Anelastic Behaviour of Commercial Die-Cast Magnesium Alloys: Effect of Temperature and Alloy Composition

Abstract

:1. Introduction

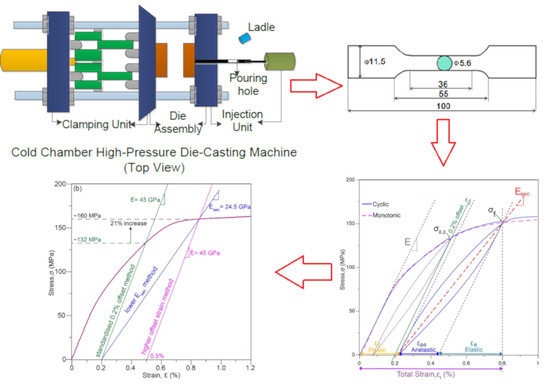

2. Materials and Methods

3. Results

4. Discussion

4.1. The Effect of Temperature

4.2. The Effect of Alloy Composition

4.3. The Effect of Anelasticity and Esec on Yield Strength Measurement

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Partridge, P.G. The crystallography and deformation modes of hexagonal close-packed metals. Met. Rev. 1967, 12, 169–194. [Google Scholar] [CrossRef]

- Akhtar, A.; Teghtsoonian, E. Solid-solution hardening in magnesium alloys. J. Investig. Med. 1968, 9, 692–697. [Google Scholar]

- Stanford, N.; Barnett, M. Solute strengthening of prismatic slip, basal slip and twinning in Mg and Mg–Zn binary alloys. Int. J. Plast. 2013, 47, 165–181. [Google Scholar] [CrossRef]

- Agnew, S.; Brown, D.; Tome, C. Validating a polycrystal model for the elastoplastic response of magnesium alloy AZ31 using in situ neutron diffraction. Acta Mater. 2006, 54, 4841–4852. [Google Scholar] [CrossRef]

- Mises, R.V. Mechanik der plastischen Formänderung von Kristallen. ZAMM 1928, 8, 161–185. [Google Scholar] [CrossRef]

- Taylor, G.I. Plastic strain in metals. J. Inst. Met. 1938, 62, 307–324. [Google Scholar]

- Barnett, M.R. Twinning and the ductility of magnesium alloys: Part I: “Tension” twins. Mater. Sci. Eng. A 2007, 464, 1–7. [Google Scholar] [CrossRef]

- Obara, T.; Yoshinga, H.; Morozumi, S. {112}<1123> Slip system in magnesium. Acta Met. 1973, 21, 845–853. [Google Scholar] [CrossRef]

- Duerig, T.; Zadno, R. An engineer’s perspective of pseudoelasticity. In Engineering Aspects of Shape Memory Alloys; Duerig, T., Melton, K.N., Stöckel, D., Wayman, C., Eds.; Butterworth-Heinemann: Oxford, UK, 1990; pp. 369–393. [Google Scholar]

- Muránsky, O.; Carr, D.; Sittner, P.; Oliver, E. In situ neutron diffraction investigation of deformation twinning and pseudoelastic-like behaviour of extruded AZ31 magnesium alloy. Int. J. Plast. 2009, 25, 1107–1127. [Google Scholar] [CrossRef]

- Gharghouri, M.A.; Weatherly, G.C.; Embury, J.D.; Root, J. Study of the mechanical properties of Mg-7.7at.% Al byin-situneutron diffraction. Philos. Mag. A 1999, 79, 1671–1695. [Google Scholar] [CrossRef]

- Lee, S.; Gharghouri, M. Pseudoelastic behavior of magnesium alloy during twinning-dominated cyclic deformation. Mater. Sci. Eng. A 2013, 572, 98–102. [Google Scholar] [CrossRef]

- Cui, Y.; Li, Y.; Wang, Z.; Ding, X.; Koizumi, Y.; Bian, H.; Lin, L.; Chiba, A. Impact of solute elements on detwinning in magnesium and its alloys. Int. J. Plast. 2017, 91, 134–159. [Google Scholar] [CrossRef]

- Mann, G.; Sumitomo, T.; Cáceres, C.; Griffiths, J. Reversible plastic strain during cyclic loading–unloading of Mg and Mg–Zn alloys. Mater. Sci. Eng. A 2007, 456, 138–146. [Google Scholar] [CrossRef]

- Nagarajan, D.; Ren, X.; Caceres, C. Anelastic behavior of Mg-Al and Mg-Zn solid solutions. Mater. Sci. Eng. A 2017, 696, 387–392. [Google Scholar] [CrossRef] [Green Version]

- Nagarajan, D. Anelasticity in cast Mg-Gd alloys. Mater. Sci. Eng. A 2017, 695, 14–19. [Google Scholar] [CrossRef] [Green Version]

- Drozdenko, D.; Čapek, J.; Clausen, B.; Vinogradov, A.; Máthis, K. Influence of the solute concentration on the anelasticity in Mg-Al alloys: A multiple-approach study. J. Alloys Compd. 2019, 786, 779–790. [Google Scholar] [CrossRef]

- Koike, J.; Fujiyama, N.; Ando, D.; Sutou, Y. Roles of deformation twinning and dislocation slip in the fatigue failure mechanism of AZ31 Mg alloys. Scr. Mater. 2010, 63, 747–750. [Google Scholar] [CrossRef]

- Caceres, C.; Sumitomo, T.; Veidt, M. Pseudoelastic behaviour of cast magnesium AZ91 alloy under cyclic loading–unloading. Acta Mater. 2003, 51, 6211–6218. [Google Scholar] [CrossRef]

- Lu, Z.; Blackmore, P. Cyclic Stress-Strain Behaviour of AM60B and AE44 Cast Magnesium Alloys and Its Impact on LCF Characterisation and Fatigue Analysis. SAE Int. J. Mater. Manuf. 2014, 7, 446–453. [Google Scholar] [CrossRef]

- Ang, H.Q.; Zhu, S.M.; Abbott, T.B.; Easton, M.A. Anelastic deformation during cyclic loading-unloading of die-cast magnesium alloys. In Proceedings of the 11th International Conference on Magnesium Alloys and Their Applications, Old Winsor, UK, 24–27 July 2018; Fan, Z., Mendis, C., Eds.; Brunel University Press: London, UK, 2018; pp. 165–168. [Google Scholar]

- Ang, H.Q.; Abbott, T.B.; Zhu, S.; Gu, C.; Easton, M.A. Proof stress measurement of die-cast magnesium alloys. Mater. Des. 2016, 112, 402–409. [Google Scholar] [CrossRef]

- Joost, W.J.; Krajewski, P.E. Towards magnesium alloys for high-volume automotive applications. Scr. Mater. 2017, 128, 107–112. [Google Scholar] [CrossRef]

- Luo, A.; Renaud, J.; Nakatsugawa, I.; Plourde, J. Magnesium castings for automotive applications. JOM 1995, 47, 28–31. [Google Scholar] [CrossRef]

- Nagarajan, D.; Caceres, C.; Griffiths, J. Anelastic Phenomena in Mg-Al Alloys. Acta Phys. Pol. A 2012, 122, 501–504. [Google Scholar] [CrossRef]

- Li, B.; Kadiri, H.E.I.; Zhang, X.Y.; Mathaudhu, S.N.; Ma, Q. Structural origin of reversible twinning, non-schmid effect, incoherent twin boundaries and texture of hexagonal close-packed metals. In Magnesium Technology 2012, Proceedings of the TMS; Mathaudhu, S.N., Sillekens, W.H., Neelameggham, N.R., Hort, N., Eds.; The Minerals, Metals & Materials Society: Orlando, FL, USA, 2012; pp. 105–110. [Google Scholar]

- Cahn, J.W. Thermodynamic and structural changes in deformation twinning of alloys. Acta Met. 1977, 25, 1021–1026. [Google Scholar] [CrossRef]

- Cáceres, C.H.; Blake, A. The strength of concentrated Mg–Zn solid solutions. Phys. Stat. Sol. A 2002, 194, 147–158. [Google Scholar] [CrossRef]

- Cáceres, C.; Rovera, D. Solid solution strengthening in concentrated Mg–Al alloys. J. Light Met. 2001, 1, 151–156. [Google Scholar] [CrossRef]

- Ang, H.Q.; Abbott, T.B.; Zhu, S.; Easton, M. Anelasticity of die-cast magnesium-aluminium based alloys under different strain rates. Mater. Sci. Eng. A 2017, 707, 101–109. [Google Scholar] [CrossRef]

- Ang, H.Q. Mechanical Properties and Deformation Behaviour of High-Pressure Die-Cast Magnesium-Aluminium based Alloys. Ph.D. Thesis, RMIT University, Melbourne, Australia, 2017. [Google Scholar]

- Aragones, J.; Goundan, K.; Kolp, S.; Osborne, R.; Ouimet, L.; Pinch, W. Development of the 2006 Corvette Z06 Structural Cast Magnesium Crossmember; SAE Technical Paper Series, 2005-01-0340; SAE International: Warrendale, PA, USA, 2005. [Google Scholar] [CrossRef]

- Luo, A.A. Recent Magnesium Alloy Development for Automotive Powertrain Applications. Mater. Sci. Forum 2003, 419–422, 57–66. [Google Scholar] [CrossRef]

- Ang, H.Q.; Zhu, S.; Abbott, T.B.; Qiu, D.; Easton, M.A. Strain-rate sensitivity of die-cast magnesium-aluminium based alloys. Mater. Sci. Eng. A 2017, 699, 239–246. [Google Scholar] [CrossRef]

- Nagasekhar, A.V.; Easton, M.A.; Cáceres, C.H. Solute content and the grain microstructure of high pressure die cast magnesium–aluminium alloys. Adv. Eng. Mater. 2009, 11, 912–919. [Google Scholar] [CrossRef]

- Zhu, S.; Abbott, T.; Gibson, M.; Nie, J.; Easton, M. Age hardening in die-cast Mg–Al–RE alloys due to minor Mn additions. Mater. Sci. Eng. A 2016, 656, 34–38. [Google Scholar] [CrossRef]

- ISO 6892-1. Metallic Materials Tensile Testing-Part 1: Method of Test at Room Temperature; International Standards Organisation (ISO): Geneva, Switzerland, 2009; p. 65. [Google Scholar]

- Dørum, C.; Hopperstad, O.; Lademo, O.-G.; Langseth, M. Numerical modelling of the structural behaviour of thin-walled cast magnesium components. Int. J. Solids Struct. 2005, 42, 2129–2144. [Google Scholar] [CrossRef]

- Easton, M.; Song, W.Q.; Abbott, T. A comparison of the deformation of magnesium alloys with aluminium and steel in tension, bending and buckling. Mater. Des. 2006, 27, 935–946. [Google Scholar] [CrossRef]

- ASTM. E8M-09: Standard test methods for tension testing of metallic materials. In Annual Book of ASTM Standards; American Society for Testing and Materials: West Conshohocken, PA, USA, 2009; p. 127. [Google Scholar]

- Avedesian, M.; Baker, H. Magnesium and Magnesium Alloys—ASM Specialty Handbook; ASM International The Materials Information Society: Novelty, OH, USA, 1999; Volume 52. [Google Scholar]

- Sumitomo, T.; Cáceres, C.; Veidt, M. The elastic modulus of cast Mg–Al–Zn alloys. J. Light Met. 2002, 2, 49–56. [Google Scholar] [CrossRef]

- Garlea, E.; Radovic, M.; Liaw, P. High-temperature dependency of elastic mechanical behavior of two wrought magnesium alloys AZ31B and ZK60A studied by resonant ultrasound spectroscopy. Mater. Sci. Eng. A 2019, 758, 86–95. [Google Scholar] [CrossRef]

- Göken, J.; Riehemann, W. Damping behaviour of AZ91 magnesium alloy with cracks. Mater. Sci. Eng. A 2003, 370, 417–421. [Google Scholar] [CrossRef]

- Hama, T.; Kariyazaki, Y.; Ochi, K.; Fujimoto, H.; Takuda, H. Springback Characteristics of Magnesium Alloy Sheet AZ31B in Draw-Bending. Mater. Trans. 2010, 51, 685–693. [Google Scholar] [CrossRef] [Green Version]

- Rettberg, L.H.; Jordon, J.B.; Horstemeyer, M.F.; Jones, J.W. Low-Cycle Fatigue Behavior of Die-Cast Mg Alloys AZ91 and AM60. Met. Mater. Trans. A 2012, 43, 2260–2274. [Google Scholar] [CrossRef]

- Chadha, G.; Allison, J.E.; Jones, J.W. The Role of Microstructure on Ductility of Die-Cast AM50 and AM60 Magnesium Alloys. Met. Mater. Trans. A 2007, 38, 286–297. [Google Scholar] [CrossRef]

- Rzychoń, T.; Kiełbus, A.; Cwajna, J.; Mizera, J. Microstructural stability and creep properties of die casting Mg–4Al–4RE magnesium alloy. Mater. Charact. 2009, 60, 1107–1113. [Google Scholar] [CrossRef]

- Zhu, S.; Nie, J.; Gibson, M.; Easton, M.; Bakke, P. Microstructure and Creep Behavior of High-Pressure Die-Cast Magnesium Alloy AE44. Met. Mater. Trans. A 2012, 43, 4137–4144. [Google Scholar] [CrossRef]

- Srinivasan, A.; Pillai, U.T.S.; Pai, B.C. Microstructure and mechanical properties of Si and Sb added AZ91 magnesium alloy. Met. Mater. Trans. A 2005, 36, 2235–2243. [Google Scholar] [CrossRef]

- Fallahi, H.; Tabarroki, M.; Davies, C. Evolution of anelastic behaviour and twinning in cyclic loading of extruded magnesium alloy ZM21. Mater. Sci. Eng. A 2020, 770, 138520. [Google Scholar] [CrossRef]

- Reed-Hill, R.; Dahlberg, E.; Slippy, W., Jr. Some anelastic effects in zirconium at room temperature resulting from prestrain at 77 deg K. Trans. Met. Soc. AIME 1965, 233, 21748. [Google Scholar]

- Barnett, M. A taylor model based description of the proof stress of magnesium AZ31 during hot working. Met. Mater. Trans. A 2003, 34, 1799–1806. [Google Scholar] [CrossRef] [Green Version]

- Agnew, S.R. Plastic anisotropy of magnesium alloy AZ31B Sheet. In Essential Readings in Magnesium Technology; Mathaudhu, S.N., Luo, A.A., Neelameggham, N.R., Nyberg, E.A., Sillekens, W.H., Eds.; Springer: Cham, Switzerland, 2016; pp. 351–356. [Google Scholar]

- Ulacia, I.; Dudamell, N.; Galvez, F.; Yi, S.; Pérez-Prado, M.; Hurtado, I. Mechanical behavior and microstructural evolution of a Mg AZ31 sheet at dynamic strain rates. Acta Mater. 2010, 58, 2988–2998. [Google Scholar] [CrossRef]

- Yoshinaga, H.; Horiuchi, R. On the Nonbasal Slip in Magnesium Crystals. Trans. Jpn. Inst. Met. 1964, 5, 14–21. [Google Scholar] [CrossRef] [Green Version]

- Chapuis, A.; Driver, J.H. Temperature dependency of slip and twinning in plane strain compressed magnesium single crystals. Acta Mater. 2011, 59, 1986–1994. [Google Scholar] [CrossRef]

- Barnett, M.; Keshavarz, Z.; Beer, A.; Atwell, D. Influence of grain size on the compressive deformation of wrought Mg–3Al–1Zn. Acta Mater. 2004, 52, 5093–5103. [Google Scholar] [CrossRef]

- Meyers, M.; Vöhringer, O.; Lubarda, V. The onset of twinning in metals: A constitutive description. Acta Mater. 2001, 49, 4025–4039. [Google Scholar] [CrossRef]

- Lu, Y.; Taheri, F.; Gharghouri, M. Monotonic and Cyclic Plasticity Response of Magnesium Alloy. Part I. Experimental Response of a High-Pressure Die Cast AM60B. Strain 2008, 47, e15–e24. [Google Scholar] [CrossRef]

- Xu, S.; Tyson, W.; Eagleson, R.; Zavadil, R.; Liu, Z.; Mao, P.-L.; Wang, C.-Y.; Hill, S.; Luo, A. Dependence of flow strength and deformation mechanisms in common wrought and die cast magnesium alloys on orientation, strain rate and temperature. J. Magnes. Alloys 2013, 1, 275–282. [Google Scholar] [CrossRef] [Green Version]

- Agnew, S.; Yoo, M.; Tomé, C. Application of texture simulation to understanding mechanical behavior of Mg and solid solution alloys containing Li or Y. Acta Mater. 2001, 49, 4277–4289. [Google Scholar] [CrossRef]

- Wonsiewicz, B.; Backofen, W. Independent slip systems and ductility of hexagonal polycrystals. Trans. Metall. Soc. AIME 1967, 239, 1422–1433. [Google Scholar]

- Agnew, S.R.; Duygulu, O. Plastic anisotropy and the role of non-basal slip in magnesium alloy AZ31B. Int. J. Plast. 2005, 21, 1161–1193. [Google Scholar] [CrossRef]

- Akhtar, A.; Teghtsoonian, E. Solid solution strengthening of magnesium single crystals—II the effect of solute on the ease of prismatic slip. Acta Met. 1969, 17, 1351–1356. [Google Scholar] [CrossRef]

- Zhu, S.; Abbott, T.B.; Nie, J.-F.; Ang, H.Q.; Qiu, D.; Nogita, K.; Easton, M.A. Re-evaluation of the mechanical properties and creep resistance of commercial magnesium die-casting alloy AE44. J. Magnes. Alloys 2021, 9, 1537–1545. [Google Scholar] [CrossRef]

- Zhang, B.; Nagasekhar, A.V.; Sivarupan, T.; Caceres, C.H. Deformation Behavior of the Percolating Intermetallic Microstructure of High Pressure Die Cast AZ91 Alloy. Adv. Eng. Mater. 2013, 15, 1059–1067. [Google Scholar] [CrossRef]

- Zhang, B.; Yang, K.V.; Nagasekhar, A.V.; Cáceres, C.H.; Easton, M. Deformation Behavior of the Percolating Eutectic Intermetallic in HPDC and Squeeze-Cast Mg Alloys. JOM 2014, 66, 2086–2094. [Google Scholar] [CrossRef]

- Ang, H.Q.; Abbott, T.B.; Zhu, S.; Easton, M.A. An Analysis of the Tensile Deformation Behavior of Commercial Die-Cast Magnesium-Aluminum-Based Alloys. Met. Mater. Trans. A 2019, 50, 3827–3841. [Google Scholar] [CrossRef]

| Alloy | Al | Mn | RE (Ce + La) | Zn | Mg |

|---|---|---|---|---|---|

| AE44 | 3.67 | 0.31 | 3.83 | <0.01 | Bal. |

| AM40 | 4.44 | 0.21 | <0.01 | 0.05 | Bal. |

| AM60 | 6.26 | 0.29 | <0.01 | 0.1 | Bal. |

| AZ91 | 8.88 | 0.19 | <0.01 | 0.74 | Bal. |

| Alloy | Temperature (°C) | Yield Strength by 0.2% Offset Method (MPa) | Yield Strength by Higher Offset Strain Method a (MPa) | Tensile Strength (MPa) | Elongation to Fracture (%) |

|---|---|---|---|---|---|

| AE44 | RT | 133.0 ± 1.4 | 161.5 ± 2.1 | 292.5 ± 6.3 | 12.4 ± 0.8 |

| 50 | 126.0 ± 5.3 | 152.7 ± 2.5 | 294.0 ± 5.6 | 20.0 ± 2.9 | |

| 100 | 116.0 ± 2.8 | 125.5 ± 2.1 | 246.0 ± 2.8 | 29.3 ± 1.9 | |

| 150 | 106.0 ± 1.4 | 111.5 ± 0.7 | 194.5 ± 0.7 | 38.1 ± 1.6 | |

| T5-aged AE44 | RT | 167.0 ± 4.2 | 194.5 ± 0.7 | 314.0 ± 8.4 | 11.4 ± 1.9 |

| 50 | 146.5 ± 2.1 | 181.0 ± 0.3 | 300.0 ± 0.0 | 15.5 ± 0.2 | |

| 100 | 144.5 ± 2.1 | 156.5 ± 2.1 | 254.0 ± 5.6 | 30.8 ± 2.3 | |

| 150 | 127.0 ± 2.8 | 134.0 ± 2.8 | 194.5 ± 2.1 | 30.7 ± 1.8 | |

| AM40 | RT | 111.8 ± 1.7 | 132.5 ± 3.0 | 287.0 ± 8.8 | 17.8 ± 1.8 |

| 50 | 109.5 ± 3.5 | 131.0 ± 1.4 | 281.0 ± 1.4 | 17.3 ± 0.4 | |

| 100 | 99.3 ± 1.2 | 109.0 ± 1.7 | 241.7 ± 7.2 | 20.9 ± 2.6 | |

| 150 | 80.0 ± 0.0 | 89.0 ± 1.4 | 177.0 ± 1.4 | 27.6 ± 1.3 | |

| AM60 | RT | 126.0 ± 1.4 | 148.0 ± 0.2 | 291.5 ± 9.1 | 13.7 ± 1.4 |

| 50 | 124.5 ± 0.7 | 149.0 ± 0.1 | 300.0 ± 2.8 | 16.1 ± 0.4 | |

| 100 | 113.0 ± 1.4 | 124.5 ± 3.5 | 278.0 ± 5.6 | 20.7 ± 2.3 | |

| 150 | 94.5 ± 2.1 | 105.5 ± 0.7 | 206.0 ± 1.4 | 25.2 ± 1.2 | |

| AZ91 | RT | 163.0 ± 2.8 | 185.5 ± 0.7 | 274.6 ± 13.3 | 6.6 ± 1.3 |

| 50 | 140.5 ± 0.7 | 173.5 ± 0.7 | 258.5 ± 0.7 | 6.3 ± 0.5 | |

| 100 | 124.5 ± 0.7 | 139.5 ± 0.7 | 270.0 ± 11.3 | 11.1 ± 1.6 | |

| 150 | 111.0 ± 6.0 | 125.0 ± 4.3 | 220.3 ± 13.1 | 20.0 ± 1.8 |

| Alloy | Near Boundaries | Centre |

|---|---|---|

| AE44 | 2–4 | 1.7 |

| T5-aged AE44 | 2–3 | 1.3 |

| AM40 | 4–7 | 3.2 |

| AM60 | 8–11 | 4.2 |

| AZ91 | 7–15 | 7.4 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ang, H.Q. Anelastic Behaviour of Commercial Die-Cast Magnesium Alloys: Effect of Temperature and Alloy Composition. Materials 2021, 14, 7220. https://doi.org/10.3390/ma14237220

Ang HQ. Anelastic Behaviour of Commercial Die-Cast Magnesium Alloys: Effect of Temperature and Alloy Composition. Materials. 2021; 14(23):7220. https://doi.org/10.3390/ma14237220

Chicago/Turabian StyleAng, Hua Qian. 2021. "Anelastic Behaviour of Commercial Die-Cast Magnesium Alloys: Effect of Temperature and Alloy Composition" Materials 14, no. 23: 7220. https://doi.org/10.3390/ma14237220

APA StyleAng, H. Q. (2021). Anelastic Behaviour of Commercial Die-Cast Magnesium Alloys: Effect of Temperature and Alloy Composition. Materials, 14(23), 7220. https://doi.org/10.3390/ma14237220