Finite Element Analysis on Initial Crack Site of Porous Structure Fabricated by Electron Beam Additive Manufacturing

Abstract

:Highlights

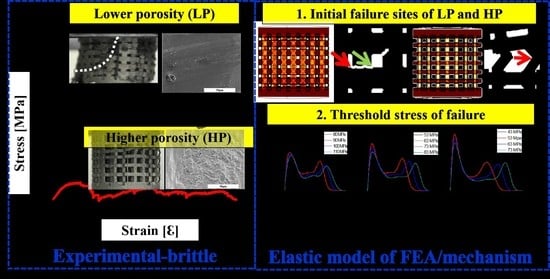

- A combination of EBAM and FEA was employed for the analysis of initial crack sites.

- The initial crack sites predicted by the elastic model were consistent with experimental results.

- The threshold stresses calculated by FEA coincided with the crack sites of specimens with different porosities.

- The collapse mechanism due to strut behavior under uniaxial compression stress was investigated.

1. Introduction

2. Materials and Methods

2.1. Specimen Preparation

2.2. EBAM Process

2.3. Compressive Stress–Strain Testing

2.4. Stress Distribution Simulation

- The deformation of material obeys linear elastic fracture mechanics.

- There were no initial defects inside the specimen, and material properties were uniform and isotropic [26].

3. Results and Discussion

3.1. Compression Stress–Strain Curves

3.2. Compressive Deformation Behavior

3.3. Local Stress Concentration Region Analyzed by FEA

4. Conclusions

- The deformation at low porosities showed a shear diagonal pattern, and the structure was brittle with a high fluctuation peak in the plateau of the compressive stress–strain curve. With an increase in porosity, the deformation behavior shifted toward a layer-by-layer collapse and showed a uniform fluctuation in the plateau region.

- In terms of the elastic model (FEA), in the low-porosity specimens, where the stress statics diagram showed a normal distribution, most of the stresses were smaller than the yield strengths. The maximum stress concentration was located at the edge of the strut and the node. In contrast, in the high-porosity specimens, the stress statics shifted the low and high stresses into two peak distributions, and the maximum stress concentration was located at the center of the struts.

- The applied threshold stresses were 100, 83, and 63 MPa for C4, C5, and C6, respectively, which were close to the experimental results (110, 68, and 62 MPa).

- By combining the compressive experimental results and FEA results, the initial failure sites of the low-porosity specimens were demonstrated to be located at the edge of the struts in the FEA results; the structure collapsed diagonally with the formation of one shear band throughout the specimen. However, the high-porosity specimens possessed maximum stresses at the center of the struts; the structures collapsed layer-by-layer.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Geng, X.; Li, Y.; Li, F.; Wang, X.; Zhang, K.; Liu, Z.; Tian, H. A new 3D printing porous trabecular titanium metal acetabular cup for primary total hip arthroplasty: A minimum 2-year follow-up of 92 consecutive patients. J. Orthop. Surg. Res. 2020, 15, 383. [Google Scholar] [CrossRef] [PubMed]

- Murr, L.E.; Gaytan, S.M.; Martinez, E.; Medina, F.; Wicker, R.B. Next generation orthopedic implants by additive manufacturing using electron beam melting. Int. J. Biomater. 2012, 2012, 245727. [Google Scholar] [CrossRef]

- Dall’Ava, L.; Hothi, H.; Di Laura, A.; Henckel, J.; Hart, A. 3D Printed Acetabular Cups for Total Hip Arthroplasty: A Review Article. Metals 2019, 9, 729. [Google Scholar] [CrossRef] [Green Version]

- Yan, R.; Luo, D.; Huang, H.; Li, R.; Yu, N.; Liu, C.; Hu, M.; Rong, Q. Electron beam melting in the fabrication of three-dimensional mesh titanium mandibular prosthesis scaffold. Sci. Rep. 2018, 8, 750. [Google Scholar] [CrossRef] [Green Version]

- Hsu, T.-I.; Jhong, Y.-T.; Tsai, M.-H. Effect of Gradient Energy Density on the Microstructure and Mechanical Properties of Ti6Al4V Fabricated by Selective Electron Beam Additive Manufacture. Materials 2020, 13, 1509. [Google Scholar] [CrossRef] [Green Version]

- Wu, S.-H.; Li, Y.; Zhang, Y.-Q.; Li, X.-K.; Yuan, C.-F.; Hao, Y.-L.; Zhang, Z.-Y.; Guo, Z. Porous titanium-6 aluminum-4 vanadium cage has better osseointegration and less micromotion than a poly-ether-ether-ketone cage in sheep vertebral fusion. Artif. Organs 2013, 37, E191–E201. [Google Scholar] [CrossRef]

- Fambri, L. Book Review: Biomaterials. An Introduction, Second Edition Edited by J. B. Park and R. S. Lakes Plenum Press, New York, 1992 ISBN 0-306-43992-1, 394 pp. J. Bioact. Compat. Polym. 1993, 8, 289–290. [Google Scholar] [CrossRef]

- Zhang, L.C.; Klemm, D.; Eckert, J.; Hao, Y.L.; Sercombe, T.B. Manufacture by selective laser melting and mechanical behavior of a biomedical Ti–24Nb–4Zr–8Sn alloy. Scr. Mater. 2011, 65, 21–24. [Google Scholar] [CrossRef]

- Kokubo, T.; Yamaguchi, S. Chemical surface modification of a titanium scaffold. In Metallic Foam Bone; Elsevier: Amsterdam, The Netherlands, 2017; pp. 161–179. [Google Scholar] [CrossRef]

- Dewidar, M.M.; Lim, J. Properties of solid core and porous surface Ti–6Al–4V implants manufactured by powder metallurgy. J. Alloys Compd. 2008, 454, 442–446. [Google Scholar] [CrossRef]

- Heimann, R.B. Thermal spraying of biomaterials. Surf. Coat. Technol. 2006, 201, 2012–2019. [Google Scholar] [CrossRef]

- Ashby, M.F.; Medalist, R.F.M. The mechanical properties of cellular solids. Met. Mater. Trans. A 1983, 14, 1755–1769. [Google Scholar] [CrossRef]

- Harrysson, O.L.; Cansizoglu, O.; Marcellin-Little, D.; Cormier, D.R.; West, H.A. Direct metal fabrication of titanium implants with tailored materials and mechanical properties using electron beam melting technology. Mater. Sci. Eng. C 2008, 28, 366–373. [Google Scholar] [CrossRef]

- Parthasarathy, J.; Starly, B.; Raman, S.; Christensen, A. Mechanical evaluation of porous titanium (Ti6Al4V) structures with electron beam melting (EBM). J. Mech. Behav. Biomed. Mater. 2010, 3, 249–259. [Google Scholar] [CrossRef] [PubMed]

- Li, S.; Xu, Q.; Wang, Z.; Hou, W.; Hao, Y.; Yang, R.; Murr, L. Influence of cell shape on mechanical properties of Ti–6Al–4V meshes fabricated by electron beam melting method. Acta Biomater. 2014, 10, 4537–4547. [Google Scholar] [CrossRef] [PubMed]

- Van Grunsven, W.; Hernandez-Nava, E.; Reilly, G.C.; Goodall, R. Fabrication and Mechanical Characterization of Titanium Lattices with Graded Porosity. Metals 2014, 4, 401–409. [Google Scholar] [CrossRef]

- Choy, S.Y.; Sun, C.-N.; Leong, K.F.; Wei, J. Compressive properties of functionally graded lattice structures manufactured by selective laser melting. Mater. Des. 2017, 131, 112–120. [Google Scholar] [CrossRef]

- Zhang, Q.; Xie, J.; London, T.; Griffiths, D.; Bhamji, I.; Oancea, V. Estimates of the mechanical properties of laser powder bed fusion Ti-6Al-4V parts using finite element models. Mater. Des. 2019, 169, 107678. [Google Scholar] [CrossRef]

- Parthasarathy, J.; Starly, B.; Raman, S. A design for the additive manufacture of functionally graded porous structures with tailored mechanical properties for biomedical applications. J. Manuf. Process. 2011, 13, 160–170. [Google Scholar] [CrossRef]

- Mazur, M.; Leary, M.; Sun, S.; Vcelka, M.; Shidid, D.; Brandt, M. Deformation and failure behavior of Ti-6Al-4V lattice structures manufactured by selective laser melting (SLM). Int. J. Adv. Manuf. Technol. 2015, 84, 1391–1411. [Google Scholar]

- Gong, H.; Rafi, K.; Gu, H.; Starr, T.; Stucker, B. Analysis of defect generation in Ti–6Al–4V parts made using powder bed fusion additive manufacturing processes. Addit. Manuf. 2014, 1, 87–98. [Google Scholar] [CrossRef]

- Van Bael, S.; Kerckhofs, G.; Moesen, M.; Pyka, G.; Schrooten, J.; Kruth, J. Micro-CT-based improvement of geometrical and mechanical controllability of selective laser melted Ti6Al4V porous structures. Mater. Sci. Eng. A 2011, 528, 7423–7431. [Google Scholar] [CrossRef]

- Lozanovski, B.; Leary, M.; Tran, P.; Shidid, D.; Qian, M.; Choong, P.; Brandt, M. Computational modelling of strut defects in SLM manufactured lattice structures. Mater. Des. 2019, 171, 107671. [Google Scholar] [CrossRef]

- Ushijima, K.; Cantwell, W.; Mines, R.; Tsopanos, S.; Smith, M. An investigation into the compressive properties of stainless steel micro-lattice structures. J. Sandw. Struct. Mater. 2010, 13, 303–329. [Google Scholar] [CrossRef]

- Smith, M.; Guan, Z.; Cantwell, W. Finite element modelling of the compressive response of lattice structures manufactured using the selective laser melting technique. Int. J. Mech. Sci. 2012, 67, 28–41. [Google Scholar] [CrossRef]

- Wysocki, B.; Maj, P.; Sitek, R.; Buhagiar, J.; Kurzydłowski, K.J.; Święszkowski, W. Laser and Electron Beam Additive Manufacturing Methods of Fabricating Titanium Bone Implants. Appl. Sci. 2017, 7, 657. [Google Scholar] [CrossRef]

- Cheng, X.; Li, S.; Murr, L.; Zhang, Z.; Hao, Y.; Yang, R.; Medina, F.; Wicker, R. Compression deformation behavior of Ti–6Al–4V alloy with cellular structures fabricated by electron beam melting. J. Mech. Behav. Biomed. Mater. 2012, 16, 153–162. [Google Scholar] [CrossRef]

- Choy, S.Y.; Sun, C.-N.; Leong, K.F.; Wei, J. Compressive properties of Ti-6Al-4V lattice structures fabricated by selective laser melting: Design, orientation and density. Addit. Manuf. 2017, 16, 213–224. [Google Scholar] [CrossRef]

- Ataee, A.; Li, Y.; Fraser, D.; Song, G.; Wen, C. Anisotropic Ti-6Al-4V gyroid scaffolds manufactured by electron beam melting (EBM) for bone implant applications. Mater. Des. 2018, 137, 345–354. [Google Scholar] [CrossRef]

- AlOmar, Z.; Concli, F. A Review of the Selective Laser Melting Lattice Structures and Their Numerical Models. Adv. Eng. Mater. 2020, 22. [Google Scholar] [CrossRef]

- Göttingen, N.v.d.z. Mathematisch-Physikalische Klasse. In Abhandlungen der Gesellschaft der Wissenschaften zu Göttingen, Mathematisch-Physikalische Klasse; Weidmannsche Buchhandlung: Frankfurt, Germany, 1913; Volume 7. [Google Scholar]

- Sun, J.; Yang, Y.; Wang, D. Mechanical properties of a Ti6Al4V porous structure produced by selective laser melting. Mater. Des. 2013, 49, 545–552. [Google Scholar] [CrossRef]

- Zhang, S.; Wei, Q.; Cheng, L.; Li, S.; Shi, Y. Effects of scan line spacing on pore characteristics and mechanical properties of porous Ti6Al4V implants fabricated by selective laser melting. Mater. Des. 2014, 63, 185–193. [Google Scholar] [CrossRef]

- Pilkey, W.D. Stress Concentration. In Formulas for Stress, Strain, and Structural Matrices; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2004; Chapter 6; pp. 255–305. [Google Scholar] [CrossRef]

- Takano, N.; Fukasawa, K.; Nishiyabu, K. Structural strength prediction for porous titanium based on micro-stress concentration by micro-CT image-based multiscale simulation. Int. J. Mech. Sci. 2010, 52, 229–235. [Google Scholar] [CrossRef]

| D (mm) | S (mm) | DPW (%) | |

|---|---|---|---|

| C1 | 1.50 | 1.25 | 25 |

| C2 | 1.75 | 1.13 | 33 |

| C3 | 2.00 | 1.00 | 40 |

| C4 | 2.50 | 0.75 | 55 |

| C5 | 2.65 | 0.68 | 59 |

| C6 | 2.80 | 0.60 | 63 |

| Mesh Condition | Element Size (mm) | Mesh Results (Count) | Calculation Stress (MPa) | |||

|---|---|---|---|---|---|---|

| Maxima | Minimum | Tetrahedron | Node | Strut Center | Node | |

| Mesh 1 (default, fine) | 2.4 | 0.3 | 47,565 | 15,065 | 488 | 371 |

| Mesh 2 (default, extra fine) | 1.15 | 0.45 | 151,909 | 41,547 | 484 | 383 |

| Mesh 3 (self-set) | 0.5 | 0.2 | 1,341,348 | 277,728 | 488 | 378 |

| Specimen | C1 | C2 | C3 | C4 | C5 | C6 |

|---|---|---|---|---|---|---|

| E—Experimental (GPa) | 9.46 ± 1.08 | 8.93 ± 0.88 | 5.67± 0.39 | 3.29 ± 0.46 | 2.73 ± 0.25 | 2.39 ± 0.33 |

| E1—FEA (GPa) | 62.79 | 50.81 | 39.91 | 22.17 | 17.9 | 13.97 |

| E2—FEA (GPa) | 10.05 | 8.13 | 6.39 | 3.55 | 2.86 | 2.24 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tsai, M.-H.; Yang, C.-M.; Hung, Y.-X.; Jheng, C.-Y.; Chen, Y.-J.; Fu, H.-C.; Chen, I.-G. Finite Element Analysis on Initial Crack Site of Porous Structure Fabricated by Electron Beam Additive Manufacturing. Materials 2021, 14, 7467. https://doi.org/10.3390/ma14237467

Tsai M-H, Yang C-M, Hung Y-X, Jheng C-Y, Chen Y-J, Fu H-C, Chen I-G. Finite Element Analysis on Initial Crack Site of Porous Structure Fabricated by Electron Beam Additive Manufacturing. Materials. 2021; 14(23):7467. https://doi.org/10.3390/ma14237467

Chicago/Turabian StyleTsai, Meng-Hsiu, Chia-Ming Yang, Yu-Xuan Hung, Chao-Yong Jheng, Yen-Ju Chen, Ho-Chung Fu, and In-Gann Chen. 2021. "Finite Element Analysis on Initial Crack Site of Porous Structure Fabricated by Electron Beam Additive Manufacturing" Materials 14, no. 23: 7467. https://doi.org/10.3390/ma14237467

APA StyleTsai, M. -H., Yang, C. -M., Hung, Y. -X., Jheng, C. -Y., Chen, Y. -J., Fu, H. -C., & Chen, I. -G. (2021). Finite Element Analysis on Initial Crack Site of Porous Structure Fabricated by Electron Beam Additive Manufacturing. Materials, 14(23), 7467. https://doi.org/10.3390/ma14237467