Investigation of the Hydrolytic Degradation Kinetics of 3D-Printed PLA Structures under a Thermally Accelerated Regime

Abstract

:1. Introduction

2. Materials and Methods

2.1. Three-Dimensionally Printed Materials

2.2. Thermally Supported Hydrolytic Degradation

2.3. Mass Loss Kinetics

2.4. High-Resolution X-ray Tomography

2.5. Measurement of the Intrinsic Viscosity

2.6. Wide-Angle X-ray Diffraction

3. Results and Discussion

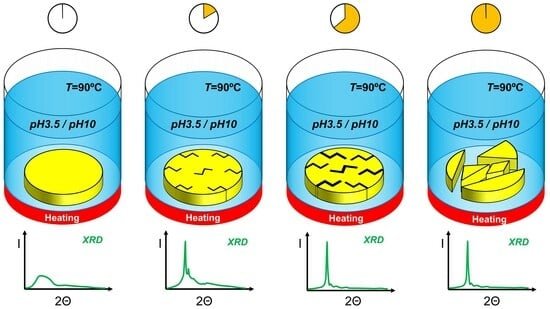

3.1. Macrostructural and Microstructural Changes

3.2. Mass Loss Kinetics

3.3. Intrinsic Viscosity Changes

3.4. Supramolecular Changes

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Ratto, J.A.; Stenhouse, P.J.; Auerbach, M.; Mitchell, J.; Farrell, R. Processing, Performance and Biodegradability of a Thermoplastic Aliphatic Polyester/Starch System. Polymer 1999, 40, 6777–6788. [Google Scholar] [CrossRef]

- Tserki, V.; Matzinos, P.; Pavlidou, E.; Vachliotis, D.; Panayiotou, C. Biodegradable Aliphatic Polyesters. Part I. Properties and Biodegradation of Poly(Butylene Succinate-Co-Butylene Adipate). Polym. Degrad. Stab. 2006, 91, 367–376. [Google Scholar] [CrossRef]

- Pitt, G.G.; Gratzl, M.M.; Kimmel, G.L.; Surles, J.; Sohindler, A. Aliphatic Polyesters II. The Degradation of Poly (DL-Lactide), Poly (ε-Caprolactone), and Their Copolymers in vivo. Biomaterials 1981, 2, 215–220. [Google Scholar] [CrossRef]

- Characteristics, F. NatureWorks PLA Polymer 4032D Biaxially Oriented Films—High Heat NatureWorks PLA Polymer 4032D; NatureWorks: Minneapolis, MN, USA, 2002; pp. 2–4. [Google Scholar]

- Pla, N.; Labels, C.F. Packaging Solutions from Nature; NatureWorks: Minneapolis, MN, USA, 2005; p. 20305. [Google Scholar]

- Karthik, T. Novel Properties of PLA Fibers. Synth. Fibres 2004, 33, 5–10. [Google Scholar] [CrossRef]

- Jahangir, A.; Rumi, T.; Khan, E.I.; Rahman, M.A.; Jahangir, M.A.; Rumi, T.M.; Wahab, A.; Sayed, Z. Bin Poly Lactic Acid (PLA) Fibres: Different Solvent Systems and Their Effect on Fibre Morphology and Diameter. Am. J. Chem. 2017, 2017, 177–186. [Google Scholar] [CrossRef]

- Manich, A.M.; Miguel, R.; Lucas, J.; Franco, F.; Baena, B.; Carilla, J.; Montero, L.; Cayuela, D. Texturing, Stretching and Relaxation Behaviour of Polylactide Multifilament Yarns. Text. Res. J. 2011, 81, 1788–1795. [Google Scholar] [CrossRef]

- Baig, G.A. Hydrolytic Stability of PLA Yarns during Textile Wet Processing. Fibers Polym. 2013, 14, 1912–1918. [Google Scholar] [CrossRef]

- Puchalski, M.; Sulak, K.; Chrzanowski, M.; Sztajnowski, S.; Krucińska, I. Effect of Processing Variables on the Thermal and Physical Properties of Poly(L-Lactide) Spun Bond Fabrics. Text. Res. J. 2015, 85, 535–547. [Google Scholar] [CrossRef]

- Liu, G.; Guan, J.; Wang, X.; Yu, J.; Ding, B. Polylactic Acid (PLA) Melt-Blown Nonwovens with Superior Mechanical Properties. ACS Sustain. Chem. Eng. 2023, 11, 4279–4288. [Google Scholar] [CrossRef]

- Litauszki, K.; Gere, D.; Czigany, T.; Kmetty, Á. Environmentally Friendly Packaging Foams: Investigation of the Compostability of Poly(Lactic Acid)-Based Syntactic Foams. Sustain. Mater. Technol. 2023, 35, e00527. [Google Scholar] [CrossRef]

- Wang, H.; Wei, Q.; Wang, X.; Gao, W.; Zhao, X. Antibacterial Properties of PLA Nonwoven Medical Dressings Coated with Nanostructured Silver. Fibers Polym. 2008, 9, 556–560. [Google Scholar] [CrossRef]

- Fouly, A.; Assaifan, A.K.; Alnaser, I.A.; Hussein, O.A.; Abdo, H.S. Evaluating the Mechanical and Tribological Properties of 3D Printed Polylactic-Acid (PLA) Green-Composite for Artificial Implant: Hip Joint Case Study. Polymers 2022, 14, 5299. [Google Scholar] [CrossRef]

- Bernardo, M.P.; da Silva, B.C.R.; Hamouda, A.E.I.; de Toledo, M.A.S.; Schalla, C.; Rütten, S.; Goetzke, R.; Mattoso, L.H.C.; Zenke, M.; Sechi, A. PLA/Hydroxyapatite Scaffolds Exhibit in vitro Immunological Inertness and Promote Robust Osteogenic Differentiation of Human Mesenchymal Stem Cells without Osteogenic Stimuli. Sci. Rep. 2022, 12, 2333. [Google Scholar] [CrossRef]

- Czekalski, J.; Krucińska, I.; Kowalska, S.; Puchalski, M. Effect of Twist Stabilisation and Dyeing on the Structural and Physical Properties of Agricultural Strings. Fibres Text. East 2013, 6, 39–44. [Google Scholar]

- Kopitar, D.; Marasovic, P.; Vrsaljko, D. Impact of Polylactic Acid Fibers in Cellulose Nonwoven Mulch Blends on Biodegradability and Performance—An Open Field Study. Polymers 2024, 16, 222. [Google Scholar] [CrossRef] [PubMed]

- Mazzanti, V.; Malagutti, L.; Mollica, F. FDM 3D Printing of Polymers Containing Natural Fillers: A Review of Their Mechanical Properties. Polymers 2019, 11, 1094. [Google Scholar] [CrossRef] [PubMed]

- Wei, X.; Li, D.; Jiang, W.; Gu, Z.; Wang, X.; Zhang, Z.; Sun, Z. 3D Printable Graphene Composite. Sci. Rep. 2015, 5, 11181. [Google Scholar] [CrossRef] [PubMed]

- Buj-Corral, I.; Sanz-Fraile, H.; Ulldemolins, A.; Tejo-Otero, A.; Domínguez-Fernández, A.; Almendros, I.; Otero, J. Characterization of 3D Printed Metal-PLA Composite Scaffolds for Biomedical Applications. Polymers 2022, 14, 2754. [Google Scholar] [CrossRef] [PubMed]

- Muthe, L.P.; Pickering, K.; Gauss, C. A Review of 3D/4D Printing of Poly-Lactic Acid Composites with Bio-Derived Reinforcements. Compos. Part C Open Access 2022, 8, 100271. [Google Scholar] [CrossRef]

- Barbosa, W.S.; Gioia, M.M.; Temporão, G.P.; Meggiolaro, M.A.; Gouvea, F.C. Impact of Multi-Lattice Inner Structures on FDM PLA 3D Printed Orthosis Using Industry 4.0 Concepts. Int. J. Interact. Des. Manuf. (IJIDeM) 2022, 17, 371–383. [Google Scholar] [CrossRef]

- Wee, J.H.; Yoo, K.D.; Sim, S.B.; Kim, H.J.; Kim, H.J.; Park, K.N.; Kim, G.H.; Moon, M.H.; You, S.J.; Ha, M.Y.; et al. Stem Cell Laden Nano and Micro Collagen/PLGA Bimodal Fibrous Patches for Myocardial Regeneration. Biomater. Res. 2022, 26, 79. [Google Scholar] [CrossRef]

- Serra, T.; Mateos-Timoneda, M.A.; Planell, J.A.; Navarro, M. 3D printed PLA-based scaffolds. Organogenesis 2013, 9, 239–244. [Google Scholar] [CrossRef] [PubMed]

- Chaigneau, L.; Perrot, A.; Brezulier, D.; Coulon, J.F.; Chevire, F.; Lebullenger, R. Bioresorbable Polylactic Acid (PLA) and Bioactive Glasses (BG) Composite: Influence of Gold Coated of BG Powder on Mechanical Properties and Chemical Reactivity. J. Mech. Behav. Biomed. Mater. 2023, 138, 105571. [Google Scholar] [CrossRef] [PubMed]

- Guo, W.; Bu, W.; Mao, Y.; Wang, E.; Yang, Y.; Liu, C.; Guo, F.; Mai, H.; You, H.; Long, Y. Magnesium Hydroxide as a Versatile Nanofiller for 3D-Printed PLA Bone Scaffolds. Polymers 2024, 16, 198. [Google Scholar] [CrossRef] [PubMed]

- Gutowska, A.; Jóźwicka, J.; Sobczak, S.; Tomaszewski, W.; Sulak, K.; Miros, P.; Owczarek, M.; Szalczyńska, M.; Ciechańska, D.; Krucińska, I. In-Compost Biodegradation of PLA Nonwovens. Fibres Text. East. Eur. 2014, 22, 99–106. [Google Scholar]

- Sikorska, W.; Richert, J.; Rydz, J.; Musioł, M.; Adamus, G.; Janeczek, H.; Kowalczuk, M. Degradability Studies of Poly(l-Lactide) after Multi-Reprocessing Experiments in Extruder. Polym. Degrad. Stab. 2012, 97, 1891–1897. [Google Scholar] [CrossRef]

- ISO 20200:2023; Plastics-Determination of the degree of disintegration of plastic materials under composting conditions in a laboratory-scale test. ISO: Geneva, Switzerland, 2019.

- Ho, K.L.G.; Pometto, A.L.; Gadea-Rivas, A.; Briceño, J.A.; Rojas, A. Degradation of Polylactic Acid (PLA) Plastic in Costa Rican Soil and Iowa State University Compost Rows. J. Environ. Polym. Degrad. 1999, 7, 173–177. [Google Scholar] [CrossRef]

- Rudnik, E.; Briassoulis, D. Degradation Behaviour of Poly(Lactic Acid) Films and Fibres in Soil under Mediterranean Field Conditions and Laboratory Simulations Testing. Ind. Crops Prod. 2011, 33, 648–658. [Google Scholar] [CrossRef]

- Puchalski, M.; Siwek, P.; Panayotov, N.; Berova, M.; Kowalska, S.; Krucińska, I. Influence of Various Climatic Conditions on the Structural Changes of Semicrystalline PLA Spun-Bonded Mulching Nonwovens during Outdoor Composting. Polymers 2019, 11, 559. [Google Scholar] [CrossRef]

- Sikorska, W.; Musioł, M.; Rydz, J.; Zięba, M.; Rychter, P.; Lewicka, K.; Šiškova, A.; Mosnáčková, K.; Kowalczuk, M.; Adamus, G. Prediction Studies of Environment-Friendly Biodegradable Polymeric Packaging Based on PLA. Influence of Specimens’ Thickness on the Hydrolytic Degradation Profile. Waste Manag. 2018, 78, 938–947. [Google Scholar] [CrossRef]

- Papageorgiou, G.Z.; Beslikas, T.; Gigis, J.; Christoforides, J.; Bikiaris, D.N. Crystallization and Enzymatic Hydrolysis of PLA Grade for Orthopedics. Adv. Polym. Technol. 2010, 29, 280–299. [Google Scholar] [CrossRef]

- Lee, S.H.; Kim, I.Y.; Song, W.S. Biodegradation of Polylactic Acid (PLA) Fibers Using Different Enzymes. Macromol. Res. 2014, 22, 657–663. [Google Scholar] [CrossRef]

- Bergaliyeva, S.; Sales, D.L.; Delgado, F.J.; Bolegenova, S.; Molina, S.I. Effect of Thermal and Hydrothermal Accelerated Aging on 3D Printed Polylactic Acid. Polymers 2022, 14, 5256. [Google Scholar] [CrossRef] [PubMed]

- Alfaro, M.E.C.; Stares, S.L.; de Oliveira Barra, G.M.; Hotza, D. Effects of Accelerated Weathering on Properties of 3D-Printed PLA Scaffolds. Mater. Today Commun. 2022, 33, 104821. [Google Scholar] [CrossRef]

- Giełdowska, M.; Puchalski, M.; Sztajnowski, S.; Krucińska, I. Evolution of the Molecular and Supramolecular Structures of PLA during the Thermally Supported Hydrolytic Degradation of Wet Spinning Fibers. Macromolecules 2022, 55, 10100–10112. [Google Scholar] [CrossRef]

- ISO 21701:2019; Textiles —Test method for accelerated hydrolysis of textile materials and biodegradation under controlled composting conditions of the resulting hydrolysate. ISO: Geneva, Switzerland, 2019.

- Rabiej, M. A Hybrid Immune-Evolutionary Strategy Algorithm for the Analysis of the Wide-Angle X-Ray Diffraction Curves of Semicrystalline Polymers. J. Appl. Crystallogr. 2014, 47, 1502–1511. [Google Scholar] [CrossRef]

- Gieldowska, M.; Puchalski, M.; Szparaga, G.; Krucińska, I. Investigation of the Influence of PLA Molecular and Supramolecular Structure on the Kinetics of Thermal-Supported Hydrolytic Degradation of Wet Spinning Fibres. Materials 2020, 13, 2111. [Google Scholar] [CrossRef]

- Kenley, R.A.; Lee, M.O.; Mahoney, T.R.; Sanders, L.M. Poly(1actide-Co-Glycolide) decomposition kinetics in vivo and in vitro. Macromolecules 1987, 20, 2398–2403. [Google Scholar] [CrossRef]

- Stoclet, G.; Séguéla, R.; Lefebvre, J.M.; Li, S.; Vert, M. Thermal and Strain-Induced Chain Ordering in Lactic Acid Stereocopolymers: Influence of the Composition in Stereomers. Macromolecules 2011, 44, 4961–4969. [Google Scholar] [CrossRef]

- Pan, P.; Inoue, Y. Polymorphism and Isomorphism in Biodegradable Polyesters. Prog. Polym. Sci. 2009, 34, 605–640. [Google Scholar] [CrossRef]

- Stoclet, G.; Seguela, R.; Vanmansart, C.; Rochas, C.; Lefebvre, J.M. WAXS Study of the Structural Reorganization of Semi-Crystalline Polylactide under Tensile Drawing. Polymer 2012, 53, 519–528. [Google Scholar] [CrossRef]

- Zhang, J.; Tashiro, K.; Tsuji, H.; Domb, A.J. Disorder-to-Order Phase Transition and Multiple Melting Behavior of Poly(L-Lactide) Investigated by Simultaneous Measurements of WAXD and DSC. Macromolecules 2008, 41, 1352–1357. [Google Scholar] [CrossRef]

- Tsai, C.C.; Wu, R.J.; Cheng, H.Y.; Li, S.C.; Siao, Y.Y.; Kong, D.C.; Jang, G.W. Crystallinity and Dimensional Stability of Biaxial Oriented Poly(Lactic Acid) Films. Polym. Degrad. Stab. 2010, 95, 1292–1298. [Google Scholar] [CrossRef]

- Zhu, Z.; Bian, Y.; Zhang, X.; Zeng, R.; Yang, B. Study of Crystallinity and Conformation of Poly(Lactic Acid) by Terahertz Spectroscopy. Anal. Chem. 2022, 94, 11104–11111. [Google Scholar] [CrossRef]

- Rabiej, M. Application of Immune and Genetic Algorithms to the Identification of a Polymer Based on Its X-Ray Diffraction Curve. J. Appl. Crystallogr. 2013, 46, 1136–1144. [Google Scholar] [CrossRef]

| Sample | pH of the Medium | A±SE | ke ± SE (days−1) | R | ton (days) |

|---|---|---|---|---|---|

| PLA1 | 3.5 | 4.843 ± 0.018 | 0.017 ± 0.007 | 0.989 | 13.8 |

| PLA1 | 10 | 4.801 ± 0.017 | 0.019 ± 0.006 | 0.993 | 10.5 |

| PLA2 | 3.5 | 4.864 ± 0.009 | 0.019 ± 0.004 | 0.998 | 13.4 |

| PLA2 | 10 | 4.762 ± 0.014 | 0.012 ± 0.005 | 0.987 | 12.9 |

| Sample | pH of the Medium | A ± SE | kd ± SE (days−1) | R | ton (days) |

|---|---|---|---|---|---|

| PLA1 | 3.5 | 4.843 ± 0.018 | 0.144 ± 0.013 | 0.991 | 2.4 |

| PLA1 | 10 | 4.801 ± 0.017 | 0.145 ± 0.014 | 0.996 | 2.1 |

| PLA2 | 3.5 | 4.864 ± 0.009 | 0.146 ± 0.012 | 0.995 | 3.0 |

| PLA2 | 10 | 4.762 ± 0.014 | 0.170 ± 0.017 | 0.985 | 2.1 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Klimczuk, B.; Rudnicka, A.; Owczarek, O.; Puszkarz, A.K.; Szparaga, G.; Puchalski, M. Investigation of the Hydrolytic Degradation Kinetics of 3D-Printed PLA Structures under a Thermally Accelerated Regime. Materials 2024, 17, 1043. https://doi.org/10.3390/ma17051043

Klimczuk B, Rudnicka A, Owczarek O, Puszkarz AK, Szparaga G, Puchalski M. Investigation of the Hydrolytic Degradation Kinetics of 3D-Printed PLA Structures under a Thermally Accelerated Regime. Materials. 2024; 17(5):1043. https://doi.org/10.3390/ma17051043

Chicago/Turabian StyleKlimczuk, Bartłomiej, Aleksandra Rudnicka, Oliwia Owczarek, Adam K. Puszkarz, Grzegorz Szparaga, and Michał Puchalski. 2024. "Investigation of the Hydrolytic Degradation Kinetics of 3D-Printed PLA Structures under a Thermally Accelerated Regime" Materials 17, no. 5: 1043. https://doi.org/10.3390/ma17051043

APA StyleKlimczuk, B., Rudnicka, A., Owczarek, O., Puszkarz, A. K., Szparaga, G., & Puchalski, M. (2024). Investigation of the Hydrolytic Degradation Kinetics of 3D-Printed PLA Structures under a Thermally Accelerated Regime. Materials, 17(5), 1043. https://doi.org/10.3390/ma17051043

.png)