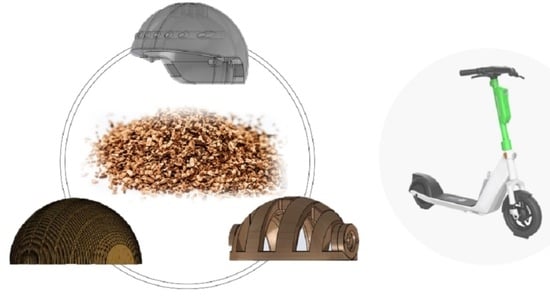

Pilot Study Investigating Effects of Changing Process Variables on Elastic and Energy-Absorbing Characteristics in Polyurethane/Agglomerated Cork Mix for Use in Micro-Transport Helmet

Abstract

:1. Introduction

2. Materials and Methods

2.1. Sample Preparation

2.2. Benchmarking Material Properties

2.3. Energy Absorption Testing

2.4. Compression Testing

3. Results

3.1. Energy Absorption

3.2. Young’s Modulus of Elasticity

3.3. Spring Constant

4. Discussion

4.1. Energy Absorption

4.2. Young’s Modulus of Elasticity

4.3. Spring Stiffness

4.4. Process Variables

4.5. Suitability for Micro-Transport Helmets

4.6. Limitations

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Brownson, A.B.; Fagan, P.V.; Dickson, S.; Civil, I.D. Electric scooter injuries at Auckland City Hospital. N. Z. Med. J. 2019, 132, 62–72. [Google Scholar] [PubMed]

- Auckland City Council. Rental e-Scooter Trial 2.0: Results, Evaluation and Recommendations; Auckland City Council: Auckland City, New Zealand, 2019; p. 77.

- Pérez-Zuriaga, A.M.; Dols, J.; Nespereira, M.; García, A.; Sajurjo-de-No, A. Analysis of the consequences of car to micromobility user side impact crashes. J. Saf. Res. 2023, 87, 168–175. [Google Scholar] [CrossRef] [PubMed]

- Posirisuk, P.; Baker, C.; Ghajari, M. Computational prediction of head-ground impact kinematics in e-scooter falls. Accid. Anal. Prev. 2022, 167, 106567. [Google Scholar] [CrossRef] [PubMed]

- Paudel, M.; Yap, F.F.; Binte Mohamed Rosli, T.; Tan, K.H.; Xu, H. A computational investigation of the dynamic factors governing severity of head injury to pedestrians involved in e-scooter collisions. Transp. Res. Interdiscip. Perspect. 2023, 22, 100972. [Google Scholar] [CrossRef]

- Wei, W.; Petit, Y.; Arnoux, P.-J.; Bailly, N. Head-ground impact conditions and helmet performance in E-scooter falls. Accid. Anal. Prev. 2023, 181, 106935. [Google Scholar] [CrossRef] [PubMed]

- United Kingdom Government. National Evaluation of e-Scooter Trials—Findings Report; Department of Transport, Ed.; United Kingdom Government: London, UK, 2022; p. 121.

- Kisun, H.; Hyunchan, K.; Mohammad, A.-R.; Seungmin, K. Designing Foldable Helmets for Micro-mobility using Sustainable Materials. Arch. Des. Res. 2023, 36, 129–143. [Google Scholar] [CrossRef]

- AS/NZS 2063:2020; Hemets for Use on Bicycles and Wheeled Recreational Devices. Standards Australia: Sydney, NSW, Australia, 2020; pp. 1–30.

- An, X.; Huang, B.; Shi, D. Cushioning properties and application of expanded polystyrene for a dynamic nonlinear system. Eng. Rep. 2023, 5, e12648. [Google Scholar] [CrossRef]

- Marten, B.; Hicks, A. Expanded Polystyrene Life Cycle Analysis Literature Review: An Analysis for Different Disposal Scenarios. Sustainability 2018, 11, 29–35. [Google Scholar] [CrossRef]

- Silva, S.P.; Sabino, M.A.; Fernandes, E.M.; Correlo, V.M.; Boesel, L.F.; Reis, R.L. Cork: Properties, capabilities and applications. Int. Mater. Rev. 2005, 50, 345–365. [Google Scholar] [CrossRef]

- Crouvisier-Urion, K.; Bellat, J.-P.; Gougeon, R.D.; Karbowiak, T. Mechanical properties of agglomerated cork stoppers for sparkling wines: Influence of adhesive and cork particle size. Compos. Struct. 2018, 203, 789–796. [Google Scholar] [CrossRef]

- Kaur, R.; Singh, P.; Tanwar, S.; Varshney, G.; Yadav, S. Assessment of Bio-Based Polyurethanes: Perspective on Applications and Bio-Degradation. Macromol 2022, 2, 284–314. [Google Scholar] [CrossRef]

- Antunes, A.; Pereira, J.; Paiva, N.; Ferra, J.; Martins, J.; Carvalho, L.; Barros-Timmons, A.; Magalhães, F.D. Effects of resin content on mechanical properties of cork-based panels bound with melamine-urea-formaldehyde and polyurethane binders. Int. J. Adhes. Adhes. 2020, 101, 102632. [Google Scholar] [CrossRef]

- Pereira, H.; Baptista, C. Influence of raw-material quality and process parameters in the production of insulation cork agglomerates. Holz Als Roh Und Werkst. 1993, 51, 301–308. [Google Scholar] [CrossRef]

- Kaczyński, P.; Ptak, M.; Fernandes, F.A.O.; Chybowski, L.; Wilhelm, J.; de Sousa, R.J.A. Development and Testing of Advanced Cork Composite Sandwiches for Energy-Absorbing Structures. Materials 2019, 12, 697. [Google Scholar] [CrossRef] [PubMed]

- Yuksel, O.; Sandberg, M.; Baran, I.; Ersoy, N.; Hattel, J.H.; Akkerman, R. Material characterization of a pultrusion specific and highly reactive polyurethane resin system: Elastic modulus, rheology, and reaction kinetics. Compos. Part B Eng. 2021, 207, 108543. [Google Scholar] [CrossRef]

- Suffo, M.; Sales, D.L.; Cortés-Triviño, E.; de la Mata, M.; Jiménez, E. Characterization and production of agglomerated cork stoppers for spirits based on a factor analysis method. Food Packag. Shelf Life 2022, 31, 100815. [Google Scholar] [CrossRef]

- Wang, X.; Yu, T.; Wu, Y.; Sheng, Y.; Wang, Y.; Hang, Y. Study on Mechanical Properties of Two-Component Polyurethane Based on Multi-Scale Molecular Simulation. Materials 2023, 16, 1006. [Google Scholar] [CrossRef] [PubMed]

- Lucio, B.; de la Fuente, J.L. Rheological cure characterization of an advanced functional polyurethane. Thermochim. Acta 2014, 596, 6–13. [Google Scholar] [CrossRef]

- Nasim, M.; Hasan, M.J.; Galvanetto, U. Impact behavior of energy absorbing helmet liners with PA12 lattice structures: A computational study. Int. J. Mech. Sci. 2022, 233, 107673. [Google Scholar] [CrossRef]

| Binder Mass (g) | Cork Mass (g) | Mix Ratio | Setting Force (kg) | Setting Pressure (kPa) | Curing Temperature (°C) |

|---|---|---|---|---|---|

| 3.5 | 5.0 | 0.7:1 | 1 | 5.3 | 40 |

| 3.5 | 5.0 | 0.7:1 | 2 | 10.6 | 40 |

| 3.5 | 5.0 | 0.7:1 | 5 | 26.5 | 40 |

| 3.5 | 5.0 | 0.7:1 | 1 | 5.3 | 50 |

| 3.5 | 5.0 | 0.7:1 | 2 | 10.6 | 50 |

| 3.5 | 5.0 | 0.7:1 | 5 | 26.5 | 50 |

| 3.5 | 5.0 | 0.7:1 | 1 | 5.3 | 70 |

| 3.5 | 5.0 | 0.7:1 | 2 | 10.6 | 70 |

| 3.5 | 5.0 | 0.7:1 | 5 | 26.5 | 70 |

| 5.0 | 5.0 | 1:1 | 1 | 5.3 | 40 |

| 5.0 | 5.0 | 1:1 | 2 | 10.6 | 40 |

| 5.0 | 5.0 | 1:1 | 5 | 26.5 | 40 |

| 5.0 | 5.0 | 1:1 | 1 | 5.3 | 50 |

| 5.0 | 5.0 | 1:1 | 2 | 10.6 | 50 |

| 5.0 | 5.0 | 1:1 | 5 | 26.5 | 50 |

| 5.0 | 5.0 | 1:1 | 1 | 5.3 | 70 |

| 5.0 | 5.0 | 1:1 | 2 | 10.6 | 70 |

| 5.0 | 5.0 | 1:1 | 5 | 26.5 | 70 |

| 7.5 | 5.0 | 1.5:1 | 1 | 5.3 | 40 |

| 7.5 | 5.0 | 1.5:1 | 2 | 10.6 | 40 |

| 7.5 | 5.0 | 1.5:1 | 5 | 26.5 | 40 |

| 7.5 | 5.0 | 1.5:1 | 1 | 5.3 | 50 |

| 7.5 | 5.0 | 1.5:1 | 2 | 10.6 | 50 |

| 7.5 | 5.0 | 1.5:1 | 5 | 26.5 | 50 |

| 7.5 | 5.0 | 1.5:1 | 1 | 5.3 | 70 |

| 7.5 | 5.0 | 1.5:1 | 2 | 10.6 | 70 |

| 7.5 | 5.0 | 1.5:1 | 5 | 26.5 | 70 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

White, D.E.; Kim, H.C.; Al-Rawi, M.; Yuan, X.; Sojan, T. Pilot Study Investigating Effects of Changing Process Variables on Elastic and Energy-Absorbing Characteristics in Polyurethane/Agglomerated Cork Mix for Use in Micro-Transport Helmet. Materials 2024, 17, 1925. https://doi.org/10.3390/ma17081925

White DE, Kim HC, Al-Rawi M, Yuan X, Sojan T. Pilot Study Investigating Effects of Changing Process Variables on Elastic and Energy-Absorbing Characteristics in Polyurethane/Agglomerated Cork Mix for Use in Micro-Transport Helmet. Materials. 2024; 17(8):1925. https://doi.org/10.3390/ma17081925

Chicago/Turabian StyleWhite, David E., Hyun Chan Kim, Mohammad Al-Rawi, Xiaowen Yuan, and Tony Sojan. 2024. "Pilot Study Investigating Effects of Changing Process Variables on Elastic and Energy-Absorbing Characteristics in Polyurethane/Agglomerated Cork Mix for Use in Micro-Transport Helmet" Materials 17, no. 8: 1925. https://doi.org/10.3390/ma17081925

APA StyleWhite, D. E., Kim, H. C., Al-Rawi, M., Yuan, X., & Sojan, T. (2024). Pilot Study Investigating Effects of Changing Process Variables on Elastic and Energy-Absorbing Characteristics in Polyurethane/Agglomerated Cork Mix for Use in Micro-Transport Helmet. Materials, 17(8), 1925. https://doi.org/10.3390/ma17081925