Influence of the Grain Orientation of Wood upon Its Sound Absorption Properties

Abstract

:1. Introduction

2. Materials and Methods

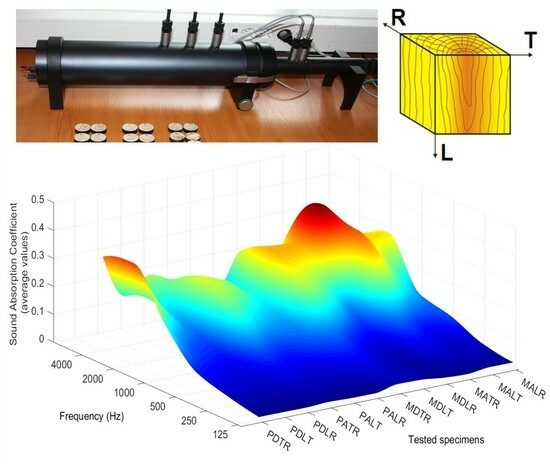

2.1. Sample Preparation

2.2. Methods

2.2.1. Density, Porosity and Tortuosity Determination

2.2.2. Sound Absorption Coefficient

2.2.3. Microscopic Anatomy of Wood Samples

3. Results and Discussions

3.1. Morphology and Pore Structure

3.2. Sound Absorption Properties

3.2.1. Sound Absorption Coefficient

3.2.2. Reflection Coefficient

3.2.3. Acoustic Impedance Ratio

4. Conclusions

- The absorption coefficient generally does not have a constant value for a certain wood species, varying according to the sound frequency and the angle of incidence of the sound waves on the material. It was concluded that the changes in the sound absorption coefficient indicate a change in the wood pore structure, for which the class of anatomical quality influences the size of this parameter;

- In the longitudinal–radial section, the class A samples, for both spruce and maple wood, presented the lowest values of the sound absorption coefficient, which confirms the use by luthiers of these categories of species and varieties;

- The frequencies at which the maximum values of the sound absorption coefficient were obtained are approximately the same for spruce wood, regardless of the quality class, in contrast to maple wood where there are differences between the frequencies at which the highest acoustic absorption occurs;

- The noise reduction coefficient (NRC) anisotropy ratio between the main sections of the wood are: spruce sample class A, TR:LT:LR: 1.0:1.35:1.50; spruce sample class D, TR:LT:LR: 1:1.16:1.12; maple sample class A, TR:LT:LR: 1:1.18:1.31; maple sample class D, TR:LT:LR: 1:1.66:2.20;

- Due to the anatomical structure, regardless of the analyzed section, both class A and class D maple wood are more homogeneous from the point of view of the reflection coefficient than spruce wood;

- Most variations in the impedance ratio for the analyzed samples are recorded below the frequency of 2000 Hz;

- The closest correlation between porosity and the acoustic absorption coefficient is recorded for the class D spruce wood samples, LR section (Table 4), and for the maple wood samples; also, those from class D, TR, and LR sections show the highest correlation between the sound absorption coefficient and porosity (Table 5).

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Bucur, V. Acoustics of Wood, 2nd ed.; Springer: Berlin, Germany, 2006; pp. 173–196. [Google Scholar]

- Watanabe, T.; Matsumoto, T.; Kinoshita, N.; Hayashi, H. Acoustical study of woods and wood products. J. Jpn. Wood Res. Soc. 1967, 13, 177–182. [Google Scholar]

- Dinulică, F.; Stanciu, M.D.; Savin, A. Correlation between Anatomical Grading and Acoustic–Elastic Properties of Resonant Spruce Wood Used for Musical Instruments. Forests 2021, 12, 1122. [Google Scholar] [CrossRef]

- Dinulica, F.; Savin, A.; Stanciu, M.D. Physical and Acoustical Properties of Wavy Grain Sycamore Maple (Acer pseudoplatanus L.) Used for Musical Instruments. Forests 2023, 14, 197. [Google Scholar] [CrossRef]

- Quintavalla, M.; Gabrielli, F.; Canevari, C. Grading materials for stringed instruments soundboards: An approach considering the orthotropic elastic and damping properties. Appl. Acoust. 2022, 187, 108521. [Google Scholar] [CrossRef]

- Viala, R.; Placet, V.; Cogan, S. Simultaneous non-destructive identification of multiple elastic and damping properties of spruce tonewood to improve grading. J. Cult. Herit. 2020, 42, 108–116. [Google Scholar] [CrossRef]

- Cao, L.; Fu, Q.; Si, Y.; Ding, B.; Yu, J. Porous materials for sound absorption. Comp. Commun. 2018, 10, 25–35. [Google Scholar] [CrossRef]

- Yang, X.H.; Ren, S.W.; Wang, W.B.; Liu, X.; Xin, F.X.; Lu, T.J. A simplistic unit cell model for sound absorption of cellular foams with fully/semi-open cells. Compos. Sci. Technol. 2015, 118, 276–283. [Google Scholar] [CrossRef]

- Delany, M.E.; Bazley, E.N. Acoustical Properties of fibrous absorbent materials. Appl. Acoust. 1970, 3, 105–116. [Google Scholar] [CrossRef]

- Smardzewski, J.; Batko, W.; Kamisiński, T.; Flach, A.; Pilch, A.; Dziurka, D.; Mirski, R.; Roszyk, E.; Majewski, A. Experimental study of wood acoustic absorption characteristics. Holzforschung 2014, 68, 467–476. [Google Scholar] [CrossRef]

- Lee, H.M.; Luo, W.; Xie, J.; Wen, G.; Lee, H.P. Studies on the sound absorption and transmission loss performances of wood-based, natural and waste materials. Acta Mech. Sin. 2021, 37, 861–873. [Google Scholar] [CrossRef]

- Oliva, D.; Hongisto, V. Sound absorption of porous materials—Accuracy of prediction method. Appl. Sci. 2013, 73, 1473–1479. [Google Scholar] [CrossRef]

- Çavuş, V.; Kara, M. Experimental Determination of Sound Transmission Loss of Some Wood Species. Kastamonu Univ. Orman Fakültesi Derg. 2020, 20, 190–199. [Google Scholar] [CrossRef]

- Shen, J.; Liu, Y.X.; Tian, Z.L.; Gang, Y.J.; Hetian, C.J. Relationship between Picea genera wood density and sound characteristic parameters. J. Huazhong Agric. Univ. 2001, 20, 181–184. [Google Scholar]

- Shen, J. Relationships between longitudinal and radial Picea genera sound vibration parameters. Front. Forest. China 2006, 1, 431–437. [Google Scholar] [CrossRef]

- Jiang, Z.-H.; Zhao, R.-J.; Fei, B.-H. Sound absorption property of wood for five eucalypt species. J. For. Res. 2004, 15, 207–210. [Google Scholar] [CrossRef]

- Ahmed, S.A.; Adamopoulos, S. Acoustic properties of modified wood under different humid conditions and their relevance for musical instruments. Appl. Acoust. 2018, 140, 92–99. [Google Scholar] [CrossRef]

- Isaac, C.W.; Pawelczyk, M.; Wrona, S. Comparative Study of Sound Transmission Losses of Sandwich Composite Double Panel Walls. Appl. Sci. 2020, 10, 1543. [Google Scholar] [CrossRef]

- Kolya, H.; Kang, C.W. High acoustic absorption properties of hackberry compared to nine different hardwood species: A novel finding for acoustical engineers. Appl. Acoust. 2020, 169, 107475. [Google Scholar] [CrossRef]

- Jang, E.S.; Kang, C.W. Sound absorption characteristics of three species (binuang, balsa and paulownia) of low density hardwood. Holzforschung 2021, 75, 1115–1124. [Google Scholar] [CrossRef]

- Iannace, G.; Ciaburro, G.; Guerriero, L.; Trematerra, A. Use of cork sheets for room acoustic correction. J. Green Build. 2020, 14, 45–55. [Google Scholar] [CrossRef]

- Jang, E.-S.; Kang, C.-W. Investigation of Sound Absorption Properties of Heat-Treated Indonesian Momala (Homalium foetidum (Roxb.) Benth.) and Korean Red Toon (Toona sinensis (A. Juss.) M. Roem.) Cross Sections. Forests 2021, 12, 1447. [Google Scholar] [CrossRef]

- Xu, W.; Fang, X.; Han, J.; Wu, Z.; Zhang, J. Effect of Coating Thickness on Sound Absorption Property of Four Wood Species Commonly Used for Piano Soundboards. Wood Fiber Sci. 2020, 52, 28–43. [Google Scholar] [CrossRef]

- Ruan, J.-Q.; Li, Z.; Xie, K.-Y.; Guo, W.; Fei, C.; Lu, M.-H.; Yang, H. Multifunctional cellulose wood with effective acoustic absorption. AIP Adv. 2022, 12, 055102. [Google Scholar] [CrossRef]

- Plötze, M.; Niemz, P. Porosity and pore size distribution of different wood types as determined by mercury intrusion porosimetry. Eur. J. Wood Wood Prod. 2011, 69, 649–665. [Google Scholar] [CrossRef]

- Pentoś, K.; Łuczycka, D.; Wysoczański, T. The Use of Complex Impedance as a Parameter for Wood Differentiation. Wood Res. 2016, 61, 13–24. [Google Scholar]

- Attenborough, K. Models for the acoustical characteristics of air filled granular materials. Acta Acoust. 1993, 1, 213–226. [Google Scholar]

- ISO 13061-2; Physical and Mechanical Properties of Wood—Test Methods for Small Clear Wood Specimens—Part 2: Determination of Density for Physical and Mechanical Tests. International Organization for Standardization: Geneva, Switzerland, 2014.

- Lorreyte, C.; Lea, P.; Henry, J.-F.; Adrien, J.; Maire, E.; Pron, H.; Randrianalisoa, J. Morphological and effective transport properties of fixed beds of wood chips: Toward realistic modeling of low-temperature pyrolysis. J. Renew. Sustain. Energy 2020, 12, 013101. [Google Scholar] [CrossRef]

- Tanaka, S.; Shiraga, K.; Ogawa, Y.; Fujii, Y.; Okumura, S. Effect of pore conformation on dielectric anisotropy of oven-dry wood evaluated using terahertz time-domain spectroscopy and eigenvalue problems for two-dimensional photonic crystals. J. Wood Sci. 2014, 60, 194–200. [Google Scholar] [CrossRef]

- Tiuc, A.-E.; Borlea, S.I.; Nemeș, O.; Vermeșan, H.; Vasile, O.; Popa, F.; Pințoi, R. New Composite Materials Made from Rigid/Flexible Polyurethane Foams with Fir Sawdust: Acoustic and Thermal Behavior. Polymers 2022, 14, 3643. [Google Scholar] [CrossRef]

- Nitu, S.A.; Sporea, N.; Iatan, N.; Durbaca, I.; Vasile, O.; Ciocoiu, G.C. Research on Obtaining Biocomposite Structures with Sound Absorbing Properties. Mat. Plast. 2022, 59, 131–137. [Google Scholar] [CrossRef]

- Curtu, I.; Stanciu, M.D.; Cosereanu, C.; Vasile, O. Assessment of acoustic properties of biodegradable composite materials with textile inserts. Mater. Plast. 2012, 49, 68–72. [Google Scholar]

- Bujoreanu, C.; Nedeff, F.; Benchea, M.; Agop, M. Experimental and theoretical considerations on sound absorption performance of waste materials including the effect of backing plates. Appl. Acoust. 2017, 119, 88–93. [Google Scholar] [CrossRef]

- Takahashi, Y.T.; Otsuru, T.R. In situ measurements of surface impedance and absorption coefficients of porous materials using two microphones and ambient noise. Appl. Acoust. 2005, 66, 845–865. [Google Scholar] [CrossRef]

- ISO 11654:1997; Acoustics: Sound Absorbers For Use in Buildings. Rating of Sound Absorption. International Organization for Standardization (ISO): Geneva, Switzerland, 1997.

- ISO 10534:1998; Acoustics—Determination of Sound Absorption Coefficient and Impedance in Impedance Tubes: Part 1: Method Using Standing Wave Ratio, Part 2: Transfer-Function Method. International Organization for Standardization (ISO): Geneva, Switzerland, 1998.

- ASTM E1050:1998; Standard Test Method for Impedance and Absorption of Acoustical Materials Using a Tube, Two Microphones and a Digital Frequency Analysis System. ASTM International: West Conshohocken, PA, USA, 1998.

- Fernea, R.; Tamas-Gavrea, D.R.; Manea, D.L.; Rosca, I.C.; Aciu, C.; Munteanu, C. Multicriterial Analysis of Several Acoustic Absorption Building Materials Based on Hemp. Procedia Eng. 2017, 181, 1005–1012. [Google Scholar] [CrossRef]

- Fernea, R.; Manea, D.L.; Tamas-Gavrea, D.R.; Rosca, I.C. Hemp-clay building materials—An investigation on acoustic, thermal and mechanical properties. Procedia Manuf. 2019, 32, 216–223. [Google Scholar] [CrossRef]

- Nechita, P.; Nastac, S. Foam-formed cellulose composite materials with potential applications in sound insulation. J. Compos. Mater. 2018, 52, 747–754. [Google Scholar] [CrossRef]

- Debeleac, C.; Nechita, P.; Nastac, S. Computational Investigations on Soundproof Applications of Foam-Formed Cellulose Materials. Polymers 2019, 11, 1223. [Google Scholar] [CrossRef]

- Nastac, S.; Nechita, P.; Debeleac, C.; Simionescu, C.; Seciureanu, M. The Acoustic Performance of Expanded Perlite Composites Reinforced with Rapeseed Waste and Natural Polymers. Sustainability 2022, 14, 103. [Google Scholar] [CrossRef]

- Cherradi, Y.; Rosca, I.C.; Cerbu, C.; Kebir, H.; Guendouz, A.; Benyoucef, M. Acoustic properties for composite materials based on alfa and wood fibers. Appl. Acoust. 2021, 174, 107759. [Google Scholar] [CrossRef]

- Trtik, P.; Dual, J.; Keunecke, D.; Mannes, D.; Niemz, P.; Stahli, P.; Kaestner, A.; Groso, A.; Stampanoni, M. 3D imaging of microstructure of spruce wood. J. Struct. Biol. 2007, 159, 46–55. [Google Scholar] [CrossRef] [PubMed]

- Van den Bulcke, J.; Boone, M.; Van Acker, J.; Stevens, M.; Van Hoorebeke, L. X-ray tomography as a tool for detailed anatomical analysis. Ann. For. Sci. 2009, 66, 508. [Google Scholar] [CrossRef]

| Samples | Wood Species | (kg/m3) | Porosity Dw | Tortuosity ks |

|---|---|---|---|---|

| SALR | Spruce | 384.9 (18) | 0.743 (0.012) | 1.160 (0.009) |

| SALT | 369.1 (65) | 0.754 (0.043) | 1.153 (0.030) | |

| SATR | 362.4 (32) | 0.758 (0.021) | 1.149 (0.016) | |

| SDLR | 395.5 (18) | 0.736 (0.012) | 1.165 (0.012) | |

| SDLT | 409.6 (9) | 0.727 (0.010) | 1.173 (0.010) | |

| SDTR | 413.2 (11) | 0.725 (0.007) | 1.175 (0.006) | |

| MALR | Maple | 589.3 (10) | 0.607 (0.007) | 1.283 (0.007) |

| MALT | 572.0 (22) | 0.619 (0.015) | 1.272 (0.015) | |

| MATR | 577.0 (17) | 0.615 (0.011) | 1.275 (0.012) | |

| MDLR | 562.4 (20) | 0.625 (0.013) | 1.265 (0.013) | |

| MDLT | 568.9 (20) | 0.621 (0.013) | 1.269 (0.013) | |

| MDTR | 524.4 (12) | 0.650 (0.007) | 1.240 (0.007) |

| Sample | Wood Species | NRC | Frequency (Hz) | |

|---|---|---|---|---|

| SALR | Spruce | 0.133 | 0.288 | 1904 |

| SALT | 0.148 | 0.357 | 1504 | |

| SATR | 0.200 | 0.456 | 1408 | |

| SDLR | 0.178 | 0.348 | 1424 | |

| SDLT | 0.159 | 0.464 | 1848 | |

| SDTR | 0.153 | 0.435 | 1560 | |

| MALR | Maple | 0.116 | 0.164 | 1512 |

| MALT | 0.130 | 0.293 | 1512 | |

| MATR | 0.141 | 0.251 | 1744 | |

| MDLR | 0.076 | 0.238 | 3008 | |

| MDLT | 0.100 | 0.209 | 1888 | |

| MDTR | 0.166 | 0.366 | 2208 |

| Samples | Wood Species | Frequency (Hz) | |||||

|---|---|---|---|---|---|---|---|

| 125 | 250 | 500 | 1000 | 2000 | 4000 | ||

| SALR | Spruce | 0.022 | 0.041 | 0.088 | 0.117 | 0.286 | 0.186 |

| SALT | 0.023 | 0.032 | 0.063 | 0.202 | 0.295 | 0.188 | |

| SATR | 0.014 | 0.043 | 0.095 | 0.299 | 0.363 | 0.269 | |

| SDLR | 0.018 | 0.025 | 0.048 | 0.121 | 0.440 | 0.230 | |

| SDLT | 0.028 | 0.033 | 0.067 | 0.199 | 0.314 | 0.172 | |

| SDTR | 0.029 | 0.051 | 0.103 | 0.249 | 0.309 | 0.257 | |

| MALR | Maple | 0.012 | 0.039 | 0.091 | 0.135 | 0.180 | 0.139 |

| MALT | 0.013 | 0.037 | 0.069 | 0.156 | 0.232 | 0.129 | |

| MATR | 0.016 | 0.040 | 0.084 | 0.202 | 0.257 | 0.198 | |

| MDLR | 0.012 | 0.031 | 0.051 | 0.083 | 0.138 | 0.237 | |

| MDLT | 0.013 | 0.033 | 0.055 | 0.105 | 0.206 | 0.177 | |

| MDTR | 0.013 | 0.037 | 0.072 | 0.193 | 0.363 | 0.336 | |

| Sound Abs. Coeff. | Density (kg/m3) | Porosity (-) | Tortuosity |

|---|---|---|---|

| SATR | −0.387 | 0.387 | −0.390 |

| SALR | −0.055 | 0.055 | −0.063 |

| SALT | 0.114 | −0.114 | 0.134 |

| SDTR | 0.279 | −0.279 | 0.277 |

| SDLR | 0.657 | −0.657 | 0.656 |

| SDLT | −0.512 | 0.512 | −0.513 |

| Sound Abs. Coeff. | Density (kg/m3) | Porosity (-) | Tortuosity |

|---|---|---|---|

| MATR | 0.390 | −0.390 | 0.389 |

| MALR | 0.136 | −0.136 | 0.137 |

| MALT | −0.487 | 0.487 | −0.487 |

| MDTR | −0.622 | 0.622 | −0.623 |

| MDLR | 0.571 | −0.571 | 0.572 |

| MDLT | 0.263 | −0.263 | 0.269 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Guiman, M.V.; Stanciu, M.D.; Roșca, I.C.; Georgescu, S.V.; Năstac, S.M.; Câmpean, M. Influence of the Grain Orientation of Wood upon Its Sound Absorption Properties. Materials 2023, 16, 5998. https://doi.org/10.3390/ma16175998

Guiman MV, Stanciu MD, Roșca IC, Georgescu SV, Năstac SM, Câmpean M. Influence of the Grain Orientation of Wood upon Its Sound Absorption Properties. Materials. 2023; 16(17):5998. https://doi.org/10.3390/ma16175998

Chicago/Turabian StyleGuiman, Maria Violeta, Mariana Domnica Stanciu, Ioan Călin Roșca, Sergiu Valeriu Georgescu, Silviu Marian Năstac, and Mihaela Câmpean. 2023. "Influence of the Grain Orientation of Wood upon Its Sound Absorption Properties" Materials 16, no. 17: 5998. https://doi.org/10.3390/ma16175998

APA StyleGuiman, M. V., Stanciu, M. D., Roșca, I. C., Georgescu, S. V., Năstac, S. M., & Câmpean, M. (2023). Influence of the Grain Orientation of Wood upon Its Sound Absorption Properties. Materials, 16(17), 5998. https://doi.org/10.3390/ma16175998