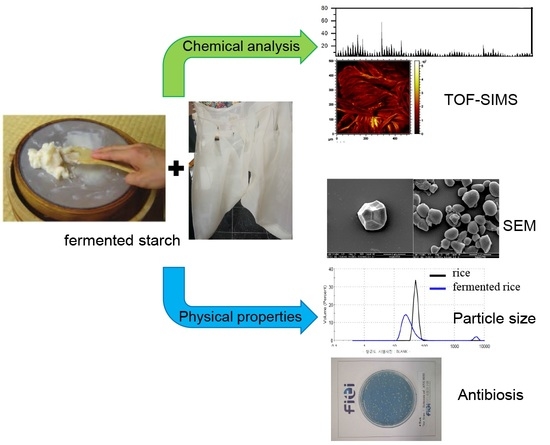

Surface Analysis of Fermented Wheat and Rice Starch Used for Coating Traditional Korean Textiles

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Methods

2.3. Instrumentation

3. Results and Discussion

3.1. Properties of the Starch and Coated Textile Samples

3.2. SEM Images of the Starch and Textile Samples

3.3. ToF-SIMS Analyses of the Starch and Textile Samples

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Hizukuri, S.; Takeda, Y.; Yasuda, M.; Suzuki, A. Multi-branched nature of amylose and the action of de-branching enzymes. Carbohydr. Res. 1981, 94, 205–213. [Google Scholar] [CrossRef]

- Pérez, S.; Bertoft, E. The molecular structures of starch components and their contribution to the architecture of starch granules: A comprehensive review. Starch-Stärke 2010, 62, 389–420. [Google Scholar] [CrossRef]

- Yu, X.; Li, B.; Wang, L.; Chen, X.; Wang, W.; Gu, Y.; Wang, Z.; Xiong, F. Effect of drought stress on the development of endosperm starch granules and the composition and physicochemical properties of starches from soft and hard wheat. J. Sci. Food Agric. 2016, 96, 2746–2754. [Google Scholar] [CrossRef] [PubMed]

- Fitzgerald, M.A.; McCouch, S.R.; Hall, R.D. Not just a grain of rice: The quest for quality. Trends Plant Sci. 2009, 14, 133–139. [Google Scholar] [CrossRef] [PubMed]

- Hizukuri, S. Relationship between the distribution of the chain length of amylopectin and the crystalline structure of starch granules. Carbohydr. Res. 1985, 141, 295–306. [Google Scholar] [CrossRef]

- Jane, J.; Chen, Y.Y.; Lee, L.F.; McPherson, A.E.; Wong, K.S.; Radosavljevic, M.; Kasemsuwan, T.K. Effects of Amylopectin Branch Chain Length and Amylose Content on the Gelatinization and Pasting Properties of Starch. Cereal Chem. 1999, 76, 629–637. [Google Scholar] [CrossRef]

- Miles, M.J.; Morris, V.J.; Orford, P.D.; Ring, S.G. The roles of amylose and amylopectin in the gelation and retrogradation of starch. Carbohydr. Res. 1985, 135, 271–281. [Google Scholar] [CrossRef]

- Avérous, L.; Halley, P. Starch Polymers: From the Field to Industrial Products. In Starch Polymers, 1st ed.; Halley, P., Avérous, L., Eds.; Elsevier: Amsterdam, The Netherlands, 2014; pp. 3–10. [Google Scholar] [CrossRef]

- Young-Mee, B.; Yong-Suk, K. Jeontongboksik, 1st ed.; Korean Traditional Costume Research Institute: Seoul, Korea, 1992; pp. 21–36. (In Korean) [Google Scholar]

- Xia, X. Technical characteristics and contemporary creation of Kemao knitted tapestry. J. Silk 2021, 58, 137–142. (In Chinese) [Google Scholar]

- Hua, W.; Hafeezulla, M. Cotton Science and Processing Technology, 1st ed.; Springer Nature: Singapore, 2020; pp. 1–547. [Google Scholar]

- Hwa, W.; Rajnesh, K.; Hafeezullah, M. Strongly Hydrophobic and Superoleophilic PMMA Based Nanocoated Cotton Fabrics. Coatings 2020, 10, 943. [Google Scholar]

- Baldwin, P.M.; Adler, J.; Davies, M.C.; Melia, C.D. High Resolution Imaging of Starch Granule Surfaces by Atomic Force Microscopy. J. Cereal Sci. 1998, 27, 255–265. [Google Scholar] [CrossRef]

- Zhu, F. Atomic force microscopy of starch systems. Crit. Rev. Food Sci. Nutr. 2017, 57, 3127–3144. [Google Scholar] [CrossRef] [PubMed]

- Ma, M.; Chen, X.; Zhou, R.; Li, H.; Sui, Z.; Corke, H. Surface microstructure of rice starch is altered by removal of granule-associated proteins. Food Hydrocoll. 2021, 121, 107038. [Google Scholar] [CrossRef]

- Blazek, J.; Gilbert, E.P. Application of small-angle X-ray and neutron scattering techniques to the characterization of starch structure: A review. Carbohydr. Polym. 2011, 85, 281–293. [Google Scholar] [CrossRef]

- Kuang, Q.; Xu, J.; Liang, Y.; Xie, F.; Tian, F.; Zhou, S.; Liu, X. Lamellar structure change of waxy corn starch during gelatinization by time-resolved synchrotron SAXS. Food Hydrocoll. 2017, 62, 43–48. [Google Scholar] [CrossRef] [Green Version]

- Mahony, C.M. Cluster secondary ion mass spectrometry of polymers and related materials. Mass Spectrom. Rev. 2010, 29, 247–293. [Google Scholar] [CrossRef]

- Lambert, J.B.; McLaughlin, C.D.; Shawl, C.E.; Xue, L. X-ray Photoelectron Spectroscopy and Archaeology. Anal. Chem. 1999, 71, 614A–620A. [Google Scholar] [CrossRef]

- Lee, J.; Kang, M.; Lee, K.; Lee, Y. Characterization of Natural Dyes and Traditional Korean Silk Fabric by Surface Analytical Techniques. Materials 2013, 6, 2007–2025. [Google Scholar] [CrossRef] [Green Version]

- Lee, J.; Doh, J.; Hahn, H.; Lee, K.; Lee, Y. Investigation of Asian lacquer films using ToF-SIMS and complementary analytical techniques. Surf. Interface Anal. 2017, 49, 479–487. [Google Scholar] [CrossRef]

- Wagner, M.S.; Graham, D.J.; Rater, B.D.; Castner, D.G. Maximizing information obtained from secondary ion mass spectra of organic thin films using multivariate analysis. Surf. Sci. 2004, 570, 78–97. [Google Scholar] [CrossRef]

- Russell, P.L.; Gough, B.M.; Greenwell, P.; Fowler, A.; Munro, H.S. A study by ESCA of the surface of native and chlorine-treated wheat starch granules: The effects of various surface treatments. J. Cereal Sci. 1987, 5, 83–100. [Google Scholar] [CrossRef]

- Baldwin, P.M.; Melia, C.D.; Davies, M.C. The Surface Chemistry of Starch Granules Studied by Time-of-Flight Secondary Ion Mass Spectrometry. J. Cereal Sci. 1997, 26, 329–346. [Google Scholar] [CrossRef]

- Ministry of Food and Drug Safety. Quantification of Saccharides by Instrumental Analysis. Available online: https://www.foodsafetykorea.go.kr/foodcode/01_03.jsp?idx=11017 (accessed on 24 November 2021). (In Korean)

- Bradstreet, R.B. Kjeldahl Method for Organic Nitrogen. Anal. Chem. 1954, 26, 185–187. [Google Scholar] [CrossRef]

| Peak 1 | Peak 2 | Peak 3 | ||

|---|---|---|---|---|

| Wheat | Size ± SD (d.nm) % Volume | 31.1 ± 8.2 85.6 | 139.1 ± 49.2 10.4 | 5590.0 ± 579.8 4 |

| 5-year fermented wheat | Size ± SD (d.nm) % Volume | 24.6 ± 18.2 97 | 5433.0 ± 643.0 3 | 0 0 |

| Rice | Size ± SD (d.nm) % Volume | 52.3 ± 8.7 100 | 0 0 | 0 0 |

| 7-year fermented rice | Size ± SD (d.nm) % Volume | 30.9 ± 19.5 93.8 | 5159.0 ± 773.3 6.2 | 0 0 |

| Amylose | Size ± SD (d.nm) % Volume | 8.9 ± 2.2 64.6 | 29.7 ± 12.5 32.6 | 401.6 ± 147.6 2.8 |

| Amylopectin | Size ± SD (d.nm) % Volume | 54.8 ± 15.6 28 | 401.5 ± 140.0 31.4 | 5385.0 ± 668.6 40.6 |

| Carbohydrate % | Protein % | Fat % | Water % | Ash % | |

|---|---|---|---|---|---|

| Wheat | 78.06 | 10.21 | 1.33 | 10.25 | 0.15 |

| 5-year fermented wheat | 86.74 | 0.41 | 0.78 | 11.98 | 0.09 |

| Rice | 81.14 | 6.37 | 0.79 | 11.62 | 0.08 |

| 7-year fermented rice | 86.89 | 0.49 | 0.86 | 11.74 | 0.02 |

| Blank | Wheat | 5-Year Wheat | Rice | 7-Year Rice | |

|---|---|---|---|---|---|

| Initial (CFU/mL) | 2.1 × 105 | 2.1 × 105 | 2.1 × 105 | 2.1 × 105 | 2.1 × 105 |

| 24 h (CFU/mL) | 1.3 × 105 | 4.8 × 105 | 1.6 × 103 | 4.8 × 105 | 1.8 × 102 |

| Percentage reduction | - | 0 | 98.8% | 0 | 99.9% |

| Ramie | Cotton | |||||||

|---|---|---|---|---|---|---|---|---|

| Glossiness Units(GU) | L* (Brightness) | a* (Red) | b* (Yellow) | Glossiness Units(GU) | L* (Brightness) | a* (Red) | b* (Yellow) | |

| Refined | 2.50 | 65.4 | −0.52 | 1.79 | 2.28 | 81.3 | 0.98 | 1.62 |

| Wheat | 2.61 | 68.4 | −0.52 | 1.28 | 2.60 | 81.2 | 0.89 | 1.74 |

| 5-year fermented wheat | 2.72 | 68.2 | −0.27 | 3.6 | 2.55 | 79.3 | 0.9 | 1.5 |

| Rice | 2.60 | 64.6 | −0.43 | 1.62 | 2.50 | 81.8 | 1.06 | 1.48 |

| 7-year fermented rice | 2.62 | 68.0 | −0.5 | 1.54 | 2.51 | 81.0 | 1.07 | 1.9 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yu, H.H.; Lee, Y.; Nam, Y.-S.; Kim, M.-H.; Lee, K.-B.; Lee, Y. Surface Analysis of Fermented Wheat and Rice Starch Used for Coating Traditional Korean Textiles. Materials 2022, 15, 2001. https://doi.org/10.3390/ma15062001

Yu HH, Lee Y, Nam Y-S, Kim M-H, Lee K-B, Lee Y. Surface Analysis of Fermented Wheat and Rice Starch Used for Coating Traditional Korean Textiles. Materials. 2022; 15(6):2001. https://doi.org/10.3390/ma15062001

Chicago/Turabian StyleYu, Hye Hyun, Youngseo Lee, Yun-Sik Nam, Man-Ho Kim, Kang-Bong Lee, and Yeonhee Lee. 2022. "Surface Analysis of Fermented Wheat and Rice Starch Used for Coating Traditional Korean Textiles" Materials 15, no. 6: 2001. https://doi.org/10.3390/ma15062001

APA StyleYu, H. H., Lee, Y., Nam, Y. -S., Kim, M. -H., Lee, K. -B., & Lee, Y. (2022). Surface Analysis of Fermented Wheat and Rice Starch Used for Coating Traditional Korean Textiles. Materials, 15(6), 2001. https://doi.org/10.3390/ma15062001