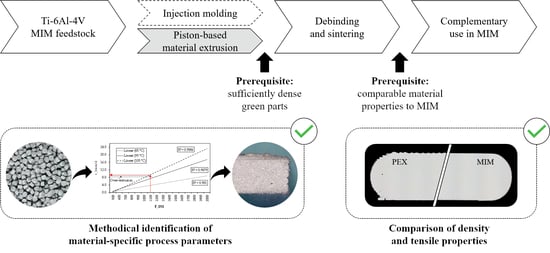

Piston-Based Material Extrusion of Ti-6Al-4V Feedstock for Complementary Use in Metal Injection Molding

Abstract

:1. Introduction

2. Materials and Methods

2.1. MIM Feedstock

2.2. Piston-Based Material Extrusion

2.2.1. Extrusion Model

- v: Printing speed [mm/s]

- A: Approximated cross-sectional area of extrusion path [mm2]

- qm: Mass flow [g/s]

- ρ: Feedstock density at RT and ET [g/mm3]

- vp: Piston speed [mm/s]

- Ap: Cross-sectional area of piston [mm2]

2.2.2. Extrusion Force

2.3. Debinding and Sintering

2.4. Methodology

2.4.1. Process Parameter Identification

- vc: Calculated printing speed [mm/s]

- qme: Experimentally determined mass flow [g/s]

2.4.2. Green Part Analysis

2.4.3. Sintered Part Analysis

3. Results and Discussion

3.1. Process Parameter Identification

- τ: Shear stress [Pa]

- rn: Nozzle radius [mm]

- rp: Piston radius [mm]

- l: Capillary length [mm]

- : Shear rate [s−1]

- η: Viscosity [Pa∙s]

3.2. Green Part Analysis

3.3. Sintered Part Analysis

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- German, R.M. Metal powder injection molding (MIM): Key trends and markets. In Handbook of Metal Injection Molding; Elsevier: Amsterdam, The Netherlands, 2019; pp. 1–21. ISBN 9780081021521. [Google Scholar]

- German, R.M.; Bose, A. Injection Molding of Metals and Ceramics; Metal Powder Industries Federation: Princeton, NJ, USA, 1997; ISBN 187895461X. [Google Scholar]

- Heaney, D.F. Powders for metal injection molding (MIM). In Handbook of Metal Injection Molding; Elsevier: Amsterdam, The Netherlands, 2019; pp. 45–56. ISBN 9780081021521. [Google Scholar]

- Enneti, R.K.; Onbattuvelli, V.P.; Gulsoy, O.; Kate, K.H.; Atre, S.V. Powder-binder formulation and compound manufacture in metal injection molding (MIM). In Handbook of Metal Injection Molding; Elsevier: Amsterdam, The Netherlands, 2019; pp. 57–88. ISBN 9780081021521. [Google Scholar]

- Gonzalez-Gutierrez, J.; Cano, S.; Schuschnigg, S.; Kukla, C.; Sapkota, J.; Holzer, C. Additive Manufacturing of Metallic and Ceramic Components by the Material Extrusion of Highly-Filled Polymers: A Review and Future Perspectives. Materials 2018, 11, 840. [Google Scholar] [CrossRef] [Green Version]

- Waalkes, L.; Längerich, J.; Holbe, F.; Emmelmann, C. Feasibility study on piston-based feedstock fabrication with Ti-6Al-4V metal injection molding feedstock. Addit. Manuf. 2020, 35, 101207. [Google Scholar] [CrossRef]

- Agarwala, M.K.; van Weeren, R.; Bandyopadhyay, A.; Safari, A.; Danforth, S.; Priedeman, W.R. Filament Feed Materials for Fused Deposition Processing of Ceramics and Metals. In 1996 International Solid Freeform Fabrication; The University of Texas at Austin: Austin, TX, USA, 1996; pp. 451–458. [Google Scholar]

- Galati, M.; Minetola, P. Analysis of Density, Roughness, and Accuracy of the Atomic Diffusion Additive Manufacturing (ADAM) Process for Metal Parts. Materials 2019, 12, 4122. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Gonzalez-Gutierrez, J.; Duretek, I.; Holzer, C.; Arbeiter, F.; Kukla, C. Filler Content and Properties of Highly Filled Filaments for Fused Filament Fabrication of Magnets. In Proceedings of the ANTEC 2017, Anaheim, CA, USA, 8–10 May 2017; pp. 1–4. [Google Scholar]

- Singh, P.; Balla, V.K.; Tofangchi, A.; Atre, S.V.; Kate, K.H. Printability studies of Ti-6Al-4V by metal fused filament fabrication (MF3). Int. J. Refract. Met. Hard Mater. 2020, 91, 105249. [Google Scholar] [CrossRef]

- Gonzalez-Gutierrez, J.; Cano, S.; Schuschnigg, S.; Holzer, C.; Kukla, C. (Eds.) Highly-Filled Polymers for Fused Filament Fabrication. In Proceedings of the 27th Leobener Kunststoff-Kolloquium: Print & Coat-Polymere in Druck-und Beschichtungstechnologien, Leoben, Austria, 19–20 April 2018. [Google Scholar]

- Gonzalez-Gutierrez, J.; Godec, D.; Guráň, R.; Spoerk, M.; Kukla, C.; Holzer, C. 3D printing conditions determination for feedstock used in fused filament fabrication (FFF) of 17-4PH stainless steel parts. In Metalurgija; Croatian Metallurgical Society (CMS): Zagreb, Croatia, 2018; pp. 117–120. [Google Scholar]

- Danforth, S.C.; Agarwala, M.K.; Bandyopadhyay, A.; Langrana, N.; Jamalabad, V.R.; Safari, A.; vanWeeren, R. Solid Freeform Fabrication Methods. U.S. Patent US5900207A, 4 May 1999. [Google Scholar]

- McNulty, T.F.; Mohammadi, F.; Bandyopadhyay, A.; Shanefield, D.J.; Danforth, S.C.; Safari, A. Development of a binder formulation for fused deposition of ceramics. Rapid Prototyp. J. 1998, 4, 144–150. [Google Scholar] [CrossRef] [Green Version]

- Singh, G.; Missiaen, J.-M.; Bouvard, D.; Chaix, J.-M. Copper extrusion 3D printing using metal injection moulding feedstock: Analysis of process parameters for green density and surface roughness optimization. Addit. Manuf. 2021, 38, 101778. [Google Scholar] [CrossRef]

- Singh, G.; Missiaen, J.-M.; Bouvard, D.; Chaix, J.-M. Additive manufacturing of 17–4 PH steel using metal injection molding feedstock: Analysis of 3D extrusion printing, debinding and sintering. Addit. Manuf. 2021, 47, 102287. [Google Scholar] [CrossRef]

- Singh, G.; Missiaen, J.-M.; Bouvard, D.; Chaix, J.-M. Copp.er additive manufacturing using MIM feedstock: Adjustment of printing, debinding, and sintering parameters for processing dense and defectless parts. Int. J. Adv. Manuf. Technol. 2021, 115, 449–462. [Google Scholar] [CrossRef]

- Lieberwirth, C.; Sarhan, M.; Seitz, H. Mechanical Properties of Stainless-Steel Structures Fabricated by Composite Extrusion Modelling. Metals 2018, 8, 84. [Google Scholar] [CrossRef] [Green Version]

- Franz, J.; Pearce, J.M. Open-Source Grinding Machine for Compression Screw Manufacturing. Inventions 2020, 5, 26. [Google Scholar] [CrossRef]

- Ampower GmbH & Co. KG. Report 2019 Metal Additive Manufacturing: The Independent Market & Technology Source; AMPOWER INSIGHTS; Ampower GmbH & Co. KG: Hamburg, Germany, 2019. [Google Scholar]

- Schlieper, G. Element22: A leader in titanium MIM leverages its expertise to advance sinter-based Ti Additive Manufacturing. In Powder Injection Moulding International; Inovar Communications Ltd.: Shrewsbury, UK, 2020; pp. 57–66. [Google Scholar]

- GÖTTFERT Werkstoff-Prüfmaschinen GmbH. RHEO-INFO: Stempel -oder Schneckenextrusion? Available online: https://www.goettfert.de/fileadmin/assets/Downloads/DE/PDF/Anwendungen/Rheo_Info/goettfert-rheo-info-Stempel-oder-Schneckenextrusion-de.pdf (accessed on 23 December 2021).

- Dave, H.K.; Davim, J.P. (Eds.) Fused Deposition Modeling Based 3D Printing; Springer: Cham, Switzerland, 2021; ISBN 9783030680244. [Google Scholar]

- Tuncer, N.; Bose, A. Solid-State Metal Additive Manufacturing: A Review. J. Miner. 2020, 72, 3090–3111. [Google Scholar] [CrossRef]

- Element22 GmbH. Datasheet SBS Feedstock Pellets Ti6Al4V PEL4-01A. Available online: https://www.element22.de/fileadmin/content/downloads/Datasheet_Element22_3DP_Pellets_PEL4-01A_V2_0.pdf (accessed on 6 February 2021).

- Lobo, H. Characterization of feedstock in metal injection molding (MIM). In Handbook of Metal Injection Molding; Elsevier: Amsterdam, The Netherlands, 2019; pp. 205–217. ISBN 9780081021521. [Google Scholar]

- HBM GmbH. Die Wheatstonesche Brückenschaltung—kurz erklärt. Available online: https://www.hbm.com/de/7163/die-wheatstonesche-brueckenschaltung-kurz-erklaert/ (accessed on 19 June 2021).

- Ebel, T. Metal injection molding (MIM) of titanium and titanium alloys. In Handbook of Metal Injection Molding; Elsevier: Amsterdam, The Netherlands, 2019; pp. 431–460. ISBN 9780081021521. [Google Scholar]

- Viehöfer, U.; Winkelmueller, W.; Lang, M.; Scharvogel, M. Verfahren Zur Pulvermetallurgischen Herstellung Von Bauteilen aus Titan Oder Titanlegierungen. EU Patent 16165222.7, 18 October 2017. [Google Scholar]

- Watschke, H.; Waalkes, L.; Schumacher, C.; Vietor, T. Development of Novel Test Specimens for Characterization of Multi-Material Parts Manufactured by Material Extrusion. Appl. Sci. 2018, 8, 1220. [Google Scholar] [CrossRef] [Green Version]

- Lepoivre, A.; Boyard, N.; Levy, A.; Sobotka, V. Heat Transfer and Adhesion Study for the FFF Additive Manufacturing Process. Procedia Manuf. 2020, 47, 948–955. [Google Scholar] [CrossRef]

- Zaky, M.T.; Soliman, F.S.; Farag, A.S. Influence of paraffin wax characteristics on the formulation of wax-based binders and their debinding from green molded parts using two comparative techniques. J. Mater. Process. Technol. 2009, 209, 5981–5989. [Google Scholar] [CrossRef]

- F04 Committee. Specification for Metal Injection Molded Titanium-6Aluminum-4Vanadium Components for Surgical Implant Applications; ASTM International: West Conshohocken, PA, USA, 2017. [Google Scholar]

- Deutsches Institut für Normung e.V. DIN EN ISO 2740: Sintermetalle, Ausgenommen Hartmetall-Zugprobestäbe; Beuth Verlag GmbH: Berlin, Germany, 2009. [Google Scholar]

- Ahn, S.-H.; Montero, M.; Odell, D.; Roundy, S.; Wright, P.K. Anisotropic material properties of fused deposition modeling ABS. Rapid Prototyp. J. 2002, 8, 248–257. [Google Scholar] [CrossRef] [Green Version]

- Durgun, I.; Ertan, R. Experimental investigation of FDM process for improvement of mechanical properties and production cost. Rapid Prototyp. J. 2014, 20, 228–235. [Google Scholar] [CrossRef]

- Torres, J.; Cole, M.; Owji, A.; DeMastry, Z.; Gordon, A.P. An app.roach for mechanical property optimization of fused deposition modeling with polylactic acid via design of experiments. Rapid Prototyp. J. 2016, 22, 387–404. [Google Scholar] [CrossRef]

- Suwanpreecha, C.; Seensattayawong, P.; Vadhanakovint, V.; Manonukul, A. Influence of Specimen Layout on 17-4PH (AISI 630) Alloys Fabricated by Low-Cost Additive Manufacturing. Metall. Mater. Trans. A 2021, 52, 1999–2009. [Google Scholar] [CrossRef]

- Kukla, C.; Duretek, I.; Gonzalez-Gutierrez, J.; Holzer, C. Rheology of PIM feedstocks. Met. Powder Rep. 2017, 72, 39–44. [Google Scholar] [CrossRef]

- Saini, D.R.; Shenoy, A.V. A new method for the determination of flow activation energy of polymer melt. J. Macromol. Sci. Part B 1983, 22, 437–449. [Google Scholar] [CrossRef]

- Deutsches Institut für Normung e.V. DIN 53014-1: Viskosimetrie Kapillarviskosimeter mit Kreis- und Rechteckquerschnitt zur Bestimmung von Fließkurven; Grundlagen, Begriffe, Benennungen; Beuth Verlag GmbH: Berlin, Germany, 1994. [Google Scholar]

- Deutsches Institut für Normung e.V. DIN 53014-2 Viskosimetrie; Kapillarviskosimeter mit Kreis- und Rechteckquerschnitt zur Bestimmung von Fließkurven; Systematische Abweichungen, Ursachen und Korrektionen; Beuth Verlag GmbH: Berlin, Germany, 1994. [Google Scholar]

- Shaikh, M.Q.; Singh, P.; Kate, K.H.; Freese, M.; Atre, S.V. Finite Element-Based Simulation of Metal Fused Filament Fabrication Process: Distortion Prediction and Experimental Verification. J. Mater. Eng. Perform. 2021, 30, 5135–5149. [Google Scholar] [CrossRef]

- Ampower GmbH & Co. KG. Design Guideline for Sinter-Based Additive Manufacturing; AMPOWER INSIGHTS: Hamburg, Germany, 2021. [Google Scholar]

- Ait-Mansour, I.; Kretzschmar, N.; Chekurov, S.; Salmi, M.; Rech, J. Design-dependent shrinkage compensation modeling and mechanical property targeting of metal FFF. Prog. Addit. Manuf. 2020, 5, 51–57. [Google Scholar] [CrossRef] [Green Version]

- Gong, H.; Snelling, D.; Kardel, K.; Carrano, A. Comparison of Stainless Steel 316L Parts Made by FDM- and SLM-Based Additive Manufacturing Processes. JOM 2019, 71, 880–885. [Google Scholar] [CrossRef]

- Schlieper, G. Tooling for metal injection molding (MIM). In Handbook of Metal Injection Molding; Elsevier: Amsterdam, The Netherlands, 2019; pp. 89–104. ISBN 9780081021521. [Google Scholar]

- Firat Hizal. Introducing Metal FFF with Ultrafuse® Filaments. Sinter-Based Additive Manufacturing Workshop; Fraunhofer IFAM: Bremen, Germany, 17 September 2021. [Google Scholar]

| Element | Ti | Al | V | C | N | Fe | O | H | Y |

|---|---|---|---|---|---|---|---|---|---|

| wt.% | Balance | 5.5–6.75 | 3.5–4.5 | ≤0.045 | ≤0.035 | ≤0.30 | ≤0.30 | ≤0.015 | ≤0.005 |

| Slicing Parameters | Values | Test Specimen |

|---|---|---|

| Nozzle diameter | 0.40 mm |  |

| Layer height | 0.20 mm | |

| Track width | 0.45 mm | |

| Flow rate | 100% | |

| Infill density | 100% | |

| Infill pattern | ±45° | |

| Bed temperature | 60 °C |

| T [°C] | Fe [N] | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 500 | 600 | 700 | 800 | 900 | 1000 | 1100 | 1200 | 1300 | 1400 | 1500 | 1600 | 1700 | 1800 | 1900 | 2000 | |

| 85 | 1.15 | 1.32 | 1.85 | 2.03 | 2.45 | 2.93 | 3.43 | 3.93 | 4.52 | 5.09 | 5.81 | 6.52 | 7.02 | 7.85 | 8.66 | 9.42 |

| 95 | 1.62 | 2.38 | 3.14 | 3.92 | 4.90 | 5.99 | 7.06 | 8.20 | 9.14 | 10.20 | 11.30 | 12.67 | 14.02 | 15.16 | 16.47 | 19.06 |

| 105 | 1.62 | 2.52 | 3.43 | 4.51 | 5.95 | 7.43 | 9.02 | 10.63 | 11.69 | 12.79 | 14.91 | 17.00 | 18.46 | 19.99 | 23.09 | 24.38 |

| Specimens | Density [%] | Tensile Properties | ||

|---|---|---|---|---|

| YS [MPa] | UTS [MPa] | ε [%] | ||

| ASTM F2885-11 | min. 96 1 | min. 680 | min. 780 | min. 10 |

| MIM reference | 99 | 900 | 1000 | 20 |

| Flat | 99.1 | 933 | 1000 | 18.5 |

| Side | 98.8 | 831 | 957 | 10.1 |

| Vertical | 98.4 | 866 | 968 | 3.4 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Waalkes, L.; Längerich, J.; Imgrund, P.; Emmelmann, C. Piston-Based Material Extrusion of Ti-6Al-4V Feedstock for Complementary Use in Metal Injection Molding. Materials 2022, 15, 351. https://doi.org/10.3390/ma15010351

Waalkes L, Längerich J, Imgrund P, Emmelmann C. Piston-Based Material Extrusion of Ti-6Al-4V Feedstock for Complementary Use in Metal Injection Molding. Materials. 2022; 15(1):351. https://doi.org/10.3390/ma15010351

Chicago/Turabian StyleWaalkes, Lennart, Jan Längerich, Philipp Imgrund, and Claus Emmelmann. 2022. "Piston-Based Material Extrusion of Ti-6Al-4V Feedstock for Complementary Use in Metal Injection Molding" Materials 15, no. 1: 351. https://doi.org/10.3390/ma15010351

APA StyleWaalkes, L., Längerich, J., Imgrund, P., & Emmelmann, C. (2022). Piston-Based Material Extrusion of Ti-6Al-4V Feedstock for Complementary Use in Metal Injection Molding. Materials, 15(1), 351. https://doi.org/10.3390/ma15010351