Analysis of Tube-to-Tubesheet Welding in Carbon Steel Heat Exchangers of a Double Plate Header Box

Abstract

:1. Introduction

2. Materials and Methods

2.1. Manufacturing of Two Models of Header Box

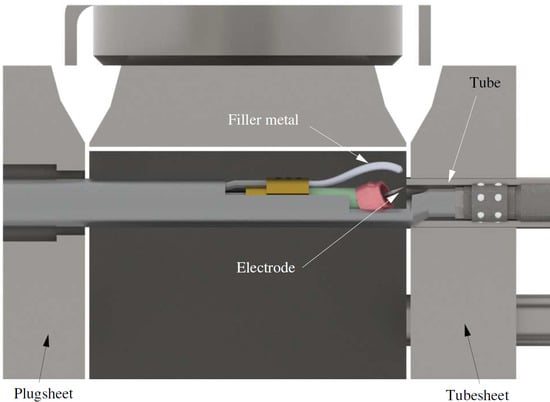

2.2. Mockup Manufacturing

Welding Specification Procedure

2.3. Macrographical Analysis

3. Results and Discussion

3.1. Parallelism Deviation

3.2. Weld Penetration

3.3. Considerations over the Header Box Manufacturing and Tube-to-Tubesheet Welding

- (1)

- Optimization of the welding sequence in the manufacturing of the header box to reduce distortion and parallelism deviation between the plugsheet and the tubesheet. As has been analyzed in this case, parallelism deviations greater than 1 mm (in absolute values) should be avoided. Obviously, a dimensional control of header boxes like the one carried out in this work could help to determine these deviations, although for productivity and economic profitability, it cannot be recommended in practical industrial procedures.

- (2)

- Control of preheating temperature, not only due to its influence on microstructural materials aspects (embrittlement/martensite formation) but also for its influence on weld penetration, is an important issue.

- (3)

- And specially, to implement improvements in the conventional orbital GTAW used for welding tube-to-tubesheet joints. These improvements should be addressed to the digitization of the positioned GTAW machine with the optimal electrode-joint distance in each hole and following the joint. In reference [21] we can find the different technologies that could be implemented in a conventional orbital GTAW machine to overcome the problems and consequences described in this article. This will enable to achieve optimal positioning and therefore, optimal weld penetration overcoming parallelism deviations of header box plates.

4. Conclusions

- A dimensional control was carried out on two header boxes of a heat exchanger in order to determine the parallelism deviations between plates (plugsheet and tubesheet). These parallelism deviations are due to the manufacturing process of the header box. They vary within −2.75 mm and 1.75 mm and may cause a bad positioning of the orbital GTAW equipment used for tube-to-tubesheet joints. Taking these values into account, the maximum error in the positioning of the welding equipment could be of around 4.5 mm.

- A coupon was designed and manufactured reproducing these deviations and for simulating the tube-to-tubesheet welding. It was determined that weld penetration decreased with increasing distance between the electrode and the joint. Negative deviations higher, in absolute values, than 1 mm result in welds do not meet the minimum requirements of manufacturing standards for this type of equipment. It was also determined that a decrease in the preheating temperature added to parallelism deviation, significantly reduced weld penetration.

- Finally, the incorporation of dimensional controls and optimization of the welding sequence during the manufacturing of the header box were discussed, and improvements in the automatic positioning automatically of this orbital GTAW equipment should be considered as the optimal solution for this kind of heat exchangers.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| GTAW | Gas Tungsten Arc Welding |

| TIG | Tungsten Inert Gas |

| MLP | Minimum leak pathThree |

| Length of leg | |

| HAZ | Heat affected zone |

| PWHT | Post Weld Heat Treatment |

| CE | Carbon Equivalent |

References

- Krüger, J. Orbital welding of tube heat exchangers. Weld. J. 2017, 96, 68–72. [Google Scholar]

- Ali, M.; Ul-Hamid, A.; Alhems, L.M.; Saeed, A. Review of common failures in heat exchangers—Part I: Mechanical and elevated temperature failures. Eng. Fail. Anal. 2020, 109, 104396. [Google Scholar] [CrossRef]

- Wang, H.; Sang, Z.; Widera, G.E.O. Connection strength and tightness of hydraulically expanded tube-to-tubesheet joints. J. Mater. Process. Technol. 2007, 194, 93–99. [Google Scholar] [CrossRef]

- Huang, T.; Zhang, G.; Liu, F. Design, manufacturing and repair of tube-to-tubesheet welds of steam generators of CPR1000 units. Nucl. Eng. Des. 2018, 333, 55–62. [Google Scholar] [CrossRef]

- Otegui, J.L.; Booman, J.N.; Massone, J. Experimental assessment of thermal grain boundary embrittlement after tubeplate failure in a petrochemical heat exchanger. Eng. Fail. Anal. 2017, 79, 140–153. [Google Scholar] [CrossRef]

- American Society of Mechanical Engineers. ASME Boiler & Pressure Vessel Code, Section VIII Division 1; Rules for Construction of Pressure Vessels; American Society of Mechanical Engineers: New York, NY, USA, 2019. [Google Scholar]

- Wei, X.L.; Ling, X. Investigation of welded structures on mechanical properties of 304L welded tube-to-tubesheet joints. Eng. Fail. Anal. 2015, 52, 90–96. [Google Scholar] [CrossRef]

- Farrahi, G.H.; Minaii, K.; Chamani, M.; Mahmoudi, A.H. Effect of residual stress on failure of tube-to-tubesheet weld in heat exchangers. Int. J. Eng. Trans. A Basics 2019, 32, 112–120. [Google Scholar] [CrossRef]

- Górka, J.; Przybyła, M.; Szmul, M.; Chudzio, A.; Ładak, D. Orbital TIG Welding of Titanium Tubes with Perforated Bottom Made of Titanium-Clad Steel. Adv. Mater. Sci. 2019, 19, 55–64. [Google Scholar] [CrossRef] [Green Version]

- Sauraw, A.; Sharma, A.K.; Fydrych, D.; Sirohi, S.; Gupta, A.; Świerczyńska, A.; Pandey, C.; Rogalski, G. Study on microstructural characterization, mechanical properties and residual stress of gtaw dissimilar joints of p91 and p22 steels. Materials 2021, 14, 6591. [Google Scholar] [CrossRef] [PubMed]

- Farrahi, G.H.; Chamani, M.; Kiyoumarsioskouei, A.; Mahmoudi, A.H. The effect of plugging of tubes on failure of shell and tube heat exchanger. Eng. Fail. Anal. 2019, 104, 545–559. [Google Scholar] [CrossRef]

- Liu, L.; Ding, N.; Shi, J.; Xu, N.; Guo, W.; Wu, C.M.L. Failure analysis of tube-to-tubesheet welded joints in a shell-tube heat exchanger. Case Stud. Eng. Fail. Anal. 2016, 7, 32–40. [Google Scholar] [CrossRef] [Green Version]

- Otegui, J.L.; Fazzini, P.G. Failure analysis of tube–tubesheet welds in cracked gas heat exchangers. Eng. Fail. Anal. 2004, 11, 903–913. [Google Scholar] [CrossRef]

- Ma, Q.L.; Xu, H.; Wang, Z.W.; Hou, F.; Xu, L.Y. Failure analysis and critical manufacturing technology research on titanium condensers. Eng. Fail. Anal. 2005, 12, 432–439. [Google Scholar] [CrossRef]

- Su, W.; Ma, N.; Sang, Z.; Widera, G.E. Investigation of fatigue strength of welded tube-to-tubesheet joint. J. Press. Vessel Technol. Trans. ASME 2009, 131, 041205. [Google Scholar] [CrossRef]

- Rongjuan, S.; Weiqiang, W.; Yan, L.; Dong, L.; Wei, L. Root cause analysis of stress corrosion at tube-to-tubesheet joints of a waste heat boiler. Eng. Fail. Anal. 2014, 45, 398–405. [Google Scholar] [CrossRef]

- Azevedo, C.R.; Beneduce Neto, F.; Brandi, S.D.; Tschiptschin, A.P. Cracking of 2.25Cr–1.0Mo steel tube/stationary tube-sheet weldment of a heat-exchanger. Eng. Fail. Anal. 2008, 15, 695–710. [Google Scholar] [CrossRef]

- Adullah, S.; Ezuber, H.M. Repair of tube-tubesheet weld cracks in a cracked gas/steam heat exchanger. J. Fail. Anal. Prev. 2011, 11, 611–617. [Google Scholar] [CrossRef]

- Vandewynckéle, A.; Vaamonde, E.; Fontán, M.; Herwig, P.; Mascioletti, A. Laser welding head tailored to tube-sheet joint requirements for heat exchangers manufacturing. Phys. Procedia 2013, 41, 144–152. [Google Scholar] [CrossRef]

- Lei, T.; Rong, Y.; Wang, H.; Huang, Y.; Li, M. A review of vision-aided robotic welding. Comput. Ind. 2020, 123, 103326. [Google Scholar] [CrossRef]

- Lei, T.; Wu, C.; Rong, Y.; Huang, Y. The development of tube-to-tubesheet welding from automation to digitization. Int. J. Adv. Manuf. Technol. 2021, 116, 779–802. [Google Scholar] [CrossRef]

- Jin, Z.; Li, H.; Zhang, C.; Wang, Q.; Gao, H. Online welding path detection in automatic tube-to-tubesheet welding using passive vision. Int. J. Adv. Manuf. Technol. 2017, 90, 3075–3084. [Google Scholar] [CrossRef]

- Lei, T.; Wang, W.; Rong, Y.; Xiong, P.; Huang, Y. Cross-lines laser aided machine vision in tube-to-tubesheet welding for welding height control. Opt. Laser Technol. 2020, 121, 105796. [Google Scholar] [CrossRef]

- Ghayad, I.; Abdel-Hamid, Z.; Gomaa, N. A Case Study: Corrosion Failure of Tube Heat Exchanger. J. Metall. Eng. 2015, 4, 57. [Google Scholar] [CrossRef]

- Nel, H.J.; Nurick, A.; Nel, A.L.; Lombaard, F. Design of unpartitioned, plug type header boxes for air-cooled heat exchangers in refinery service. Am. Soc. Mech. Eng. Press. Vessel. Pip. Div. (Publ.) PVP 2012, 1, 451–460. [Google Scholar] [CrossRef]

- Beyers, W.A.; Zapke, A.; Venter, G. Improved Cover Type Header Box Design Procedure. R&D J. 2015, 31, 76–85. [Google Scholar]

- Beyers, W.A.; Venter, G. Modelling the structural behaviour of a round nozzle to flat plate interface in pressure vessels. Int. J. Press. Vessel. Pip. 2021, 190, 104257. [Google Scholar] [CrossRef]

- Dana, M.M.; Javidi, M. Corrosion simulation via coupling computational fluid dynamics and NORSOK CO2 corrosion rate prediction model for an outlet header piping of an air-cooled heat exchanger. Eng. Fail. Anal. 2021, 122, 105285. [Google Scholar] [CrossRef]

- American Society of Mechanical Engineers. ASME Boiler & Pressure Vessel Code. In Section II. Part A; Ferrous Material Specifications; American Society of Mechanical Engineers: New York, NY, USA, 2019. [Google Scholar]

- American Society of Mechanical Engineers. ASME Boiler & Pressure Vessel Code. In Section IX. Qualification Standard for Welding, Brazing, and Fusing Procedures, Welders, Brazers, and Welding, Brazing, and Fusing Operators; American Society of Mechanical Engineers: New York, NY, USA, 2019. [Google Scholar]

- International Organization for Standardization. ISO 4063:2009; Welding and Allied Processes. Nomenclature of Processes and Reference Numbers. International Organization for Standardization: Geneva, Switzerland, 2009.

- American Society of Mechanical Engineers. ASME Boiler & Pressure Vessel Code. In Section II. Part C; Specifications for Welding Rods, Electrodes, and Filler Metals; American Society of Mechanical Engineers: New York, NY, USA, 2019. [Google Scholar]

- International Organization for Standardization. ISO 14175:2008; Welding Consumables. Gases and Gas Mixtures for Fusion Welding and Allied Processes. International Organization for Standardization: Geneva, Switzerland, 2008.

- International Organization for Standardization. ISO 15614-8:2016; Specification and Qualification of Welding Procedures for Metallic Materials. Welding Procedure Test. Part8: Welding of Tubes to Tube-Plate Joints. International Organization for Standardization: Geneva, Switzerland, 2016.

| SA-516 Gr. 70 (Tubesheet) | SA-210 Gr. A1 (Tube) | ||

|---|---|---|---|

| Element | Composition % | Element | Composition % |

| Carbon, max | 0.28 (50 mm thickness) | Carbon, max | 0.27 |

| Manganese | Heat analysis 0.85–1.20 Product analysis 0.79–1.30 | Manganese, max | 0.93 |

| Phosphorus, max | 0.025 | Phosphorus, max | 0.035 |

| Sulfur, max | 0.025 | Sulfur, max | 0.035 |

| Silicon | Heat analysis 0.15–0.40 Product analysis 0.13–0.45 | Silicon, min | 0.10 |

| Carbon Equivalent (CE) | 0.5 | Carbon Equivalent (CE) | 0.42 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

García González, J.; Hernández-Ortega, J.J.; Jiménez-Ballesta, A.-E.; Pedreño, R.Z. Analysis of Tube-to-Tubesheet Welding in Carbon Steel Heat Exchangers of a Double Plate Header Box. Materials 2022, 15, 261. https://doi.org/10.3390/ma15010261

García González J, Hernández-Ortega JJ, Jiménez-Ballesta A-E, Pedreño RZ. Analysis of Tube-to-Tubesheet Welding in Carbon Steel Heat Exchangers of a Double Plate Header Box. Materials. 2022; 15(1):261. https://doi.org/10.3390/ma15010261

Chicago/Turabian StyleGarcía González, José, Juan José Hernández-Ortega, Ana-Eva Jiménez-Ballesta, and Rosendo Zamora Pedreño. 2022. "Analysis of Tube-to-Tubesheet Welding in Carbon Steel Heat Exchangers of a Double Plate Header Box" Materials 15, no. 1: 261. https://doi.org/10.3390/ma15010261

APA StyleGarcía González, J., Hernández-Ortega, J. J., Jiménez-Ballesta, A. -E., & Pedreño, R. Z. (2022). Analysis of Tube-to-Tubesheet Welding in Carbon Steel Heat Exchangers of a Double Plate Header Box. Materials, 15(1), 261. https://doi.org/10.3390/ma15010261