Feasibility of Using New Sustainable Mineral Additions for the Manufacture of Eco-Cements

Abstract

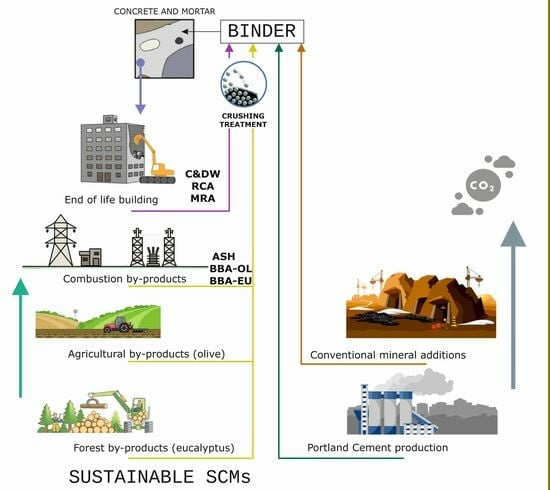

:1. Introduction

2. Properties of the Materials and Processing Systems Applied

2.1. Properties and Processing of Sustainable Materials

2.1.1. Description of Sustainable Materials

- (i.)

- Biomass bottom ash from biomass from the olive industry (BBA-OL). This type of ash was collected from the Puente Genil combustion plant in Cordoba, Southern Spain (37°26′58.6″ N 4°48′41.5″ W);

- (ii.)

- Biomass bottom ash from eucalyptus forest pruning biomass (BBA-EU). Collected from the Ence treatment plant in Mérida, Western Spain (38°51′09.7″ N 6°21′32.9″ W).

- (i.)

- An MRA refers to a granular material obtained from the recovery and processing of CDW with various types of stony materials, such as concrete, bricks, ceramics, asphalt and other stony elements;

- (ii.)

- An RCA is obtained by crushing and processing waste concrete, such as fragments from structures, pavements, blocks or other disused concrete elements. These concrete waste materials are treated to remove impurities and then crushed to suitable sizes for use as aggregates in new construction projects.

2.1.2. Processing of Sustainable Materials

- (i.)

- Firstly, the materials to be processed (BBA-OL, BBA-EU, MRA and RCA) were introduced into a jaw crusher until the aggregate size was significantly reduced;

- (ii.)

- Subsequently, the material was sieved through a 1 mm sieve, obtaining a material yield of approximately 60%;

- (iii.)

- The above process was repeated with a material size greater than 1 mm. In this second screening phase, the yield of the pulverised material exceeded 80%.

2.1.3. Experimental Methods of Characterisation Properties and Results

Particle Size Distribution

Real Density

Sulphate, Chloride and Organic Matter Content

X-ray Fluorescence and X-ray Diffraction

Fourier Transformation Infrared Spectroscopy

2.2. Properties of Conventional Materials

2.2.1. Cements

2.2.2. Limestone Filler

3. Experimental Methods and Results of Sustainable Cements

3.1. Mix Proportions

3.2. Test Procedures and Results of Mechanical Properties

3.2.1. Frattini Test

3.2.2. Compressive and Flexural Strength

3.2.3. Setting Time and Volumetric Expansion

4. Conclusions

- -

- Although the R30 and Blaine fineness results indicated that the p-BBA-EU sample had a lower reactivity due to its smaller specific surface area, the pozzolanicity and mechanical strength results were positive. This suggests that a higher specific surface area for p-BBA-EU could enhance its cementitious properties.

- -

- While great amounts of chlorine and sulphates are present in recycled supplementary cementitious materials, specifically in p-BBA-OL due to its agricultural origin, these values do not have a detrimental impact on the cementitious matrix or its potential use in reinforced concrete.

- -

- The analysed by-products exhibited a less crystalline structure than the limestone filler. Additionally, minerals from the silicate group (in BBA-OL, BBA-EU and the MRA) and portlandite (in the RCA) phases were found. This mineralogy indicated the reactive potential of the analysed materials, translating into an enhancement of the properties of the developed cements.

- -

- The evaluation of the pozzolanic capacity of each of the analysed by-products showed that p-BBA-EU and p-BBA-OL are materials with high pozzolanicity values. In the long term, it was observed that p-MRA also acquired a pozzolanic capacity. This property leads to the possibility of applying these by-products as SCMs, providing the resulting material with cementitious properties.

- -

- The mortar mixture containing the additions of p-MRA and p-RCA is the one with the best mechanical behaviour at 28 days, reaching 85% of the resistance of the control mortar mixture.

- -

- In the long term, the addition of p-BBA-EU shows greater hardening, reaching 95% of the long-term strength of the control mortar mix.

- -

- Biomass bottom ash powder, regardless of its nature, shows a higher long-term hardening than MRA or RCA powder.

- -

- The addition of the four analysed byproducts entailed an increase in both the initial and final setting times, along with a slight rise in soundness. However, all measured parameters adhere to the limits specified in EN 197-1 and do not negatively affect the developed sustainable cements. This implies their possible use as cementitious additives.

Author Contributions

Funding

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Bamigboye, G.; Olukanni, D.; Adedeji, A.; Ojewumi, M.; Jolayemi, K. Experimental and modelling of flexural strength produced from granite-gravel combination in self-compacting concrete. Int. J. Civ. Eng. Technol. 2018, 9, 437–447. [Google Scholar]

- Ross, C.A.; Tedesco, J.W.; Kuennen, S.T. Effects of strain rate on concrete strength. Mater. J. 1995, 92, 37–47. [Google Scholar]

- Breysse, D. Nondestructive evaluation of concrete strength: An historical review and a new perspective by combining NDT methods. Constr. Build. Mater. 2012, 33, 139–163. [Google Scholar] [CrossRef]

- Domone, P. A review of the hardened mechanical properties of self-compacting concrete. Cem. Concr. Compos. 2007, 29, 1–12. [Google Scholar] [CrossRef]

- Peck, M. Concrete: Design, Construction, Examples; De Gruyter: Berlin, Germany, 2006. [Google Scholar]

- Mohamad, N.; Muthusamy, K.; Embong, R.; Kusbiantoro, A.; Hashim, M.H. Environmental impact of cement production and Solutions: A review. Mater. Today Proc. 2022, 48, 741–746. [Google Scholar] [CrossRef]

- Li, Q.; Li, J.; Zhang, S.; Huang, X.; Wang, X.; Wang, Y.; Ni, W. Research Progress of Low-Carbon Cementitious Materials Based on Synergistic Industrial Wastes. Energies 2023, 16, 2376. [Google Scholar] [CrossRef]

- García-Gusano, D.; Garraín, D.; Herrera, I.; Cabal, H.; Lechón, Y. Life Cycle Assessment of applying CO2 post-combustion capture to the Spanish cement production. J. Clean. Prod. 2015, 104, 328–338. [Google Scholar] [CrossRef]

- Chaudhury, R.; Sharma, U.; Thapliyal, P.; Singh, L. Low-CO2 emission strategies to achieve net zero target in cement sector. J. Clean. Prod. 2023, 417, 137466. [Google Scholar]

- Juarez, R.I.C.; Finnegan, S. The environmental impact of cement production in Europe: A holistic review of existing EPDs. Clean. Environ. Syst. 2021, 3, 100053. [Google Scholar] [CrossRef]

- Degefa, A.B.; Park, S.; Yang, B.; Park, S. Predicting the Degree of Reaction of Supplementary Cementitious Materials in Hydrated Portland Cement. Sustainability 2023, 15, 15471. [Google Scholar] [CrossRef]

- Environment, U.; Scrivener, K.L.; John, V.M.; Gartner, E.M. Eco-efficient cements: Potential economically viable solutions for a low-CO2 cement-based materials industry. Cem. Concr. Res. 2018, 114, 2–26. [Google Scholar]

- Snellings, R.; Suraneni, P.; Skibsted, J. Future and emerging supplementary cementitious materials. Cem. Concr. Res. 2023, 171, 107199. [Google Scholar] [CrossRef]

- Afroz, S.; Zhang, Y.; Nguyen, Q.D.; Kim, T.; Castel, A. Effect of limestone in General Purpose cement on autogenous shrinkage of high strength GGBFS concrete and pastes. Constr. Build. Mater. 2022, 327, 126949. [Google Scholar] [CrossRef]

- Giergiczny, Z. Fly ash and slag. Cem. Concr. Res. 2019, 124, 105826. [Google Scholar] [CrossRef]

- Snellings, R. Assessing, understanding and unlocking supplementary cementitious materials. RILEM Tech. Lett. 2016, 1, 50–55. [Google Scholar] [CrossRef]

- Khankhaje, E.; Kim, T.; Jang, H.; Kim, C.; Kim, J. Properties of pervious concrete incorporating fly ash as partial replacement of cement: A review. Dev. Built Environ. 2023, 14, 100130. [Google Scholar] [CrossRef]

- Moon, G.D.; Oh, S.; Jung, S.H.; Choi, Y.C. Effects of the fineness of limestone powder and cement on the hydration and strength development of PLC concrete. Constr. Build. Mater. 2017, 135, 129–136. [Google Scholar] [CrossRef]

- Panesar, D.K.; Zhang, R. Performance comparison of cement replacing materials in concrete: Limestone fillers and supplementary cementing materials–A review. Constr. Build. Mater. 2020, 251, 118866. [Google Scholar] [CrossRef]

- Xu, D.; Tang, J.; Hu, X.; Zhou, Y.; Yu, C.; Han, F.; Liu, J. Influence of silica fume and thermal curing on long-term hydration, microstructure and compressive strength of ultra-high performance concrete (UHPC). Constr. Build. Mater. 2023, 395, 132370. [Google Scholar] [CrossRef]

- Amin, M.; Zeyad, A.M.; Tayeh, B.A.; Agwa, I.S. Effect of ferrosilicon and silica fume on mechanical, durability, and microstructure characteristics of ultra high-performance concrete. Constr. Build. Mater. 2022, 320, 126233. [Google Scholar] [CrossRef]

- Fernandez, R.; Martirena, F.; Scrivener, K.L. The origin of the pozzolanic activity of calcined clay minerals: A comparison between kaolinite, illite and montmorillonite. Cem. Concr. Res. 2011, 41, 113–122. [Google Scholar] [CrossRef]

- Sabir, B.; Wild, S.; Bai, J. Metakaolin and calcined clays as pozzolans for concrete: A review. Cem. Concr. Compos. 2001, 23, 441–454. [Google Scholar] [CrossRef]

- Sharma, M.; Bishnoi, S.; Martirena, F.; Scrivener, K. Limestone calcined clay cement and concrete: A state-of-the-art review. Cem. Concr. Res. 2021, 149, 106564. [Google Scholar] [CrossRef]

- Avet, F.; Boehm-Courjault, E.; Scrivener, K. Investigation of CASH composition, morphology and density in Limestone Calcined Clay Cement (LC3). Cem. Concr. Res. 2019, 115, 70–79. [Google Scholar] [CrossRef]

- Šovljanski, O.; Tomić, A.; Markov, S. Relationship between bacterial contribution and self-healing effect of cement-based materials. Microorganisms 2022, 10, 1399. [Google Scholar] [CrossRef]

- Vermeer, C.M.; Rossi, E.; Tamis, J.; Jonkers, H.M.; Kleerebezem, R. From waste to self-healing concrete: A proof-of-concept of a new application for polyhydroxyalkanoate. Resour. Conserv. Recycl. 2021, 164, 105206. [Google Scholar] [CrossRef]

- Barbudo, A.; De Brito, J.; Evangelista, L.; Bravo, M.; Agrela, F. Influence of water-reducing admixtures on the mechanical performance of recycled concrete. J. Clean. Prod. 2013, 59, 93–98. [Google Scholar] [CrossRef]

- Pacheco, J.; De Brito, J.; Chastre, C.; Evangelista, L. Experimental investigation on the variability of the main mechanical properties of concrete produced with coarse recycled concrete aggregates. Constr. Build. Mater. 2019, 201, 110–120. [Google Scholar] [CrossRef]

- Asensio, E.; Medina, C.; Frías, M.; de Rojas, M.I.S. Characterization of ceramic-based construction and demolition waste: Use as pozzolan in cements. J. Am. Ceram. Soc. 2016, 99, 4121–4127. [Google Scholar] [CrossRef]

- Asensio, E.; Medina, C.; Frías, M.; Sánchez de Rojas, M.I. Fired clay-based construction and demolition waste as pozzolanic addition in cements. Design of new eco-efficient cements. J. Clean. Prod. 2020, 265, 121610. [Google Scholar] [CrossRef]

- Ge, Z.; Wang, Y.; Sun, R.; Wu, X.; Guan, Y. Influence of ground waste clay brick on properties of fresh and hardened concrete. Constr. Build. Mater. 2015, 98, 128–136. [Google Scholar] [CrossRef]

- Tironi, A.; Trezza, M.A.; Scian, A.N.; Irassar, E.F. Assessment of pozzolanic activity of different calcined clays. Cem. Concr. Compos. 2013, 37, 319–327. [Google Scholar] [CrossRef]

- Lavat, A.E.; Trezza, M.A.; Poggi, M. Characterization of ceramic roof tile wastes as pozzolanic admixture. Waste Manag. 2009, 29, 1666–1674. [Google Scholar] [CrossRef] [PubMed]

- Rosales, J.; Cabrera, M.; Lopez-Alonso, M.; Díaz-López, J.; Agrela, F. Specialized concrete made of processed biomass ash: Lightweight, self-compacting, and geopolymeric concrete. In The Structural Integrity of Recycled Aggregate Concrete Produced with Fillers and Pozzolans; Elsevier: Amsterdam, The Netherlands, 2022; pp. 199–239. [Google Scholar]

- Beltrán, M.G.; Barbudo, A.; Agrela, F.; Jiménez, J.R.; de Brito, J. Mechanical performance of bedding mortars made with olive biomass bottom ash. Constr. Build. Mater. 2016, 112, 699–707. [Google Scholar] [CrossRef]

- Rosales, J.; Cabrera, M.; Beltrán, M.G.; López, M.; Agrela, F. Effects of treatments on biomass bottom ash applied to the manufacture of cement mortars. J. Clean. Prod. 2017, 154, 424–435. [Google Scholar] [CrossRef]

- Cabrera, M.; Galvin, A.P.; Agrela, F.; Beltran, M.G.; Ayuso, J. Reduction of leaching impacts by applying biomass bottom ash and recycled mixed aggregates in structural layers of roads. Materials 2016, 9, 228. [Google Scholar] [CrossRef]

- Galvín, A.P.; López-Uceda, A.; Ayuso, J.; Jimenez Romero, J.R.; Barbudo, A. Leaching behaviour of stabilised expansive soil with biomass bottom ashes as eco-agents. Biomass Convers. Biorefinery 2021, 11, 715–725. [Google Scholar] [CrossRef]

- Thomas, B.S.; Yang, J.; Mo, K.H.; Abdalla, J.A.; Hawileh, R.A.; Ariyachandra, E. Biomass ashes from agricultural wastes as supplementary cementitious materials or aggregate replacement in cement/geopolymer concrete: A comprehensive review. J. Build. Eng. 2021, 40, 102332. [Google Scholar] [CrossRef]

- Carrasco, B.; Cruz, N.; Terrados, J.; Corpas, F.; Pérez, L. An evaluation of bottom ash from plant biomass as a replacement for cement in building blocks. Fuel 2014, 118, 272–280. [Google Scholar] [CrossRef]

- Medina, J.M.; del Bosque, I.S.; Frías, M.; de Rojas, M.S.; Medina, C. Durability of new blended cements additioned with recycled biomass bottom ASH from electric power plants. Constr. Build. Mater. 2019, 225, 429–440. [Google Scholar] [CrossRef]

- Rosales, M.; Rosales, J.; Agrela, F.; de Rojas, M.S.; Cabrera, M. Design of a new eco-hybrid cement for concrete pavement, made with processed mixed recycled aggregates and olive biomass bottom ash as supplementary cement materials. Constr. Build. Mater. 2022, 358, 129417. [Google Scholar] [CrossRef]

- Cerón Cerón, A.M.; Gutiérrez Arango, C. Elaboración de Unidades de Mampostería Perforada de Concreto Utilizando Relaves Provenientes de la Minería de Agregados; Universidad Santo Tomás: Bogotá, Colombia, 2019. [Google Scholar]

- Castellano, C.C.; Bonavetti, V.L.; Irassar, E.F. Cementos mezclas: Influencia del tamaño de las partículas de escoria. Concreto Cem. Investig. Desarro. 2013, 4, 2–14. [Google Scholar]

- de Brito, J.; Agrela, F.; Silva, R.V. Construction and demolition waste. In New Trends in Eco-Efficient and Recycled Concrete; Elsevier: Amsterdam, The Netherlands, 2019; pp. 1–22. [Google Scholar]

- Sarkkinen, M.; Kujala, K.; Kemppainen, K.; Gehör, S. Effect of biomass fly ashes as road stabilisation binder. Road Mater. Pavement Des. 2018, 19, 239–251. [Google Scholar] [CrossRef]

- Rajamma, R.; Senff, L.; Ribeiro, M.; Labrincha, J.A.; Ball, R.; Allen, G.C.; Ferreira, V. Biomass fly ash effect on fresh and hardened state properties of cement based materials. Compos. Part B: Eng. 2015, 77, 1–9. [Google Scholar] [CrossRef]

- Roca, L.F.; Moral, J.; Viruega, J.R.; Ávila, A.; Oliveira, R.; Trapero, A. Copper fungicides in the control of olive diseases. Olea 2007, 26, 48–50. [Google Scholar]

- Xing, P.; Mason, P.; Chilton, S.; Lloyd, S.; Jones, J.; Williams, A.; Nimmo, W.; Pourkashanian, M. A comparative assessment of biomass ash preparation methods using X-ray fluorescence and wet chemical analysis. Fuel 2016, 182, 161–165. [Google Scholar] [CrossRef]

- Hinojosa, M.; Galvín, A.P.; Agrela, F.; Perianes, M.; Barbudo, A. Potential use of biomass bottom ash as alternative construction material: Conflictive chemical parameters according to technical regulations. Fuel 2014, 128, 248–259. [Google Scholar] [CrossRef]

- Cabrera, M.; Díaz-López, J.L.; Agrela, F.; Rosales, J. Eco-efficient cement-based materials using biomass bottom ash: A review. Appl. Sci. 2020, 10, 8026. [Google Scholar] [CrossRef]

- Banerjee, S.S.; Joshi, M.V.; Jayaram, R.V. Treatment of oil spills using organo-fly ash. Desalination 2006, 195, 32–39. [Google Scholar] [CrossRef]

- Yusuf, M.O. Bond Characterization in Cementitious Material Binders Using Fourier-Transform Infrared Spectroscopy. Appl. Sci. 2023, 13, 3353. [Google Scholar] [CrossRef]

- Romero, E.; Quirantes, M.; Nogales, R. Characterization of biomass ashes produced at different temperatures from olive-oil-industry and greenhouse vegetable wastes. Fuel 2017, 208, 1–9. [Google Scholar] [CrossRef]

- Uchino, T.; Sakka, T.; Iwasaki, M. Interpretation of hydrated states of sodium silicate glasses by infrared and Raman analysis. J. Am. Ceram. Soc. 1991, 74, 306–313. [Google Scholar] [CrossRef]

- Osswald, J.; Fehr, K. FTIR spectroscopic study on liquid silica solutions and nanoscale particle size determination. J. Mater. Sci. 2006, 41, 1335–1339. [Google Scholar] [CrossRef]

- Fernández-Carrasco, L.; Torrens-Martín, D.; Morales, L.; Martínez-Ramírez, S. Infrared spectroscopy in the analysis of building and construction materials. Infrared Spectrosc.—Mater. Sci. Eng. Technol. 2012, 510, 369–382. [Google Scholar]

- Lodeiro, I.G.; Macphee, D.E.; Palomo, A.; Fernández-Jiménez, A. Effect of alkalis on fresh C–S–H gels. FTIR analysis. Cem. Concr. Res. 2009, 39, 147–153. [Google Scholar] [CrossRef]

- Argiz, C.; Sanjuán, M.Á.; Menéndez, E. Effect of mixes made of coal bottom ash and fly ash on the mechanical strength and porosity of Portland cement. Mater. Construcción 2013, 63, 49–64. [Google Scholar]

- Park, B.; Choi, Y.C. Effects of fineness and chemical activators on the hydration and physical properties of high-volume fly-ash cement pastes. J. Build. Eng. 2022, 51, 104274. [Google Scholar] [CrossRef]

- Jo, B.-W.; Kim, C.-H.; Tae, G.-h.; Park, J.-B. Characteristics of cement mortar with nano-SiO2 particles. Constr. Build. Mater. 2007, 21, 1351–1355. [Google Scholar] [CrossRef]

- Bogas, J.; Carriço, A.; Pereira, M. Mechanical characterization of thermal activated low-carbon recycled cement mortars. J. Clean. Prod. 2019, 218, 377–389. [Google Scholar] [CrossRef]

- Ribeiro, D.V.; Yuan, S.Y.; Morelli, M.R. Effect of chemically treated leather shaving addition on characteristics and microstructure of OPC mortars. Mater. Res. 2012, 15, 136–143. [Google Scholar] [CrossRef]

- Rosales, J.; Rosales, M.; Díaz-López, J.L.; Agrela, F.; Cabrera, M. Effect of Processed Volcanic Ash as Active Mineral Addition for Cement Manufacture. Materials 2022, 15, 6305. [Google Scholar] [CrossRef]

- Salvo, M.; Rizzo, S.; Caldirola, M.; Novajra, G.; Canonico, F.; Bianchi, M.; Ferraris, M. Biomass ash as supplementary cementitious material (SCM). Adv. Appl. Ceram. 2015, 114 (Suppl. S1), S3–S10. [Google Scholar] [CrossRef]

- Tironi, A.; Cravero, F.; Scian, A.N.; Irassar, E.F. Pozzolanic activity of calcined halloysite-rich kaolinitic clays. Appl. Clay Sci. 2017, 147, 11–18. [Google Scholar] [CrossRef]

- Liu, Y.; Lei, S.; Lin, M.; Li, Y.; Ye, Z.; Fan, Y. Assessment of pozzolanic activity of calcined coal-series kaolin. Appl. Clay Sci. 2017, 143, 159–167. [Google Scholar] [CrossRef]

- Zhao, Y.; Gao, J.; Liu, C.; Chen, X.; Xu, Z. The particle-size effect of waste clay brick powder on its pozzolanic activity and properties of blended cement. J. Clean. Prod. 2020, 242, 118521. [Google Scholar] [CrossRef]

- Ardoğa, M.K.; Erdoğan, S.T.; Tokyay, M. Effect of particle size on early heat evolution of interground natural pozzolan blended cements. Constr. Build. Mater. 2019, 206, 210–218. [Google Scholar] [CrossRef]

- Etxeberria, M.; Vázquez, E.; Marí, A.; Barra, M. Influence of amount of recycled coarse aggregates and production process on properties of recycled aggregate concrete. Cem. Concr. Res. 2007, 37, 735–742. [Google Scholar] [CrossRef]

- Tabsh, S.W.; Abdelfatah, A.S. Influence of recycled concrete aggregates on strength properties of concrete. Constr. Build. Mater. 2009, 23, 1163–1167. [Google Scholar] [CrossRef]

- Topçu, İ.B.; Şengel, S. Properties of concretes produced with waste concrete aggregate. Cem. Concr. Res. 2004, 34, 1307–1312. [Google Scholar] [CrossRef]

- Medina, J.M.; del Bosque, I.S.; Frías, M.; de Rojas, M.S.; Medina, C. Design and properties of eco-friendly binary mortars containing ash from biomass-fuelled power plants. Cem. Concr. Compos. 2019, 104, 103372. [Google Scholar] [CrossRef]

- BS EN 197-1:2011; Cement–Part 1: Composition, Specifications and Conformity Criteria for Common Cements. European Committee for Standardisation: London, UK, 2011.

- Nochaiya, T.; Wongkeo, W.; Chaipanich, A. Utilization of fly ash with silica fume and properties of Portland cement–fly ash–silica fume concrete. Fuel 2010, 89, 768–774. [Google Scholar] [CrossRef]

- Li, G.; Zhou, C.; Ahmad, W.; Usanova, K.I.; Karelina, M.; Mohamed, A.M.; Khallaf, R. Fly ash application as supplementary cementitious material: A review. Materials 2022, 15, 2664. [Google Scholar] [CrossRef]

- Grzeszczyk, S.; Kupka, T.; Kałamarz, A.; Sudoł, A.; Jurowski, K.; Makieieva, N.; Oleksowicz, K.; Wrzalik, R. Characterization of eggshell as limestone replacement and its influence on properties of modified cement. Constr. Build. Mater. 2022, 319, 126006. [Google Scholar] [CrossRef]

- Bouasker, M.; Mounanga, P.; Turcry, P.; Loukili, A.; Khelidj, A. Chemical shrinkage of cement pastes and mortars at very early age: Effect of limestone filler and granular inclusions. Cem. Concr. Compos. 2008, 30, 13–22. [Google Scholar] [CrossRef]

- Dhandapani, Y.; Santhanam, M.; Kaladharan, G.; Ramanathan, S. Towards ternary binders involving limestone additions—A review. Cem. Concr. Res. 2021, 143, 106396. [Google Scholar] [CrossRef]

- Paris, J.M.; Roessler, J.G.; Ferraro, C.C.; DeFord, H.D.; Townsend, T.G. A review of waste products utilized as supplements to Portland cement in concrete. J. Clean. Prod. 2016, 121, 1–18. [Google Scholar] [CrossRef]

- Meko, B.; Ighalo, J.O. Utilization of Cordia Africana wood sawdust ash as partial cement replacement in C 25 concrete. Clean. Mater. 2021, 1, 100012. [Google Scholar] [CrossRef]

- Frías, M.; Savastano, H.; Villar, E.; de Rojas, M.I.S.; Santos, S. Characterization and properties of blended cement matrices containing activated bamboo leaf wastes. Cem. Concr. Compos. 2012, 34, 1019–1023. [Google Scholar] [CrossRef]

- He, X.; Zheng, Z.; Yang, J.; Su, Y.; Wang, T.; Strnadel, B. Feasibility of incorporating autoclaved aerated concrete waste for cement replacement in sustainable building materials. J. Clean. Prod. 2020, 250, 119455. [Google Scholar] [CrossRef]

- Kim, Y.J.; Choi, Y.W. Utilization of waste concrete powder as a substitution material for cement. Constr. Build. Mater. 2012, 30, 500–504. [Google Scholar] [CrossRef]

- Pitarch, A.; Reig, L.; Tomás, A.; Forcada, G.; Soriano, L.; Borrachero, M.; Payá, J.; Monzó, J. Pozzolanic activity of tiles, bricks and ceramic sanitary-ware in eco-friendly Portland blended cements. J. Clean. Prod. 2021, 279, 123713. [Google Scholar] [CrossRef]

- Velardo, P.; del Bosque, I.S.; de Rojas, M.S.; De Belie, N.; Medina, C. Design and evaluation of physical, mechanical and micro-structural properties of eco-friendly binary-blended mortars using biomass bottom ash or construction and demolition waste powder. Cem. Concr. Compos. 2023, 143, 105252. [Google Scholar] [CrossRef]

| Properties | p-BBA-OL | p-BBA-EU | p-MRA | p-RCA | |

|---|---|---|---|---|---|

| Grain size distribution, R30 (µm) (%) | 0.43 | 27.02 | 1.09 | 10.11 | |

| Real density (kg/m3) | 2609 | 2331 | 2591 | 2402 | |

| Blaine fineness (cm2/g) | 5080 | 2650 | 5600 | 4460 | |

| Organic matter content (%) | 2.50 | 2.16 | 0.80 | 0.61 | |

| Acid-soluble sulphate (% SO3) | 0.122 | 0.053 | 0.393 | 0.64 | |

| Chloride content (%) | 1.196 | 0.323 | 0.414 | 0.139 | |

| Main components XRF (%) | |||||

| P | 1.25 | 0.33 | 0.20 | 0.05 | |

| Si | 10.5 | 22.0 | 12.0 | 11.40 | |

| Ca | 19.6 | 6.36 | 15.7 | 18.7 | |

| Al | 1.90 | 3.44 | 2.49 | 2.21 | |

| S | 0.04 | 0.06 | 0.214 | 0.42 | |

| K | 4.46 | 2.56 | 1.57 | 0.72 | |

| Mg | 2.35 | 1.16 | 2.89 | 0.80 | |

| Na | 0.191 | 0.73 | 0.31 | 0.23 | |

| Fe | 1.33 | 3.07 | 1.42 | 1.28 | |

| Material | OPC I | LF | p-BBA-OL | p-BBA-EU | p-MRA | p-RCA |

|---|---|---|---|---|---|---|

| Wavenumbers (cm−1) | 3642 | 1800 | 3466 | 1420 | 3600 | 3635 |

| 1435 | 1434 | 1430 | 1052 | 1435 | 1796 | |

| 1150 | 1410 | 1040 | 783 | 1060 | 1437 | |

| 1100 | 876 | 966 | 691 | 1028 | 1000 | |

| 930 | 714 | 874 | 460 | 876 | 876 | |

| 880 | 460 | 775 | 783 | |||

| 660 | 714 | 714 | ||||

| 527 | 460 | 467 |

| Properties | OPC I | CEM IV | LF |

|---|---|---|---|

| Real Density (kg/m3) | 3160 | 3010 | 2670 |

| Blaine fineness (cm2/g) | 4120 | 4370 | 6550 |

| Chloride content (%) | 0.03 | 0.09 | 0.007 |

| Main components XRF (%) | |||

| P2O5 | 0.15 | 0.43 | 0.02 |

| SiO2 | 17.37 | 30.43 | 1.41 |

| CaO | 67.64 | 44.25 | 54.54 |

| Al2O3 | 3.96 | 15.53 | 0.04 |

| SO3 | 3.99 | 2.64 | 0.09 |

| K2O | 1.03 | 1.17 | 0.02 |

| MgO | 3.13 | 2.06 | 0.50 |

| Na2O | 0.32 | 0.38 | 0.28 |

| Fe2O3 | 2.41 | 3.11 | 0.02 |

| Mixture | Dosages Serie (g) | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| SNS | OPC I | CEM IV | LF | p-BBA-OL | p-BBA-EU | p-MRA | p-RCA | Water | |

| M-OPC I | 1350 | 450 | - | - | - | - | - | - | 225 |

| M-CEM IV | 1350 | - | 450 | - | - | - | - | - | 225 |

| M-LF | 1350 | 337.5 | - | 112.5 | - | - | - | - | 225 |

| M-BBA-OL | 1350 | 337.5 | - | - | 112.5 | - | - | - | 225 |

| M-BBA-EU | 1350 | 337.5 | - | - | - | 112.5 | - | - | 225 |

| M-MRA | 1350 | 337.5 | - | - | - | - | 112.5 | - | 225 |

| M-RCA | 1350 | 337.5 | - | - | - | - | - | 112.5 | 225 |

| Mechanical Performance (MPa) | 7 Days | 28 Days | 90 Days | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Compressive | Flexural | Compressive | Flexural | Compressive | Flexural | |||||||

| µ | σ | µ | σ | µ | σ | µ | σ | µ | σ | µ | σ | |

| M-OPC I | 51.81 | 1.32 | 7.52 | 0.10 | 61.41 | 0.69 | 9.34 | 0.08 | 65.17 | 0.63 | 10.21 | 0.08 |

| M-OPC II | 47.21 | 1.11 | 7.18 | 0.17 | 51.36 | 0.87 | 8.72 | 0.10 | 56.43 | 0.51 | 9.44 | 0.06 |

| M-LF | 29.74 | 1.12 | 5.24 | 0.33 | 33.86 | 0.84 | 6.07 | 0.11 | 36.27 | 0.70 | 6.72 | 0.11 |

| M-BBA-OL | 30.67 | 1.03 | 5.89 | 0.21 | 38.46 | 0.69 | 6.52 | 0.09 | 47.35 | 0.52 | 7.64 | 0.11 |

| M-BBA-EU | 34.34 | 0.82 | 6.15 | 0.08 | 43.12 | 0.54 | 7.28 | 0.06 | 54.57 | 0.50 | 8.92 | 0.11 |

| M-MRA | 35.75 | 2.08 | 6.46 | 0.25 | 44.66 | 1.25 | 7.65 | 0.16 | 52.38 | 0.97 | 8.45 | 0.18 |

| M-RCA | 34.94 | 0.76 | 6.31 | 0.10 | 43.82 | 0.54 | 7.24 | 0.07 | 51.87 | 0.55 | 8.34 | 0.08 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Moreno, S.; Rosales, M.; Rosales, J.; Agrela, F.; Díaz-López, J.L. Feasibility of Using New Sustainable Mineral Additions for the Manufacture of Eco-Cements. Materials 2024, 17, 777. https://doi.org/10.3390/ma17040777

Moreno S, Rosales M, Rosales J, Agrela F, Díaz-López JL. Feasibility of Using New Sustainable Mineral Additions for the Manufacture of Eco-Cements. Materials. 2024; 17(4):777. https://doi.org/10.3390/ma17040777

Chicago/Turabian StyleMoreno, S., M. Rosales, J. Rosales, F. Agrela, and J. L. Díaz-López. 2024. "Feasibility of Using New Sustainable Mineral Additions for the Manufacture of Eco-Cements" Materials 17, no. 4: 777. https://doi.org/10.3390/ma17040777

APA StyleMoreno, S., Rosales, M., Rosales, J., Agrela, F., & Díaz-López, J. L. (2024). Feasibility of Using New Sustainable Mineral Additions for the Manufacture of Eco-Cements. Materials, 17(4), 777. https://doi.org/10.3390/ma17040777