Effect of Strain Rates and Heat Exposure on Polyamide (PA12) Processed via Selective Laser Sintering

Abstract

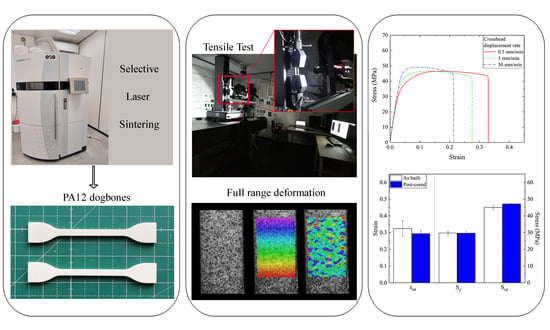

:1. Introduction

2. Materials and Methods

2.1. 3D Printing of Polyamide Samples

2.2. Thermal Analysis

2.3. Mechanical Testing

3. Results and Discussion

3.1. Thermal Analysis of Powder and Sintered PA

3.2. Results of Quasi-Static Tensile Tests

3.3. Effect of Crosshead Displacement Rate on the Mechanical Properties of 3D-Printed Nylon

3.4. Effect of Post-Processing Thermal Treatment on the Mechanical Properties of 3D-Printed Nylon

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Erhard, G.; Thompson, M.; Erhard, G. Designing with Plastics; Hanser: Munich, Germany, 2006; ISBN 978-3-446-22590-9. [Google Scholar]

- Jagadeesh, P.; Mavinkere Rangappa, S.; Siengchin, S.; Puttegowda, M.; Thiagamani, S.M.K.; Rajeshkumar, G.; Hemath Kumar, M.; Oladijo, O.P.; Fiore, V.; Moure Cuadrado, M.M. Sustainable Recycling Technologies for Thermoplastic Polymers and Their Composites: A Review of the State of the Art. Polym. Compos. 2022, 43, 5831–5862. [Google Scholar] [CrossRef]

- Korycki, A.; Garnier, C.; Irusta, S.; Chabert, F. Evaluation of Fatigue Life of Recycled Opaque PET from Household Milk Bottle Wastes. Polymers 2022, 14, 3466. [Google Scholar] [CrossRef] [PubMed]

- Kulkarni, P.; Ravekar, V.; Rama Rao, P.; Waigokar, S.; Hingankar, S. Recycling of Waste HDPE and PP Plastic in Preparation of Plastic Brick and Its Mechanical Properties. Clean. Mater. 2022, 5, 100113. [Google Scholar] [CrossRef]

- Di, L.; Yang, Y. Towards Closed-Loop Material Flow in Additive Manufacturing: Recyclability Analysis of Thermoplastic Waste. J. Clean. Prod. 2022, 362, 132427. [Google Scholar] [CrossRef]

- Gibson, I.; Rosen, D.; Stucker, B.; Khorasani, M. Additive Manufacturing Technologies, 3rd ed.; Springer: Cham, Switzerland, 2021; ISBN 978-3-030-56126-0. [Google Scholar]

- ISO/ASTM 52900; Additive Manufacturing—General Principles—Fundamentals and Vocabulary. ASTM International: Switzerland, 2022.

- Alfano, M.; Morano, C.; Bruno, L.; Muzzupappa, M.; Pagnotta, L. Analysis of Debonding in Bio-Inspired Interfaces Obtained by Additive Manufacturing. Procedia Struct. Integr. 2018, 8, 604–609. [Google Scholar] [CrossRef]

- Morano, C.; Bruno, L.; Pagnotta, L.; Alfano, M. Analysis of Crack Trapping in 3D Printed Bio-Inspired Structural Interfaces. Procedia Struct. Integr. 2018, 12, 561–566. [Google Scholar] [CrossRef]

- Ali, M.; Sari, R.K.; Sajjad, U.; Sultan, M.; Ali, H.M. Effect of Annealing on Microstructures and Mechanical Properties of PA-12 Lattice Structures Proceeded by Multi Jet Fusion Technology. Addit. Manuf. 2021, 47, 102285. [Google Scholar] [CrossRef]

- Kusoglu, I.M.; Doñate-Buendía, C.; Barcikowski, S.; Gökce, B. Laser Powder Bed Fusion of Polymers: Quantitative Research Direction Indices. Materials 2021, 14, 1169. [Google Scholar] [CrossRef]

- Brighenti, R.; Cosma, M.P.; Marsavina, L.; Spagnoli, A.; Terzano, M. Laser-Based Additively Manufactured Polymers: A Review on Processes and Mechanical Models. J. Mater. Sci. 2021, 56, 961–998. [Google Scholar] [CrossRef]

- El Magri, A.; Bencaid, S.E.; Vanaei, H.R.; Vaudreuil, S. Effects of Laser Power and Hatch Orientation on Final Properties of PA12 Parts Produced by Selective Laser Sintering. Polymers 2022, 14, 3674. [Google Scholar] [CrossRef]

- Simha Martynková, G.; Slíva, A.; Kratošová, G.; Čech Barabaszová, K.; Študentová, S.; Klusák, J.; Brožová, S.; Dokoupil, T.; Holešová, S. Polyamide 12 Materials Study of Morpho-Structural Changes during Laser Sintering of 3D Printing. Polymers 2021, 13, 810. [Google Scholar] [CrossRef]

- Stoia, D.I.; Marsavina, L.; Linul, E. Mode I Critical Energy Release Rate of Additively Manufactured Polyamide Samples. Theor. Appl. Fract. Mech. 2021, 114, 102968. [Google Scholar] [CrossRef]

- Wolf, M.; Drummer, D. Joining laser-sintered with injection-molded Parts Made of PA12 Using Infrared Welding. Polym. Eng. Sci. 2021, 61, 514–525. [Google Scholar] [CrossRef]

- Bai, J.; Goodridge, R.D.; Hague, R.J.M.; Song, M. Improving the Mechanical Properties of Laser-Sintered Polyamide 12 through Incorporation of Carbon Nanotubes. Polym. Eng. Sci. 2013, 53, 1937–1946. [Google Scholar] [CrossRef]

- Vasquez, M.; Haworth, B.; Hopkinson, N. Methods for Quantifying the Stable Sintering Region in Laser Sintered Polyamide-12. Polym. Eng. Sci. 2013, 53, 1230–1240. [Google Scholar] [CrossRef] [Green Version]

- Pavan, M.; Craeghs, T.; Puyvelde, P.V.; Kruth, J.-P.; Dewulf, W. Understanding The Link between Process Parameters, Microstructure and Mechanical Properties of Laser Sintered PA12 Parts through X-Ray Computed Tomography. In Proceedings of the 2nd International Conference on Progress in Additive Manufacturing, Singapore, 16–19 May 2016; p. 9. [Google Scholar]

- Caulfield, B.; McHugh, P.E.; Lohfeld, S. Dependence of Mechanical Properties of Polyamide Components on Build Parameters in the SLS Process. J. Mater. Process. Technol. 2007, 182, 477–488. [Google Scholar] [CrossRef]

- Pilipović, A.; Brajlih, T.; Drstvenšek, I. Influence of Processing Parameters on Tensile Properties of SLS Polymer Product. Polymers 2018, 10, 1208. [Google Scholar] [CrossRef] [Green Version]

- Fiocchi, J.; Tuissi, A.; Biffi, C.A. Heat Treatment of Aluminium Alloys Produced by Laser Powder Bed Fusion: A Review. Mater. Des. 2021, 204, 109651. [Google Scholar] [CrossRef]

- Bhandari, S.; Lopez-Anido, R.A.; Gardner, D.J. Enhancing the Interlayer Tensile Strength of 3D Printed Short Carbon Fiber Reinforced PETG and PLA Composites via Annealing. Addit. Manuf. 2019, 30, 100922. [Google Scholar] [CrossRef]

- Song, Y.; Li, Y.; Song, W.; Yee, K.; Lee, K.-Y.; Tagarielli, V.L. Measurements of the Mechanical Response of Unidirectional 3D-Printed PLA. Mater. Des. 2017, 123, 154–164. [Google Scholar] [CrossRef]

- Yang, C.; Tian, X.; Li, D.; Cao, Y.; Zhao, F.; Shi, C. Influence of Thermal Processing Conditions in 3D Printing on the Crystallinity and Mechanical Properties of PEEK Material. J. Mater. Process. Technol. 2017, 248, 1–7. [Google Scholar] [CrossRef]

- ASTM D-638-14; Test Method for Tensile Properties of Plastics. ASTM International: West Conshohocken, PA, USA, 2022.

- Pavan, M.; Faes, M.; Strobbe, D.; Van Hooreweder, B.; Craeghs, T.; Moens, D.; Dewulf, W. On the Influence of Inter-Layer Time and Energy Density on Selected Critical-to-Quality Properties of PA12 Parts Produced via Laser Sintering. Polym. Test. 2017, 61, 386–395. [Google Scholar] [CrossRef]

- Messiha, M.; Frank, A.; Heimink, J.; Arbeiter, F.; Pinter, G. Mechanisms of Rapid Fracture in PA12 Grades. Theor. Appl. Fract. Mech. 2022, 117, 103145. [Google Scholar] [CrossRef]

- EOS. PA 2200 Material Datasheet. 2008. Available online: https://www.epfl.ch/schools/sti/ateliers/wp-content/uploads/2018/05/sls_PA2200_EOS.pdf (accessed on 16 May 2023).

- Torres, J.; Cotelo, J.; Karl, J.; Gordon, A.P. Mechanical Property Optimization of FDM PLA in Shear with Multiple Objectives. JOM 2015, 67, 1183–1193. [Google Scholar] [CrossRef]

- Akhoundi, B.; Nabipour, M.; Hajami, F.; Shakoori, D. An Experimental Study of Nozzle Temperature and Heat Treatment (Annealing) Effects on Mechanical Properties of High-Temperature Polylactic Acid in Fused Deposition Modeling. Polym. Eng. Sci. 2020, 60, 979–987. [Google Scholar] [CrossRef]

- Powell, D.; Rennie, A.E.W.; Geekie, L.; Burns, N. Understanding Powder Degradation in Metal Additive Manufacturing to Allow the Upcycling of Recycled Powders. J. Clean. Prod. 2020, 268, 122077. [Google Scholar] [CrossRef]

- Mirzababaei, S.; Paul, B.K.; Pasebani, S. Metal Powder Recyclability in Binder Jet Additive Manufacturing. JOM 2020, 72, 3070–3079. [Google Scholar] [CrossRef]

- Dadbakhsh, S.; Verbelen, L.; Verkinderen, O.; Strobbe, D.; Van Puyvelde, P.; Kruth, J.-P. Effect of PA12 Powder Reuse on Coalescence Behaviour and Microstructure of SLS Parts. Eur. Polym. J. 2017, 92, 250–262. [Google Scholar] [CrossRef]

- Cai, C.; Tey, W.S.; Chen, J.; Zhu, W.; Liu, X.; Liu, T.; Zhao, L.; Zhou, K. Comparative Study on 3D Printing of Polyamide 12 by Selective Laser Sintering and Multi Jet Fusion. J. Mater. Process. Technol. 2021, 288, 116882. [Google Scholar] [CrossRef]

- Al-Maharma, A.Y.; Patil, S.P.; Markert, B. Effects of Porosity on the Mechanical Properties of Additively Manufactured Components: A Critical Review. Mater. Res. Express 2020, 7, 122001. [Google Scholar] [CrossRef]

- Choren, J.A.; Heinrich, S.M.; Silver-Thorn, M.B. Young’s Modulus and Volume Porosity Relationships for Additive Manufacturing Applications. J. Mater. Sci. 2013, 48, 5103–5112. [Google Scholar] [CrossRef]

- Rodriguez, J.F.; Thomas, J.P.; Renaud, J.E. Characterization of the Mesostructure of Fused-deposition Acrylonitrile-butadiene-styrene Materials. Rapid Prototyp. J. 2000, 6, 175–186. [Google Scholar] [CrossRef]

- Pertuz-Comas, A.D.; Díaz, J.G.; Meneses-Duran, O.J.; Niño-Álvarez, N.Y.; León-Becerra, J. Flexural Fatigue in a Polymer Matrix Composite Material Reinforced with Continuous Kevlar Fibers Fabricated by Additive Manufacturing. Polymers 2022, 14, 3586. [Google Scholar] [CrossRef] [PubMed]

- Morano, C.; Crocco, M.C.; Formoso, V.; Pagnotta, L. Effect of Induced Plastic Strain on the Porosity of PA12 Printed through Selective Laser Sintering Studied by X-Ray Computed Micro-Tomography. Int. J. Adv. Manuf. Technol. 2023, 125, 3229–3240. [Google Scholar] [CrossRef]

- Morano, C.; Pagnotta, L. Additive Manufactured Parts Produced by Selective Laser Sintering Technology: Porosity Formation Mechanisms. J. Polym. Eng. 2023. [Google Scholar] [CrossRef]

- Morano, C.; Pagnotta, L. On Powder Bed Fusion Manufactured Parts: Porosity and Its Measurement. CMS 2023, 16. [Google Scholar] [CrossRef]

- Yao, B.; Li, Z.; Zhu, F. Effect of Powder Recycling on Anisotropic Tensile Properties of Selective Laser Sintered PA2200 Polyamide. Eur. Polym. J. 2020, 141, 110093. [Google Scholar] [CrossRef]

- Dewulf, W.; Pavan, M.; Craeghs, T.; Kruth, J.-P. Using X-Ray Computed Tomography to Improve the Porosity Level of Polyamide-12 Laser Sintered Parts. CIRP Ann. 2016, 65, 205–208. [Google Scholar] [CrossRef]

- Stichel, T.; Frick, T.; Laumer, T.; Tenner, F.; Hausotte, T.; Merklein, M.; Schmidt, M. A Round Robin Study for Selective Laser Sintering of Polyamide 12: Microstructural Origin of the Mechanical Properties. Opt. Laser Technol. 2017, 89, 31–40. [Google Scholar] [CrossRef]

- Razaviye, M.K.; Tafti, R.A.; Khajehmohammadi, M. An Investigation on Mechanical Properties of PA12 Parts Produced by a SLS 3D Printer: An Experimental Approach. CIRP J. Manuf. Sci. Technol. 2022, 38, 760–768. [Google Scholar] [CrossRef]

- Meyer, T.; Harland, A.; Haworth, B.; Holmes, C.; Lucas, T.; Sherratt, P. The Influence of Different Melt Temperatures on the Mechanical Properties of Injection Molded PA-12 and the Post Process Detection by Thermal Analysis. Int. Polym. Process. 2017, 32, 90–101. [Google Scholar] [CrossRef]

- Abbott, C.S.; Sperry, M.; Crane, N.B. Relationships between Porosity and Mechanical Properties of Polyamide 12 Parts Produced Using the Laser Sintering and Multi-Jet Fusion Powder Bed Fusion Processes. J. Manuf. Process. 2021, 70, 55–66. [Google Scholar] [CrossRef]

- Azgomi, N.; Tetteh, F.; Duntu, S.H.; Boakye-Yiadom, S. Effect of Heat Treatment on the Microstructural Evolution and Properties of 3D-Printed and Conventionally Produced Medical-Grade Ti6Al4V ELI Alloy. Met. Mater Trans A 2021, 52, 3382–3400. [Google Scholar] [CrossRef]

- Wang, K.; Long, H.; Chen, Y.; Baniassadi, M.; Rao, Y.; Peng, Y. Heat-Treatment Effects on Dimensional Stability and Mechanical Properties of 3D Printed Continuous Carbon Fiber-Reinforced Composites. Compos. Part A Appl. Sci. Manuf. 2021, 147, 106460. [Google Scholar] [CrossRef]

- de Avila, E.; Eo, J.; Kim, J.; Kim, N.P. Heat Treatment Effect on Mechanical Properties of 3D Printed Polymers. MATEC Web Conf. 2019, 264, 02001. [Google Scholar] [CrossRef] [Green Version]

| Printing Parameters | Inner Volume | Outer Volume |

|---|---|---|

| Laser power [W] | 21 | 16 |

| Scanning speed [mm/s] | 2500 | 1500 |

| Hatching scan spacing [mm] | 0.25 | |

| Energy density [mJ/m2] | 33.6 | 42.7 |

| Layer thickness [mm] | 0.1 | |

| Chamber temperature [°C] | 168 | |

| Powder composition | 50% virgin–50%recycled | |

| Production Technology | Displacement Rate [mm/min] | E [GPa] | Sy [MPa] | Sut [MPa] | Ultimate Strain | |

|---|---|---|---|---|---|---|

| This work | SLS | 0.5 | 1.65 | 27.6 | 47.1 | 29.9 |

| 5 | 1.68 | 35.1 | 48.6 | 28.1 | ||

| 50 | 1.66 | 41.9 | 50.4 | 21.1 | ||

| Meyer et al. [47] | Injection molding | 50 | 1.01 ÷ 1.09 | 35.6 ÷ 36.9 | 53 ÷ 68 | 180 ÷ 330 |

| Pavan et al. [19] | SLS | 2 | 1.68 | - | 47.1 | 14.7 |

| Abbott et al. [48] | SLS | 2 | 1.71 | - | 45.8 | 18.2 |

| MJF | 1.51 | - | 44.2 | 1.51 | ||

| Razaviye [46] | SLS | 5 | 1.31 | - | 43.39 | 5.65 |

| Cai et al. [35] | SLS | 10 | 1.61 | - | 43.9 | 26.6 |

| MJF | 1.39 | - | 44.5 | 15.9 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Morano, C.; Alfano, M.; Pagnotta, L. Effect of Strain Rates and Heat Exposure on Polyamide (PA12) Processed via Selective Laser Sintering. Materials 2023, 16, 4654. https://doi.org/10.3390/ma16134654

Morano C, Alfano M, Pagnotta L. Effect of Strain Rates and Heat Exposure on Polyamide (PA12) Processed via Selective Laser Sintering. Materials. 2023; 16(13):4654. https://doi.org/10.3390/ma16134654

Chicago/Turabian StyleMorano, Chiara, Marco Alfano, and Leonardo Pagnotta. 2023. "Effect of Strain Rates and Heat Exposure on Polyamide (PA12) Processed via Selective Laser Sintering" Materials 16, no. 13: 4654. https://doi.org/10.3390/ma16134654

APA StyleMorano, C., Alfano, M., & Pagnotta, L. (2023). Effect of Strain Rates and Heat Exposure on Polyamide (PA12) Processed via Selective Laser Sintering. Materials, 16(13), 4654. https://doi.org/10.3390/ma16134654