Large-Scale Preparation of Silver Nanowire-Based Flexible Transparent Film Heaters by Slot-Die Coating

Abstract

:1. Introduction

2. Materials and Methods

2.1. Preparation of AgNW TCF Heaters

2.2. Characterization

3. Results and Discussion

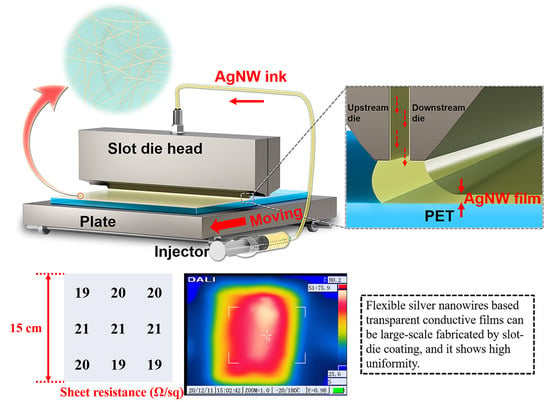

3.1. Construction of AgNW TCF by Slot-Die Coating

3.2. Optoelectric Performance Optimization of Slot-Die Coated AgNW TCFs

3.3. Joule Heating Performance of AgNW TCF Based Heaters

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Sharma, S.; Shriwastava, S.; Kumar, S.; Bhatt, K.; Tripathi, C.C. Alternative transparent conducting electrode materials for flexible optoelectronic devices. Opto-Electron. Rev. 2018, 26, 223–235. [Google Scholar] [CrossRef]

- Jeong, H.; Park, S.; Lee, J.; Won, P.; Ko, S.-H.; Lee, D. Fabrication of Transparent Conductive Film with Flexible Silver Nanowires Using Roll-to-Roll Slot-Die Coating and Calendering and Its Application to Resistive Touch Panel. Adv. Electron. Mater. 2018, 4, 243. [Google Scholar] [CrossRef]

- Woo, Y.S. Transparent Conductive Electrodes Based on Graphene-Related Materials. Micromachines 2018, 10, 13. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Xu, Y.; Liu, J. Graphene as Transparent Electrodes: Fabrication and New Emerging Applications. Small 2016, 12, 1400–1419. [Google Scholar] [CrossRef] [PubMed]

- Zhou, Y.; Tanaka, S.; Azumi, R. The use of acids in the exfoliation of carbon nanotubes and its application toward fabricating chemically stable and highly conducting transparent films. Appl. Surf. Sci. 2020, 515, 14602. [Google Scholar] [CrossRef]

- Chen, J.; Zhu, Y.; Jiang, W. A stretchable and transparent strain sensor based on sandwich-like PDMS/CNTs/PDMS composite containing an ultrathin conductive CNT layer. Compos. Sci. Technol. 2019, 186, 107938. [Google Scholar] [CrossRef]

- Dimitrov, D.; Tsai, C.-L.; Petrov, S.; Marinova, V.; Petrova, D.; Napoleonov, B.; Blagoev, B.; Strijkova, V.; Hsu, K.Y.; Lin, S.H. Atomic Layer-Deposited Al-Doped ZnO Thin Films for Display Applications. Coatings 2020, 10, 539. [Google Scholar] [CrossRef]

- Topolovsek, P.; Lamberti, F.; Gatti, T.; Cito, A.; Ball, J.M.; Menna, E.; Gadermaier, C.; Petrozza, A. Functionalization of transparent conductive oxide electrode for TiO2-free perovskite solar cells. J. Mater. Chem. A 2017, 5, 11882–11893. [Google Scholar] [CrossRef]

- Zhou, J.; Gao, Q.; Fukawa, T.; Shirai, H.; Kimura, M. Macroporous conductive polymer films fabricated by electrospun nanofiber templates and their electromechanical properties. Nanotechnology 2011, 22, 275501. [Google Scholar] [CrossRef]

- Vosgueritchian, M.; Lipomi, D.J.; Bao, Z. Highly Conductive and Transparent PEDOT:PSS Films with a Fluorosurfactant for Stretchable and Flexible Transparent Electrodes. Adv. Funct. Mater. 2012, 22, 421–428. [Google Scholar] [CrossRef]

- Bai, S.; Guo, X.; Zhang, X.; Zhao, X.; Yang, H. Ti3C2Tx MXene -AgNW composite flexible transparent conductive films for EMI shielding. Compos. Part A: Appl. Sci. Manuf. 2021, 149, 106545. [Google Scholar] [CrossRef]

- Esteki, K.; Manning, H.G.; Sheerin, E.; Ferreira, M.S.; Boland, J.J.; da Rocha, C.G. Tuning the electro-optical properties of nanowire networks. Nanoscale 2021, 13, 15369–15379. [Google Scholar] [CrossRef] [PubMed]

- Lee, H.B.; Jin, W.-Y.; Ovhal, M.M.; Kumar, N.; Kang, J.-W. Flexible transparent conducting electrodes based on metal meshes for organic optoelectronic device applications: A review. J. Mater. Chem. C 2019, 7, 1087–1110. [Google Scholar] [CrossRef]

- Kim, H.; Gilmore, C.M.; Piqué, A.; Horwitz, J.S.; Mattoussi, H.; Murata, H.; Kafafi, Z.H.; Chrisey, D.B. Electrical, optical, and structural properties of indium–tin–oxide thin films for organic light-emitting devices. J. Appl. Phys. 1999, 86, 6451–6461. [Google Scholar] [CrossRef]

- Patil, J.J.; Chae, W.H.; Trebach, A.; Carter, K.; Lee, E.; Sannicolo, T.; Grossman, J.C. Failing Forward: Stability of Transparent Electrodes Based on Metal Nanowire Networks. Adv. Mater. 2021, 33, e2004356. [Google Scholar] [CrossRef] [PubMed]

- Zhu, S.; Gao, Y.; Hu, B.; Li, J.; Su, J.; Fan, Z.; Zhou, J. Transferable self-welding silver nanowire network as high performance transparent flexible electrode. Nanotechnology 2013, 24, 335202. [Google Scholar] [CrossRef] [Green Version]

- Mallikarjuna, K.; Vattikuti, S.V.P.; Manne, R.; Manjula, G.; Munirathnam, K.; Mallapur, S.; Marraiki, N.; Mohammed, A.; Reddy, L.V.; Rajesh, M.; et al. Sono-Chemical Synthesis of Silver Quantum Dots Immobilized on Exfoliated Graphitic Carbon Nitride Nanostructures Using Ginseng Extract for Photocatalytic Hydrogen Evolution, Dye Degradation, and Antimicrobial Studies. Nanomaterials 2021, 11, 2918. [Google Scholar] [CrossRef]

- Zhou, L.; Hu, Y.; Gao, H.; Gao, Y.; Zhu, W.; Zhan, L.; Liu, H.; Chen, Y.; Hu, K.; Wang, P.; et al. Moisture-Assisted Formation of High-Quality Silver Nanowire Transparent Conductive Films with Low Junction Resistance. Coatings 2021, 11, 671. [Google Scholar] [CrossRef]

- Azani, M.R.; Hassanpour, A.; Torres, T. Benefits, Problems, and Solutions of Silver Nanowire Transparent Conductive Electrodes in Indium Tin Oxide (ITO)-Free Flexible Solar Cells. Adv. Energy Mater. 2020, 10, 2002536. [Google Scholar] [CrossRef]

- Xu, W.; Xu, Q.; Huang, Q.; Tan, R.; Shen, W.; Song, W. Fabrication of Flexible Transparent Conductive Films with Silver Nanowire by Vacuum Filtration and PET Mold Transfer. J. Mater. Sci. Technol. 2016, 32, 158–161. [Google Scholar] [CrossRef]

- Yu, S.; Liu, X.; Wu, M.; Dong, H.; Wang, X.; Li, L. All-Solution-Processed Molybdenum Oxide-Encapsulated Silver Nanowire Flexible Transparent Conductors with Improved Conductivity and Adhesion. ACS Appl. Mater. Interfaces 2021, 13, 14470–14478. [Google Scholar] [CrossRef] [PubMed]

- You, S.; Park, Y.S.; Choi, H.W.; Kim, K.H. Properties of Silver Nanowire/Zinc Oxide Transparent Bilayer Thin Films for Optoelectronic Applications. J. Nanosci. Nanotechnol. 2015, 15, 8656–8661. [Google Scholar] [CrossRef] [PubMed]

- Jiang, D.; Wang, Y.; Li, B.; Sun, C.; Wu, Z.; Yan, H.; Xing, L.; Qi, S.; Li, Y.; Liu, H.; et al. Flexible Sandwich Structural Strain Sensor Based on Silver Nanowires Decorated with Self-Healing Substrate. Macromol. Mater. Eng. 2019, 304, 1900074. [Google Scholar] [CrossRef]

- Madaria, A.R.; Kumar, A.; Zhou, C. Large scale, highly conductive and patterned transparent films of silver nanowires on arbitrary substrates and their application in touch screens. Nanotechnology 2011, 22, 245201. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Zhang, Y.; Bai, S.; Chen, T.; Yang, H.; Guo, X. Facile preparation of flexible and highly stable graphene oxide-silver nanowire hybrid transparent conductive electrode. Mater. Res. Express 2020, 7, 016413. [Google Scholar] [CrossRef] [Green Version]

- Triambulo, R.E.; Cheong, H.-G.; Park, J.-W. All-solution-processed foldable transparent electrodes of Ag nanowire mesh and metal matrix films for flexible electronics. Org. Electron. 2014, 15, 2685–2695. [Google Scholar] [CrossRef]

- Liang, J.; Tong, K.; Pei, Q. A Water-Based Silver-Nanowire Screen-Print Ink for the Fabrication of Stretchable Conductors and Wearable Thin-Film Transistors. Adv. Mater. 2016, 28, 5986–5996. [Google Scholar] [CrossRef]

- Xu, X.; Liu, Z.; He, P.; Yang, J. Screen printed silver nanowire and graphene oxide hybrid transparent electrodes for long-term electrocardiography monitoring. J. Phys. D Appl. Phys. 2019, 52, 455401. [Google Scholar] [CrossRef]

- Wang, B.-Y.; Lee, E.-S.; Lim, D.-S.; Kang, H.W.; Oh, Y.-J. Roll-to-roll slot die production of 300 mm large area silver nanowire mesh films for flexible transparent electrodes. RSC Adv. 2017, 7, 7540–7546. [Google Scholar] [CrossRef] [Green Version]

- Tang, H.; Feng, H.; Wang, H.; Wan, X.; Liang, J.; Chen, Y. Highly Conducting MXene–Silver Nanowire Transparent Electrodes for Flexible Organic Solar Cells. ACS Appl. Mater. Interfaces 2019, 11, 25330–25337. [Google Scholar] [CrossRef]

- Ye, S.; Rathmell, A.R.; Chen, Z.; Stewart, I.E.; Wiley, B.J. Metal Nanowire Networks: The Next Generation of Transparent Conductors. Adv. Mater. 2014, 26, 6670–6687. [Google Scholar] [CrossRef] [PubMed]

- Kim, D.-J.; Shin, H.-I.; Ko, E.-H.; Kim, K.-H.; Kim, T.-W.; Kim, H.-K. Roll-to-roll slot-die coating of 400 mm wide, flexible, transparent Ag nanowire films for flexible touch screen panels. Sci. Rep. 2016, 6, 34322. [Google Scholar] [CrossRef] [PubMed]

- Shin, K.; Park, J.; Lee, C. A 250-mm-width, flexible, and continuous roll-to-roll slot-die coated carbon nanotube/silver nanowire film fabrication and a study on the effect of anti-reflective overcoat. Thin Solid Films 2016, 598, 95–102. [Google Scholar] [CrossRef]

| Material | Method | Mean Value of Rs (Ω/sq) | T at 550 nm (%) | The Standard Deviation of Rs (Ω/sq) | Reference |

|---|---|---|---|---|---|

| AgNW | Slot-die | 20 | 96.9 | 0.9 | Our work |

| AgNW | 30.9 | 86.0 | 11.4 | [2] | |

| AgNW | 32 | 86.2 | / | [29] | |

| AgNW | 30 | 89 | / | [32] | |

| Carbon nanotube (CNT)/AgNW | 102 | 87.03 | / | [33] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, C.; Zhang, X.; Shan, J.; Li, Z.; Guo, X.; Zhao, X.; Yang, H. Large-Scale Preparation of Silver Nanowire-Based Flexible Transparent Film Heaters by Slot-Die Coating. Materials 2022, 15, 2634. https://doi.org/10.3390/ma15072634

Liu C, Zhang X, Shan J, Li Z, Guo X, Zhao X, Yang H. Large-Scale Preparation of Silver Nanowire-Based Flexible Transparent Film Heaters by Slot-Die Coating. Materials. 2022; 15(7):2634. https://doi.org/10.3390/ma15072634

Chicago/Turabian StyleLiu, Cuilan, Xuyang Zhang, Jiaqi Shan, Zhengliang Li, Xingzhong Guo, Xiaoyu Zhao, and Hui Yang. 2022. "Large-Scale Preparation of Silver Nanowire-Based Flexible Transparent Film Heaters by Slot-Die Coating" Materials 15, no. 7: 2634. https://doi.org/10.3390/ma15072634

APA StyleLiu, C., Zhang, X., Shan, J., Li, Z., Guo, X., Zhao, X., & Yang, H. (2022). Large-Scale Preparation of Silver Nanowire-Based Flexible Transparent Film Heaters by Slot-Die Coating. Materials, 15(7), 2634. https://doi.org/10.3390/ma15072634