Polypyrrole Decorated Flower-like and Rod-like ZnO Composites with Improved Microwave Absorption Performance

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation of ZnO Flower and ZnO Rod

2.3. Preparation of Flower-like ZnO/PPy and Rod-like ZnO/PPy Composites

2.4. Characterization

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Che, R.C.; Peng, L.M.; Duan, X.F.; Chen, Q.; Liang, A.X. Microwave absorption enhancement and complex permittivity and permeability of Fe encapsulated within carbon nanotubes. Adv. Mater. 2004, 16, 401–405. [Google Scholar] [CrossRef]

- Liu, X.F.; Zhang, D.J.; Zhao, R.Z.; Zhang, Y.H.; Zhang, M.; Wang, J.J.; Qin, G.W.; Zhang, X.F. Tuning microwave absorption properties by hybriding heterogeneous components for core@shell structural Fe@SiC flakes. J. Magn. Magn. Mater. 2018, 462, 46–52. [Google Scholar] [CrossRef]

- Lin, Y.; Dai, J.J.; Yang, H.B.; Wang, L.; Wang, F. Graphene multilayered sheets assembled by porous Bi2Fe4O9 microspheres and the excellent electromagnetic wave absorption properties. Chem. Eng. J. 2018, 334, 1740–1748. [Google Scholar] [CrossRef]

- Wu, H.J.; Wu, G.L.; Ren, Y.Y.; Yang, L.; Wang, L.D.; Li, X.H. Co2+/Co3+ ratio dependence of electromagnetic wave absorption in hierarchical NiCo2O4-CoNiO2 hybrids. J. Mater. Chem. C 2015, 3, 7677–7690. [Google Scholar] [CrossRef]

- Liu, L.D.; Duan, Y.P.; Ma, L.X.; Liu, S.H.; Yu, Z. Microwave absorption properties of a wave-absorbing coating employing carbonyl-iron powder and carbon black. Appl. Surf. Sci. 2010, 257, 842–846. [Google Scholar] [CrossRef]

- Li, K.X.; Xu, J.L.; Yan, X.D.; Liu, L.; Chen, X.B.; Luo, Y.S.; He, J.; Shen, D.Z. The origin of the strong microwave absorption in black TiO2. Appl. Phys. Lett. 2016, 108, 183102. [Google Scholar] [CrossRef]

- Cai, M.; Shui, A.Z.; Wang, X.; He, C.; Qian, J.J.; Du, B. A facile fabrication and high-performance electromagnetic microwave absorption of ZnO nanoparticles. J. Alloys Compd. 2020, 842, 155638. [Google Scholar] [CrossRef]

- Wu, F.; Xie, A.M.; Sun, M.X.; Wang, Y.; Wang, M.Y. Reduced graphene oxide (RGO) modified spongelike polypyrrole (PPy) aerogel for excellent electromagnetic absorption. J. Mater. Chem. A 2015, 3, 14358–14369. [Google Scholar] [CrossRef]

- Guo, Y.F.; Li, J.Y.; Meng, F.B.; Wei, W.; Yang, Q.; Li, Y.; Wang, H.G.; Peng, F.X.; Zhou, Z.W. Hybridization-induced polarization of graphene sheets by intercalation-polymerized polyaniline toward high performance of microwave absorption. ACS Appl. Mater. Interfaces 2019, 11, 17100–17107. [Google Scholar] [CrossRef]

- Gang, Q.; Akhtar, M.N.; Boudaghi, R. Development of high-efficient double layer microwave absorber based on Fe3O4/carbon fiber and Fe3O4/rGO. J. Magn. Magn. Mater. 2021, 537, 168181. [Google Scholar] [CrossRef]

- Fang, Y.; Li, H.; Akhtar, M.N.; Shi, L. High-efficiency microwave absorber based on carbon Fiber@La0.7Sr0.3MnO@NiO composite for X-band applications. Ceram. Int. 2021, 47, 20438–20446. [Google Scholar] [CrossRef]

- Zhu, X.; Wang, X.; Liu, K.; Yuan, H.; Boudaghi, R.; Akhtar, M.N. Thickness optimization towards microwave absorption enhancement in three-layer absorber based on SrFe12O19, SiO2@SrFe12O19 and MWCNTs@SrFe12O19 nanocomposites. J. Alloys Compd. 2021, 873, 159818. [Google Scholar] [CrossRef]

- Li, Y.; Wu, X.; Chen, J.; Cao, A.; Boudaghi, R.; Akhtar, M.N. Effect of filler loading and thickness parameters on the microwave absorption characteristic of double-layered absorber based on MWCNT/BaTiO3/pitted carbonyl iron composite. Ceram. Int. 2021, 14, 19538–19545. [Google Scholar] [CrossRef]

- Li, L.; Dang, X.; Boudaghi, R.; Akhtar, M.N. Microwave absorption characteristic of a double-layer X-band absorber based on MWCNTs/La0.6Sr0.4Mn0.5Fe0.5O4 coated with PEDOT polymer. Ceram. Int. 2021, 12, 17736–17744. [Google Scholar] [CrossRef]

- Cao, Y.; Farouk, N.; Mortezaei, N.; Yumashev, A.V.; Akhtar, M.N.; Arabmarkadeh, A. Investigation on microwave absorption characteristics of ternary MWCNTs/CoFe2O4/FeCo nanocomposite coated with conductive PEDOT-Polyaniline Co-polymers. Ceram. Int. 2021, 47, 12244–12251. [Google Scholar] [CrossRef]

- Cao, Y.; Mohamed, A.M.; Sharifi, A.; Akhtar, M.N. Microwave absorption characteristics of polyaniline@Ba0.5Sr0.5Fe12O19@MWCNTs nanocomposite in X-band frequency. J. Magn. Magn. Mater. 2021, 524, 167653. [Google Scholar] [CrossRef]

- Wei, H.J.; Yin, X.W.; Hou, Z.X.; Jiang, F.R.; Xu, H.L.; Li, M.H.; Zhang, L.T.; Cheng, L.F. A novel SiC-based microwave absorption ceramic with Sc2Si2O7 as transparent matrix. J. Eur. Ceram. Soc. 2018, 38, 4189–4197. [Google Scholar] [CrossRef]

- Xie, A.M.; Wu, F.; Sun, M.X.; Dai, X.Q.; Xu, Z.H.; Qiu, Y.Y.; Wang, Y.; Wang, M.Y. Self-assembled ultralight three-dimensional polypyrrole aerogel for effective electromagnetic absorption. Appl. Phys. Lett. 2015, 106, 222902. [Google Scholar] [CrossRef]

- Liu, T.S.; Liu, N.; An, Q.D.; Xiao, Z.Y.; Zhai, S.R.; Li, Z.C. Designed construction of Ti3C2TX@PPY composites with enhanced microwave absorption performance. J. Alloys Compd. 2019, 802, 445–457. [Google Scholar] [CrossRef]

- Shafi, M.A.; Bouich, A.; Fradi, K.; Guaita, J.M.; Khan, L.; Mari, B. Effect of deposition cycles on the properties of ZnO thin films deposited by spin coating method for CZTS-based solar cells. Optik 2022, 258, 168854. [Google Scholar] [CrossRef]

- Daouli, A.; Jabraoui, H.; Hartiti, B.; Bouich, A.; Soucase, B.M.; Comini, E.; Badawi, M. Impact of Sn doping on the hydrogen detection characteristics of ZnO thin films: Insights from experimental and DFT combination. Appl. Surf. Sci. 2022, 574, 151585. [Google Scholar]

- Li, Q.; Kumar, V.; Li, Y.; Zhang, H.; Marks, T.J.; Chang, R.P. Fabrication of ZnO nanorods and nanotubes in aqueous solutions. Chem. Mater. 2005, 5, 1001–1006. [Google Scholar] [CrossRef]

- Wang, Y.; Gao, X.; Wu, X.; Zhang, W.; Luo, C.; Liu, P. Facile design of 3D hierarchical NiFe2O4/N-GN/ZnO composite as a high performance electromagnetic wave absorber. Chem. Eng. J. 2019, 375, 121942. [Google Scholar] [CrossRef]

- Luo, J.; Zhang, K.; Cheng, M.; Gu, M.; Sun, X. MoS2 spheres decorated on hollow porous ZnO microspheres with strong wideband microwave absorption. Chem. Eng. J. 2020, 380, 122625. [Google Scholar] [CrossRef]

- Wen, F.; Hou, H.; Xiang, J.; Zhang, X.; Su, Z.; Yuan, S.; Liu, Z. Fabrication of carbon encapsulated Co3O4 nanoparticles embedded in porous graphitic carbon nanosheets for microwave absorber. Carbon 2015, 89, 372–377. [Google Scholar] [CrossRef]

- Michielssen, E.; Sajer, J.M.; Ranjithan, S.; Mittra, R. Design of lightweight, broad-band microwave absorbers using genetic algorithms. IEEE Trans. Microw. Theory Tech. 1993, 41, 1024–1031. [Google Scholar] [CrossRef]

- Khani, O.; Nemati, F.; Farrokhi, H.; Jazirehpour, M. Synthesis and characterization of electromagnetic properties of polypyrrole nanorods prepared via self-reactive MnO2 template. Synth. Met. 2016, 220, 567–572. [Google Scholar] [CrossRef]

- Song, C.; Yin, X.; Han, M.; Li, X.; Hou, Z.; Zhang, L.; Cheng, L. Three-dimensional reduced graphene oxide foam modified with ZnO nanowires for enhanced microwave absorption properties. Carbon 2017, 116, 50–58. [Google Scholar] [CrossRef]

- Wang, H.C.; Ma, N.; Yan, Z.R.; Deng, L.; He, J.; Hou, Y.L.; Jiang, Y.; Yu, G.H. Cobalt/polypyrrole nanocomposites with controllable electromagnetic properties. Nanoscale 2015, 7, 7189–7196. [Google Scholar] [CrossRef]

- Ren, X.; Wang, J.; Yin, H.; Tang, Y.; Fan, H.; Yuan, H.; Huang, L. Hierarchical CoFe2O4@PPy hollow nanocubes with enhanced microwave absorption. Appl. Surf. Sci. 2022, 575, 151752. [Google Scholar] [CrossRef]

- Bi, Y.; Ma, M.; Liu, Y.; Tong, Z.; Wang, R.; Chung, K.L.; Hu, L. Microwave absorption enhancement of 2-dimensional CoZn/C@MoS2@PPy composites derived from metal-organic framework. J. Colloid Interface Sci. 2021, 600, 209–218. [Google Scholar] [CrossRef]

- Yin, Y.; Liu, X.; Wei, X.; Yu, R.; Shui, J. Porous CNTs/Co composite derived from zeolitic imidazolate framework: A lightweight, ultrathin, and highly efficient electromagnetic wave absorber. ACS Appl. Mater. Interfaces 2016, 50, 34686–34698. [Google Scholar] [CrossRef] [PubMed]

- Wei, S.; Wang, X.; Zhang, B.; Yu, M.; Zheng, Y.; Wang, Y.; Liu, J. Preparation of hierarchical core-shell C@NiCo2O4@Fe3O4 composites for enhanced microwave absorption performance. Chem. Eng. J. 2017, 314, 477–487. [Google Scholar] [CrossRef]

- Cheng, Y.; Zhao, Y.; Zhao, H.; Lv, H.; Qi, X.; Cao, J.; Du, Y. Engineering morphology configurations of hierarchical flower-like MoSe2 spheres enable excellent low-frequency and selective microwave response properties. Chem. Eng. J. 2019, 372, 390–398. [Google Scholar] [CrossRef]

- Zhang, X.; Ji, G.; Liu, W.; Quan, B.; Liang, X.; Shang, C.; Du, Y. Thermal conversion of an Fe3O4@metal–organic framework: A new method for an efficient Fe-Co/nanoporous carbon microwave absorbing material. Nanoscale 2015, 7, 12932–12942. [Google Scholar] [CrossRef] [PubMed]

- Wu, F.; Xia, Y.; Wang, Y.; Wang, M. Two-step reduction of self-assembed three-dimensional (3D) reduced graphene oxide (RGO)/zinc oxide (ZnO) nanocomposites for electromagnetic absorption. J. Mater. Chem. A 2014, 2, 20307–20315. [Google Scholar] [CrossRef]

| Absorber | RLmin (dB) | Optimum Thickness (mm) | Bandwidth (GHz) RL < −10 dB | References |

|---|---|---|---|---|

| ZnO nanoparticles | −37.7 | 2.1 | 3.1 | [7] |

| Ti3C2TX@PPy | −49.5 | 3.6 | 5.1 | [19] |

| ZnO/MoS2 | −35.8 | 2.5 | 10.2 | [24] |

| PPy nanorods | −45 | 3.1 | 5.6 | [27] |

| ZnO nws/RGO foam/PDMS | −27.8 | 4.8 | 4.2 | [28] |

| Co/PPy | −33 | 2.0 | 4.7 | [29] |

| CoFe2O4@PPy | −43.8 | 3.0 | 5.7 | [30] |

| CoZn/C@MoS2@PPy | −49.1 | 1.5 | 4.5 | [31] |

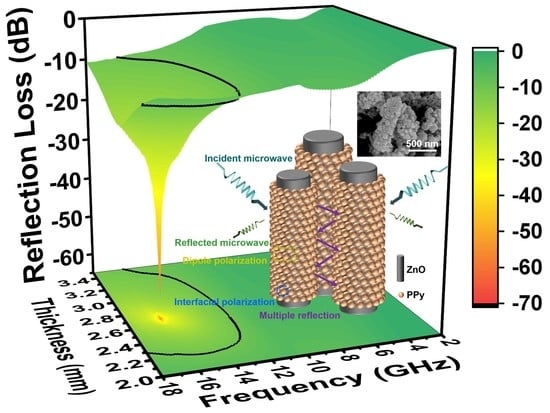

| Rod-like ZnO/PPy | −59.7 | 2.7 | 6.4 | This work |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, L.; Lv, Y.; Ye, X.; Ma, L.; Chen, S.; Wu, Y.; Wang, Q. Polypyrrole Decorated Flower-like and Rod-like ZnO Composites with Improved Microwave Absorption Performance. Materials 2022, 15, 3408. https://doi.org/10.3390/ma15093408

Zhang L, Lv Y, Ye X, Ma L, Chen S, Wu Y, Wang Q. Polypyrrole Decorated Flower-like and Rod-like ZnO Composites with Improved Microwave Absorption Performance. Materials. 2022; 15(9):3408. https://doi.org/10.3390/ma15093408

Chicago/Turabian StyleZhang, Leilei, Yihua Lv, Xiaoyun Ye, Lian Ma, Song Chen, Yuping Wu, and Qianting Wang. 2022. "Polypyrrole Decorated Flower-like and Rod-like ZnO Composites with Improved Microwave Absorption Performance" Materials 15, no. 9: 3408. https://doi.org/10.3390/ma15093408

APA StyleZhang, L., Lv, Y., Ye, X., Ma, L., Chen, S., Wu, Y., & Wang, Q. (2022). Polypyrrole Decorated Flower-like and Rod-like ZnO Composites with Improved Microwave Absorption Performance. Materials, 15(9), 3408. https://doi.org/10.3390/ma15093408