Microstructure and Texture Evolution during Superplastic Deformation of SP700 Titanium Alloy

Abstract

:1. Introduction

2. Materials and Experiment

3. Results

3.1. Microstructure Evolution

3.1.1. Initial Microstructure of the SP700 Alloy Sheet

3.1.2. Microstructure Evolution during Superplastic Deformation

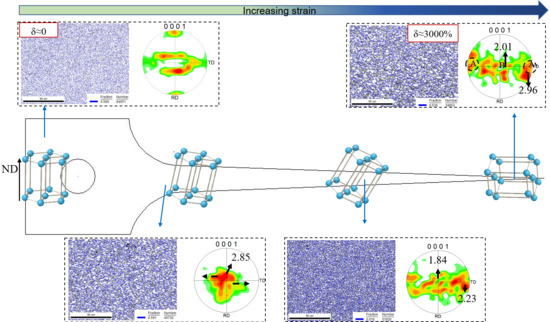

3.2. Texture Evolution during Superplastic Deformation

4. Discussion

4.1. Microstructure Aspects of Superplasticity

4.2. Texture Aspects of Superplasticity

5. Conclusions

- (1)

- The SP700 alloy sheet with a grain size of 1.3 μm showed excellent superplasticity at 760 °C with the fraction elongation up to 3000% using the maximum m value method.

- (2)

- During the superplastic deformation process, the microstructure kept fine equiaxed grains with the grain size increasing from 2.5 μm to 5.5 μm as the strain increased. Meanwhile, the β phase volume fraction increased from 30% to 40% due to the diffusion of Al, Mo, Fe, and V elements with the higher value of [Mo]eq in the β phase.

- (3)

- During the deformation process, the intensity of the texture and the dominant texture changed as the deformation strain increased, indicating that the grain rotation occurred. The grain boundary sliding accommodated by the grain rotation and dislocation slip was the main deformation mechanism of SP700 alloy.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Leyens, C.; Peters, M. Titanium and Titanium Alloys: Fundamentals and Applications; Wiley-VCH: Weinheim, Germany, 2003. [Google Scholar]

- Sha, W.; Malinov, S. Titanium Alloys: Modelling of Microstructure, Properties and Applications. Aircr. Eng. Aerosp. Technol. 2009, 81, cae.003. [Google Scholar] [CrossRef]

- Imayev, V.; Gaisin, R.; Rudskoy, A.; Nazarova, T.; Shaimardanov, R.; Imayev, R. Extraordinary superplastic properties of hot worked Ti-45Al-8Nb-0.2C alloy. J. Alloys Compd. 2016, 663, 217–224. [Google Scholar] [CrossRef]

- Froes, F.H. Titanium Physical Metallurgy Processing and Applications; ASM International: Novelty, OH, USA, 2015. [Google Scholar]

- Basri, H. The Effect of Bottom Profile Dimples on the Femoral Head on Wear in Metal-on-Metal Total Hip Arthroplasty. J. Funct. Biomater. 2021, 12, 38. [Google Scholar] [CrossRef]

- Jamari, J. Tresca Stress Simulation of Metal-on-Metal Total Hip Arthroplasty during Normal Walking Activity. Materials 2021, 14, 7554. [Google Scholar] [CrossRef]

- Kaibyshev, O.A. Current problems of superplasticity. Czechoslov. J. Phys. B 1988, 38, 395–400. [Google Scholar] [CrossRef]

- Barnes, A.J. Superplastic Forming 40 Years and Still Growing. J. Mater. Eng. Perform. 2013, 22, 2935–2949. [Google Scholar] [CrossRef]

- Kaibyshev, O.A.; Safiullin, R.V.; Lutfullin, R.Y.; Valiakhmetov, O.R.; Galeyev, R.M.; Dutta, A.; Raghu, T.; Saha, G.G. Advanced superplastic forming and diffusion bonding of titanium alloy. Mater. Sci. Technol. 2013, 22, 343–348. [Google Scholar] [CrossRef]

- Mohamed, F.A. Micrograin superplasticity: Characteristics and utilization. Materials 2011, 4, 1194–1223. [Google Scholar] [CrossRef] [Green Version]

- Khanna, N.; Davim, J.P. Design-of-experiments application in machining titanium alloys for aerospace structural components. Measurement 2015, 61, 280–290. [Google Scholar] [CrossRef]

- Langdon, T.G. Seventy-five years of superplasticity: Historic developments and new opportunities. J. Mater. Sci. 2009, 44, 5998–6010. [Google Scholar] [CrossRef]

- Patankar, S.N.; Escobedo, J.P.; Field, D.P.; Salishchev, G.; Galeyev, R.M.; Valiakhmetov, O.R. Superior superplastic behavior in fine-grained Ti-6Al-4V sheet. J. Alloys Compd. 2002, 345, 221–227. [Google Scholar] [CrossRef]

- Ratochka, I.V.; Lykova, O.N.; Mishin, I.P.; Naydenkin, E.V. The Influence of Structure and Phase Composition of Titanium Alloy on Superplastic Deformation. Russ. Phys. J. 2018, 61, 1702–1708. [Google Scholar] [CrossRef]

- Meier, M.L.; Lesuer, D.R.; Mukherjee, A.K. α grain size and β volume fraction aspects of the superplasticity of Ti-6Al-4V. Mater. Sci. Eng. 1991, 136, 71–78. [Google Scholar] [CrossRef]

- Ratochka, I.V.; Mishin, I.P.; Lykova, O.N.; Naydenkin, E.V. Superplastic Deformation of Titanium Alloy with Different Structure and Phase Composition. Russ. Phys. J. 2020, 63, 680–687. [Google Scholar] [CrossRef]

- Alabort, E.; Barba, D.; Shagiev, M.R.; Murzinova, M.A.; Reed, R.C. Alloys-By-Design: Application to titanium alloys for optimal superplasticity. Acta Mater. 2019, 178, 275–287. [Google Scholar] [CrossRef]

- Kim, J.S.; Chang, Y.W.; Lee, C.S. Mechanical and Microstructural Analysis on the Superplastic Deformation Behavior of Two-Phase Ti-6Al-4V Alloy. Met. Mater. 1998, 4, 771–777. [Google Scholar] [CrossRef]

- Li, X.-F.; Xu, F.-F.; Hu, L.; Zhu, F.-H.; Chen, J. Tensile deformation behavior of coarse-grained Ti-55 titanium alloy with different hydrogen additions. Rare Met. 2020, 40, 2092–2098. [Google Scholar] [CrossRef]

- Kotov, A.D.; Mikhailovskaya, A.V.; Mosleh, A.O.; Pourcelot, T.P.; Prosviryakov, A.S.; Portnoi, V.K. Superplasticity of an Ultrafine-Grained Ti–4% Al–1% V–3% Mo Alloy. Phys. Met. Metallogr. 2019, 120, 60–68. [Google Scholar] [CrossRef]

- Motyka, M.; Sieniawski, J. The Effect of α-Phase Grains Morphology in Initial Microstructure on Superplasticity of Two-Phase Titanium Alloys. Mater. Sci. Forum 2016, 838–839, 143–149. [Google Scholar] [CrossRef]

- Motyka, M.; Sieniawski, J.; Ziaja, W. Microstructural aspects of superplasticity in Ti–6Al–4V alloy. Mater. Sci. Eng. A 2014, 599, 57–63. [Google Scholar] [CrossRef]

- Roy, S.; Suwas, S. Deformation mechanisms during superplastic testing of Ti–6Al–4V–0.1B alloy. Mater. Sci. Eng. A 2013, 574, 205–217. [Google Scholar] [CrossRef]

- Liu, Z.; Li, P.; Xiong, L.; Liu, T.; He, L. High-temperature tensile deformation behavior and microstructure evolution of Ti55 titanium alloy. Mater. Sci. Eng. A 2017, 680, 259–269. [Google Scholar] [CrossRef]

- Liu, Z.; Li, P.; Geng, L.; Liu, T.; Gao, H. Microstructure and texture evolution of TA32 titanium alloy during superplastic deformation. Mater. Sci. Eng. A 2017, 699, 71–80. [Google Scholar] [CrossRef]

- Wang, J.; Xu, Y.; Zhang, W.; Wang, W. A finite-strain thermomechanical model for severe superplastic deformation of Ti-6Al-4V at elevated temperature. J. Alloys Compd. 2019, 787, 1336–1344. [Google Scholar] [CrossRef]

- Liu, C.; Zhou, G.; Wang, X.; Liu, J.; Li, J.; Zhang, H.; Chen, L. Rheological Law and Mechanism for Superplastic Deformation of Ti-6Al-4V. Materials 2019, 12, 3520. [Google Scholar] [CrossRef] [Green Version]

- Ashby, M.; Verrall, R. Diffusion-accommodated flow and superplasticity. Acta Metall. 1973, 21, 149–163. [Google Scholar] [CrossRef]

- Geckinli, A. Grain boundary sliding model for superplastic deformation. Metal Sci. 1983, 17, 12–18. [Google Scholar] [CrossRef]

- Guo, W.; Jia, Q.; Li, R.; Li, W. The Superplastic Deformation Behavior and Phase Evolution of Ti-6Al-4V Alloy at Constant Tensile Velocity. High Temp. Mater. Process. 2017, 36, 55–62. [Google Scholar] [CrossRef]

- Kim, J.S.; Kim, J.H.; Lee, Y.T.; Park, C.G.; Lee, C.S. Microstructural analysis on boundary sliding and its accommodation mode during superplastic deformation of Ti-6Al-4V alloy. Mater. Sci. Eng. A 1999, 263, S0921–S5093. [Google Scholar] [CrossRef]

- Sato, E.; Kuribayashi, K.; Horiuchi, R. A Mechanism of Superplastic Deformation and Deformation Induced Grain Growth Based on Grain Switching. MRS Proc. 1990, 196, 27. [Google Scholar] [CrossRef]

- Alabort, E.; Kontis, P.; Barba, D.; Dragnevski, K.; Reed, R.C. On the mechanisms of superplasticity in Ti–6Al–4V. Acta Mater. 2016, 105, 449–463. [Google Scholar] [CrossRef] [Green Version]

- Matsumoto, H.; Yoshida, K.; Lee, S.-H.; Ono, Y.; Chiba, A. Ti–6Al–4V alloy with an ultrafine-grained microstructure exhibiting low-temperature–high-strain-rate superplasticity. Mater. Lett. 2013, 98, 209–212. [Google Scholar] [CrossRef]

- Mishra, R.S.; Mukherjee, A.K. The Origin of High Strain Rate Superplasticity. Mater. Sci. Forum 1997, 243–245, 315–320. [Google Scholar] [CrossRef]

- Zherebtsov, S.V.; Kudryavtsev, E.A.; Salishchev, G.A.; Straumal, B.B.; Semiatin, S.L. Microstructure evolution and mechanical behavior of ultrafine Ti-6Al-4V during low-temperature superplastic deformation. Acta Mater. 2016, 121, 152–163. [Google Scholar] [CrossRef]

- Valiev, R.Z. Applications of Severe Plastic Deformations for Materials Nanostructuring Aimed at Advanced Properties. In Nanostructured Materials by High-Pressure Severe Plastic Deformation; Springer: Dordrecht, The Netherlands, 2006. [Google Scholar] [CrossRef]

- Kosaka, Y.; Gudipati, P. Superplastic Forming Properties of TIMETAL®54M (Ti-5%Al-4%V-0.6%Mo-0.4%Fe) Sheets. Key Eng. Mater. 2010, 433, 311–317. [Google Scholar] [CrossRef]

- Kosaka, Y.; Gudipati, P. Superplasticity and Characterization of TIMETAL®54M Sheets. Mater. Sci. Forum 2016, 838–839, 190–195. [Google Scholar] [CrossRef]

- Qu, Y.; Wang, M.; Lei, L.; Huang, X.; Wang, L.; Qin, J.; Lu, W.; Zhang, D. Behavior and modeling of high temperature deformation of an α + β titanium alloy. Mater. Sci. Eng. A 2012, 555, 99–105. [Google Scholar] [CrossRef]

- Salishchev, G.A.; Galeyev, R.M.; Malisheva, S.P.; Valaikhmetov, O.R. Low Temperature Superplasticity of Submicrocrystalline Titanium Alloys. Mater. Sci. Forum 1996, 243–245, 585–590. [CrossRef]

- Ogawa, A.; Niikura, M.; Ouchi, C.; Minikawa, K.; Yamada, M. Development and Applications of Titanium Alloy SP-700. J. Test. Eval. 1996, 24, 100–109. [Google Scholar]

- Cai, J.-M.; Xu, C.; Hao, M.-Y.; Huang, X.; Ma, J.-M.; Cao, C.-X. Fatigue Crack Growth Characteristics of Fine Structures of SP700 and Ti-6Al-4V Titanium Alloys. J. Aeronaut. Mater. 2006, 26, 71–74. [Google Scholar]

- Han, D.; Zhao, Y.; Zeng, W. Effect of Zr Addition on the Mechanical Properties and Superplasticity of a Forged SP700 Titanium Alloy. Materials 2021, 14, 906. [Google Scholar] [CrossRef]

- Li, C.; Mingjie, F.; Yuansong, Z. Superplastic deformation Microstructure and property of laser welding Ti-4.5Al-3V-2Mo-2Fe alloy. Rare Met. Mater. Eng. 2018, 8, 2555–2560. [Google Scholar]

- Fu, M.; Zeng, Y.; Han, X.; Lv, F.; Wang, F. Microsturcture and mechanical property of superplastic deformed Ti-4.5Al-3V-2Mo-2Fe alloy sheet. Aeronaut. Manuf. Technol. 2021, 64, 76–81,88. [Google Scholar]

- Mingjie, F.; Jizhong, L.; Yuansong, Z. Superplastic Deformation Behavior of Friction Stir Welded Ti-4.5Al-3V-2Mo-2Fe Alloy. Chin. J. Rare Met. 2020, 44, 1–7. [Google Scholar]

- Horita, Z.; Furukawa, M.; Nemoto, M.; Barnes, A.J.; Langdon, T.G. Superplastic forming at high strain rates after severe plastic deformation. Acta Mater. 2000, 48, 3633–3640. [Google Scholar] [CrossRef]

- Wisbey, A.; Geary, B.; Davies, D.P.; Ward-Close, C.M. Superplastic Deformation and Diffusion Bonding of the Low Deformation Temperature Titanium Alloy SP700. Mater. Sci. Forum 1994, 170–172, 293–298. [Google Scholar] [CrossRef]

- Backofen, W.A. Superplasticity in an Al-Zn alloy. Trans. ASM 1964, 57, 980–990. [Google Scholar]

- Wang, G.; Fu, M.W. Maximum m Value Superplasticity Deformation for Ti-6Al-4V Titanium Alloy. In Proceedings of the 7th Asia Pacific Conference on Materials Processing, Singapore, 4–6 December 2006. [Google Scholar]

- Polkowski, W.; Jóźwik, P.; Bojar, Z. EBSD and X-ray diffraction study on the recrystallization of cold rolled Ni3Al based intermetallic alloy. J. Alloys Compd. 2014, 614, 226–233. [Google Scholar] [CrossRef]

- Shen, J.; Sun, Y.; Ning, Y.; Yu, H.; Yao, Z.; Hu, L. Superplasticity induced by the competitive DRX between BCC beta and HCP alpha in Ti-4Al-3V-2Mo-2Fe alloy. Mater. Charact. 2019, 153, 304–317. [Google Scholar] [CrossRef]

- Nakajima, H.; Koiwa, M. Diffusion in Titanium. Bull. Jpn. Inst. Met. 2007, 30, 775–782. [Google Scholar] [CrossRef] [Green Version]

- Min, J.; Guo, Y.; Niu, J.; Cao, J.; Sun, Z.; Chang, H. The Characteristic of Fe as a beta-Ti Stabilizer in Ti Alloys. Materials 2021, 14, 7516. [Google Scholar] [CrossRef]

- Valiev, R.; Langdon, T. An investigation of the role of intragranular dislocation strain in the superplastic Pb-62% Sn eutectic alloy. Acta Metall. Mater. 1993, 41, 949–954. [Google Scholar] [CrossRef]

- Bai, Q.; Lin, J.; Dean, T.A.; Balint, D.S.; Gao, T.; Zhang, Z. Modelling of dominant softening mechanisms for Ti-6Al-4V in steady state hot forming conditions. Mater. Sci. Eng. 2013, 559, 352–358. [Google Scholar] [CrossRef]

- Semiatin, S.L.; Corbett, M.W.; Fagin, P.N.; Salishchev, G. Dynamic-coarsening behavior of an α/β titanium alloy. Metall. Mater. Trans. A 2006, 37, 1125–1136. [Google Scholar] [CrossRef]

- Momeni, A.; Abbasi, S.M. Effect of hot working on flow behavior of Ti-6Al-4V alloy in single phase and two phase regions. Mater. Des. 2010, 31, 3599–3604. [Google Scholar] [CrossRef]

| Element | Ti | Al | V | Fe | Mo | O | H |

|---|---|---|---|---|---|---|---|

| wt.% | Bal. | 4.36 | 3.10 | 1.94 | 2.00 | 0.12 | <0.001 |

| Position | Phase | Ti | Al | V | Fe | Mo | [Mo]eq |

|---|---|---|---|---|---|---|---|

| Grip | β | 83.53 | 3.93 | 4.29 | 3.20 | 5.05 | 17.20 |

| α | 92.50 | 5.30 | 1.27 | 0.09 | 0.84 | 1.95 | |

| Tip | β | 81.03 | 2.59 | 5.47 | 4.79 | 6.12 | 23.67 |

| α | 92.67 | 5.69 | 0.95 | 0.08 | 0.60 | 1.46 |

| Position in the Specimen | Before Test | Grip | Near Grip | Middle of the Gauge | Tip |

|---|---|---|---|---|---|

| Fraction of LAGBs/% | 21 | 7 | 5 | 9 | 15 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tian, N.; Ye, W.; Song, X.; Hui, S. Microstructure and Texture Evolution during Superplastic Deformation of SP700 Titanium Alloy. Materials 2022, 15, 1808. https://doi.org/10.3390/ma15051808

Tian N, Ye W, Song X, Hui S. Microstructure and Texture Evolution during Superplastic Deformation of SP700 Titanium Alloy. Materials. 2022; 15(5):1808. https://doi.org/10.3390/ma15051808

Chicago/Turabian StyleTian, Ning, Wenjun Ye, Xiaoyun Song, and Songxiao Hui. 2022. "Microstructure and Texture Evolution during Superplastic Deformation of SP700 Titanium Alloy" Materials 15, no. 5: 1808. https://doi.org/10.3390/ma15051808

APA StyleTian, N., Ye, W., Song, X., & Hui, S. (2022). Microstructure and Texture Evolution during Superplastic Deformation of SP700 Titanium Alloy. Materials, 15(5), 1808. https://doi.org/10.3390/ma15051808