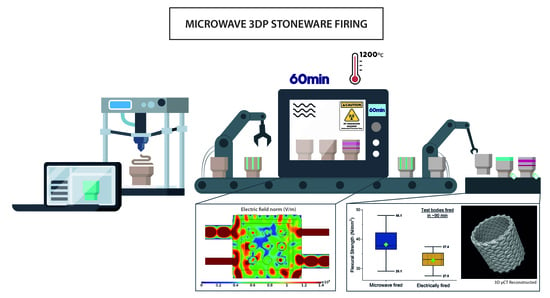

A 3D-Printed Ceramics Innovative Firing Technique: A Numerical and Experimental Study

Abstract

:1. Introduction

1.1. Summary of 3D Printing

1.2. Microwave Firing Overview

2. Materials and Methods

2.1. Stoneware 3D Printing

2.2. Microwave and Electric Firing

2.3. Methods

3. Results

3.1. Samples Complex Permittivity

| Sample | Dielectric Constant (ε′) | Dielectric Loss (ε″) |

|---|---|---|

| Greenware | 10.43 | 0.94 |

| Dried greenware | 3.67 | 0.30 |

| Stoneware | 4.21 | 0.07 |

| SiC | 10.74 | 0.74 |

3.2. Microwave Firing Simulation

3.3. Experimental (Microwave and Electrically Fired Samples)

3.3.1. Aesthetic Evaluation

3.3.2. Spatial Temperature Evaluation

| Firing Method | Ring Diameter (mm) | Ring Temperature (°C) 1 | Ring-Corrected Temperature (°C) | |

|---|---|---|---|---|

| Electric | 10 h (Ref.) | 19.29 | 1203 | - |

| 60 min | 19.84 | 1097 | 1200 | |

| 87 min | 19.80 | 1109 | ||

| Microwave 2 | 1 | 19.84 | 1097 | 1200 |

| 2 | 19.79 | 1112 | 1215 | |

| 3 | 19.87 | 1086 | 1189 | |

| 4 | 19.62 | 1153 | 1256 | |

| 5 | 19.86 | 1090 | 1193 | |

| 6 | 19.78 | 1115 | 1218 | |

| 7 | 19.83 | 1100 | 1203 | |

| 8 | 19.82 | 1103 | 1206 | |

| 9 | 19.89 | 1079 | 1182 | |

3.3.3. Flexural Tests

3.3.4. Morphology and Porosity/µCT Evaluation

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Fonseca, A.T. Tecnologia do Processamento Cerâmico; Universidade Aberta: Lisbon, Portugal, 2000; ISBN 972-674-320-6. [Google Scholar]

- Romanczuk-Ruszuk, E.; Sztorch, B.; Pakuła, D.; Gabriel, E.; Nowak, K.; Przekop, R.E. 3D Printing Ceramics—Materials for Direct Extrusion Process. Ceramics 2023, 6, 364–385. [Google Scholar] [CrossRef]

- Chen, Z.; Sun, X.; Shang, Y.; Xiong, K.; Xu, Z.; Guo, R.; Cai, S.; Zheng, C. Dense Ceramics with Complex Shape Fabricated by 3D Printing: A Review. J. Adv. Ceram. 2021, 10, 195–218. [Google Scholar] [CrossRef]

- Zocca, A.; Lima, P.; Günster, J. LSD-Based 3D Printing of Alumina Ceramics. J. Ceram. Sci. Technol. 2017, 8, 141–148. [Google Scholar] [CrossRef]

- Chan, S.S.L.; Pennings, R.M.; Edwards, L.; Franks, G.V. 3D Printing of Clay for Decorative Architectural Applications: Effect of Solids Volume Fraction on Rheology and Printability. Addit. Manuf. 2020, 35, 101335. [Google Scholar] [CrossRef]

- Revelo, C.F.; Colorado, H.A. 3D Printing of Kaolinite Clay Ceramics Using the Direct Ink Writing (DIW) Technique. Ceram. Int. 2018, 44, 5673–5682. [Google Scholar] [CrossRef]

- Chen, Z.; Li, Z.; Li, J.; Liu, C.; Lao, C.; Fu, Y.; Liu, C.; Li, Y.; Wang, P.; He, Y. 3D Printing of Ceramics: A Review. J. Eur. Ceram. Soc. 2019, 39, 661–687. [Google Scholar] [CrossRef]

- Lima, P.; Zocca, A.; Acchar, W.; Günster, J. 3D Printing of Porcelain by Layerwise Slurry Deposition. J. Eur. Ceram. Soc. 2018, 38, 3395–3400. [Google Scholar] [CrossRef]

- Choi, J.H.; Kang, E.T.; Lee, J.W.; Kim, U.S.; Cho, W.S. Materials and Process Development for Manufacturing Porcelain Figures Using a Binder Jetting 3D Printer. J. Ceram. Process. Res. 2018, 19, 43–49. [Google Scholar]

- Peng, E.; Zhang, D.; Ding, J. Ceramic Robocasting: Recent Achievements, Potential, and Future Developments. Adv. Mater. 2018, 30, 1–14. [Google Scholar] [CrossRef]

- Smay, J.E.; Cesarano, J.; Lewis, J.A. Colloidal Inks for Directed Assembly of 3-D Periodic Structures. Langmuir 2002, 18, 5429–5437. [Google Scholar] [CrossRef]

- Shapeways: Consumer 3D Printing. Available online: https://www.shapeways.com/industry/consumer (accessed on 24 December 2021).

- Paoletti, I. Mass Customization with Additive Manufacturing: New Perspectives for Multi Performative Building Components in Architecture. Procedia Eng. 2017, 180, 1150–1159. [Google Scholar] [CrossRef]

- Balani, S.B.; Ghaffar, S.H.; Chougan, M.; Pei, E.; Şahin, E. Processes and Materials Used for Direct Writing Technologies: A Review. Results Eng. 2021, 11, 100257. [Google Scholar] [CrossRef]

- Hu, F.; Mikolajczyk, T.; Pimenov, D.Y.; Gupta, M.K. Extrusion-Based 3D Printing of Ceramic Pastes: Mathematical Modeling and In Situ Shaping Retention Approach. Materials 2021, 14, 1137. [Google Scholar] [CrossRef] [PubMed]

- Santos, T.; Hennetier, L.; Costa, V.A.F.; Costa, L.C. Microwave vs. Conventional Porcelain Firing: Macroscopic Properties. Int. J. Appl. Ceram. Technol. 2020, 17, 2277–2285. [Google Scholar] [CrossRef]

- Santos, T.; Costa, V.A.F.; Costa, L.C. Ovalization and Other Porcelain Flaws When Fired Using Microwave Technology. In Proceedings of the 1st Iberic Conference on Theoretical and Experimental Mechanics and Materials/11th National Congress on Experimental Mechanics, Porto, Portugal, 4–7 November 2018; Gomes, J.F.S., Ed.; INEGI: Porto, Portugal, 2018; pp. 1043–1054, ISBN 978-989-20-8771-9. [Google Scholar]

- Chandrasekaran, S.; Ramanathan, S.; Basak, T. Microwave Material Processing—A Review. AIChE J. 2012, 58, 330–363. [Google Scholar] [CrossRef]

- Aguilar-Reynosa, A.; Romaní, A.; Rodríguez-Jasso, R.M.; Aguilar, C.N.; Garrote, G.; Ruiz, H.A. Microwave Heating Processing as Alternative of Pretreatment in Second-Generation Biorefinery: An Overview. Energy Convers. Manag. 2017, 136, 50–65. [Google Scholar] [CrossRef]

- Sun, J.; Wang, W.; Yue, Q. Review on Microwave-Matter Interaction Fundamentals and Efficient Microwave-Associated Heating Strategies. Materials 2016, 9, 231. [Google Scholar] [CrossRef]

- Singh, S.; Gupta, D.; Jain, V.; Sharma, A.K. Microwave Processing of Materials and Applications in Manufacturing Industries: A Review. Mater. Manuf. Process. 2015, 30, 1–29. [Google Scholar] [CrossRef]

- Incropera, F.P.; DeWitt, D.P.; Bergman, L.T.; Lavine, A.S. Fundamentals of Heat and Mass Transfer, 6th ed.; John Wiley Sons: Hoboken, NJ, USA, 2007. [Google Scholar]

- Oghbaei, M.; Mirzaee, O. Microwave versus Conventional Sintering: A Review of Fundamentals, Advantages and Applications. J. Alloys Compd. 2010, 494, 175–189. [Google Scholar] [CrossRef]

- Rybakov, K.I.; Olevsky, E.A.; Krikun, E.V. Microwave Sintering: Fundamentals and Modeling. J. Am. Ceram. Soc. 2013, 96, 1003–1020. [Google Scholar] [CrossRef]

- Zeng, Y.; Chen, R.; Yang, M.; Wang, H.; Guo, H.; Shi, Y.; Huang, Z.; Qi, J.; Shi, Q.; Lu, T. Fast Fabrication of High Quality Li2TiO3–Li4SiO4 Biphasic Ceramic Pebbles by Microwave Sintering: In Comparison with Conventional Sintering. Ceram. Int. 2019, 45, 19022–19026. [Google Scholar] [CrossRef]

- Zuo, F.; Carry, C.; Saunier, S.; Marinel, S.; Goeuriot, D. Comparison of the Microwave and Conventional Sintering of Alumina: Effect of MgO Doping and Particle Size. J. Am. Ceram. Soc. 2013, 96, 1732–1737. [Google Scholar] [CrossRef]

- Ramesh, S.; Zulkifli, N.; Tan, C.Y.; Wong, Y.H.; Tarlochan, F.; Ramesh, S.; Teng, W.D.; Sopyan, I.; Bang, L.T.; Sarhan, A.A.D. Comparison between Microwave and Conventional Sintering on the Properties and Microstructural Evolution of Tetragonal Zirconia. Ceram. Int. 2018, 44, 8922–8927. [Google Scholar] [CrossRef]

- Sharma, C.; Singh, K.L.; Singh, A.P.; Sharma, P.; Mago, S.; Naithani, V.; Chadha, R.K. Comparison of Microwave and Conventionally Sintered Manganese and Niobium Doped Lanthanum Germanate Based Apatites by Micro Raman Spectroscopy. Mater. Chem. Phys. 2020, 240, 122040. [Google Scholar] [CrossRef]

- Pitolli Lyra, G.; Santos, V.; Maria de Jesus Agnolon Pallone, E.; Herta Goldschmidt Aliaga Kiminami, R.; Carlos De Santis, B.; Adriano Rossignolo, J. Microwave Hybrid Fast Sintering of Red Clay Ceramics. Int. J. Appl. Ceram. Technol. 2021, 18, 705–715. [Google Scholar] [CrossRef]

- Santos, T.; Gomes, C.S.F.; Hennetier, L.; Costa, V.A.F.; Costa, L.C. Global Insight into Microwave Stoneware Firing: Macro and Micro Structural Changes. Int. J. Appl. Ceram. Technol. 2021, 18, 1801–1813. [Google Scholar] [CrossRef]

- Santos, T.; Gomes, C.S.F.; Santos, N.F.; Costa, V.A.F.; Costa, L.C. Global Insight into Microwave Stoneware Firing: Crystallochemical Transformations. Ceram. Int. 2022, 48, 21492–21501. [Google Scholar] [CrossRef]

- CSP, S.r.l. Delta WASP 40100 Clay. Available online: https://www.3dwasp.com/en/ceramic-3d-printer-delta-wasp-40100-clay/ (accessed on 26 May 2023).

- Ceramic Bodies—MCS Portugal. Available online: https://mota-sc.com/en/produtos_mcs/ceramic-bodies/ (accessed on 23 September 2021).

- Santos, T.; Hennetier, L.; Costa, V.A.F.; Costa, L.C. Microwave versus Conventional Porcelain Firing: Temperature Measurement. J. Manuf. Process. 2019, 41, 92–100. [Google Scholar] [CrossRef]

- Santos, T.; Costa, L.C.; Hennetier, L.; Valente, M.A.; Monteiro, J.; Sousa, J. Microwave Processing of Porcelain Tableware Using a Multiple Generator Configuration. Appl. Therm. Eng. 2013, 50, 677–682. [Google Scholar] [CrossRef]

- Zhao, C.; Vleugels, J.; Groffils, C.; Luypaert, P.J.; Van Der Biest, O. Hybrid Sintering with a Tubular Susceptor in a Cylindrical Single-Mode Microwave Furnace. Acta Mater. 2000, 48, 3795–3801. [Google Scholar] [CrossRef]

- Bhattacharya, M.; Basak, T. A Review on the Susceptor Assisted Microwave Processing of Materials. Energy 2016, 97, 306–338. [Google Scholar] [CrossRef]

- Catala-Civera, J.M.; Canos, A.J.; Plaza-Gonzalez, P.; Gutierrez, J.D.; Garcia-Banos, B.; Penaranda-Foix, F.L. Dynamic Measurement of Dielectric Properties of Materials at High Temperature During Microwave Heating in a Dual Mode Cylindrical Cavity. IEEE Trans. Microw. Theory Tech. 2015, 63, 2905–2914. [Google Scholar] [CrossRef]

- Garcia-Baños, B.; Reinosa, J.J.; Fernández, J.F.; Palza-González, P.J. Dielectric Properties of Ceramic Frits up to 1200 °C and Correlation with Thermal Analyses. In Proceedings of the 15th International Conference on Microwave and High Frequency Heating, AMPERE 2015, Krakow, Poland, 14–17 September 2015; pp. 1–7. [Google Scholar]

- Ferro GmbH Performance Pigments and Colors. Process Temperature Control Rings (PTCR)—Technical Information IS05. 2012, pp. 1–6. Available online: https://www.ferro.com/-/media/files/resources/industrial-specialty-materials/technical/ferro-industrial-specialty-materials-process-temperature-control-rings-ptcr-questions-and-answers.pdf (accessed on 11 September 2021).

- Pert, E.; Carmel, Y.; Birnboim, A.; Olorunyolemi, T.; Gershon, D.; Calame, J.; Lloyd, I.K.; Wilson, O.C. Temperature Measurements during Microwave Processing: The Significance of Thermocouple Effects. J. Am. Ceram. Soc. 2001, 84, 1981–1986. [Google Scholar] [CrossRef]

- Varga, G. The Structure of Kaolinite and Metakaolinite. J. Silic. Based Compos. Mater. 2007, 59, 6–9. [Google Scholar] [CrossRef]

- Bellotto, M.; Gualtieri, A.; Artioli, G.; Clark, S.M. Kinetic Study of the Kaolinite-Mullite Reaction Sequence. Part I: Kaolinite Dehydroxylation. Phys. Chem. Miner. 1995, 22, 207–214. [Google Scholar] [CrossRef]

- Gualtieri, A.; Bellotto, M.; Artioli, G.; Clark, S.M. Kinetic Study of the Kaolinite-Mullite Reaction Sequence. Part II: Mullite Formation. Phys. Chem. Miner. 1995, 22, 215–222. [Google Scholar] [CrossRef]

- Levin, E.M.; Robbins, C.R.; McMurdie, H.F. Phase Diagrams for Ceramists, 3rd ed.; Reser, M.K., Ed.; American Chemical Society: Columbus, OH, USA, 1964. [Google Scholar]

- ASTM C1161-13; Standard Test Method for Flexural Strength of Advanced Ceramics at Ambient Temperature. ASTM: West Conshohocken, PA, USA, 2018. [CrossRef]

- Keysight Technologies. Basics of Measuring the Dielectric Properties of Materials. Available online: https://www.keysight.com/us/en/assets/7018-01284/application-notes/5989-2589.pdf (accessed on 11 September 2021).

- Birnbaum, G.; Franeau, J. Measurement of the Dielectric Constant and Loss of Solids and Liquids by a Cavity Perturbation Method. J. Appl. Phys. 1949, 20, 817–818. [Google Scholar] [CrossRef]

- Parkash, A.; Vaid, J.K.; Mansingh, A. Measurement of Dielectric Parameters at Microwave Frequencies by Cavity-Perturbation Technique. IEEE Trans. Microw. Theory Tech. 1979, 27, 791–795. [Google Scholar] [CrossRef]

- Devesa, S.; Graça, M.P.; Costa, L.C. Structural, Morphological and Dielectric Properties of BiNbO4 Ceramics Prepared by the Sol-Gel Method. Mater. Res. Bull. 2016, 78, 128–133. [Google Scholar] [CrossRef]

- Carter, R.G. Accuracy of Microwave Cavity Perturbation Measurements. IEEE Trans. Microw. Theory Tech. 2001, 49, 918–923. [Google Scholar] [CrossRef]

- Menezes, R.R.; Souto, P.M.; Kiminami, R.H.G.A. Microwave Fast Sintering of Submicrometer Alumina. Mater. Res. 2010, 13, 345–350. [Google Scholar] [CrossRef]

- Meredith, R. Engineers’ Handbook of Industrial Microwave Heating; Institution of Electrical Engineers: London, UK, 1998; Volume 25, ISBN 0852969163. [Google Scholar]

- Mbakop, T.T.; Deutou, J.G.N.; Boubakar, L.; Billong, N.; Melo, U.C.; Kamseu, E.; Sglavo, V.M. Enhancing the Crystallization Phenomena and Strength of Porcelain Stoneware: The Role of CaO. J. Therm. Anal. Calorim. 2021, 144, 91–106. [Google Scholar] [CrossRef]

- Romero, M.; Pérez, J.M. Relation between the Microstructure and Technological Properties of Porcelain Stoneware. A Review. Mater. Constr. 2015, 65, e065. [Google Scholar] [CrossRef]

- Dondi, M.; Ercolani, G.; Guarini, G.; Melandri, C.; Raimondo, M.; Rocha e Almendra, E.; Tenorio Cavalcante, P.M. The Role of Surface Microstructure on the Resistance to Stains of Porcelain Stoneware Tiles. J. Eur. Ceram. Soc. 2005, 25, 357–365. [Google Scholar] [CrossRef]

- Flávio, J.S.; Arantes; Douglas, F.; Galesi; Eduardo Quinteiro, A.O.B. Closed Porosity in Porcelain Tile. In Proceedings of the Qualicer, Castellón, Spain, 28–31January 2002; pp. 139–142. Available online: https://www.researchgate.net/publication/263369231_Closed_Porosity_in_Porcelain_Tile (accessed on 23 December 2021).

- Prasad, S.; Monaco, E.A.; Kim, H.; Davis, E.L.; Brewer, J.D. Comparison of Porcelain Surface and Flexural Strength Obtained by Microwave and Conventional Oven Glazing. J. Prosthet. Dent. 2009, 101, 20–28. [Google Scholar] [CrossRef]

| Sample | Stoneware—STW90iEX |

|---|---|

| Humidity (%) | 25 |

| Particle size distribution D(50) (µm) | 9.8 |

| Residue (45 µm) (%) | 3.7 |

| 3D printing specifications | |

| Nozzle diameter (mm) | 3 |

| Layer height (mm) | 2.5 |

| Layer width (mm) | ~4 |

| Scanning speed (mm/s) | 23 |

| Firing Method | Firing Data | Flexural Strength (N/mm2) | |

|---|---|---|---|

| Value | Std. | ||

| Electric | 10 h (reference) | 45.7 | 3.6 |

| 60 min | 35.8 | 2.1 | |

| 87 min | 34.0 | 2.1 | |

| Microwave | 87 min | 40.9 | 4.4 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Santos, T.; Ramani, M.; Devesa, S.; Batista, C.; Franco, M.; Duarte, I.; Costa, L.; Ferreira, N.; Alves, N.; Pascoal-Faria, P. A 3D-Printed Ceramics Innovative Firing Technique: A Numerical and Experimental Study. Materials 2023, 16, 6236. https://doi.org/10.3390/ma16186236

Santos T, Ramani M, Devesa S, Batista C, Franco M, Duarte I, Costa L, Ferreira N, Alves N, Pascoal-Faria P. A 3D-Printed Ceramics Innovative Firing Technique: A Numerical and Experimental Study. Materials. 2023; 16(18):6236. https://doi.org/10.3390/ma16186236

Chicago/Turabian StyleSantos, Tiago, Melinda Ramani, Susana Devesa, Catarina Batista, Margarida Franco, Isabel Duarte, Luís Costa, Nelson Ferreira, Nuno Alves, and Paula Pascoal-Faria. 2023. "A 3D-Printed Ceramics Innovative Firing Technique: A Numerical and Experimental Study" Materials 16, no. 18: 6236. https://doi.org/10.3390/ma16186236

APA StyleSantos, T., Ramani, M., Devesa, S., Batista, C., Franco, M., Duarte, I., Costa, L., Ferreira, N., Alves, N., & Pascoal-Faria, P. (2023). A 3D-Printed Ceramics Innovative Firing Technique: A Numerical and Experimental Study. Materials, 16(18), 6236. https://doi.org/10.3390/ma16186236