Influence of Pre-Heat Treatment on the Deformation Behaviors, Microstructural Characteristics, and Mechanical Properties of a Continuously Cast Al-Cu-Mg Alloy during Continuous Extrusion Process

Abstract

:1. Introduction

2. Materials and Methods

3. Results and Discussion

3.1. Microstructural Characteristics of the Initial CC and ACC 2024 Al Alloy Samples

3.2. Deformation Behaviors of CC and ACC 2024 Al Alloy Specimens

3.2.1. Flow Stress Evolution

3.2.2. Constitutive Modeling

3.2.3. Microstructure of Hot Compressed CC and ACC 2024 Al Alloy Specimens

3.3. Finite Element Analysis of Continuous Extrusion Forming

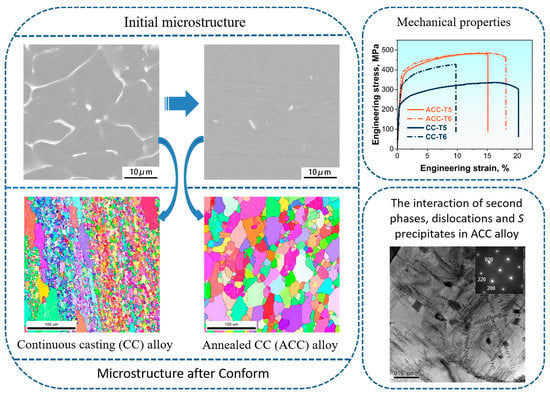

3.4. Microstructure Characterization after the Conform Process

3.5. Mechanical Properties

3.6. TEM Microstructure Characteristics

3.7. Discussion

4. Conclusions

- (1)

- The CC and ACC samples showed different flow behavior during hot compression, owing to the variant deformation mechanism. ACC samples after pre-heat treatment owned higher resistance to deformation, which reflected higher flow stress and higher value of Q. DRV happened in both CC and ACC samples, while DRX was advanced in ACC sample during hot deformation.

- (2)

- After the Conform Process, ACC alloy attained the enhanced online solid solution, which could be directly subjected to AA treatment to achieve good mechanical performance. The tensile strength of ACC-T5 sample (481 MPa) was identical to ACC-T6 (485 MPa) with good ductility, which exceeded the mechanical properties of CC-T5 and CC-T6 samples remarkably.

- (3)

- After pre-heat treatment, the higher supersaturation solid solubility and numerous dispersoids (T phases) were observed in the ACC sample by dissolving the coarse particles in CC specimen. TEM microstructures showed that large number of dislocations were captured by the particles and many S phases precipitated around the particles. Tangling dislocations and stimulating precipitation of S phase were the main reasons for the enhanced mechanical properties.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Li, Q.; Zhang, X.; Wang, L.; Qiao, J. The Effect of Extrusion and Heat Treatment on the Microstructure and Tensile Properties of 2024 Aluminum Alloy. Materials 2022, 15, 7566. [Google Scholar] [CrossRef] [PubMed]

- Shen, T.; Fan, C.H.; Hu, Z.Y.; Wu, Q.; Ni, Y.M.; Chen, Y.Z. Effect of strain rate on microstructure and mechanical properties of spray-formed Al–Cu–Mg alloy. Trans. Nonferrous Metal. Soc. 2022, 32, 1096–1104. [Google Scholar] [CrossRef]

- Tomczyk, A.; Seweryn, A.; Grądzka-Dahlke, M. The Effect of Dynamic Recrystallization on Monotonic and Cyclic Behaviour of Al-Cu-Mg Alloy. Materials 2018, 11, 874. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Yin, D.Y.; Liu, H.Q.; Chen, Y.Q.; Yi, D.Q.; Wang, B.; Wang, B.; Shen, F.H.; Fu, S.; Tang, C.; Pan, S.P. Effect of grain size on fatigue-crack growth in 2524 aluminium alloy. Int. J. Fatigue 2016, 84, 9–16. [Google Scholar] [CrossRef]

- Staszczyk, A.; Sawicki, J.; Adamczyk-Cieslak, B. A Study of Second-Phase Precipitates and Dispersoid Particles in 2024 Aluminum Alloy after Different Aging Treatments. Materials 2019, 12, 4168. [Google Scholar] [CrossRef] [Green Version]

- Hu, Z.Y.; Fan, C.H.; Shen, T.; Ou, L.; Dai, N.S.; Wang, L. Effect of aging treatment on evolution of S′ phase in rapid cold punched Al−Cu−Mg alloy. Trans. Nonferrous Metal. Soc. 2021, 31, 1930–1938. [Google Scholar] [CrossRef]

- Zhang, L.; Luo, H. Precipitation Behavior during Aging Operations in an Ultrafine-Grained Al-Cu-Ng Alloy Produced by High-Strain-Rate Processing. Materials 2022, 15, 8687. [Google Scholar] [CrossRef]

- Ringer, S.P.; Hono, K.; Polmear, I.J.; Sakurai, T. Precipitation processes during the early stages of ageing in Al-Cu-Mg alloys. Appl. Surf. Sci. 1996, 94, 253–260. [Google Scholar] [CrossRef]

- Wang, S.C.; Starink, M.J.; Gao, N. Precipitation hardening in Al–Cu–Mg alloys revisited. Scr. Mater. 2006, 54, 287–291. [Google Scholar] [CrossRef]

- Kovarik, L.; Court, S.A.; Fraser, H.L.; Mills, M.J. GPB zones and composite GPB/GPBII zones in Al–Cu–Mg alloys. Acta Mater. 2008, 56, 4804–4815. [Google Scholar] [CrossRef]

- Song, Y.F.; Ding, X.F.; Xiao, L.R.; Zhao, X.J.; Cai, Z.Y.; Guo, L.; Li, Y.W.; Zheng, Z.Z. Effects of two-stage aging on the dimensional stability of Al-Cu-Mg alloy. J. Alloys Compd. 2017, 701, 508–514. [Google Scholar] [CrossRef]

- Esin, V.A.; Briez, L.; Sennour, M.; Köster, A.; Gratiot, E.; Crépin, J. Precipitation-hardness map for Al–Cu–Mg alloy (AA2024-T3). J. Alloys Compd. 2021, 854, 157–164. [Google Scholar] [CrossRef]

- Xu, X.F.; Zhao, Y.G.; Ma, B.D.; Zhang, M. Rapid precipitation of T-phase in the 2024 aluminum alloy via cyclic electropulsing treatment. J. Alloys Compd. 2014, 610, 506–510. [Google Scholar] [CrossRef]

- Sunde, J.K.; Johnstone, D.N.; Wenner, S.; van Helvoort, A.T.J.; Midgley, P.A.; Holmestad, R. Crystallographic relationships of T-/S-phase aggregates in an Al–Cu–Mg–Ag alloy. Acta Mater. 2019, 166, 587–596. [Google Scholar] [CrossRef] [Green Version]

- Chen, Y.Q.; Pan, S.P.; Liu, W.H.; Liu, X.; Tang, C.P. Morphologies, orientation relationships, and evolution of the T-phase in an Al-Cu-Mg-Mn alloy during homogenisation. J. Alloys Compd. 2017, 709, 213–226. [Google Scholar] [CrossRef]

- Feng, Z.Q.; Yang, Y.Q.; Huang, B.; Li, M.H.; Chen, Y.X.; Ru, J.G. Crystal substructures of the rotation-twinned T (Al20Cu2Mn3) phase in 2024 aluminum alloy. J. Alloys Compd. 2014, 583, 445–451. [Google Scholar] [CrossRef]

- Jia, Z.H.; Xie, Z.Q.; Xiang, K.Y.; Ding, L.P.; Weng, Y.Y.; Liu, Q. Effect of heat treatment and extrusion processing on the microstructure and mechanical properties of spray formed 7055 alloy. Mater. Charact. 2022, 183, 111619. [Google Scholar] [CrossRef]

- Li, Y.; Lu, B.; Yu, W.; Fu, J.; Xu, G.; Wang, Z. Two-stage homogenization of Al-Zn-Mg-Cu-Zr alloy processed by twin-roll casting to improve L12 Al3Zr precipitation, recrystallization resistance, and performance. J. Alloys Compd. 2021, 882, 160789. [Google Scholar] [CrossRef]

- Liu, Q.B.; Fan, G.L.; Tan, Z.Q.; Li, Z.Q.; Zhang, D.; Wang, J.; Zhang, H. Precipitation of Al3Zr by two-step homogenization and its effect on the recrystallization and mechanical property in 2195 Al–Cu–Li alloys. Mater. Sci. Eng. A 2021, 821, 141637. [Google Scholar] [CrossRef]

- Wu, H.; Wen, S.P.; Huang, H.; Li, B.L.; Wu, X.L.; Gao, K.Y.; Wang, W.; Nie, Z.R. Effects of homogenization on precipitation of Al3(Er,Zr) particles and recrystallization behavior in a new type Al-Zn-Mg-Er-Zr alloy. Mater. Sci. Eng. A 2017, 689, 313–322. [Google Scholar] [CrossRef]

- Lin, H.; Zhu, K.; Liu, Q.; Chen, L.; Wang, Z.; Li, X. Microstructural Characterization of the As-Cast and Homogenized Al-Cu-Mg-Ag Alloy. Materials 2023, 16, 433. [Google Scholar] [CrossRef]

- Liu, F.; Liu, Z.Y.; Jia, P.X. Effect of T-phase on microstructure of the hot rolled Al–Cu–Mg alloy. J. Alloys Compd. 2020, 825, 154190. [Google Scholar] [CrossRef]

- Li, Y.; Liu, Z.Y.; Lin, L.H.; Peng, J.T.; Ning, A.L. Deformation behavior of an Al–Cu–Mg–Mn–Zr alloy during hot compression. J. Mater. Sci. 2011, 46, 3708–3715. [Google Scholar] [CrossRef]

- Li, H.Y.; Yu, W.C.; Wang, X.Y.; Du, R.; You, W. Investigation on Microstructural Evolution and Properties of an Al-Cu-Li Alloy with Mg and Zn Microalloying during Homogenization. Metals 2018, 8, 1010. [Google Scholar] [CrossRef] [Green Version]

- Shen, Z.J.; Liu, C.H.; Ding, Q.Q.; Wang, S.B.; Wei, X.; Chen, L.; Li, J.X.; Zhang, Z. The structure determination of Al20Cu2Mn3 by near atomic resolution chemical mapping. J. Alloys Compd. 2014, 601, 25–30. [Google Scholar] [CrossRef]

- Wang, Y.; Yang, B.W.; Gao, M.Q.; Guan, R.G. Deformation behavior and dynamic recrystallization during hot compression in homogenized Al–6Mg–0.8Mn alloys. Mater. Sci. Eng. A 2022, 840, 142953. [Google Scholar] [CrossRef]

- Chen, Y.Q.; Pan, S.P.; Zhu, B.X.; Liu, X.; Liu, W.H.; Tang, S.W. The evolution of orientation relationships during the transformation of a twin-free T-particle to tenfold T-twins in an Al alloy during homogenisation. Mater. Charact. 2018, 141, 59–73. [Google Scholar] [CrossRef]

- Zhao, Y.; Song, B.Y.; Pei, J.Y.; Jia, C.B.; Li, B.; Guo, L.L. Effect of deformation speed on the microstructure and mechanical properties of AA6063 during continuous extrusion process. J. Mater. Process. Tech. 2013, 213, 1855–1863. [Google Scholar] [CrossRef]

- Zhao, Y.; Song, B.Y.; Yan, Z.Y.; Zhang, X.; Pei, J.Y. Microstructure and mechanical properties of extrusion welds in continuous extrusion of AA6063 aluminium alloy with double billets. J. Mater. Process. Tech. 2016, 235, 149–157. [Google Scholar] [CrossRef]

- Wanjara, P.; Jahazi, M.; Monajati, H.; Yue, S.; Immarigeon, J.P. Hot working behavior of near-α alloy IMI834. Mater. Sci. Eng. A 2005, 396, 50–60. [Google Scholar] [CrossRef]

- Philippart, I.; Rack, H.J. High temperature dynamic yielding in metastable Ti–6.8Mo–4.5F–1.5Al. Mater. Sci. Eng. A 1998, 243, 196–200. [Google Scholar] [CrossRef]

- Ankem, S.; Shyue, J.G.; Vijayshankar, M.N.; Arsenault, R.J. The effect of volume per cent of phase on the high temperature tensile deformation of two-phase Ti-Mn alloys. Mater. Sci. Eng. A 1989, 111, 51–61. [Google Scholar] [CrossRef]

- Chamanfar, A.; Jahazi, M.; Gholipour, J.; Wanjara, P.; Yue, S. Evolution of flow stress and microstructure during isothermal compression of Waspaloy. Mater. Sci. Eng. A 2014, 615, 497–510. [Google Scholar] [CrossRef]

- Zener, C.; Hollomon, J.H. Effect of Strain Rate Upon Plastic Flow of Steel. J. Appl. Phys. 1944, 15, 22–32. [Google Scholar] [CrossRef]

- Sellars, C.M.; McTegart, W.J. On the mechanism of hot deformation. Acta Metall. 1966, 14, 1136–1138. [Google Scholar] [CrossRef]

- Bo, G.W.; Wang, Y.L.; Liu, M.C.; Tang, J.; Jiang, F.L.; Teng, J.; Xiao, G.; Fu, D.F.; Zhang, H. Experimental and modeling investigations of the non-isothermal and isothermal precipitations in an Al-Cu-Mg-Zr alloy with various pre-precipitation microstructures. Mater. Des. 2022, 217, 110640. [Google Scholar] [CrossRef]

- Parel, T.S.; Wang, S.C.; Starink, M.J. Hardening of an Al–Cu–Mg alloy containing Types I and II S phase precipitates. Mater. Des. 2010, 31, S2–S5. [Google Scholar] [CrossRef]

- Kim, I.S.; Song, M.Y.; Kim, J.H.; Hong, S.K. Effect of added Mg on the clustering and two-step aging behavior of Al-Cu alloys. Mater. Sci. Eng. A 2020, 798, 140123. [Google Scholar] [CrossRef]

- Feng, Z.Q.; Yang, Y.Q.; Huang, B.; Luo, X.; Li, M.H.; Han, M.; Fu, M.S. Variant selection and the strengthening effect of S precipitates at dislocations in Al–Cu–Mg alloy. Acta Mater. 2011, 59, 2412–2422. [Google Scholar] [CrossRef]

- Wang, S.C.; Starink, M.J. Two types of S phase precipitates in Al–Cu–Mg alloys. Acta Mater. 2007, 55, 933–941. [Google Scholar] [CrossRef] [Green Version]

- Feng, Z.Q.; Yang, Y.Q.; Huang, B.; Han, M.; Luo, X.; Ru, J.G. Precipitation process along dislocations in Al–Cu–Mg alloy during artificial aging. Mater. Sci. Eng. A 2010, 528, 706–714. [Google Scholar] [CrossRef]

- Sun, L.; Guo, Y.Y.; Chen, L.; Zhao, G.Q. Effects of solution and aging treatments on the microstructure and mechanical properties of cold rolled 2024 Al alloy sheet. J. Mater. Res. Technol. 2021, 12, 1126–1142. [Google Scholar] [CrossRef]

- Shih, H.C.; Ho, N.J.; Huang, J.C. Precipitation behaviors in Al-Cu-Mg and 2024 aluminum alloys. Metall. Mater. Trans. A 1996, 27, 2479–2494. [Google Scholar] [CrossRef]

- Gourdet, S.; Montheillet, F. An experimental study of the recrystallization mechanism during hot deformation of aluminium. Mater. Sci. Eng. A 2000, 283, 274–288. [Google Scholar] [CrossRef]

- Jia, L.; Ren, X.P.; Hou, H.L.; Zhang, Y.L. Microstructural evolution and superplastic deformation mechanisms of as-rolled 2A97 alloy at low-temperature. Mater. Sci. Eng. A 2019, 759, 19–29. [Google Scholar] [CrossRef]

- Odoh, D.; Mahmoodkhani, Y.; Whitney, M.; Wells, M. Prediction of the Hot Flow Stress Behavior of AA6063 Including Mg2Si Dissolution. J. Mater. Eng. Perform. 2017, 26, 1186–1194. [Google Scholar] [CrossRef]

- Zhu, H.L.; Couper, M.J.; Dahle, A.K. Effect of process variables on Mg-Si particles and extrudability of 6xxx series aluminum extrusions. JOM 2011, 63, 66–71. [Google Scholar] [CrossRef]

- Engler, O.; Hirsch, J. Recrystallization Textures and Plastic Anisotropy in Al-Mg-Si Sheet Alloys. Mater. Sci. Forum 1996, 217, 479–486. [Google Scholar] [CrossRef]

- Hu, Z.Y.; Fan, C.H.; Zheng, D.S.; Liu, W.L.; Chen, X.H. Microstructure evolution of Al–Cu–Mg alloy during rapid cold punching and recrystallization annealing. Trans. Nonferrous Metal. Soc. 2019, 29, 1816–1823. [Google Scholar] [CrossRef]

- Atkins, A.G. Deformation-mechanism maps (the plasticity and creep of metals and ceramics). J. Mech. Work. Technol. 1984, 9, 224–225. [Google Scholar] [CrossRef]

- Bate, P. The effect of deformation on grain growth in Zener pinned systems. Acta Mater. 2001, 49, 1453–1461. [Google Scholar] [CrossRef]

- Humphreys, F.J.; Hatherly, M. Recrystallization and Related Annealing Phenomena, 2nd ed.; Elsevier: Amsterdam, The Netherlands, 2004; pp. 557–615. [Google Scholar]

- Sitdikov, O.; Sakai, T.; Avtokratova, E.; Kaibyshev, R.; Tsuzaki, K.; Watanabe, Y. Microstructure behavior of Al–Mg–Sc alloy processed by ECAP at elevated temperature. Acta Mater. 2008, 56, 821–834. [Google Scholar] [CrossRef]

- Nikulin, I.; Kipelova, A.; Malopheyev, S.; Kaibyshev, R. Effect of second phase particles on grain refinement during equal-channel angular pressing of an Al–Mg–Mn alloy. Acta Mater. 2012, 60, 487–497. [Google Scholar] [CrossRef]

- Lee, W.S.; Chen, T.H.; Gong, Q.J. Dynamic Shear Behaviour of Unweldable Aluminum-Scandium (Al-Sc) Alloy. Mater. Trans. 2007, 48, 500–509. [Google Scholar] [CrossRef] [Green Version]

- Marceau, R.K.W.; Sha, G.; Ferragut, R.; Dupasquier, A.; Ringer, S.P. Solute clustering in Al–Cu–Mg alloys during the early stages of elevated temperature ageing. Acta Mater. 2010, 58, 4923–4939. [Google Scholar] [CrossRef]

- Nacházel, J.; Palán, J.; Dlouhý, J.; Sláma, P.; Nový, Z. Effects of Rotary Swaging Parameters and Artificial Ageing on Mechanical Properties and Microstructure of 2024 Precipitation-Hardenable Aluminium Alloy. Materials 2020, 13, 143. [Google Scholar] [CrossRef] [Green Version]

- Wang, Z.X.; Chen, M.; Jiang, H.H.; Li, H.; Li, S. Effect of artificial ageing on strength and ductility of an Al-Cu-Mg-Mn alloy subjected to solutionizing and room-temperature rolling. Mater. Charact. 2020, 165, 110383. [Google Scholar] [CrossRef]

- Moy, C.K.S.; Weiss, M.; Xia, J.H.; Sha, G.; Ringer, S.P.; Ranzi, G. Influence of heat treatment on the microstructure, texture and formability of 2024 aluminium alloy. Mater. Sci. Eng. A 2012, 552, 48–60. [Google Scholar] [CrossRef]

- Yuan, J.; Liu, Q.; Pan, S.H.; Li, J.X.; Murali, N.; Wang, S.; Li, X.C. Nano-treating promoted solute dissolution for novel high strength Al-Cu-Mg alloys. Materialia 2022, 24, 101466. [Google Scholar] [CrossRef]

| α/MPa−1 | n | Q/(KJ·mol−1) | A/s−1 | |

|---|---|---|---|---|

| CC | 0.019974 | 4.0621 | 224.0402 | 7.2710 × 1014 |

| ACC | 0.014391 | 5.3905 | 297.8640 | 3.2845 × 1020 |

| Sample | UTS/MPa | YS/MPa | Elongation/% |

|---|---|---|---|

| CC-T5 | 335 | 222.9 | 20.2 |

| ACC-T5 | 481 | 361 | 15.1 |

| CC-T6 | 427 | 321.7 | 9.78 |

| ACC-T6 | 485 | 379.2 | 18.1 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Qin, R.; Chen, W.; Tang, J.; Jiang, F.; Chen, Y.; Zhang, H. Influence of Pre-Heat Treatment on the Deformation Behaviors, Microstructural Characteristics, and Mechanical Properties of a Continuously Cast Al-Cu-Mg Alloy during Continuous Extrusion Process. Materials 2023, 16, 3042. https://doi.org/10.3390/ma16083042

Qin R, Chen W, Tang J, Jiang F, Chen Y, Zhang H. Influence of Pre-Heat Treatment on the Deformation Behaviors, Microstructural Characteristics, and Mechanical Properties of a Continuously Cast Al-Cu-Mg Alloy during Continuous Extrusion Process. Materials. 2023; 16(8):3042. https://doi.org/10.3390/ma16083042

Chicago/Turabian StyleQin, Renbao, Wentian Chen, Jie Tang, Fulin Jiang, Yonggang Chen, and Hui Zhang. 2023. "Influence of Pre-Heat Treatment on the Deformation Behaviors, Microstructural Characteristics, and Mechanical Properties of a Continuously Cast Al-Cu-Mg Alloy during Continuous Extrusion Process" Materials 16, no. 8: 3042. https://doi.org/10.3390/ma16083042

APA StyleQin, R., Chen, W., Tang, J., Jiang, F., Chen, Y., & Zhang, H. (2023). Influence of Pre-Heat Treatment on the Deformation Behaviors, Microstructural Characteristics, and Mechanical Properties of a Continuously Cast Al-Cu-Mg Alloy during Continuous Extrusion Process. Materials, 16(8), 3042. https://doi.org/10.3390/ma16083042