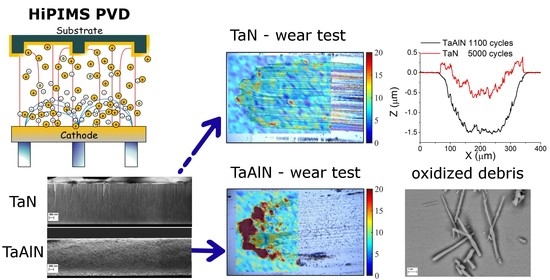

Mechanical and Tribological Properties of Ta-N and Ta-Al-N Coatings Deposited by Reactive High Power Impulse Magnetron Sputtering

Abstract

:1. Introduction

2. Materials and Methods

2.1. Film Deposition

2.2. Film Characterization

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Santecchia, E.; Hamouda, A.M.S.; Musharavati, F.; Zalnezhad, E.; Cabibbo, M.; Spigarelli, S. Wear resistance investigation of titanium nitride-based coatings. Ceram. Int. 2015, 41, 10349–10379. [Google Scholar] [CrossRef]

- Tkadletz, M.; Schalk, N.; Daniel, R.; Keckes, J.; Czettl, C.; Mitterer, C. Advanced characterization methods for wear resistant hard coatings: A review on recent progress. Surf. Coat. Technol. 2016, 285, 31–46. [Google Scholar] [CrossRef]

- Bouaouina, B.; Besnard, A.; Abaidia, S.E.; Haid, F. Residual stress, mechanical and microstructure properties of multilayer Mo2N/CrN coating produced by RF Magnetron discharge. Appl. Surf. Sci. 2017, 395, 117–121. [Google Scholar] [CrossRef] [Green Version]

- Das, S.; Guha, S.; Ghadai, R.; Swain, B.P.A. Comparative analysis over different properties of TiN, TiAlN and TiAlSiN thin film coatings grown in nitrogen gas atmosphere. Mat. Chem. Phys. 2021, 258, 123866. [Google Scholar] [CrossRef]

- Ma, F.L.; Li, J.L.; Zeng, Z.X.; Gao, Y.M. Structural, mechanical and tribocorrosion behaviour in artificial seawater of CrN/AlN nano-multilayer coatings on F690 steel substrates. Appl. Surf. Sci. 2018, 428, 404–414. [Google Scholar] [CrossRef]

- Chen, Y.I.; Lin, J.H.; Chou, C.C. Oxidation resistance and mechanical properties of Ta–Al–N coatings. Surf. Coat. Technol. 2016, 303, 41–47. [Google Scholar] [CrossRef]

- Liu, X.; Ma, G.J.; Sun, G.; Duan, Y.P.; Liu, S.H. Effect of deposition and annealing temperature on mechanical properties of TaN film. Appl. Surf. Sci. 2011, 258, 1033–1037. [Google Scholar] [CrossRef]

- Kim, S.K.; Cha, B.C. Deposition of tantalum nitride thin films by D.C. magnetron sputtering. Thin Solid Film. 2005, 475, 202–207. [Google Scholar] [CrossRef]

- Tan, P.; Fu, L.; Teng, J.; Zhu, J.; Yang, W.; Li, D.; Zhou, L. Effect of texture on wear resistance of tantalum nitride film. Tribol. Int. 2019, 133, 126–135. [Google Scholar] [CrossRef]

- Gladczuk, L.; Patel, A.; Demaree, J.D.; Sosnowski, M. Sputter deposition of bcc tantalum films with TaN underlayers for protection of steel. Thin Solid Film. 2005, 476, 295–302. [Google Scholar] [CrossRef]

- Zhang, Y.; Zheng, Y.; Li, Y.; Wang, L.; Bai, Y.; Qiang, Z.; Xiong, X.; Cheng, Y.; Tang, Z.; Deng, Y.; et al. Tantalum nitride-decorated titanium with enhanced resistance to microbiologically induced corrosion and mechanical property for dental application. PLoS ONE 2015, 10, e0130774. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Jin, W.; Wang, G.; Peng, X.; Li, W.; Qasim, A.M.; Chu, P.K. Tantalum nitride films for corrosion protection of biomedical Mg-Y-RE alloy. J. Alloys Compd. 2018, 764, 947–958. [Google Scholar] [CrossRef]

- Mendizabal, L.; Bayón, R.; G-Berasategui, E.; Barriga, J.; Gonzalez, J.J. Effect of N2 flow rate on the microstructure and electrochemical behavior of TaNx films deposited by modulated pulsed power. Thin Solid Film. 2016, 610, 1–9. [Google Scholar] [CrossRef]

- Liu, K.Y.; Lee, J.W.; Wu, F.B. Fabrication and tribological behavior of sputtering TaN coatings. Surf. Coat. Technol. 2014, 259, 123–128. [Google Scholar] [CrossRef]

- Schutze, M.; Bender, R.; Schutze, K.G. Corrosion Resistance of High-Performance Materials, 2nd ed.; Wiley-VCH: Frankfurt, Germany, 2012. [Google Scholar]

- Takeyama, M.; Noya, A.; Sase, T.; Ohta, A.; Sasaki, K. Properties of TaNx films as diffusion barriers in the thermally stable Cu/Si contact systems. J. Vac. Sci. Technol. B 1996, 14, 674–678. [Google Scholar] [CrossRef]

- Min, K.H.; Chun, K.C.; Kim, K.B. Comparative study of tantalum and tantalum nitrides (Ta2N and TaN) as a diffusion barrier for Cu metallization. J. Vac. Sci. Technol. B 1996, 14, 3263–3269. [Google Scholar] [CrossRef]

- Lovejoy, M.L.; Patrizi, G.A.; Roger, D.J.; Barbour, J.C. Thin-film tantalum-nitride resistor technology for phosphide-based optoelectronics. Thin Solid Film. 1996, 290–291, 513–517. [Google Scholar] [CrossRef]

- Cherfi, D.E.; Guemmaz, M.; Bourahli, M.E.H.; Ouadfel, M.A.; Maabed, S. Effects of nitrogen flow rate on the structural, morphological and optical properties of TaN thin films grown by the DC magnetron sputtered technique. Acta Phys. Pol. A 2019, 136, 849–854. [Google Scholar] [CrossRef]

- Chatterjee, S.; Shudarshan, T.S.; Chandrashekhar, S. Modelling and experimental studies of properties of TiN coatings. J. Mater. Sci. 1992, 27, 1989–2006. [Google Scholar] [CrossRef]

- Jiang, H.; Wang, C.; Zhang, W.; Si, X.; Li, Y. Influences of film thickness on the electrical properties of TaNx thin films deposited by reactive DC magnetron sputtering. J. Mat. Sci. Technol. 2010, 26, 597–600. [Google Scholar] [CrossRef]

- Hieber, K. Structural and electrical properties of Ta and Ta nitrides deposited by chemical vapour deposition. Thin Solid Film. 1974, 24, 157–164. [Google Scholar] [CrossRef]

- Riekkinen, T.; Molarius, J.; Laurila, T.; Nurmela, A.; Suni, I.; Kivilahti, J. Reactive sputter deposition and properties of TaxN thin films. Microelectron. Eng. 2002, 64, 289–297. [Google Scholar] [CrossRef]

- Shin, C.S.; Kim, Y.W.; Gall, D.; Greene, J.E.; Petrov, I. Phase composition and microstructure of polycrystalline and epitaxial TaNx layers grown on oxidized Si(001) and MgO(001) by reactive magnetron sputter deposition. Thin Solid Film. 2002, 402, 172–182. [Google Scholar] [CrossRef]

- Koller, C.M.; Marihart, H.; Bolvardi, H.; Kolozsvari, S.; Mayrhofer, P.H. Structure, phase evolution, and mechanical properties of DC, pulsed DC, and high power impulse magnetron sputtered Ta–N films. Surf. Coat. Technol. 2018, 347, 304–312. [Google Scholar] [CrossRef]

- Guo, X.; Niu, Y.; Chen, M.; Sun, W.; Zhu, S.; Wang, F. Stoichiometry and tribological behavior of thick Ta(N) coatings produced by direct current magnetron sputtering (DCMS). Appl. Surf. Sci. 2018, 427, 1071–1079. [Google Scholar] [CrossRef]

- Kouznetsov, V.; Macák, K.; Schneider, J.M.; Helmersson, U.; Petrov, I. A novel pulsed magnetron sputter technique utilizing very high target power densities. Surf. Coat. Technol. 1999, 122, 290–293. [Google Scholar] [CrossRef]

- Sarakinos, K.; Alami, J.; Konstantinidis, S. High power pulsed magnetron sputtering: A review on scientific and engineering state of the art. Surf. Coat. Technol. 2010, 204, 1661–1684. [Google Scholar] [CrossRef]

- Lundin, D.; Minea, T.; Gudmundsson, J.T. High Power Impulse Magnetron Sputtering, Fundamentals, Technologies, Challenges and Applications, 1st ed.; Elsevier: Amsterdam, The Netherlands, 2020. [Google Scholar]

- Sandu, C.S.; Sanjinés, R.; Benkahoul, M.; Medjani, M.; Lévy, F. Formation of composite ternary thin films by magnetron sputtering co-deposition. Surf. Coat. Technol. 2006, 201, 4083–4089. [Google Scholar] [CrossRef]

- Deng, B.; Tao, Y.; Guo, D. Effects of vanadium ion implantation on microstructure, mechanical and tribological properties of TiN coatings. Appl. Surf. Sci. 2012, 258, 9080–9086. [Google Scholar] [CrossRef]

- Anğay, F.; Camelio, S.; Eyidi, D.; Krause, B.; Abadias, G. Structure, electrical, and optical properties of reactively sputter-deposited Ta—Al—N thin films. J. Appl. Phys. 2022, 131, 105303. [Google Scholar] [CrossRef]

- Chauhan, K.V.; Rawal, S.K. A review paper on tribological and mechanical properties of ternary nitride based coatings. Proc. Technol. 2014, 14, 430–437. [Google Scholar] [CrossRef] [Green Version]

- Lutterotti, L.; Scardi, P. Simultaneous structure and size-strain refinement by the Rietveld method. J. Appl. Cryst. 1990, 23, 246–252. [Google Scholar] [CrossRef]

- Lutterotti, L.; Chateigner, D.; Ferrari, S.; Ricote, J. Texture, residual stress and structural analysis of thin films using a combined X-ray analysis. Thin Solid Film. 2004, 450, 34–41. [Google Scholar] [CrossRef]

- Young, R.A. The Rietveld Method; International Union of Crystallography, Oxford University Press: Oxford, UK, 1993. [Google Scholar]

- Carneiro, J.O.; Teixeira, V.; Azevedo, S. Residual Stresses in Thin Films Evaluated by Different Experimental Techniques; Encyclopedia of Thermal Stresses; Hetnarski, R.B., Ed.; Springer: Dordrecht, The Netherlands, 2014. [Google Scholar]

- Wei, C.-T.; Shieh, D.H.-P. Effects of processing variables on tantalum nitride by reactive-ion-assisted magnetron sputtering deposition. Jpn. J. Appl. Phys. 2006, 45, 6405–6410. [Google Scholar] [CrossRef]

- Stoney, G.G. The tension of metallic films deposited by electrolysis. Proc. R. Soc. Lond. A 1909, 82, 172–175. [Google Scholar]

- Ardigo, M.R.; Ahmed, M.; Besnard, A. Stoney formula: Investigation of curvature measurements by optical profilometer. Adv. Mater. Res. 2014, 966, 361–366. [Google Scholar] [CrossRef] [Green Version]

- Contreras Romero, E.; Cortínez Osorio, J.; Talamantes Soto, R.; Hurtado Macías, A.; Gómez Botero, M. Microstructure, mechanical and tribological performance of nanostructured TiAlTaN-(TiAlN/TaN)n coatings: Understanding the effect of quaternary/multilayer volume fraction. Surf. Coat. Technol. 2019, 377, 124875. [Google Scholar] [CrossRef]

- Hopcroft, M.A.; Nix, W.D.; Kenny, T.W. What is the Young’s Modulus of Silicon? J. Microelectromech. Syst. 2010, 19, 229–238. [Google Scholar] [CrossRef] [Green Version]

- Korsunsky, A.M.; McGurk, M.R.; Bull, S.J.; Page, T.F. On the hardness of coated systems. Surf. Coat. Technol. 1998, 99, 171–183. [Google Scholar] [CrossRef]

- Oliver, W.C.; Pharr, G.M. An improved technique for determining hardness and elastic modulus using load and displacement sensing indentation experiments. J. Mater. Res. 1992, 7, 1564–1583. [Google Scholar] [CrossRef]

- Oliver, W.C.; Pharr, G.M. Measurement of hardness and elastic modulus by instrumented indentation: Advances in understanding and refinements to methodology. J. Mater. Res. 2004, 19, 3–20. [Google Scholar] [CrossRef]

- Leyland, A.; Matthews, A. On the significance of the H/E ratio in wear control: A nanocomposite coating approach to optimised tribological behaviour. Wear 2000, 246, 1–11. [Google Scholar] [CrossRef]

- Kot, M.; Lackner, J.M.; Major, L. Microscale interpretation of tribological phenomena in Ti/TiN soft-hard multilayer coatings on soft austenite steel substrates. Bull. Polish Acad. Sci. Technol. Sci. 2011, 59, 343–355. [Google Scholar]

- Musil, J.; Novak, P.; Cerstvy, R.; Soukup, Z. Tribological and mechanical properties of nanocrystalline-TiC/a-C nanocomposite thin films. J. Vac. Sci. Technol. A 2010, 28, 244–249. [Google Scholar] [CrossRef]

- Musil, J. Hard and superhard nanocomposite coatings. Surf. Coat. Technol. 2000, 125, 322–330. [Google Scholar] [CrossRef]

- Musil, J. Hard nanocomposite coatings: Thermal stability, oxidation resistance and toughness. Surf. Coat. Technol. 2012, 207, 50–65. [Google Scholar] [CrossRef]

- Tsui, T.Y.; Pharr, G.M.; Oliver, W.C.; Bhatia, C.S.; White, R.L.; Anders, S.; Anders, A.; Brown, I.G. Nanoindentation and nanoscratching of hard carbon coatings for magnetic disks. Mater. Res. Soc. Symp. Proc. 1995, 383, 447–452. [Google Scholar] [CrossRef] [Green Version]

- EN 1071-3:2005; Advanced Technical Ceramic—Methods of Test for Ceramic Coatings. Part 3: Determination of Adhesion and Other Mechanical Failure Modes by Scratch Test. iTeh, Inc.: Newark, DE, USA, 2005.

- Bushan, B. Modern Tribology Handbook; CRC Press LLC: Boca Raton, FL, USA, 2001. [Google Scholar]

- ASTM G133-02; Standard Test Method for Linearly Reciprocating Ball-on-Flat Sliding Wear. ASTM: West Conshehoken, PA, USA, 2002.

- Archard, J.F. Contact and rubbing of flat surfaces. J. Appl. Phys. 1953, 24, 981–988. [Google Scholar] [CrossRef]

- Koller, C.M.; Glatz, S.A.; Riedl, H.; Kolozsvári, S.; Polcik, P.; Bolvardi, H.; Mayrhofer, P.H. Structure and mechanical properties of architecturally designed Ti-Al-N and Ti-Al-Ta-N-based multilayers. Surf. Coat. Technol. 2020, 385, 125355. [Google Scholar] [CrossRef]

- Lee, W.H.; Lin, J.C.; Lee, C. Characterization of tantalum nitride films deposited by reactive sputtering of Ta in N2/Ar gas mixtures. Mater. Chem. Phys. 2001, 68, 266–271. [Google Scholar] [CrossRef]

- Elangovan, T.; Murugeshan, S.; Mangalaraj, D.; Kuppusami, P.; Khan, S.; Sudha, C.; Ganesan, V.; Divakar, R.; Mohandas, E. Synthesis and high temperature XRD studies of tantalum nitride thin films prepared by reactive pulsed dc magnetron sputtering. J. Alloys Compd. 2011, 509, 6400–6407. [Google Scholar] [CrossRef]

- Tsukimoto, S.; Moriyama, M.; Murakami, M. Microstructure of amorphous tantalum nitride thin films. Thin Solid Film. 2004, 460, 222–226. [Google Scholar] [CrossRef]

- Stavrev, M.; Fischer, D.; Wenzel, C.; Drescher, K.; Mattern, N. Crystallographic and morphological characterization of reactively sputtered Ta, TaN and TaNO thin films. Thin Solid Film. 1997, 307, 79–88. [Google Scholar] [CrossRef]

- Anwar, U.H. The effect of deposition conditions on the properties of Zr-carbide, Zr-nitride and Zr-carbonitride coatings—A review. Mater. Adv. 2020, 1, 988–1011. [Google Scholar]

- Alishahi, M.; Mahboubi, F.; Mousavi Khoie, S.M.; Aparicio, M.; Lopez-Elvira, E.; Mendez, J.; Gago, R. Structural properties and corrosion resistance of tantalum nitride coatings produced by reactive DC magnetron sputtering. RSC Adv. 2016, 6, 89061. [Google Scholar] [CrossRef]

- Schalk, N.; Weirather, T.; Sabitzer, C.; Hirn, S.; Terziyska, V.L.; Gangopadhyay, S.; Czettl, C.; Polcik, P.; Kathrein, M.; Mitterer, C. Combinatorial synthesis of Cr1−xAlxN and Ta1−xAlxN coatings using industrial scale co-sputtering. Surf. Eng. 2016, 32, 252–257. [Google Scholar] [CrossRef]

- Koller, C.M.; Kirnbauer, A.; Rachbauer, R.; Kolozsv’ari, S.; Mayrhofer, P.H. Thermally-induced phase transformation sequence of arc evaporated Ta–Al–N coatings. Scr. Mater. 2016, 113, 75–78. [Google Scholar] [CrossRef]

- Mikula, M.; Sangiovanni, D.G.; Plašienka, D.; Roch, T.; Čaplovičová, M.; Truchlý, M.; Satrapinskyy, L.; Bystrický, R.; Tonhauzerová, D.; Vlčková, D.; et al. Thermally induced age hardening in tough Ta-Al-N coatings via spinodal decomposition. J. Appl. Phys. 2017, 121, 155304. [Google Scholar] [CrossRef]

- Deambrosis, S.M.; Zin, V.; Montagner, F.; Mortalò, C.; Fabrizio, M.; Miorin, E. Effect of temperature and deposition technology on the microstructure, chemistry and tribo-mechanical characteristics of Ti-B based thin films by magnetron sputtering. Surf. Coat. Technol. 2021, 405, 126556. [Google Scholar] [CrossRef]

- Greczynski, G.; Jensen, J.; Hultman, L. CrNx Films prepared by DC magnetron sputtering and high-power pulsed magnetron sputtering: A comparative study. IEEE Trans. Plasma Sci. 2010, 38, 3046–3056. [Google Scholar] [CrossRef] [Green Version]

- Srivastava, A.; Chauhan, M.; Singh, R.K. Pressure induced phase transitions in transition metal nitrides: Ab initio study. Phys. Status Solidi B 2011, 248, 2793–2800. [Google Scholar] [CrossRef]

- Geils, R.H.; Potter, D.I. Phase equilibria in the metal-rich side of the Ta-N system. Metall. Trans. 1973, 4, 1469–1474. [Google Scholar] [CrossRef]

- Lundin, D.; Stahl, M.; Kersten, H.; Helmersson, U. Energy flux measurements in high power impulse magnetron sputtering. J. Phys. D Appl. Phys. 2009, 42, 185202. [Google Scholar] [CrossRef]

- Oettel, H.; Wiedemann, R. Residual stresses in PVD hard coatings. Surf. Coat. Technol. 1995, 76–77, 265–273. [Google Scholar] [CrossRef]

- Xu, J.; Luo, H.; Ju, H.; Yu, L.; Zhou, G. Microstructure, mechanical and tribological properties of TaWN composite films. Vacuum 2017, 146, 246–251. [Google Scholar] [CrossRef]

- Shin, C.S.; Gall, D.; Kim, Y.W.; Hellgren, N.; Petrov, I.; Greene, J.E. Development of preferred orientation in polycrystalline NaCl-structure δ-TaN layers grown by reactive magnetron sputtering: Role of low-energy ion surface interactions. J. Appl. Phys. 2002, 92, 5084–5093. [Google Scholar] [CrossRef]

- Zhou, Z.; Rainforth, W.M.; Tan, C.C.; Zeng, P.; Ojeda, J.J.; Romero-Gonzalez, M.E.; Hovsepian, P.E.H. The role of the tribofilm and roll-like debris in the wear of nanoscale nitride PVD coatings. Wear 2007, 263, 1328–1334. [Google Scholar] [CrossRef]

- Luo, Q.; Rainforth, W.M.; Münz, W.D. Wear mechanisms of monolithic and multicomponent nitride coatings grown by combined arc etching and unbalanced magnetron sputtering. Surf. Coat. Technol. 2001, 146–147, 430–435. [Google Scholar] [CrossRef]

- Woydt, M.; Skopp, A.; Dörfel, I.; Witke, K. Wear engineering oxides/Anti-wear oxides. Wear 1998, 218, 84–95. [Google Scholar] [CrossRef]

- Rainforth, W.M. The wear behaviour of oxide ceramics—A Review. J. Mater. Sci. 2004, 39, 6705–6721. [Google Scholar] [CrossRef]

- Yang, Q.; Zhao, L.R.; Patnaik, P.C.; Zeng, X.T. Wear resistant TiMoN coatings deposited by magnetron sputtering. Wear 2006, 261, 119–125. [Google Scholar] [CrossRef]

- Lima, L.P.B.; Diniz, J.A.; Doi, I.; Miyoshi, J.; Silva, A.R.; Fo, J.G. Oxygen incorporation and dipole variation in tantalum nitride film used as metal-gate electrode. J. Vac. Sci. Technol. B 2012, 30, 042202. [Google Scholar] [CrossRef]

- Stoehr, M.; Shin, C.S.; Petrov, I.; Greene, J.E. Raman scattering from epitaxial TaNx (0.94 ≤ x ≤ 1.37) layers grown on MgO(001). J. Appl. Phys. 2007, 101, 123509. [Google Scholar] [CrossRef]

| Sample | Target | Bias (V) | Deposition Rate (nm/min) | N% at. | Al% at. | Ta% at. |

|---|---|---|---|---|---|---|

| TaN1 | Ta | −50 | 7.1 | 61.7 ± 0.8 | / | 38.3 ± 0.8 |

| TaN2 | −75 | 6.6 | 62.6 ± 0.5 | / | 37.4 ± 0.5 | |

| TaN3 | −100 | 7.4 | 62.5 ± 0.9 | / | 37.5 ± 0.9 | |

| TaAlN1 | TaAl | −50 | 16.7 | 61.0 ± 0.9 | 16.5 ± 0.4 | 22.5 ± 0.5 |

| TaAlN2 | −75 | 16.0 | 59.7 ± 0.2 | 17.1 ± 0.1 | 23.1 ± 0.2 | |

| TaAlN3 | −100 | 17.3 | 58.9 ± 0.7 | 17.4 ± 0.3 | 23.6 ± 0.4 |

| Sample | Bias (V) | a (Å) | Av. Cryst. Size (nm) | T(111) | T(200) | T(220) |

|---|---|---|---|---|---|---|

| TaAlN1 | −50 | 4.327 | 13 ± 1 | 0.11 | 0.06 | 0.83 |

| TaAlN2 | −75 | 4.320 | 15 ± 1 | 0.11 | 0.04 | 0.85 |

| TaAlN3 | −100 | 4.326 | 22 ± 2 | 0.10 | 0.02 | 0.88 |

| Ref. (ICDD 49–1283) | - | 4.339 | - | 0.49 | 0.32 | 0.19 |

| Sample | Bias | Scratch | Wear | |

|---|---|---|---|---|

| Lc1 | CoF | Specific Wear Rate k | ||

| (V) | (N) | 10−6 mm3/Nm | ||

| TaN1 | −50 | 34 ± 5 | Not Evaluable | Not Evaluable |

| TaN2 | −75 | 34 ± 2 | 0.61 ± 0.11 | 2.45 ± 0.07 |

| TaN3 | −100 | 36.8 ± 0.7 | 0.70 ± 0.12 | 2.28 ± 0.04 |

| TaAlN1 | −50 | 34.3 ± 0.4 | 0.69 ± 0.12 | 54.0 ± 0.3 |

| TaAlN2 | −75 | 33 ± 1 | 0.71 ± 0.11 | 46.3 ± 0.1 |

| TaAlN3 | −100 | 33.1 ± 0.8 | 0.73 ± 0.13 | 44.0 ± 0.4 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zin, V.; Montagner, F.; Deambrosis, S.M.; Mortalò, C.; Litti, L.; Meneghetti, M.; Miorin, E. Mechanical and Tribological Properties of Ta-N and Ta-Al-N Coatings Deposited by Reactive High Power Impulse Magnetron Sputtering. Materials 2022, 15, 3354. https://doi.org/10.3390/ma15093354

Zin V, Montagner F, Deambrosis SM, Mortalò C, Litti L, Meneghetti M, Miorin E. Mechanical and Tribological Properties of Ta-N and Ta-Al-N Coatings Deposited by Reactive High Power Impulse Magnetron Sputtering. Materials. 2022; 15(9):3354. https://doi.org/10.3390/ma15093354

Chicago/Turabian StyleZin, Valentina, Francesco Montagner, Silvia Maria Deambrosis, Cecilia Mortalò, Lucio Litti, Moreno Meneghetti, and Enrico Miorin. 2022. "Mechanical and Tribological Properties of Ta-N and Ta-Al-N Coatings Deposited by Reactive High Power Impulse Magnetron Sputtering" Materials 15, no. 9: 3354. https://doi.org/10.3390/ma15093354

APA StyleZin, V., Montagner, F., Deambrosis, S. M., Mortalò, C., Litti, L., Meneghetti, M., & Miorin, E. (2022). Mechanical and Tribological Properties of Ta-N and Ta-Al-N Coatings Deposited by Reactive High Power Impulse Magnetron Sputtering. Materials, 15(9), 3354. https://doi.org/10.3390/ma15093354