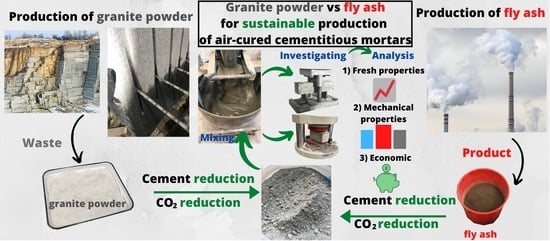

Granite Powder vs. Fly Ash for the Sustainable Production of Air-Cured Cementitious Mortars

Abstract

:1. Introduction

2. Materials and Methods

2.1. Designing of the Composite Mixes and the Preparation of Samples

2.2. Determination of the Basic Properties of Binders

2.2.1. Morphological Properties

2.2.2. Chemical Properties

2.3. Determination of the Consistency of the Fresh Mortars

2.4. Determination of the Basic Physical Properties of the Hardened Mortars

2.5. Determination of the Basic Mechanical Properties of the Hardened Mortars

3. Results

3.1. Determination of the Basic Properties of the Binders

3.1.1. Determination of the Basic Morphological Properties of the Binders

3.1.2. Chemical Properties of the Binders

3.1.3. Granular Analysis of the Binders and Fine Aggregate

3.2. The Consistency of the Mortars

3.3. Results of the Basic Physical Properties of the Air-Cured Hardened Composites

3.4. Results of the Basic Mechanical Properties of the Air-Cured Hardened Composites

4. Economic Analysis of the Potential Use of Granite Powder vs. Fly Ash for the Production of Air-Cured Cementitious Mortars

4.1. Analysis of the Mechanical Performance of the Cementitious Mortars

4.2. Economic Analysis of the Cementitious Composites

4.3. Combined Economic and Mechanical Performance of the Composites

5. Conclusions

- Granite powder and fly ash have different morphological properties, whereas the properties of granite powder are similar to the morphology properties of cement;

- The addition of granite powder in cementitious mixes changes the consistency of the mix, becoming denser, whereas fly ash changes the consistency of the mix to be more fluid;

- The addition of granite powder and fly ash causes a decrease in the mechanical properties of cementitious mortars in the first 28 days of curing. After this time, an improvement in the mechanical properties of mortars with the addition of fly ash can be observed. In the case of mortars with the addition of granite powder, this effect was not observed;

- Replacing the cement resulted in a decrease in compressive strength; however, it was observed that with the increased amount of cement replacement with the addition of granite powder (especially in 30% replacement), no significant decrease in compressive strength was detected. This may be indicative of the filler effect of granite powder in cementitious composites;

- It was observed that the increased w/c ratio decreases the compressive strength and bending tensile strength of mortars (compared with reference mortar); it was also observed that the brittleness of mortars decreases with the time of curing, and modification of mortars with the addition of granite powder or fly ash does not change brittleness significantly;

- It was observed that the economic properties of mortars modified with the addition of granite powder are significantly better than those of mortars modified with the addition of fly ash.

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Benhelal, E.; Zahedi, G.; Shamsaei, E.; Bahadori, A. Global strategies and potentials to curb CO2 emissions in cement industry. J. Clean. Prod. 2013, 51, 142–161. [Google Scholar] [CrossRef]

- Usón, A.A.; López-Sabirón, A.M.; Ferreira, G.; Sastresa, E.L. Uses of alternative fuels and raw materials in the cement industry as sustainable waste management options. Renew. Sustain. Energy Rev. 2013, 23, 242–260. [Google Scholar] [CrossRef]

- Ali, M.; Saidur, R.; Hossain, M. A review on emission analysis in cement industries. Renew. Sustain. Energy Rev. 2011, 15, 2252–2261. [Google Scholar] [CrossRef]

- Madlool, N.; Saidur, R.; Hossain, M.; Rahim, N. A critical review on energy use and savings in the cement industries. Renew. Sustain. Energy Rev. 2011, 15, 2042–2060. [Google Scholar] [CrossRef]

- Hewlett, P.C.; Liska, M. Lea’s Chemistry of Cement and Concrete; Elsevier: Amsterdam, The Netherlands, 2019. [Google Scholar]

- Pulselli, R.; Simoncini, E.; Ridolfi, R.; Bastianoni, S. Specific emergy of cement and concrete: An energy-based appraisal of building materials and their transport. Ecol. Indic. 2008, 8, 647–656. [Google Scholar] [CrossRef]

- Letelier, V.; Henríquez-Jara, B.I.; Manosalva, M.; Moriconi, G. Combined use of waste concrete and glass as a replacement for mortar raw materials. Waste Manag. 2019, 94, 107–119. [Google Scholar] [CrossRef]

- Martínez-Lage, I.; Vázquez-Burgo, P.; Velay-Lizancos, M. Sustainability evaluation of concretes with mixed recycled aggregate based on holistic approach: Technical, economic and environmental analysis. Waste Manag. 2020, 104, 9–19. [Google Scholar] [CrossRef]

- Li, L.; Wang, Y.; Tan, Y.; Kwan, A. Filler technology of adding granite dust to reduce cement content and increase strength of mortar. Powder Technol. 2019, 342, 388–396. [Google Scholar] [CrossRef]

- Szymanowski, J.; Sadowski, Ł. Functional and adhesive properties of cement-based overlays modified with amorphous silica nanospheres. J. Adhes. 2019, 96, 207–228. [Google Scholar] [CrossRef]

- Chu, S.; Kwan, A. Co-addition of metakaolin and silica fume in mortar: Effects and advantages. Constr. Build. Mater. 2019, 197, 716–724. [Google Scholar] [CrossRef]

- Chu, S.; Li, L.; Kwan, A. Development of extrudable high strength fiber reinforced concrete incorporating nano calcium carbonate. Addit. Manuf. 2021, 37, 101617. [Google Scholar] [CrossRef]

- Chen, Z.; Chu, S.; Lee, Y.; Lee, H. Coupling effect of γ-dicalcium silicate and slag on carbonation resistance of low carbon materials. J. Clean. Prod. 2020, 262, 121385. [Google Scholar] [CrossRef]

- Chu, S.; Yao, J. A strength model for concrete made with marine dredged sediment. J. Clean. Prod. 2020, 274, 122673. [Google Scholar] [CrossRef]

- Chu, S.; Ye, H.; Huang, L.; Li, L. Carbon fiber reinforced geopolymer (FRG) mix design based on liquid film thickness. Constr. Build. Mater. 2021, 269, 121278. [Google Scholar] [CrossRef]

- Chen, J.; Guan, G.; Ng, P.; Kwan, A.; Chu, S. Packing optimization of paste and aggregate phases for sustainability and performance improvement of concrete. Adv. Powder Technol. 2021. [Google Scholar] [CrossRef]

- Chu, S. Effect of paste volume on fresh and hardened properties of concrete. Constr. Build. Mater. 2019, 218, 284–294. [Google Scholar] [CrossRef]

- Maddalena, R.; Roberts, J.J.; Hamilton, A. Can Portland cement be replaced by low-carbon alternative materials? A study on the thermal properties and carbon emissions of innovative cements. J. Clean. Prod. 2018, 186, 933–942. [Google Scholar] [CrossRef]

- D’Urso, A.; Cutraro, V.; Catania, C.; Rapisarda, F.; Garaffo, G.; Calì, M. Closed Cycle Drying Process to Retrain Industrial Sludge into Construction Products. Int. J. Adv. Sci. Eng. Inf. Technol. 2019, 9, 1783–1788. [Google Scholar] [CrossRef]

- Puertas, F.; García-Díaz, I.; Barba, A.; Gazulla, M.; Palacios, M.; Gómez, M.; Martínez-Ramírez, S. Ceramic wastes as alternative raw materials for Portland cement clinker production. Cem. Concr. Compos. 2008, 30, 798–805. [Google Scholar] [CrossRef]

- Golewski, G.L. The influence of microcrack width on the mechanical parameters in concrete with the addition of fly ash: Consideration of technological and ecological benefits. Constr. Build. Mater. 2019, 197, 849–861. [Google Scholar] [CrossRef]

- Golewski, G.L. Green concrete composite incorporating fly ash with high strength and fracture toughness. J. Clean. Prod. 2018, 172, 218–226. [Google Scholar] [CrossRef]

- Giergiczny, Z. Fly ash and slag. Cem. Concr. Res. 2019, 124, 105826. [Google Scholar] [CrossRef]

- Liu, X.; Li, T.; Tian, W.; Wang, Y.; Chen, Y. Study on the durability of concrete with FNS fine aggregate. J. Hazard. Mater. 2020, 381, 120936. [Google Scholar] [CrossRef]

- Ahmaruzzaman, M. A review on the utilization of fly ash. Prog. Energy Combust. Sci. 2010, 36, 327–363. [Google Scholar] [CrossRef]

- Sadowski, Ł.; Nikoo, M.; Shariq, M.; Joker, E.; Czarnecki, S.; Nikoo, M. The Nature-Inspired Metaheuristic Method for Predicting the Creep Strain of Green Concrete Containing Ground Granulated Blast Furnace Slag. Materials 2019, 12, 293. [Google Scholar] [CrossRef] [Green Version]

- Seghir, N.T.; Benaimeche, O.; Krzywiński, K.; Sadowski, Ł. Ultrasonic Evaluation of Cement-Based Building Materials Modified Using Marble Powder Sourced from Industrial Wastes. Buildings 2020, 10, 38. [Google Scholar] [CrossRef] [Green Version]

- Sadowski, Ł.; Piechówka-Mielnik, M.; Widziszowski, T.; Gardynik, A.; Mackiewicz, S. Hybrid ultrasonic-neural prediction of the compressive strength of environmentally friendly concrete screeds with high volume of waste quartz mineral dust. J. Clean. Prod. 2019, 212, 727–740. [Google Scholar] [CrossRef]

- Chajec, A. Towards the sustainable use of granite powder waste for manufacturing of cementitious composites. MATEC Web Conf. 2020, 322, 01005. [Google Scholar] [CrossRef]

- Al-Hamaie, H.D.; Khushefati, W.H. Granite Sludge Reuse in Mortar and Concrete. J. Appl. Sci. 2013, 13, 444–450. [Google Scholar] [CrossRef] [Green Version]

- Da Silva, J.L.; Campos, D.B.D.C.; Lordsleem, A.C.; Povoas, Y.V. Influence of the partial substitution of fine aggregate by granite powder in mortar on the process of natural carbonation. Waste Manag. Res. 2020, 38, 254–262. [Google Scholar] [CrossRef] [PubMed]

- Yazıcı, H.; Yardımcı, M.Y.; Yiğiter, H.; Aydın, S.; Türkel, S. Mechanical properties of reactive powder concrete containing high volumes of ground granulated blast furnace slag. Cem. Concr. Compos. 2010, 32, 639–648. [Google Scholar] [CrossRef]

- Gupta, L.K.; Vyas, A.K. Impact on mechanical properties of cement sand mortar containing waste granite powder. Constr. Build. Mater. 2018, 191, 155–164. [Google Scholar] [CrossRef]

- Sadek, D.M.; El-Attar, M.M.; Ali, H.A. Reusing of marble and granite powders in self-compacting concrete for sustainable development. J. Clean. Prod. 2016, 121, 19–32. [Google Scholar] [CrossRef]

- Bakhoum, E.S.; Garas, G.L.K.; Allam, M.E.; Ezz, H. The Role of Nano-Technology in Sustainable Construction: A Case Study of Using Nano Granite Waste Particles in Cement Mortar. Eng. J. 2017, 21, 217–227. [Google Scholar] [CrossRef]

- Gao, X.; Yuan, B.; Yu, Q.L.; Brouwers, H.J.H. Characterization and application of municipal solid waste incineration (MSWI) bottom ash and waste granite powder in alkali activated slag. J. Clean. Prod. 2017, 164, 410–419. [Google Scholar] [CrossRef] [Green Version]

- Chowaniec, A.; Sadowski, Ł.; Żak, A. The chemical and microstructural analysis of the adhesive properties of epoxy resin coatings modified using waste glass powder. Appl. Surf. Sci. 2020, 504, 144373. [Google Scholar] [CrossRef]

- Chowaniec, A.; Ostrowski, K. Epoxy resin coatings modified with waste glass powder for sustainable construction. Czas. Tech. 2018, 8, 99–109. [Google Scholar] [CrossRef] [Green Version]

- Chajec, A.; Sadowski, Ł. The Effect of Steel and Polypropylene Fibers on the Properties of Horizontally Formed Concrete. Materials 2020, 13, 5827. [Google Scholar] [CrossRef]

- Chajec, A.; Krzywiński, K.; Sadowski, Ł.; Ostrowski, K. The influence of polypropylene fibres on the properties of fresh and hardened concrete. Czas. Tech. 2019, 5, 71–82. [Google Scholar] [CrossRef] [Green Version]

- Popek, M.; Sadowski, Ł.; Szymanowski, J. Abrasion Resistance of Concrete Containing Selected Mineral Powders. Procedia Eng. 2016, 153, 617–622. [Google Scholar] [CrossRef] [Green Version]

- Galińska, A.; Czarnecki, S. The Effect of Mineral Powders Derived from Industrial Wastes on Selected Mechanical Properties of Concrete. IOP Conf. Ser.: Mater. Sci. Eng. 2017, 245, 032039. [Google Scholar] [CrossRef]

- Polish Committee for Standardization. Tests for Geometrical Properties of Aggregates—Part 1: Determination of Particle Size Distribution-Sieving Method; PN-EN 933-1:2012; Polish Committee for Standardization: Warsaw, Poland, 2012. [Google Scholar]

- Polish Committee for Standardization. Methods of Testing Cement—Part 1: Determination of Strength; PN-EN 196-1:2016; Polish Committee for Standardization: Warsaw, Poland, 2016. [Google Scholar]

- Gu, X.; Tran, Y.; Hong, L. Quantification of coarse aggregate shape in concrete. Front. Struct. Civ. Eng. 2014, 8, 308–321. [Google Scholar] [CrossRef]

- Ostrowski, K.; Stefaniuk, D.; Sadowski, Ł.; Krzywiński, K.; Gicala, M.; Różańska, M. Potential use of granite waste sourced from rock processing for the application as coarse aggregate in high-performance self-compacting concrete. Constr. Build. Mater. 2020, 238, 117794. [Google Scholar] [CrossRef]

- Polish Committee for Standardization. Methods of Testing Cement—Part 6: Determination of Fineness; PN-EN 196-6:2011; Polish Committee for Standardization: Warsaw, Poland, 2011. [Google Scholar]

- Polish Committee for Standardization. Building Mortars-Testing of Physical and Mechanical Properties; PN-B-04500:1985; Polish Committee for Standardization: Warsaw, Poland, 1985. [Google Scholar]

- Polish Committee for Standardization. Methods of Test for Mortar for Masonry—Part 11: Determination of Flexural and Compressive Strength of Hardened Mortar; PN-EN 1015-11:2001; Polish Committee for Standardization: Warsaw, Poland, 2001. [Google Scholar]

- Fernlund, J. Image analysis method for determining 3-D shape of coarse aggregate. Cem. Concr. Res. 2005, 35, 1629–1637. [Google Scholar] [CrossRef]

- Ostrowski, K.; Sadowski, Ł.; Stefaniuk, D.; Wałach, D.; Gawenda, T.; Oleksik, K.; Usydus, I. The Effect of the Morphology of Coarse Aggregate on the Properties of Self-Compacting High-Performance Fibre-Reinforced Concrete. Materials 2018, 11, 1372. [Google Scholar] [CrossRef] [Green Version]

- Singh, S.; Nagar, R.; Agrawal, V.; Rana, A.; Tiwari, A. Sustainable utilization of granite cutting waste in high strength concrete. J. Clean. Prod. 2016, 116, 223–235. [Google Scholar] [CrossRef]

- Shamsabadi, E.A.; Ghalehnovi, M.; De Brito, J.; Khodabakhshian, A. Performance of Concrete with Waste Granite Powder: The Effect of Superplasticizers. Appl. Sci. 2018, 8, 1808. [Google Scholar] [CrossRef] [Green Version]

- Hou, P.-K.; Kawashima, S.; Wang, K.-J.; Corr, D.J.; Qian, J.-S.; Shah, S.P. Effects of colloidal nanosilica on rheological and mechanical properties of fly ash–cement mortar. Cem. Concr. Compos. 2013, 35, 12–22. [Google Scholar] [CrossRef] [Green Version]

- Supit, S.W.; Shaikh, F.U.; Sarker, P.K. Effect of ultrafine fly ash on mechanical properties of high volume fly ash mortar. Constr. Build. Mater. 2014, 51, 278–286. [Google Scholar] [CrossRef]

- Elangovan, G. Experimental study of concrete by partial replacement of cement with granite dust powder. Int. J. Eng. Technol. Sci. 2015, 2, 2349–3976. [Google Scholar]

- Mármol, I.; Ballester, P.; Cerro, S.; Monrós, G.; Morales, J.; Sánchez, L.J. Use of granite sludge wastes for the production of coloured cement-based mortars. Cem. Concr. Compos. 2010, 32, 617–622. [Google Scholar] [CrossRef]

- Kurda, R.; De Brito, J.; Silvestre, J.D. Combined Economic and Mechanical Performance Optimization of Recycled Aggregate Concrete with High Volume of Fly Ash. Appl. Sci. 2018, 8, 1189. [Google Scholar] [CrossRef] [Green Version]

| Series of Mixes [-] | Cement CEM I 42.5R [kg/m3] | Water [kg/m3] | Fly Ash [kg/m3] | Granite Powder [kg/m3] | Dried Quartz Sand [kg/m3] | Water/Cement Ratio [-] |

|---|---|---|---|---|---|---|

| Ref. | 280 | 140 | 0 | 0 | 840 | 0.50 |

| FA10 | 252 | 140 | 28 | 0 | 840 | 0.56 |

| FA20 | 224 | 140 | 56 | 0 | 840 | 0.63 |

| FA30 | 196 | 140 | 84 | 0 | 840 | 0.71 |

| GP10 | 252 | 140 | 0 | 28 | 840 | 0.56 |

| GP20 | 224 | 140 | 0 | 56 | 840 | 0.63 |

| GP30 | 196 | 140 | 0 | 84 | 840 | 0.71 |

| Series | MPR7days | ΔMPR7days | MPR28days | ΔMPR28days | MPR90days | ΔMPR90days |

|---|---|---|---|---|---|---|

| Ref | 100% | 1.00 | 100% | 1.00 | 100% | 1.00 |

| FA10 | 98% | 0.98 | 94% | 0.94 | 102% | 1.02 |

| FA20 | 83% | 0.83 | 90% | 0.90 | 99% | 0.99 |

| FA30 | 75% | 0.75 | 81% | 0.81 | 97% | 0.97 |

| GP10 | 96% | 0.96 | 76% | 0.76 | 91% | 0.91 |

| GP20 | 93% | 0.93 | 77% | 0.77 | 86% | 0.86 |

| GP30 | 80% | 0.80 | 79% | 0.79 | 86% | 0.86 |

| Series | ccement [€] | cwater [€] | cFA [€] | cGP [€] | csand [€] | cmixes [€] | ECR | ΔECR |

|---|---|---|---|---|---|---|---|---|

| - | - | [%] | [-] | |||||

| Ref | 74.66 | 2.50 | 0.00 | 0.00 | 45.30 | 122.46 | 100 | 1.00 |

| FA10 | 67.19 | 2.50 | 3.43 | 0.00 | 45.30 | 118.42 | 97 | 0.97 |

| FA20 | 59.73 | 2.50 | 6.85 | 0.00 | 45.30 | 114.38 | 93 | 0.93 |

| FA30 | 52.26 | 2.50 | 10.28 | 0.00 | 45.30 | 110.34 | 90 | 0.90 |

| GP10 | 67.19 | 2.50 | 0.00 | 0.52 | 45.30 | 115.51 | 94 | 0.94 |

| GP20 | 59.73 | 2.50 | 0.00 | 1.03 | 45.30 | 108.56 | 89 | 0.89 |

| GP30 | 52.26 | 2.50 | 0.00 | 1.55 | 45.30 | 101.61 | 83 | 0.83 |

| Series | MPR7days [%] | MPR28days [%] | MPR90days [%] | ECR [%] |

|---|---|---|---|---|

| Ref | 100 | 100 | 100 | 100 |

| FA10 | 109 | 94 | 102 | 97 |

| FA20 | 92 | 90 | 99 | 93 |

| FA30 | 84 | 81 | 97 | 90 |

| GP10 | 96 | 76 | 91 | 94 |

| GP20 | 93 | 77 | 86 | 89 |

| GP30 | 80 | 79 | 86 | 83 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chajec, A. Granite Powder vs. Fly Ash for the Sustainable Production of Air-Cured Cementitious Mortars. Materials 2021, 14, 1208. https://doi.org/10.3390/ma14051208

Chajec A. Granite Powder vs. Fly Ash for the Sustainable Production of Air-Cured Cementitious Mortars. Materials. 2021; 14(5):1208. https://doi.org/10.3390/ma14051208

Chicago/Turabian StyleChajec, Adrian. 2021. "Granite Powder vs. Fly Ash for the Sustainable Production of Air-Cured Cementitious Mortars" Materials 14, no. 5: 1208. https://doi.org/10.3390/ma14051208

APA StyleChajec, A. (2021). Granite Powder vs. Fly Ash for the Sustainable Production of Air-Cured Cementitious Mortars. Materials, 14(5), 1208. https://doi.org/10.3390/ma14051208