Sol–Gel Photonic Glasses: From Material to Application †

Abstract

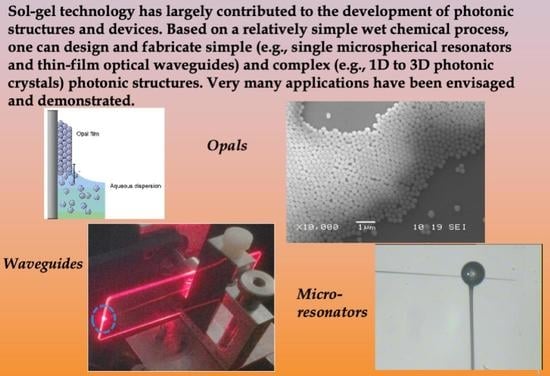

:1. Introduction

2. Sol–gel-Derived Silicate Glasses for Photonics

3. Sol–gel Optical Waveguides

| Glass | Waveguide | n | Loss dB/cm | Wavelength µm | Note | Reference |

|---|---|---|---|---|---|---|

| Silica-titania (vc) | planar | 1.6–1.9 | <1.0 | 0.6328 | [60] | |

| Silica-titania (1:1) | planar | 1.72 | 0.6 | 0.6328 | [61] | |

| Silica-titania Si-Ti-Al (vc) | planar | 1.7–1.8 | <0.5 average | 0.6328 | Aging effects | [62] |

| Silica-titania (vc) | slab | ~1.8 | 0.06 | 0.677 | [59] | |

| Bulk silica xerogel | channel | 2.9 0.7 | 0.6 | 2-line fs-micromachined | [57] | |

| Silica-zirconia + photosensitizer (vc) | channel | 1.48–1.52 | 0.1 | 1.55 | UV exposure | [63] |

| Hybrid organic-inorganic | channel | 1.502–1.562 | 0.5 1.5 | 1.310 1.550 | Laser writing and etching | [64] |

| Hybrid silica-phenil groups | planar | ~1.50–1.55 | 0.23 | 0.6328 | [65] | |

| Hybrid Si-Ce | slab | 1.47 | 1.5 | 0.6328 | Si, Ti, Zr, Ce | [66] |

| Zn-Si glass-ceramic | slab | 1.529 | 1.4 | 0.6328 | [67] | |

| Tin-silica Eu3+ glass-ceramic | slab | 1.557 | 0.5 ± 0.2 | 0.6328 | Photorefractive | [68] |

| Hybrid Zr-doped TMSPM | slab and channel | 0.16 (slab) | 1.550 | Photolithography | [69] |

4. Sol–gel Derived Photonic Micro- and Nanostructures

4.1. Three-Dimensional (3D) Photonic Crystals

4.2. Spherical and Bottle Microresonators

4.3. One-Dimensional (1D) Microcavities

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Morse, D.L.; Evenson, J.W. Welcome to the Glass Age. Int. J. Appl. Glass Sci. 2016, 7, 409–412. [Google Scholar] [CrossRef]

- Duran, A.; Parker, J. (Eds.) Welcome to Glass Age; CSIC: Madrid, Spain, 2022. [Google Scholar]

- Le Losq, C.; Cicconi, M.R.; Greaves, G.N.; Neuville, D.R. Silicate Glasses. In Handbook of Glass; Musgraves, J.D., Hu, J., Calvez, L., Eds.; Springer: Cham, Switzerland, 2019; pp. 441–503. [Google Scholar] [CrossRef]

- Tamura, Y.; Sakuma, H.; Morita, K.; Suzuki, M.; Yamamoto, Y.; Shimada, K.; Honma, Y.; Sohma, K.; Fujii, T.; Hasegawa, T. Lowest-ever 0.1419-dB/km loss optical fiber. In Proceedings of the Optical Fiber Communications Conference (OFC), Los Angeles, CA, USA, 19–23 March 2017; p. Th5D.1. [Google Scholar]

- Butt, M.A.; Tyszkiewicz, C.; Karasiński, P.; Zięba, M.; Kaźmierczak, A.; Zdończyk, M.; Duda, Ł.; Guzik, M.; Olszewski, J.; Martynkien, T.; et al. Optical Thin Films Fabrication Techniques—Towards a Low-Cost Solution for the Integrated Photonic Platform: A Review of the Current Status. Materials 2022, 15, 4591. [Google Scholar] [CrossRef] [PubMed]

- Ferrari, M.; Righini, G.C. Rare-Earth-Doped Glasses for Integrated Optical Amplifiers. In Physics and Chemistry of Rare-Earth Ions Doped Glasses; Sooraj Hussain, N., Da Silva Santos, J.D., Eds.; Trans Tech Publications Ltd.: Bäch, Switzerland, 2008; Volume 46–47, pp. 69–118. [Google Scholar]

- Piegari, A.; Flory, F. Optical Thin Films and Coatings: From Materials to Applications, 2nd ed.; Elsevier: Amsterdam, The Netherlands, 2018. [Google Scholar]

- Ebelmen, J.J. Recherches sur les combinaisons des acides borique et silicique avec les éthers. Ann. Chim. Phys. 1846, 16, 129–166. [Google Scholar]

- Graham, T.J. On the properties of silicic acid and other analogous substances. Proc. R. Soc. Lond. 1864, 13, 335–341. [Google Scholar]

- Patrick, W.A. Silica Gel and Process of Making Same. U.S. Patent 1,297,724, 18 March 1919. [Google Scholar]

- Geffcken, W.; Berger, E. Verfahren zur Änderung des Reflexionsvermögens Optischer Gläser. Deutsches Reichspatent. German Patent 736411, 6 May 1939. [Google Scholar]

- Dislich, H.; Hinz, P. History and principles of the sol-gel process, and some new multicomponent oxide coatings. J. Non-Cryst. Solids 1982, 48, 11–16. [Google Scholar] [CrossRef]

- Miller, S.E. Integrated optics: An introduction. Bell Syst. Tech. J. 1969, 48, 20592069. [Google Scholar] [CrossRef]

- Ulrich, R.; Weber, H.P. Solution-Deposited Thin Films as Passive and Active Light-Guides. Appl. Opt. 1972, 11, 428–434. [Google Scholar] [CrossRef]

- Almeida, R.; Martucci, A.; Santos, L.F.; Rojas-Hernandez, R.E. (Eds.) Sol-Gel Derived Optical and Photonic Materials; Elsevier—Wooodhead Publishing: Duxford, UK, 2020. [Google Scholar]

- Owens, G.J.; Singh, R.K.; Foroutan, F.; Alqaysi, M.; Han, C.-M.; Mahapatra, C.; Kim, H.-W.; Knowles, J.C. Sol–gel based materials for biomedical applications. Prog. Mater. Sci. 2016, 77, 1–79. [Google Scholar] [CrossRef] [Green Version]

- Data Extracted by the Present Authors from Clarivate Web of Science Using ‘Sol Gel Glass*’ as a Search Keyword in ‘Topic’. Available online: https://www.webofknowledge.com (accessed on 20 January 2023).

- Lukowiak, A.; Chiasera, A.; Chiappini, A.; Righini, G.C.; Ferrari, M. Active Sol-Gel Materials, Fluorescence Spectra and Lifetimes. In Handbook of Sol-Gel Science and Technology; Klein, L., Aparicio, M., Jitianu, A., Eds.; Springer: Cham, Switzerland, 2017; pp. 1–43. [Google Scholar] [CrossRef]

- Data Extracted by the Present Authors from Clarivate Web of Science Using ‘Sol Gel Photonic Glass*’ as a Search Keyword in ‘Topic’. Available online: https://www.webofknowledge.com (accessed on 10 January 2023).

- Dunn, B.; Zink, J.I. Optical-properties of sol-gel glasses doped with organic-molecules. J. Mater. Chem. 1991, 1, 903–913. [Google Scholar] [CrossRef]

- Ramaswamy, R.; Chia, T.; Srivastava, R.; Miliou, A.; West, J. Gel silica waveguides. Proc. SPIE 1988, 878, 86–93. [Google Scholar] [CrossRef]

- Najafi, S.I. (Ed.) Selected Papers on Sol-Gel for Photonics; SPIE Press: Bellingham, WA, USA, 1998; Volume MS148. [Google Scholar]

- Orignac, X.; Barbier, D.; Min Du, X.; Almeida, R.M.; McCarthy, O.; Yeatman, E. Sol-gel silica/titania-on-silicon Er/Yb-doped waveguides for optical amplification at 1.5 µm. Opt. Mat. 1999, 12, 1–18. [Google Scholar] [CrossRef]

- Jamalaiah, B.C.; Khan, P.S. Sr3Gd(PO4)3: Dy3+ phosphors for lighting applications. J. Sol.-Gel. Sci. Technol. 2023, 105, 266–277. [Google Scholar] [CrossRef]

- Al-Qahtani, S.D.; Alzahrani, S.O.; Snari, R.M.; Zehbah Al-Ahmed, A.; Alkhamis, K.; Alhasani, M.; El-Metwaly, M.N. Preparation of photoluminescent and photochromic smart glass window using sol-gel technique and lanthanides-activated aluminate phosphor. Ceram. Int. 2022, 48, 17489–17498. [Google Scholar] [CrossRef]

- de Lima Rezende, T.K.; Pereira Barbosa, H.; de Oliveira Lima, K.; Góes, M.S.; de Lima, R.C.; Rocha Gonçalves, R.; Ferrari, J.L. Simultaneous excitation at IR and UV of RE3+ triply doped SiO2-Gd2O3 materials for energy conversion purposes. Ceram. Int. 2021, 47, 35187–35200. [Google Scholar] [CrossRef]

- Trabelsi, F.; Mercier, F.; Blanquet, E.; Crisci, A.; Salhi, R. Synthesis of upconversion TiO2:Er3+-Yb3+ nanoparticles and deposition of thin films by spin coating technique. Ceram. Int. 2020, 46, 28183–28192. [Google Scholar] [CrossRef]

- Enrichi, F.; Righini, G.C. (Eds.) Solar Cells and Light Management; Elsevier: Amsterdam, The Netherlands, 2020. [Google Scholar]

- Torres-García, S.; Hernández-Álvarez, C.; Medina-Alayón, M.; Acosta-Mora, P.; Yanes, A.C.; del-Castillo, J.; Menéndez-Velázquez, A.; Méndez-Ramos, J. Tailoring luminescent patterns with rare-earth photonic materials for anti-counterfeiting applications: A lightkey. Ceram. Int. 2022; in press. [Google Scholar] [CrossRef]

- Davis, K.M.; Tomozawa, M. An infrared spectroscopic study of water-related species in silica glasses. J. Non. Cryst. Solids 1996, 201, 177–198. [Google Scholar] [CrossRef]

- Fardad, M.A.; Yeatman, E.M.; Dawnay, E.J.C.; Green, M.; Horowitz, F. Effects of H2O on structure of acid-catalysed SiO2 sol-gel films. J. Non. Cryst. Solids 1995, 183, 260–267. [Google Scholar] [CrossRef]

- Andrianasolo, B.; Ferrari, M.; Monteil, A.; Duval, E.; Serughetti, A.; Campostrini, R.; Carturan, G.; Montagna, M.; Rossi, F. Densification process in silica sol-gel: Monitoring by optical and Raman spectroscopy. J. Phys. IV Fr. 1991, 1, C7-501–C7-504. [Google Scholar] [CrossRef]

- Campostrini, R.; Carturan, G.; Ferrari, M.; Montagna, M.; Pilla, O. Luminescence of Eu3+ ions during thermal densification of SiO2 gel. J. Mater. Res. 1992, 7, 745–753. [Google Scholar] [CrossRef]

- Bouajaj, A.; Monteil, A.; Bovier, C.; Ferrari, M.; Piazza, A. Site distribution and thermalization effects in Europium-doped silica glasses. J. Phys. IV Fr. 1994, 4, C4-579–C4-582. [Google Scholar] [CrossRef]

- Armellini, C.; Del Longo, L.; Ferrari, M.; Montagna, M.; Pucker, G.; Sagoo, P. Effect of Pr3+ doping on the OH content of silica xerogels. J. Sol.-Gel. Sci. Technol. 1998, 13, 599–603. [Google Scholar] [CrossRef]

- Pucker, G.; Parolin, S.; Moser, E.; Montagna, M.; Ferrari, M.; Del Longo, L. Raman and luminescence studies of Tb3+ doped monolithic silica xerogels. Spectrochim. Acta Part A Mol. Biomol. Spectr. 1998, 54, 2133–2142. [Google Scholar] [CrossRef]

- Zhou, Y.; Lam, Y.L.; Wang, S.S.; Liu, H.L.; Kam, C.H.; Chan, Y.C. Fluorescence enhancement of Er3+ -doped sol–gel glass by aluminum codoping. Appl. Phys. Lett. 1997, 71, 587–589. [Google Scholar] [CrossRef]

- Bhaktha, S.N.B.; Beclin, F.; Bouazaoui, M.; Capoen, B.; Chiasera, A.; Ferrari, M.; Kinowski, C.; Righini, G.C.; Robbe, O.; Turrell, S. Enhanced fluorescence from Eu3+ in low-loss silica glass-ceramic waveguides with high SnO2 content. Appl. Phys. Lett. 2008, 93, 211904. [Google Scholar] [CrossRef]

- Silversmith, A.J.; Nguyen, T.T.; Campbell, D.L.; Boye, D.M.; Ortiz, C.P.; Hoffman, K.R. Fluorescence yield in rare-earth-doped sol–gel silicate glasses. J. Lumin. 2009, 129, 1501–1504. [Google Scholar] [CrossRef]

- Beyler, A.P.; Boye, D.M.; Hoffman, K.R.; Silversmith, A.J. Fluorescence enhancement in rare earth doped sol-gel glass by N,N dimethylformamide as a drying control chemical additive. Phys. Procedia 2011, 13, 4–8. [Google Scholar] [CrossRef] [Green Version]

- Silversmith, A.J.; Beyler, A.P.; Arpino, K.E.; Boye, D.M.; Hoffman, K.R. Mechanisms of fluorescence enhancement in rare earth sol–gel glass containing Al3+. J. Lumin. 2011, 131, 457–460. [Google Scholar] [CrossRef]

- Wang, X.; Lou, F.; Wang, S.; Yu, C.; Chen, D.; Hu, L. Spectroscopic properties of Tm3+/Al3+ co-doped sol–gel silica glass. Opt. Mat. 2015, 42, 287–292. [Google Scholar] [CrossRef]

- Levchenko, V.; Reisfeld, R. Enhancement of fluorescence of EuEDTA chelate complex in sol-gel glasses by surface plasmons of copper nanoparticles. Opt. Mat. 2017, 74, 187–190. [Google Scholar] [CrossRef]

- Nogami, M.; Van Tuyen, H.; Hung, L.X.; Quang, V.X. SnO2-nanocrystals for enhancing the fluorescence of Eu3+ ions in sol–gel-derived glasses. J. Phys. Chem. Solids 2020, 139, 109312. [Google Scholar] [CrossRef]

- Jiao, Y.; Guo, M.; Wang, R.; Shao, C.; Hu, L. Influence of Al/Er ratio on the optical properties and structures of Er3+/ Al3+ co-doped silica glasses. J. Appl. Phys. 2021, 129, 053104. [Google Scholar] [CrossRef]

- Dehingia, N.; Gogoi, P.; Dutta, P. Ag nanoparticle enhanced radiative behaviour of Eu3+ ions in sol-gel silica matrix. Ceram. Int. 2021, 47, 23404–23412. [Google Scholar] [CrossRef]

- Arai, K.; Namikawa, H.; Kumata, K.; Honda, T.; Ishi, Y.; Handa, T. Aluminum or phosphorus co-doping effects on the fluorescence and structural properties of neodymium-doped silica glass. J. Appl. Phys. 1986, 59, 3430–3436. [Google Scholar] [CrossRef]

- Armellini, C.; Ferrari, M.; Montagna, M.; Pucker, G.; Bernard, C.; Monteil, A. Terbium (III) doped silica xerogels: Effect of aluminium (III) co-doping. J. Non-Cryst. Solids 1999, 245, 115–121. [Google Scholar] [CrossRef]

- Monteil, A.; Chaussedent, S.; Alombert-Goget, G.; Gaumer, M.; Obriot, J.; Ribeiro, S.J.L.; Messaddeq, Y.; Chiasera, A.; Ferrari, M. Clustering of rare earth in glasses, aluminium effect: Experiments and modelling. J. Non-Cryst. Solids 2004, 348, 44–50. [Google Scholar] [CrossRef] [Green Version]

- Alombert-Goget, G.; Gaumer, N.; Obriot, J.; Rammal, A.; Chaussedent, S.; Monteil, A.; Portales, H.; Chiasera, A.; Ferrari, M. Aluminium effect on photoluminescence properties of sol-gel-derived silicate glasses activated by rare-earth ions. J. Non-Cryst. Solids 2005, 351, 1754–1758. [Google Scholar] [CrossRef] [Green Version]

- Righini, G.C.; Chiappini, A. Glass optical waveguides: A review of fabrication techniques. Opt. Eng. 2014, 53, 071819. [Google Scholar] [CrossRef]

- Guglielmi, M.; Colombo, P.; Mancinelli, L.; Righini, G.C.; Pelli, S. Planar and strip optical waveguides by sol-gel method and laser densification. In Proceedings of the SPIE 1513, Glasses for Optoelectronics II, Hague, The Netherlands, 12–14 March 1991; pp. 44–49. [Google Scholar] [CrossRef]

- Pelli, S.; Righini, G.C.; Scaglione, A.; Guglielmi, M.; Martucci, A. Direct laser writing of ridge optical waveguides in silica-titania glass sol-gel films. Opt. Mat. 1996, 5, 119–126. [Google Scholar] [CrossRef]

- Low, D.K.Y.; Zhang, X.; Xie, H.; Li, Z.; Lim, G.C.; Pani, S.K.; Wong, C.C. Direct writing of buried waveguides in hybrid organic-inorganic sol-gel by femtosecond laser pulses. In Proceedings of the ICALEO2005: 24th International Congress on Laser Materials Processing and Laser Microfabrication, Miami, FL, USA, 31 October–3 November 2005. Paper M402. [Google Scholar] [CrossRef]

- Pani, S.K.; Quiling, Y.; Wong, C.C.; Low, D.K.Y.; Zhang, X.; Iyer, M.K. Fabrication of buried hybrid sol–gel optical waveguides by femtosecond laser direct writing. Thin Solid Film. 2006, 504, 336–340. [Google Scholar] [CrossRef]

- Dima, A.; Gagliardi, M.; Liu, D.; Perrie, W.; Williams, C.J.; Rendina, I.; Dearden, G.; Watkins, K.G. Nano-Silicon Sol-Gel Film Refraction Index Modulation with Femtosecond Laser. In Solid State Phenomena; Trans Tech Publications: Bäch, Switzerland, 2009; Volume 154, pp. 101–106. [Google Scholar] [CrossRef]

- Santos, S.N.C.; Paula, K.T.; Couto, F.A.; Facure, M.H.M.; Correa, D.S.; Mendonca, C.R. Femtosecond laser micromachining optical waveguides on transparent silica xerogels. Opt. Mat. 2022, 132, 112819. [Google Scholar] [CrossRef]

- Sebastián, A.; Jana, J. Sol-Gel Thin Film Processing for Integrated Waveguide Sensors. Front. Mater. 2021, 8, 629822. [Google Scholar] [CrossRef]

- Karasiński, P.; Zięba, M.; Gondek, E.; Nizioł, J.; Gorantla, S.; Rola, K.; Bachmatiuk, A.; Tyszkiewicz, C. Sol-Gel Derived Silica-Titania Waveguide Films for Applications in Evanescent Wave Sensors—Comprehensive Study. Materials 2022, 15, 7641. [Google Scholar] [CrossRef]

- Lukosz, W.; Tiefenthaler, K. Embossing technique for fabricating integrated optical components in hard inorganic waveguiding materials. Opt. Lett. 1983, 8, 537–539. [Google Scholar] [CrossRef] [Green Version]

- Tiefenthaler, K.; Briguet, V.; Buser, E.; Horisberger, M.; Lukosz, W. Preparation of planar optical SiO2-TiO2 and LiNbO3 waveguides with a dip coating method and embossing technique for fabricating grating couplers and channel waveguides. Proc. SPIE 1983, 401, 165–173. [Google Scholar] [CrossRef]

- Weisenbacht, L.; Zelinski, B.J.J. The attenuation of sol-gel waveguides measured as a function of wavelength and sample age. Proc. SPIE Sol-Gel Opt. III 1994, 2288, 630–639. [Google Scholar] [CrossRef]

- Coudray, P.; Etienne, P.; Moreau, Y.; Porque, J.; Najafi, S. Sol–gel channel waveguide on silicon: Fast direct imprinting and low-cost fabrication. Opt. Commun. 1997, 143, 199–202. [Google Scholar] [CrossRef]

- Oubaha, M.; Kribich, R.K.; Copperwhite, R.; Etienne, P.; O’Dwyer, K.; MacCraith, B.D.; Moreau, Y. New inorganic sol–gel material with high transparency at 1.55 µm. Opt. Commun. 2005, 253, 346–351. [Google Scholar] [CrossRef]

- Pang, Fu-Fei; Han, Xui-You; Cai, Hai-Wen; Qu, Rong-Hui; Fang, Zu-Jie A low loss planar waveguide by using organic-inorganic Sol-Gel. Proc. SPIE 2006, 6025, 401–405. [CrossRef]

- Rey-García, F.; Flores Arias, M.T.; Gómez-Reino, C.; de la Fuente, G.; Assenmacher, W.; Mader, W. Planar step-index waveguides obtained via sol-gel synthesis from organometallic precursors. J. Sol.-Gel. Sci. Technol. 2013, 68, 39–45. [Google Scholar] [CrossRef]

- Kandula, K.R.; Sarkar, A.; Bhaktha, B.N.S. Sol-gel fabrication and characterization of ZnO and Zn2SiO4nanoparticles embedded silica glass-ceramic waveguides. Opt. Mat. Express 2013, 3, 2078–2085. [Google Scholar] [CrossRef]

- Lukowiak, A.; Zur, L.; Tran, T.N.L.; Meneghetti, M.; Berneschi, S.; Nunzi Conti, G.; Pelli, S.; Trono, C.; Bhaktha, B.N.S.; Zonta, D.; et al. Sol–Gel-Derived Glass-Ceramic Photorefractive Films for Photonic Structures. Crystals 2017, 7, 61. [Google Scholar] [CrossRef] [Green Version]

- Kong, H.S.; Kang, K.S. Thermal effects and photoluminescence of zirconium doped hybrid sol gel waveguide. Mater. Lett. 2019, 234, 272–274. [Google Scholar] [CrossRef]

- Yamamoto, E.; Mori, S.; Shimojima, A.; Wada, H.; Kuroda, K. Fabrication of colloidal crystals composed of pore-expanded mesoporous silica nanoparticles prepared by a controlled growth method. Nanoscale 2017, 9, 2464–2470. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Quandt, A.; Ferrari, M.; Chiappini, A. Glass Nanospheres and Photonic Crystals. In Glass Micro- and Nanospheres; Righini, G.C., Ed.; Jenny Stanford Pub.: Singapore, 2019; Chapter 2; pp. 41–99. [Google Scholar]

- Chiappini, A.; Armellini, C.; Chiasera, A.; Ferrari, M.; Jestin, Y.; Mattarelli, M.; Montagna, M.; Moser, E.; Nunzi Conti, G.; Pelli, S.; et al. Design of photonic structures by sol gel-derived silica nanospheres. J. Non-Cryst. Solids 2007, 353, 674–678. [Google Scholar] [CrossRef]

- Righini, G.C.; Ferrari, M. Photoluminescence of rare-earth-doped glasses. Riv. Nuovo Cim. 2005, 28, 1–53. [Google Scholar] [CrossRef]

- Chiappini, A.; Armellini, C.; Chiasera, A.; Jestin, Y.; Ferrari, M.; Matterelli, M.; Montagna, M.; Moser, E.; Tosello, C.; Zampedri, L.; et al. Er3+-activated silica inverse opals synthesized by the sol-gel method. Optoelectron. Lett. 2007, 3, 184–187. [Google Scholar] [CrossRef]

- Chiappini, A.; Pasquardini, L.; Nodehi, S.; Armellini, C.; Bazzanella, N.; Lunelli, L.; Pelli, S.; Ferrari, M.; Pietralunga, S.M. Fluorescent Aptamer Immobilization on Inverse Colloidal Crystals. Sensors 2018, 18, 4326. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Gonçalves, M.C.; Fortes, L.M.; Almeida, R.M.; Chiasera, A.; Chiappini, A.; Ferrari, M. 3-D rare earth-doped colloidal photonic crystals. Opt. Mat. 2009, 31, 1315–1318. [Google Scholar] [CrossRef]

- Righini, G.C.; Dumeige, Y.; Féron, P.; Ferrari, M.; Nunzi Conti, G.; Ristic, D.; Soria, S. Whispering gallery mode microresonators: Fundamentals and applications. Riv. Nuovo Cim. 2011, 34, 435–488. [Google Scholar] [CrossRef]

- Ward, J.; Benson, O. WGM microresonators: Sensing, lasing and fundamental optics with microspheres. Laser Phot. Rev. 2011, 5, 553–570. [Google Scholar] [CrossRef]

- Vahala, K.; Cai, M. Fiber coupled ultra high Q microsphere resonators. In Conference on Lasers and Electro-Optics; OSA Technical Digest: Washington, DC, USA, 2000; Paper CMN3. [Google Scholar]

- Tebeneva, T.S.; Shitikov, A.E.; Benderov, O.V.; Lobanov, V.E.; Bilenko, I.A.; Rodin, A.V. Ultrahigh-Q WGM microspheres from ZBLAN for the mid-IR band. Opt. Lett. 2022, 47, 6325–6328. [Google Scholar] [CrossRef] [PubMed]

- von Klitzing, W.; Jahier, E.; Long, R.; Lissillour, F.; Lefèvre-Seguin, V.; Hare, J.; Raimond, J.-M.; Haroche, S. Very Low Threshold Lasing in Er3+ Doped ZBLAN Microsphere. Electron. Lett. 1999, 35, 1745–1746. [Google Scholar] [CrossRef]

- Righini, G.C.; Armellini, C.; Chiasera, A.; Jestin, Y.; Ferrari, M.; Chiappini, A.; Montagna, M.; Arfuso Duverger, C.; Féron, P.; Berneschi, S.; et al. Er3+-activated sol-gel silica derived spherical microresonators. Glass Technol.-Eur. J. Glass Sci. Technol. Part A 2007, 48, 200–203. Available online: https://hal.archives-ouvertes.fr/hal-00275674 (accessed on 10 January 2023).

- Sumetsky, M. Optical bottle microresonators. Prog. Quantum Electron. 2019, 64, 1–30. [Google Scholar] [CrossRef] [Green Version]

- Sandoghdar, V.S.; Treussart, F.; Hare, J.; Lefèvre-Seguin, V.; Raimond, J.M.; Haroche, S. Very low threshold whispering-gallery-mode microsphere laser. Phys. Rev. A. 1996, 54, 1777. [Google Scholar] [CrossRef]

- Lissillour, F.; Féron, P.; Dubreuil, N.; Dupriez, P.; Poulain, M.; Stéphan, G. Erbium-doped microspherical lasers at 1.56 µm. Electr. Lett. 2000, 36, 1382–1384. [Google Scholar] [CrossRef]

- Zhu, S.; Bowen, X.; Bo, J.; Lei, S.; Xinliang, Z. Tunable Brillouin and Raman microlasers using hybrid microbottle resonators. Nanophotonics 2019, 8, 931–940. [Google Scholar] [CrossRef]

- Palma, G.; Falconi, C.; Nazabal, V.; Yano, T.; Kishi, T.; Kumagai, T.; Ferrari, M.; Prudenzano, F. Modeling of Whispering Gallery Modes for Rare Earth Spectroscopic Characterization. IEEE Photonics Technol. Lett. 2015, 27, 1861–1863. [Google Scholar] [CrossRef]

- Ristic, D.; Berneschi, S.; Camerini, M.; Farnesi, D.; Chiappini, A.; Chiasera, A.; Ferrari, M.; Pelli, S.; Trono, C.; Lukowiak, A.; et al. Photoluminescence and Lasing in Whispering Gallery Mode Glass Microspherical Resonators. J. Lumin. 2016, 170, 755–760. [Google Scholar] [CrossRef]

- Righini, G.C.; Brenci, M.; Chiasera, A.; Feron, P.; Ferrari, M.; Nunzi Conti, G.; Pelli, S. Whispering gallery mode resonators for microlasers and microsensors. Proc. SPIE ICO20 Mater. Nanostructures 2006, 6029, 602903. [Google Scholar] [CrossRef]

- Abdelayem, H. Microspherical-Fiber Laser System. In Frontiers in Optics, OSA Technical Digest; Optica Publishing Group: Washington, DC, USA, 2006; Paper LWB5. [Google Scholar] [CrossRef]

- Han, M.; Wang, A. Temperature compensation of optical microresonators using a surface layer with negative thermo-optic coefficient. Opt. Lett. 2007, 32, 1800–1802. [Google Scholar] [CrossRef] [PubMed]

- Ristić, D.; Mazzola, M.; Chiappini, A.; Rasoloniaina, A.; Féron, P.; Ramponi, R.; Righini, G.C.; Cibiel, G.; Ivanda, M.; Ferrari, M. Tailoring of the free spectral range and geometrical cavity dispersion of a microsphere by a coating layer. Opt. Lett. 2014, 39, 5173–5176. [Google Scholar] [CrossRef] [PubMed]

- Yang, Y.; Lei, F.; Kasumie, S.; Xu, L.; Ward, J.M.; Yang, L.; Chormaic, S.N. Tunable erbium-doped microbubble laser fabricated by sol-gel coating. Opt. Express 2017, 25, 1308–1313. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Righini, G.C.; Berneschi, S.; Nunzi Conti, G.; Pelli, S.; Moser, E.; Retoux, R.; Féron, P.; Gonçalves, R.R.; Speranza, G.; Jestin, Y.; et al. Er3+-doped silica-hafnia films for optical waveguides and spherical resonators. J. Non-Cryst. Solids 2009, 355, 1853–1860. [Google Scholar] [CrossRef]

- Ristić, D.; Chiappini, A.; Mazzola, M.; Féron, P.; Gebavi, H.; Zhivotkov, D.; Ivanda, M.; Ferrari, M. Lasing properties of Er3+ activated SiO2-HfO2 coated microspheres. Proc. SPIE Fiber Lasers Glass Photonics Mater. Through Appl. 2018, 10683, 106830G. [Google Scholar] [CrossRef]

- Ristić, D.; Rasoloniaina, A.; Chiappini, A.; Féron, P.; Pelli, S.; Nunzi Conti, G.; Ivanda, M.; Righini, G.C.; Cibiel, G.; Ferrari, M. About the role of phase matching between a coated microsphere and a tapered fiber: Experimental study. Opt. Express 2013, 21, 20954–20963. [Google Scholar] [CrossRef] [Green Version]

- Almeida, R.M.; Marques, A.C.; Chiasera, A.; Chiappini, A.; Ferrari, M. Rare-earth doped photonic crystal microcavities prepared by sol-gel. J. Non-Cryst. Solids 2007, 353, 490–493. [Google Scholar] [CrossRef]

- Jasieniak, J.; Sada, C.; Chiasera, A.; Ferrari, M.; Martucci, A.; Mulvaney, P. Sol-gel based vertical optical microcavities with quantum dot defect layers. Adv. Funct. Mater. 2008, 18, 3772–3779. [Google Scholar] [CrossRef]

- Chiasera, A.; Jasieniak, J.; Normani, S.; Valligatla, S.; Lukowiak, A.; Taccheo, S.; Narayana, D.R.; Righini, G.C.; Marciniak, M.; Martucci, A.; et al. Hybrid 1-D dielectric microcavity: Fabrication and spectroscopic assessment of glass-based sub-wavelength structures. Ceram. Int. 2015, 41, 7429–7433. [Google Scholar] [CrossRef]

- Chiasera, A.; Meroni, C.; Scotognella, F.; Boucher, Y.G.; Galzerano, G.; Lukowiak, A.; Ristic, D.; Speranza, G.; Valligatla, S.; Varas, S.; et al. Coherent emission from fully Er3+ doped monolithic 1-D dielectric microcavity fabricated by rf-sputtering. Opt. Mat. 2019, 87, 107–111. [Google Scholar] [CrossRef] [Green Version]

- Prusakova, V.; Armellini, C.; Carpentiero, A.; Chiappini, A.; Collini, C.; Dirè, S.; Ferrari, M.; Lorenzelli, L.; Nardello, M.; Normani, S.; et al. Morphologic, structural, and optical characterization of sol-gel derived TiO2 thin films for memristive devices. Phys. Status Solidi C 2015, 12, 192–196. [Google Scholar] [CrossRef]

- Lodh, S.; Chakraborty, R. Bandgap Engineering of Sol–Gel Spin-Coated TiO2 Thin Film on Glass Substrate. In Photonics, Plasmonics and Information Optics: Research and Technological Advances; Deyasi, A., Debnath, P., Datta, A.K., Bhattacharyya, S., Eds.; CRC Press: Boca Raton, FL, USA, 2021; Chapter 2. [Google Scholar]

- Akshay, V.R.; Arun, B.; Mandal, G.; Mutta, G.R.; Chanda, A.; Vasundhara, M. Observation of Optical Band-Gap Narrowing and Enhanced Magnetic Moment in Co-Doped Sol–Gel-Derived Anatase TiO2 Nanocrystals. J. Phys. Chem. C 2018, 122, 26592–26604. [Google Scholar] [CrossRef]

- Deubener, J.; Allix, M.; Davis, M.J.; Durán, A.; Höche, T.; Honma, T.; Komatsu, T.; Krüger, S.; Mitra, I.; Müller, R.; et al. Updated definition of glass-ceramics. J. Non-Cryst. Solids 2018, 501, 3–10. [Google Scholar] [CrossRef]

- Pawlik, N.; Szpikowska-Sroka, B.; Goryczka, T.; Pisarski, W.A. Sol-Gel Glass-Ceramic Materials Containing CaF2:Eu3+ Fluoride Nanocrystals for Reddish-Orange Photoluminescence Applications. Appl. Sci. 2019, 9, 5490. [Google Scholar] [CrossRef] [Green Version]

- Tran, T.N.L.; Armellini, C.; Varas, S.; Carpentiero, A.; Chiappini, A.; Głuchowski, P.; Iacob, E.; Ischia, G.; Scotognella, F.; Bollani, M.; et al. Assessment of SnO2-nanocrystal-based luminescent glass-ceramic waveguides for integrated photonics. Ceram. Int. 2021, 47, 5534–5541. [Google Scholar] [CrossRef]

- Dash, A.; Pal, S.K.; Rai, S.B. Up-conversion study of CaF2 based oxy-fluoride core-shell particulate nano-glass ceramics via sol-gel method: Effect of Yb3+ concentration and cell viability study. Optik 2020, 222, 165304. [Google Scholar] [CrossRef]

- Secu, M.; Secu, C.; Bartha, C. Optical Properties of Transparent Rare-Earth Doped Sol-Gel Derived Nano-Glass Ceramics. Materials 2021, 14, 6871. [Google Scholar] [CrossRef]

- Cruz, M.E.; Castro, Y.; Duran, A. Transparent oxyfluoride glass-ceramics obtained by different sol-gel routes. J. Sol.-Gel. Sci. Technol. 2022, 102, 523–533. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Righini, G.C.; Armellini, C.; Ferrari, M.; Carlotto, A.; Carpentiero, A.; Chiappini, A.; Chiasera, A.; Lukowiak, A.; Tran, T.N.L.; Varas, S. Sol–Gel Photonic Glasses: From Material to Application. Materials 2023, 16, 2724. https://doi.org/10.3390/ma16072724

Righini GC, Armellini C, Ferrari M, Carlotto A, Carpentiero A, Chiappini A, Chiasera A, Lukowiak A, Tran TNL, Varas S. Sol–Gel Photonic Glasses: From Material to Application. Materials. 2023; 16(7):2724. https://doi.org/10.3390/ma16072724

Chicago/Turabian StyleRighini, Giancarlo C., Cristina Armellini, Maurizio Ferrari, Alice Carlotto, Alessandro Carpentiero, Andrea Chiappini, Alessandro Chiasera, Anna Lukowiak, Thi Ngoc Lam Tran, and Stefano Varas. 2023. "Sol–Gel Photonic Glasses: From Material to Application" Materials 16, no. 7: 2724. https://doi.org/10.3390/ma16072724

APA StyleRighini, G. C., Armellini, C., Ferrari, M., Carlotto, A., Carpentiero, A., Chiappini, A., Chiasera, A., Lukowiak, A., Tran, T. N. L., & Varas, S. (2023). Sol–Gel Photonic Glasses: From Material to Application. Materials, 16(7), 2724. https://doi.org/10.3390/ma16072724