |

| - | - | HgO | 0.009 | - | - | - | - |

| - | - | As2O3 | 0.001 | - | - | - | - |

| Sample Name | Vertical Feret Diameter, µm | Horizontal Feret Diameter, µm | Strut Thickness, µm | Closed Cells’ Content, % |

|---|---|---|---|---|

| PUR | 193 ± 15 | 207 ± 16 | 20 ± 1 | 88 |

| PUR + FA5p | 150 ± 6 | 156 ± 7 | 17 ± 1 | 82 |

| PUR + FA10p | 138 ± 8 | 147 ± 8 | 19 ± 1 | 77 |

| PUR + FA15p | 170 ± 12 | 148 ± 11 | 22 ± 1 | 78 |

| PUR + FA20p | 181 ± 11 | 170 ± 10 | 22 ± 1 | 78 |

| PUR + M5p | 154 ± 8 | 149 ± 7 | 20 ± 1 | 83 |

| PUR + M10p | 169 ± 12 | 173 ± 11 | 21 ± 1 | 77 |

| PUR + M15p | 196 ± 18 | 192 ± 20 | 20 ± 1 | 70 |

| PUR + M20p | 152 ± 11 | 158 ± 9 | 20 ± 1 | 76 |

| Wavenumber, cm−1 | Characteristic Vibration |

|---|---|

| 3330 1730 1510–1530 1310 1230 2970, 2870–2930 1450, 1410, 1340 1090 770–920 1600, 2280 | Stretching vibration of N–H groups Stretching vibration of C=O bonds Bending vibration of N–H groups Stretching vibration of C–N bonds Stretching vibration of C–O bonds Symmetric and asymmetric stretching vibrations of C–H bonds in CH2 groups in aliphatic chains and CH3 end groups Vibrations of methylene and methyl groups δ bonds between C and O (ether bonds; related to the polyol structure) Skeletal vibrations of C–C bonds and aromatic rings (related to the isocyanate structure) Phenyl ring vibration (related to the isocyanate structure) |

| Wavenumber, cm−1 | Characteristic Vibration |

|---|---|

| 1060 | Asymmetric stretching vibration of Si–O(Si) |

| 800–770 | Symmetric stretching vibration of Si–O–Si |

| 460 | Bending vibration of O–Si–O in silicate tetrahedra |

| 550 | Al in tetrahedral positions |

| Sample Name | Compressive Strength, kPa |

|---|---|

| PUR | 191.6 ± 14.4 |

| PUR + FA5p | 210.9 ± 11.5 |

| PUR + FA10p | 196.5 ± 15.9 |

| PUR + FA15p | 201.3 ± 27.1 |

| PUR + FA20p | 243.5 ± 9.4 |

| PUR + M5p | 234.5 ± 11.3 |

| PUR + M10p | 236.1 ± 11.3 |

| PUR + M15p | 235.2 ± 15.2 |

| PUR + M20p | 235.7 ± 25.0 |

| Sample Name | Tg,1, °C | ΔCp,1, J g−1 K−1 | Tg,2,°C | ΔCp,2, J g−1 K−1 |

|---|---|---|---|---|

| PUR | 43 | 0.19 | 150 | 0.26 |

| PUR + FA5p | −26 | 0.05 | 160 | 0.22 |

| PUR + FA10p | −22 | 0.06 | 126 | 0.26 |

| PUR + FA15p | −3 | 0.01 | 113 | 0.13 |

| PUR + FA20p | −12 | 0.02 | 103 | 0.25 |

| PUR + M5p | −32 | 0.07 | 131 | 0.31 |

| PUR + M10p | −46 | 0.01 | 128 | 0.24 |

| PUR + M15p | −42 | 0.06 | 128 | 0.35 |

| PUR + M20p | −33 | 0.08 | 147 | 0.15 |

| Sample Name | T5%, °C | T10%, °C | T50%, °C | T1, °C | R1, % °C−1 | T2, °C | R2, % °C−1 | Residue at 590 °C, % |

|---|---|---|---|---|---|---|---|---|

| PUR | 172 | 238 | 329 | 306 | 0.79 | - | - | 28 |

| PUR + 5FA | 183 | 251 | 322 | 307 | 0.81 | 457 | 0.11 | 19 |

| PUR + 10FA | 191 | 253 | 326 | 308 | 0.73 | 451 | 0.10 | 20 |

| PUR + 15FA | 178 | 249 | 332 | 298 | 0.66 | 447 | 0.09 | 26 |

| PUR + 20FA | 191 | 255 | 336 | 302 | 0.64 | 448 | 0.09 | 29 |

| PUR + 5M | 176 | 245 | 313 | 301 | 0.90 | 451 | 0.09 | 17 |

| PUR + 10M | 187 | 250 | 325 | 301 | 0.81 | 450 | 0.09 | 22 |

| PUR + 15M | 185 | 254 | 334 | 305 | 0.77 | 459 | 0.09 | 26 |

| PUR + 20M | 184 | 254 | 342 | 304 | 0.71 | 449 | 0.08 | 31 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kuźnia, M.; Magiera, A.; Zygmunt-Kowalska, B.; Kaczorek-Chrobak, K.; Pielichowska, K.; Szatkowski, P.; Benko, A.; Ziąbka, M.; Jerzak, W. Fly Ash as an Eco-Friendly Filler for Rigid Polyurethane Foams Modification. Materials 2021, 14, 6604. https://doi.org/10.3390/ma14216604

Kuźnia M, Magiera A, Zygmunt-Kowalska B, Kaczorek-Chrobak K, Pielichowska K, Szatkowski P, Benko A, Ziąbka M, Jerzak W. Fly Ash as an Eco-Friendly Filler for Rigid Polyurethane Foams Modification. Materials. 2021; 14(21):6604. https://doi.org/10.3390/ma14216604

Chicago/Turabian StyleKuźnia, Monika, Anna Magiera, Beata Zygmunt-Kowalska, Katarzyna Kaczorek-Chrobak, Kinga Pielichowska, Piotr Szatkowski, Aleksandra Benko, Magdalena Ziąbka, and Wojciech Jerzak. 2021. "Fly Ash as an Eco-Friendly Filler for Rigid Polyurethane Foams Modification" Materials 14, no. 21: 6604. https://doi.org/10.3390/ma14216604

APA StyleKuźnia, M., Magiera, A., Zygmunt-Kowalska, B., Kaczorek-Chrobak, K., Pielichowska, K., Szatkowski, P., Benko, A., Ziąbka, M., & Jerzak, W. (2021). Fly Ash as an Eco-Friendly Filler for Rigid Polyurethane Foams Modification. Materials, 14(21), 6604. https://doi.org/10.3390/ma14216604