Durability of Reinforced Concrete with Additions of Natural Pozzolans of Volcanic Origin

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials and Sample Preparation

2.2. Tests and Methods

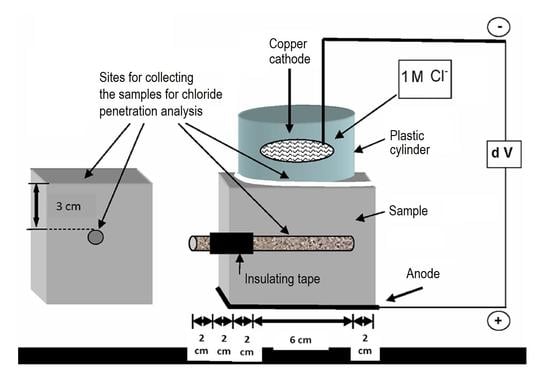

2.3. Modification of the Accelerated Integral Method

2.4. Determination of the Durability

3. Results and Discussion

3.1. Characterization of the Components and the Concrete

3.2. Modified Integral Method

3.3. Penetration of Aggressive Species

3.4. Estimation of Durability

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Najimi, M.; Jamshidi, M.; Pourkhorshidi, A. Durability of concretes containing natural pozzolan. Proc. Inst. Civ. Eng. Constr. Mater. 2008, 161, 113–118. [Google Scholar] [CrossRef]

- Concrete needs to lose its colossal carbon footprint. Nature 2021, 597, 593–594. [CrossRef] [PubMed]

- Miller, S.A.; Horvath, A.; Monteiro, P.J.M. Readily implementable techniques can cut annual CO2 emissions from the production of concrete by over 20%. Environ. Res. Lett. 2016, 11, 074029. [Google Scholar] [CrossRef] [Green Version]

- Fan, C.; Miller, S.A. Reducing greenhouse gas emissions for prescribed concrete compressive strength. Constr. Build. Mater. 2018, 167, 918–928. [Google Scholar] [CrossRef]

- Tayeh, B.A.; Hamada, H.M.; Almeshal, I.; Bakar, B.H.A. Durability and mechanical properties of cement concrete comprising pozzolanic materials with alkali-activated binder: A comprehensive review. Case Stud. Constr. Mater. 2022, 17, e01429. [Google Scholar] [CrossRef]

- Abiodun, Y.O.; Olanrewaju, O.A.; Gbenebor, O.P.; Ochulor, E.F.; Obasa, D.V.; Adeosun, S.O. Cutting cement industry CO2 emissions through metakaolin use in construction. Atmosphere 2022, 13, 1494. [Google Scholar] [CrossRef]

- Amran, M.; Makul, N.; Fediuk, R.; Lee, Y.H.; Vatin, N.I.; Lee, Y.Y.; Mohammed, K. Global carbon recoverability experiences from the cement industry. Case Stud. Constr. Mater. 2022, 17, e01439. [Google Scholar] [CrossRef]

- Andrew, R.M. Global CO2 Emissions from cement production, 1928–2018. Earth Syst. Sci. Data 2019, 11, 1675–1710. [Google Scholar] [CrossRef] [Green Version]

- Qaidi, S.; Najm, H.M.; Abed, S.M.; Ahmed, H.U.; Al Dughaishi, H.; Al Lawati, J.; Sabri, M.M.; Alkhatib, F.; Milad, A. Fly ash-based geopolymer composites: A review of the compressive strength and microstructure analysis. Materials 2022, 15, 7098. [Google Scholar] [CrossRef] [PubMed]

- Ababneh, A.; Matalkah, F. Potential use of jordanian volcanic tuffs as supplementary cementitious materials. Case Stud. Constr. Mater. 2018, 8, 193–202. [Google Scholar] [CrossRef]

- Costafreda, J.L.; Martín, D.A.; Presa, L.; Parra, J.L. Altered volcanic tuffs from Los Frailes Caldera. A study of their pozzolanic properties. Molecules 2021, 26, 5348. [Google Scholar] [CrossRef]

- Rakhimov, R.Z.; Rakhimova, N.R.; Gaifullin, A.R.; Morozov, V.P. Properties of portland cement pastes enriched with addition of calcined marl. J. Build. Eng. 2017, 11, 30–36. [Google Scholar] [CrossRef]

- Sobol, K.; Markiv, T.; Terlyha, V.; Franus, W. Peculiarities of hydration processes of cements containing natural zeolite. Bud. Archit. 2015, 14, 105–113. [Google Scholar] [CrossRef]

- Xia, J.; Guan, Q.; Zhou, Y.; Wang, J.; Gao, C.; He, Y.; Wang, Z.; Song, P. Use of natural pozzolans in high-performance concrete for the Mombasa–Nairobi railway. Adv. Cem. Res. 2021, 33, 318–330. [Google Scholar] [CrossRef]

- Papadakis, V.G.; Tsimas, S. Supplementary cementing materials in concrete. Part I: Efficiency and design. Cem. Concr. Res. 2002, 32, 1525–1532. [Google Scholar] [CrossRef]

- Wasim, M.; Abadel, A.; Abu Bakar, B.H.; Alshaikh, I.M.H. Future directions for the application of zero carbon concrete in civil engineering—A review. Case Stud. Constr. Mater. 2022, 17, e01318. [Google Scholar] [CrossRef]

- Fazilati, M.; Mohammadi Golafshani, E. Durability properties of concrete containing amorphous silicate tuff as a type of natural cementitious material. Constr. Build. Mater. 2020, 230, 117087. [Google Scholar] [CrossRef]

- Khan, K.; Amin, M.N. Influence of fineness of volcanic ash and its blends with quarry dust and slag on compressive strength of mortar under different curing temperatures. Constr. Build. Mater. 2017, 154, 514–528. [Google Scholar] [CrossRef]

- Khan, K.; Amin, M.N.; Saleem, M.U.; Qureshi, H.J.; Al-Faiad, M.A.; Qadir, M.G. Effect of fineness of basaltic volcanic ash on pozzolanic reactivity, ASR expansion and drying shrinkage of blended cement mortars. Materials 2019, 12, 2603. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Khan, K.; Amin, M.N.; Usman, M.; Imran, M.; Al-Faiad, M.A.; Shalabi, F.I. Effect of fineness and heat treatment on the pozzolanic activity of natural volcanic ash for its utilization as supplementary cementitious materials. Crystals 2022, 12, 302. [Google Scholar] [CrossRef]

- Kushnir, A.R.L.; Heap, M.J.; Griffiths, L.; Wadsworth, F.B.; Langella, A.; Baud, P.; Reuschlé, T.; Kendrick, J.E.; Utley, J.E.P. The fire resistance of high-strength concrete containing natural zeolites. Cem. Concr. Compos. 2021, 116, 103897. [Google Scholar] [CrossRef]

- Robayo-Salazar, R.A.; de Gutiérrez, M.; Puertas, F. Study of synergy between a natural volcanic pozzolan and a granulated blast furnace slag in the production of geopolymeric pastes and mortars. Constr. Build. Mater. 2017, 157, 151–160. [Google Scholar] [CrossRef]

- Takahashi, T.; Shoji, S. Distribution and classification of volcanic ash soils. Glob. Environ. Res. 2002, 6, 83–97. [Google Scholar]

- Lemougna, P.N.; MacKenzie, K.J.D.; Melo, U.F.C. Synthesis and thermal properties of inorganic polymers (geopolymers) for structural and refractory applications from volcanic ash. Ceram. Int. 2011, 37, 3011–3018. [Google Scholar] [CrossRef]

- Kouamo Tchakoute, H.; Elimbi, A.; Diffo Kenne, B.B.; Mbey, J.A.; Njopwouo, D. Synthesis of geopolymers from volcanic ash via the alkaline fusion method: Effect of Al2O3/Na2O molar ratio of soda–volcanic ash. Ceram. Int. 2013, 39, 269–276. [Google Scholar] [CrossRef]

- Mertens, G.; Snellings, R.; Van Balen, K.; Bicer-Simsir, B.; Verlooy, P.; Elsen, J. Pozzolanic reactions of common natural zeolites with lime and parameters affecting their reactivity. Cem. Concr. Res. 2009, 39, 233–240. [Google Scholar] [CrossRef]

- Kitsopoulos, K.P.; Dunham, A.C. Heulandite and mordenite-rich tuffs from Greece: A potential source for pozzolanic materials. Miner. Depos. 1996, 31, 576–583. [Google Scholar] [CrossRef]

- Martínez-Ramírez, S.; Blanco-Varela, M.T.; Ereña, I.; Gener, M. Pozzolanic reactivity of zeolitic rocks from two different Cuban Deposits: Characterization of reaction products. Appl. Clay Sci. 2006, 32, 40–52. [Google Scholar] [CrossRef]

- Fragoulis, D.; Chaniotakis, E.; Stamatakis, M.G. Zeolitic tuffs of Kimolos Island, Aegean Sea, Greece and their industrial potential. Cem. Concr. Res. 1997, 27, 889–905. [Google Scholar] [CrossRef]

- Varela, M.T.B.; Ramírez, S.M.; Ereña, I.; Gener, M.; Carmona, P. Characterization and pozzolanicity of zeolitic rocks from two Cuban deposits. Appl. Clay Sci. 2006, 33, 149–159. [Google Scholar]

- Liebig, E.; Althaus, E. Pozzolanic activity of volcanic tuff and Suevite: Effects of calcination. Cem. Concr. Res. 1998, 28, 567–575. [Google Scholar] [CrossRef]

- Zhang, M.H.; Malhotra, V.M. Characteristics of a thermally activated alumino-silicate pozzolanic material and its use in concrete. Cem. Concr. Res. 1995, 25, 1713–1725. [Google Scholar] [CrossRef]

- Çavdar, A.; Yetgin, Ş. Availability of tuffs from Northeast of Turkey as natural pozzolan on cement, some chemical and mechanical relationships. Constr. Build. Mater. 2007, 21, 2066–2071. [Google Scholar] [CrossRef]

- Hunyak, O.; Sobol, K.; Markiv, T.; Bidos, V. The effect of natural pozzolans on properties of vibropressed interlocking concrete blocks in different curing conditions. Prod. Eng. Arch. 2019, 22, 3–6. [Google Scholar] [CrossRef] [Green Version]

- Markiv, T.; Sobol, K.; Franus, M.; Franus, W. Mechanical and durability properties of concretes incorporating natural zeolite. Arch. Civ. Mech. Eng. 2016, 16, 554–562. [Google Scholar] [CrossRef]

- Dedeloudis, C.; Zervaki, M.; Sideris, K.; Juenger, M.; Alderete, N.; Kamali-Bernard, S.; Villagrán, Y.; Snellings, R. Natural pozzolans. RILEM State-Art Rep. 2018, 25, 181–231. [Google Scholar]

- Rojas, M.F.; Cabrera, J. The Effect of temperature on the hydration rate and stability of the hydration phases of Metakaolin–Lime–Water systems. Cem. Concr. Res. 2002, 32, 133–138. [Google Scholar] [CrossRef]

- Shi, C. Pozzolanic reaction and microstructure of chemical activated lime-fly ash pastes. ACI Mater. J. 1998, 95, 537–545. [Google Scholar]

- Janotka, I.; Krajči, L. Utilization of natural zeolite in Portland cement of increased sulphate resistance. ACI Spec. Publ. 2003, 221, 223–229. [Google Scholar]

- Ahmadi, B.; Shekarchi, M. Use of natural zeolite as a supplementary cementitious material. Cem. Concr. Compos. 2010, 32, 134–141. [Google Scholar] [CrossRef]

- Mostafa, N.Y.; El-Hemaly, S.A.S.; Al-Wakeel, E.I.; El-Korashy, S.A.; Brown, P.W. Characterization and evaluation of the pozzolanic activity of Egyptian industrial by-products: I: Silica fume and dealuminated Kaolin. Cem. Concr. Res. 2001, 31, 467–474. [Google Scholar] [CrossRef]

- Çullu, M.; Bolat, H.; Vural, A.; Tuncer, E. Investigation of pozzolanic activity of volcanic rocks from the Northeast of the Black Sea. Sci. Eng. Compos. Mater. 2016, 23, 315–323. [Google Scholar] [CrossRef]

- Turanli, L.; Uzal, B.; Bektas, F. Effect of large amounts of natural pozzolan addition on properties of blended cements. Cem. Concr. Res. 2005, 35, 1106–1111. [Google Scholar] [CrossRef]

- Hu, J.Y.; Zhang, S.S.; Chen, E.; Li, W.G. A review on corrosion detection and protection of existing reinforced concrete (RC) structures. Constr. Build. Mater. 2022, 325, 126718. [Google Scholar] [CrossRef]

- Bouteiller, V.; Tissier, Y.; Marie-Victoire, E.; Chaussadent, T.; Joiret, S. The application of electrochemical chloride extraction to reinforced concrete—A review. Constr. Build. Mater. 2022, 351, 128931. [Google Scholar] [CrossRef]

- Syll, A.S.; Kanakubo, T. Impact of corrosion on the bond strength between concrete and rebar: A systematic review. Materials 2022, 15, 7016. [Google Scholar] [CrossRef]

- Boschmann Käthler, C.; Poulsen, S.L.; Sørensen, H.E.; Angst, U.M. Investigations of accelerated methods for determination of chloride threshold for reinforcement corrosion in concrete. Sustain. Resilient Infrastruct. 2021, 6, 1–12. [Google Scholar] [CrossRef]

- Kaid, N.; Cyr, M.; Julien, S.; Khelafi, H. Durability of Concrete containing a natural pozzolan as defined by a performance-based approach. Constr. Build. Mater. 2009, 23, 3457–3467. [Google Scholar] [CrossRef]

- Fajardo, G.; Valdez, P.; Pacheco, J. Corrosion of steel rebar embedded in natural pozzolan based mortars exposed to chlorides. Constr. Build. Mater. 2009, 23, 768–774. [Google Scholar] [CrossRef]

- Andrade, C.; Arriaga, L.Q. Cursos Avanzados Eduardo Torroja: Durabilidad, Rehabilitación y Sostenibilidad; Instituto de Ciencias de la Construcción Ediuardo Torroja: Madrid, Spain, 2014. [Google Scholar]

- Valenta, O. General analysis of the methods of testing the durability of concrete. Mater. Struct. 1970, 3, 333–345. [Google Scholar]

- Fagerlund, G. Prediction of the Service Life of Concrete Exposed to Frost Action; Swedish Cement and Concrete Research Institute: Stockholm, Sweden, 1979. [Google Scholar]

- Tuutti, K. Corrosion of Steel in Concrete; Swedish Cement and Concrete Research Institute: Stockholm, Sweden, 1982. [Google Scholar]

- Real Decreto 1247/2008, de 18 de Julio, por el que se aprueba la instrucción de hormigón estructural (EHE-08). 2008. Available online: https://www.boe.es/eli/es/rd/2008/07/18/1247 (accessed on 10 November 2022).

- Hernández Gutiérrez, L.E. Caracterización Geomecánica de las Rocas Volcánicas de las Islas Canarias; Universidad de La Laguna: La Laguna, Spain, 2014. [Google Scholar]

- Cánovas, M.F. Hormigón; Servicio de Publicaciones Colegio de Ingenieros de Caminos, Canales y Puertos: Madrid, Spain, 2002. [Google Scholar]

- C311/C311M−13; Standard Test Methods for Sampling and testing Fly Ash or natural Pozzolans for Use in Portland-Cement Concrete. ASTM International: West Conshohocken, PA, USA, 2013.

- UNE 80303-2:2011; Cements with Additional Characteristics. Part 2: Sea water Resisting Cements. AENOR, Asociación Española de Normalización y Certificación: Madrid, Spain, 2011.

- UNE-EN 196-5; Methods of Testing Cement—Part 5: Pozzolanicity Test for Pozzolanic Cement. AENOR, Asociación Española de Normalización y Certificación: Madrid, Spain, 2011.

- UNE-EN 12390-1; Testing Hardened Concrete—Part 1: Shape, Dimensions and other Requirements for Specimens and Moulds. AENOR, Asociación Española de Normalización y Certificación: Madrid, Spain, 2001.

- UNE-EN 12390-2; Testing Hardened Concrete—Part 2: Making and curing Specimens for strength Test. AENOR, Asociación Española de Normalización y Certificación: Madrid, Spain, 2009.

- UNE-EN 12390-3; Testing Hardened Concrete—Part 3: Compressive Strength of Test Specimens. AENOR, Asociación Española de Normalización y Certificación: Madrid, Spain, 2009.

- UNE-EN 196-1:2005; Methods of Testing Cement—Part 1: Determination of Strength. AENOR, Asociación Española de Normalización y Certificación: Madrid, Spain, 2005.

- UNE-EN 12350-2; Testing Fresh Concrete—Part 2: Slump Test. AENOR, Asociación Española de Normalización y Certificación: Madrid, Spain, 2009.

- UNE-EN 12390-7; Testing Hardened Concrete—Part 7: Density of Hardened Concrete. AENOR, Asociación Española de Normalización y Certificación: Madrid, Spain, 2009.

- UNE 83988-1; Concrete Durability. Test Methods. Determination of the Electrical Resistivity. Part 1: Direct Test (Reference Method). AENOR, Asociación Española de Normalización y Certificación: Madrid, Spain, 2008.

- UNE 83988-2:2008; Concrete durability. Test methods. Determination of the Electrical Resistivity. Part 2: Four Points or Wenner Method. AENOR, Asociación Española de Normalización y Certificación: Madrid, Spain, 2008.

- UNE 83309:1990 EX; Concrete Tests. Determination of the Depth of Penetration of Water under Pressure. AENOR, Asociación Española de Normalización y Certificación: Madrid, Spain, 1990.

- UNE-EN 12390-8:2001; Testing Hardened Concrete—Part 8: Depth of Penetration of Water under Pressure. AENOR, Asociación Española de Normalización y Certificación: Madrid, Spain, 2001.

- UNE-EN 1936; Natural Stone Test Methods—Determination of Real Density and Apparent Density, and of Total and Open Porosity. AENOR, Asociación Española de Normalización y Certificación: Madrid, Spain, 2007.

- UNE 83980:2014; Concrete Durability. Test Methods. Determination of the Water Absorption, Density and Accessible Porosity for Water in Concrete. AENOR, Asociación Española de Normalización y Certificación: Madrid, Spain, 2014.

- UNE 112011:1994; Assembly Corrosion. Determination of the Carbonatation Depth for in Service Concrete. AENOR, Asociación Española de Normalización y Certificación: Madrid, Spain, 1994.

- UNE 112011:2011; Corrosion of Concrete Reinforcement Steel. Determination of the carbonatation Depth for In-Service Concrete. AENOR, Asociación Española de Normalización y Certificación: Madrid, Spain, 2011.

- UNE 83993-1:2013; Durability of Concrete. Test Method. Measurement of Carbonation Penetration Rate in Hardened Concrete. Part 1: Natural Method. AENOR, Asociación Española de Normalización y Certificación: Madrid, Spain, 2013.

- UNE 83993-2:2013; Durability of Concrete. Test Method. Measurement of Carbonation Penetration Rate in Hardened Concrete. Part 2: Accelerated Method. AENOR, Asociación Española de Normalización y Certificación: Madrid, Spain, 2013.

- PrNE 83986:2009; Ensayo de Durabilidad del Hormigón. Determinación de la Difusión de Iones Cloruro. AENOR, Asociación Española de Normalización y Certificación: Madrid, Spain, 2009.

- CEN/TS 12390-11:2010; Testing Hardened Concrete—Part 11: Determination of the Chloride Resistance of Concrete, Unidirectional Diffusion. ITeh Inc.: Wien, Austria, 2010.

- UNE-EN 14629:2007; Products And Systems For The Protection And Repair Of concrete structures—Test methods—Determination of Chloride Content in Hardened Concrete. AENOR, Asociación Española de Normalización y Certificación: Madrid, Spain, 2007.

- UNE 83987:2014; Concrete Durability. Test Methods. Measurement of Chloride Diffusion Coefficient in Hardened Concrete. Multiregime Method. AENOR, Asociación Española de Normalización y Certificación: Madrid, Spain, 2014.

- UNE 83992-2:2012 EX; Durability of Concrete. Test Methods. Chloride Penetration Tests on Concrete. Part 2: Integral Accelerated Method. AENOR, Asociación Española de Normalización y Certificación: Madrid, Spain, 2012.

- UNE 112072:2011; Laboratory measurement of Corrosion Speed Using the Polarization Resistance Technique. AENOR, Asociación Española de Normalización y Certificación: Madrid, Spain, 2011.

- Annex 9—Additional Considerations on Durability According to the EHE-08. Available online: https://www.mitma.gob.es/recursos_mfom/annex_9.pdf (accessed on 10 November 2022).

- ASTM C618-22; Standard Specification for Coal Fly Ash and Raw or Calcined Natural Pozzolan for Use in Concrete. ASTM International: West Conshohocken, PA, USA, 2022.

- Limbachiya, M.; Meddah, M.S.; Ouchagour, Y. Use of recycled concrete aggregate in fly-ash concrete. Constr. Build. Mater. 2012, 27, 439–449. [Google Scholar] [CrossRef]

- Kim, Y.; Hanif, A.; Kazmi, S.M.S.; Munir, M.J.; Park, C. Properties enhancement of recycled aggregate concrete through pretreatment of coarse aggregates—Comparative assessment of assorted techniques. J. Clean. Prod. 2018, 191, 339–349. [Google Scholar] [CrossRef]

- Kim, T.; Davis, J.M.; Ley, M.T.; Kang, S.; Amrollahi, P. Fly ash particle characterization for predicting concrete compressive strength. Constr. Build. Mater. 2018, 165, 560–571. [Google Scholar] [CrossRef]

- Lee, H.; Hanif, A.; Usman, M.; Sim, J.; Oh, H. Performance evaluation of concrete incorporating glass powder and glass sludge wastes as supplementary cementing material. J. Clean. Prod. 2018, 170, 683–693. [Google Scholar] [CrossRef]

- Zhang, R.; Panesar, D.K. Mechanical properties and rapid chloride permeability of carbonated concrete containing reactive MgO. Constr. Build. Mater. 2018, 172, 77–85. [Google Scholar] [CrossRef]

- Real Decreto 956/2008; Instrucción para la Recepción de Cementos RC-08. Government of Spain: Madrid, Spain, 2008.

| II/A-P/42.5R MR | |

|---|---|

| Loss on ignition (LOI) | 3.4 |

| Insoluble residue | 10.1 |

| Chloride (Cl−, %) | 0.01 |

| Sulphates (SO3, %) | 3.38 |

| Initial setting time (min) | 150 |

| Pozzolan content (%) | 19 |

| Clinker content (%) | 76 |

| Gypsum content (%) | 5 |

| End of hardening (EH, min) | 215 |

| Compressive strength at 7 days (N/mm2) | 37.0 |

| Compressive strength at 28 days (N/mm2) | 51.6 |

| Code | D1P | D3P | D3PZT | D3PZQ | D4P | D4PZT | D4PZQ |

|---|---|---|---|---|---|---|---|

| Type of Aggregates | Reference | Reference | Tuff Pozzolan | Quarry Pozzolan | Reference | Tuff Pozzolan | Quarry Pozzolan |

| Characteristic resistance (N/mm2) | HA-35 | HA-30 | HA-30 | HA-30 | HA-25 | HA-25 | HA-25 |

| Cement content (kg/m3) | 325 | 300 | 240 | 240 | 300 | 300 | 300 |

| Pozzolan content (kg/m3) | - | - | 60 | 60 | - | 60 | 60 |

| Basalt gravel (kg/m3) | 806.19 | 945.75 | 945.75 | 945.75 | 945.75 | 945.75 | 945.75 |

| Basalt sand (kg/m3) | 688.08 | 502 | 502 | 502 | 502 | 442 | 442 |

| African sand (kg/m3) | 250.23 | 296.75 | 296.75 | 296.75 | 296.75 | 296.75 | 296.75 |

| Water content (L/m3) | 156 | 167 | 167 | 167 | 198 | 195 | 195 |

| Cement ratio (%) | 0.51 | 0.56 | 0.57 | 0.57 | 0.76 | 0.73 | 0.73 |

| Tuff Pozzolan | Quarry Pozzolan | |

|---|---|---|

| UNE Sieves | % Passing Through | |

| 0.158 | 16.02 | 16.02 |

| 0.112 | 14.38 | 14.38 |

| 0.080 | 12.75 | 12.75 |

| 0.051 | 11.11 | 11.11 |

| 0.027 | 7.85 | 7.85 |

| 0.021 | 6.21 | 6.21 |

| 0.015 | 6.21 | 6.21 |

| 0.011 | 6.21 | 6.21 |

| 0.008 | 4.58 | 4.58 |

| 0.003 | 2.94 | 2.94 |

| SiO2 | Al2O3 | Fe2O3 | CaO | MgO | Na2O | K2O | MnO | P2O5 | TiO2 | LOI | SO4 |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 50.19 | 17.35 | 3.08 | 1.45 | 1.31 | 6.42 | 4.94 | 0.15 | 0.10 | 0.64 | 14.38 | 0.21 |

| Aggregate | Origin | Size | Absorption Coefficient |

|---|---|---|---|

| Sand | Siliceous | 0/2 | 1.50 |

| Sand | Basaltic | 0/4 | 3.95 |

| Gravel | Basaltic | 10/20 | 3.65 |

| Sample | Aggregate | Flexural Strength (N/mm2) | Compressive Strength (N/mm2) | RAI (%) |

|---|---|---|---|---|

| Cement (I/42.5 R/SR) | Reference | 10.1 | 5.4 | 100 |

| 75% Cement + 25% PZT | Tuff pozzolan | 9.1 | 5.4 | 100 |

| 75% Cement + 25% PZQ | Quarry pozzolan | 8.7 | 4.8 | 88.9 |

| Code | D1P | D3P | D3PZT | D3PZQ | D4P | D4PZT | D4PZQ |

|---|---|---|---|---|---|---|---|

| Type of aggregates | 53 | 52.5 | 54.7 | 54.7 | 52.5 | 54.7 | 54.7 |

| Consistency (cm) | 4 | 15 | 15 | 19 | 10 | 11.5 | 10.5 |

| Fresh density (kg/m3) | 2399 | 2475 | 2379 | 2423 | 2335 | 2365 | 2365 |

| Density after 24 h (kg/m3) | 2421 | 2449 | 2356 | 2408 | 2320 | 2343 | 2353 |

| Density after 28 d (kg/m3) | 2428 | 2468 | 2391 | 2437 | 2339 | 2364 | 2374 |

| Dry density (kg/m3) | 2324 | 2359 | 2255 | 2282 | 2110 | 2269 | 2278 |

| Accumulated porosity (%) | 14.33 | 15.5 | 18.4 | 20.34 | 22.5 | 15.59 | 15.4 |

| RCS of concrete (N/mm2) | 57 | 52.79 | 51.34 | 50 | 38.14 | 46.54 | 43.72 |

| RIM after 28 d (Ω m) | 115.4 | 109.9 | 106.6 | 79.4 | 107.5 | 120 | 105.3 |

| RIC after 28 d (Ω m) | 109.5 | 111.9 | 104.1 | 80.7 | 99.8 | 120.6 | 95.3 |

| RID after 28 d (Ω m) | 112 | 121.8 | 109.8 | 86.8 | 104.8 | 118.3 | 103.1 |

| Natural VCO2 (mm/year½) | 0 | 1.41 | 1.41 | 1.54 | 3.15 | 2.4 | 2.81 |

| Accelerated VCO2 (mm/year½) | 0 | 7.55 | 14.05 | 15.6 | 17.67 | 14.64 | 16.48 |

| Profile XCl (mm) | 4.2 | 11.8 | 13.5 | 13 | 13.8 | 13 | 14.8 |

| Profile VCl (mm/year½) | 8.46 | 23.66 | 27.04 | 26.04 | 27.85 | 26.18 | 29.7 |

| Pond, Dns × 10−8 (cm2/s) | 0.6329 | 4.1 | 6.363 | 7.789 | 7.205 | 4.492 | 5.841 |

| Multi-regime, Dns × 10−8 (cm2/s) | 3.0516 | 3.5094 | 2.3337 | 2.8636 | 4.8058 | 2.3694 | 2.4799 |

| Initial/final intensity (mA) | 5.2/9.45 | 5.72/15.71 | 4.89/8.33 | 5.62/10.17 | |||

| Initial/final resistance (Ω) | 2.307/1.270 | 2.098/0.764 | 2.045/1.440 | 2.135/1.180 | |||

| Integral, Dns × 10−8 (cm2/s) | 4.019 | 3.191 | 4.019 | 6.028 | |||

| Depassivation time (s) | 2,332,800 | 2,937,600 | 2,332,800 | 1,555,200 |

| Sample | fck + 8 (N/mm2) | Kc | ti (Year) | dr (mm) | Vcorr (μm/Year) | tp (Year) | tL (Year) (tL = ti + tp) |

|---|---|---|---|---|---|---|---|

| fck + 8, and binder coefficients, a′ = 360 and b′ = −1.2 | |||||||

| D1 | 43 | 3.95 | 57.80 | 45 | 20 | 15 | 72.80 |

| D3 | 38 | 4.58 | 42.97 | 25 | 2 | 83.33 | 126.30 |

| D4 | 33 | 5.42 | 30.62 | 20 | 3 | 44.44 | 75.07 |

| D1 | 43 | 3.95 | 57.80 | 45 | 20 | 15 | 72.80 |

| fck + 8, and binder coefficients, a′ = 1800 and b′ = −1.7 | |||||||

| D1 | 43 | 3.01 | 99.42 | 45 | 20 | 15 | 114.42 |

| D3 | 38 | 3.71 | 65.31 | 25 | 2 | 83.33 | 148.64 |

| D4 | 33 | 4.72 | 40.42 | 20 | 3 | 44.44 | 84.87 |

| Sample | fcm (N/mm2) | Kc | ti (Year) | dr (mm) | Vcorr (μm/Year) | tp (Years) | tL (Year) (tL = ti + tp) |

|---|---|---|---|---|---|---|---|

| Type of binder, Portland cement (a′ = 1800 and b′ = −1.7) | |||||||

| D1P | 57.00 | 1.86 | 259.22 | 45 | 20 | 15 | 274.22 |

| D3P | 52.79 | 2.12 | 199.70 | 25 | 2 | 83.33 | 283.03 |

| D3PZT | 51.34 | 2.23 | 181.66 | 25 | 2 | 83.33 | 264.99 |

| D3PZQ | 50.00 | 2.33 | 166.03 | 25 | 2 | 83.33 | 249.37 |

| D4P | 38.14 | 3.69 | 66.13 | 20 | 3 | 44.44 | 110.57 |

| D4PZT | 46.54 | 2.63 | 130.11 | 20 | 3 | 44.44 | 174.55 |

| D4PZQ | 43.72 | 2.92 | 105.20 | 20 | 3 | 44.44 | 149.64 |

| Type of binder, Portland cement + 28% fly ash (a′ =360 and b′ = −1.2) | |||||||

| D1P | 57 | 2.81 | 113.69 | 45 | 20 | 15 | 128.69 |

| D3P | 52.79 | 3.08 | 94.57 | 25 | 2 | 83.33 | 177.91 |

| D3PZT | 51.34 | 3.19 | 88.46 | 25 | 2 | 83.33 | 171.79 |

| D3PZQ | 50 | 3.29 | 83.02 | 25 | 2 | 83.33 | 166.35 |

| D4P | 38.14 | 4.56 | 43.35 | 20 | 3 | 44.44 | 87.79 |

| D4PZT | 46.54 | 3.59 | 69.89 | 20 | 3 | 44.44 | 114.34 |

| D4PZQ | 43.72 | 3.87 | 60.15 | 20 | 3 | 44.44 | 104.60 |

| Sample | D(t0) × 10−7 (cm2/s) | D(t = 50) × 10−9 (cm2/s) | KCL (mm/Year½) | ti (Year) | dr (mm) | Vcorr (μm/Year) | tp (Year) | tL (Year) (tL = ti + tp) |

|---|---|---|---|---|---|---|---|---|

| D1P | 0.90 | 3.53 | 2.56 | 137.14 | 45 | 20 | 15.00 | 152.14 |

| D3P | 1.09 | 4.27 | 3.21 | 87.49 | 25 | 2 | 83.33 | 170.83 |

| D4P | 1.49 | 5.84 | 3.75 | 64.00 | 20 | 3 | 44.44 | 108.45 |

| Sample | D(t0) × 10−8 (cm2/s) | D(t = 50) × 10−9 (cm2/s) | KCL (mm/Year½) | ti (Year) | dr (mm) | Vcorr (μm/Year) | tp (Year) | tL (Year) (tL = ti + tp) |

|---|---|---|---|---|---|---|---|---|

| D1P | 0.63 | 0.45 | 2.15 | 194.47 | 45 | 20 | 15.00 | 209.47 |

| D3P | 4.10 | 2.88 | 6.35 | 22.32 | 25 | 2 | 83.33 | 105.66 |

| D3PZT | 6.36 | 4.47 | 7.49 | 16.06 | 25 | 2 | 83.33 | 99.39 |

| D3PZQ | 4.88 | 3.43 | 6.86 | 19.13 | 25 | 2 | 83.33 | 102.46 |

| D4P | 7.21 | 5.06 | 8.78 | 11.68 | 20 | 3 | 44.44 | 56.12 |

| D4PZT | 4.49 | 3.15 | 6.82 | 19.34 | 20 | 3 | 44.44 | 63.79 |

| D4PZQ | 5.84 | 4.10 | 7.72 | 15.12 | 20 | 3 | 44.44 | 59.56 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Santana, J.J.; Rodríguez-Brito, N.; Blanco-Peñalver, C.; Mena, V.F.; Souto, R.M. Durability of Reinforced Concrete with Additions of Natural Pozzolans of Volcanic Origin. Materials 2022, 15, 8352. https://doi.org/10.3390/ma15238352

Santana JJ, Rodríguez-Brito N, Blanco-Peñalver C, Mena VF, Souto RM. Durability of Reinforced Concrete with Additions of Natural Pozzolans of Volcanic Origin. Materials. 2022; 15(23):8352. https://doi.org/10.3390/ma15238352

Chicago/Turabian StyleSantana, Juan J., Natalia Rodríguez-Brito, Concepción Blanco-Peñalver, Vicente F. Mena, and Ricardo M. Souto. 2022. "Durability of Reinforced Concrete with Additions of Natural Pozzolans of Volcanic Origin" Materials 15, no. 23: 8352. https://doi.org/10.3390/ma15238352

APA StyleSantana, J. J., Rodríguez-Brito, N., Blanco-Peñalver, C., Mena, V. F., & Souto, R. M. (2022). Durability of Reinforced Concrete with Additions of Natural Pozzolans of Volcanic Origin. Materials, 15(23), 8352. https://doi.org/10.3390/ma15238352