1. Introduction

Recently, Bi-based multiferroic materials have been attracting considerable attention because of their varied applications. BiFeO

3 is a well-known example of multiferroic material with a rhombohedrally distorted perovskite structure (space group:

R3

c). Displaying ferroelectric properties, BiFeO

3 has a high transition temperature (

TC) of 1100 K [

1] and exhibits very large spontaneous polarization (100–150 µC/cm

2) at room temperature (RT) [

2,

3]. With regard to magnetism, the magnetic transition temperature of BiFeO

3 is above RT (

TN = 653 K) [

4]; however, it is antiferromagnetic and has a

G-type spin configuration. In this configuration, the nearest neighboring Fe moments are aligned antiparallel to each other, and there is a six-fold degeneracy resulting in an effective “easy magnetization plane” for the orientation of the magnetic moments within the (111) plane. Owing to the Dzyaloshinskii-Moriya (DM) interaction, the symmetry allows for canting of the antiferromagnetic sublattices resulting in weak local spontaneous magnetization [

5], which is macroscopically canceled by the spiral spin structure in which the antiferromagnetic axis rotates through the crystal with an incommensurate long-wavelength period of 62 nm. This spiral spin structure might be suppressed in film form and magnetic moment due to a weak ferromagnetism of ~0.1 μ

B/Fe atom being observed. However, this small magnetic moment is not suitable for applications such as spintronics because weak magnetic moments and spin-filter effects are difficult to detect using a magnetic sensor. Recently, it was proposed that substitution of iron atoms at the

B sites with other 3

d transition atoms, such as cobalt, would result in a local ferrimagnetic spin configuration or the collapse of the spiral spin structure leading to macroscopic magnetization. Indeed, the magnetic moment has been reported to increase when the Fe atom in BiFeO

3 is replaced with Mn or Co atom [

6,

7,

8]. As a result, these materials are in growing demand for use in spintronics applications. In addition, magnetization increases with increasing Co substitution in the rhombohedral structure [

9]; the crystal symmetry changes from rhombohedral to tetragonal at 15–20 at.% of Co substitution [

10,

11]. Based on this information, in this study, 10 at.% Co-substituted BiFeO

3 was used. When used for spintronics applications such as multivalued memory that uses a spin-filter structure, a few-nanometer-thick high-quality film, a flat surface/interface, and good compatibility with the thin metal film process are required. The actual spin-filter structure designed by us consists of conductive La doped SrTiO

3 sub./Co-substituted BiFeO

3/AlO

x/metal magnetic layer/cap layer. The Co-substituted BiFeO

3 layer was prepared by heat treatment for crystalizing perovskite structure and AlO

x and the metal magnetic layer were deposited at ambient temperature to exclude interfacial oxidation. The schematic illustration of stacking structure of spin-filter device is shown in

Figure 1. Various methods for preparing Co-substituted BiFeO

3 epitaxial films, such as metalorganic chemical vapor deposition (MOCVD) [

10] and chemical solution deposition (CSD) [

11], have been reported. However, these chemical processes are not suitable for metal processes due to carbon impurities. One of the promising methods for preparing both oxides and metals layers are radio frequency (r.f.) sputtering [

12]. However, there is no report of Co-substituted BiFeO

3 thin epitaxial films fabricated by r.f. magnetron sputtering. The aim in this study is to determine the preparation conditions of single phase Co-substituted BiFeO

3 [Bi(Fe

0.9Co

0.1)O

3] epitaxial films on SrTiO

3 (100) substrates by conventional r.f. magnetron sputtering.

Figure 1.

Schematic illustration of stacking structure of spin-filter device using Bi(Fe0.9Co0.1)O3.

Figure 1.

Schematic illustration of stacking structure of spin-filter device using Bi(Fe0.9Co0.1)O3.

3. Results and Discussion

The films deposited by r.f. magnetron sputtering using Ar and Ar + O

2 gases at an ambient temperature had an amorphous and/or nanocrystalline structure. In order to crystallize the perovskite structure of Bi(Fe

0.9Co

0.1)O

3 films, the samples were annealed under both vacuum and air conditions at various temperatures. In the case of the samples annealed under vacuum conditions, secondary phases such as BiO

x were formed; therefore, the experimental data of the vacuum condition is not discussed in this paper.

Figure 2(a) shows the annealing temperature dependence of the θ/2θ XRD patterns for the Bi(Fe

0.9Co

0.1)O

3 films annealed in air. The Ar gas was used for sputtering. The formation of the perovskite structure in XRD patterns was identified by the high angle peak of (003) Bi(Fe

0.9Co

0.1)O

3, because the lattice mismatch decreased with increasing Co content. The films crystallized above the annealing temperature of 500 °C with a broad unknown peak of 2θ = 27° (indicated as blue-circle in

Figure 2(a)); however, the perovskite phase was not observed at 500 °C. After annealing at 600 °C, only the perovskite peaks of (003) Bi(Fe

0.9Co

0.1)O

3 was observed near the peaks of the (003) SrTiO

3 substrate. [

Figure 2(a)] At 700 °C, the secondary phases of BiO

x were observed, and the peak of the perovskite structure became weak. The dependence of phase formation on annealing temperature is almost the same as that of the CSD process [

13]; however; it is lower than that of the MOCVD method [

10].

Figure 2.

(a) X-ray diffraction (XRD) patterns for the Bi(Fe0.9Co0.1)O3 films annealed at different temperatures, (b) and (c) Ar and Ar + O2 (3:1) gas pressure dependence during sputtering, (d) Input power dependences of the XRD patterns at Ar gas pressure of 0.15 Pa annealed at 600 °C, and (e) Ar and Ar + O2 gas pressure dependence of the XRD peak intensity ratio of (200) Bi2O3/(003) Bi(Fe0.9Co0.1)O3. A single phase Bi(Fe0.9Co0.1)O3 film was formed with low Ar gas pressure and annealed at 600°C in air.

Figure 2.

(a) X-ray diffraction (XRD) patterns for the Bi(Fe0.9Co0.1)O3 films annealed at different temperatures, (b) and (c) Ar and Ar + O2 (3:1) gas pressure dependence during sputtering, (d) Input power dependences of the XRD patterns at Ar gas pressure of 0.15 Pa annealed at 600 °C, and (e) Ar and Ar + O2 gas pressure dependence of the XRD peak intensity ratio of (200) Bi2O3/(003) Bi(Fe0.9Co0.1)O3. A single phase Bi(Fe0.9Co0.1)O3 film was formed with low Ar gas pressure and annealed at 600°C in air.

The influence of a variety of gases and gas pressures on the formation of single phase Bi(Fe

0.9Co

0.1)O

3 films was also investigated.

Figure 2(b) and (c) show the Ar and Ar + O

2 gas pressure dependence of the XRD patterns. The annealing temperature was fixed at 600 °C in air because BiO

x of secondary phase has a tendency to suppress at 600 °C. Single phase Bi(Fe

0.9Co

0.1)O

3 films formed at low Ar gas pressure, and secondary phases of (220) Bi

2O

3 formed at 2θ = 32° when the gas pressure increased to 0.20 Pa. This tendency of gas pressure is roughly consistent with the case of BiFeO

3 films [

14,

15,

16]. In the case of Ar + O

2 gas, secondary phases of (220) Bi

2O

3 formed for all gas pressures [

Figure 2(c)].

Figure 2(d) shows the input power dependence of the XRD patterns with an Ar gas pressure of 0.15 Pa annealed at 600 °C. It was observed that the secondary phases of BiO

x increased with increasing input power. Therefore, low sputtering power is needed to obtain single phase Bi(Fe

0.9Co

0.1)O

3.

Figure 2(e) shows the Ar and Ar + O

2 gas pressure dependence of the XRD peak intensity ratio of (220) Bi

2O

3/ (003) Bi(Fe

0.9Co

0.1)O

3. For an Ar + O

2 gas pressure of 0.10 Pa [

Figure 2(c)], (220) Bi

2O

3 was not observed; therefore, an unknown XRD peak at 2θ = 35° was obtained as the secondary phase. The quantity of the secondary phase of Bi

2O

3 has a tendency to increase with increasing gas pressure. The sputtering conditions and optimal condition for obtaining single phase of Bi(Fe

0.9Co

0.1)O

3 film was summarized in

Table 1. From these results, it can be considered that the formation of single phase Bi(Fe

0.9Co

0.1)O

3 films was sensitive to preparation processes; the single phase formed at relatively low Ar gas pressure, low sputtering power, and post-annealing at 600 °C in air.

Table 1.

Sputtering parameters and optimal conditions for preparing single phase of Bi(Fe0.9Co0.1)O3. The symbol (*) indicates the parameter in which the single phase was observed.

Table 1.

Sputtering parameters and optimal conditions for preparing single phase of Bi(Fe0.9Co0.1)O3. The symbol (*) indicates the parameter in which the single phase was observed.

| Temperature (°C) | Ar+O2 gas pressure (Pa) | Ar gas pressure (Pa) | Input Power (W) |

|---|

| as-depo. | 0.10 | 0.10 | 10* |

| 500 | 0.15 | 0.15* | 15 |

| 600* | 0.20 | 0.20 | 20 |

| 700 | 0.25 | | |

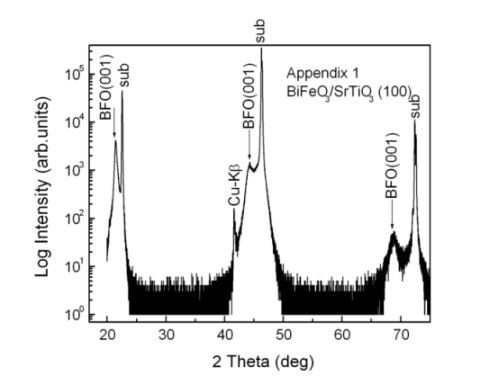

We confirmed that the single phase Bi(Fe

0.9Co

0.1)O

3 film prepared at an Ar gas pressure of 0.15 Pa and annealed at 600 °C in air contained an epitaxial structure.

Figure 3(a) shows the XRD profiles magnified around SrTiO

3 (003). The peak position of Bi(Fe

0.9Co

0.1)O

3 prepared by the CSD method is indicated as a dotted line [

11]. The XRD peak position of Bi(Fe

0.9Co

0.1)O

3 (003) was close to that previously reported, and the lattice parameter of a = 0.3948 nm in Bi(Fe

0.9Co

0.1)O

3 film was almost the same as that of Bi(Fe

0.9Co

0.1)O

3 film prepared by CSD method (a = 0.394 nm [

11]). However, the peak intensity is relatively weak.

Figure 3(b) shows the phi-scan measurement at Psi = 45° using the BiFeO

3 (202) and SrTiO

3 (202) peaks. We did not change sample configuration against beam line when measuring BiFeO

3 and SrTiO

3 layer. The peaks of Bi(Fe

0.9Co

0.1)O

3 were observed to be the same as that of SrTiO

3 substrate; this indicates that the Bi(Fe

0.9Co

0.1)O

3 films were epitaxially grown on the SrTiO

3 substrate with cube-on-cube: [001](001) Bi(Fe

0.9Co

0.1)O

3//[001](001) SrTiO

3.

The composition of Bi(Fe

0.9Co

0.1)O

3 film prepared at an Ar gas pressure of 0.15 Pa and annealed at 600 °C was confirmed by plan-view FE-SEM and SEM-EDX.

Figure 4 shows SEM image, and elementary mapping images of Bi, Fe, Co, and O, respectively, captured by SEM-EDX. The elemental mapping for each element did not show obvious agglomeration of elements, indicating that the larger impurity grains were not formed on surface of film. However, further investigation of smaller grains around the size of superparamagnetic limit of Co should be confirmed by transmission electron microscopy (TEM) observation.

Figure 3.

(

a) XRD profile around Bi(Fe

0.9Co

0.1)O

3 (300). The peak position of Bi(Fe

0.9Co

0.1)O

3 prepared by CSD method is indicated by the dotted line [

11]; (

b) phi-scan measurement at Psi = 45° using the BiFeO

3 (202) and SrTiO

3 (202) peaks.

Figure 3.

(

a) XRD profile around Bi(Fe

0.9Co

0.1)O

3 (300). The peak position of Bi(Fe

0.9Co

0.1)O

3 prepared by CSD method is indicated by the dotted line [

11]; (

b) phi-scan measurement at Psi = 45° using the BiFeO

3 (202) and SrTiO

3 (202) peaks.

Figure 4.

(a) SEM image, and elementary mapping images of (b) Bi, (c) Fe, (d) O, and (e) Co using SEM-EDX for single phase Bi(Fe0.9Co0.1)O3 epitaxial films.

Figure 4.

(a) SEM image, and elementary mapping images of (b) Bi, (c) Fe, (d) O, and (e) Co using SEM-EDX for single phase Bi(Fe0.9Co0.1)O3 epitaxial films.

The magnetic property of single phase Bi(Fe

0.9Co

0.1)O

3 epitaxial films was measured using the SQUID magnetometer at 300 K for the in-plane direction. The result is shown in

Figure 5(a) and

Figure 5(b). A saturation magnetization of 20 emu/cm

3 was observed along with a weak remanent magnetization. When compared with epitaxial and polycrystalline BiFeO

3 films, the magnetization was clearly enhanced. This magnetization might be attributed to local ferrimagnetism and/or suppression of long-range incommensurate spin cycloids and/or moderation of short-range canted

G-type antiferromagnetism. However, further investigation of the spin structure using X-ray magnetic circular dichroism (XMCD) and neutron diffraction analysis is necessary to understand the origin of the magnetism of Bi(Fe

0.9Co

0.1)O

3 films. In order to compare our results with previous works, we plotted magnetization values as a function of Co concentration.

Figure 5(c) shows Co concentration of magnetization measured at 30 and 50 kOe at 300 K for various preparation methods [

7,

9,

17]. A magnetization of 20 emu/cm

3 at a Co concentration of 10 at.% is almost consistent with previous reports that used a different preparation method. In accordance with the magneto-electric effect in the rhombohedral structure of BiFeO

3 [

18], the Bi(Fe

0.9Co

0.1)O

3 film is expected to display macroscopic magnetization changes in their electric field. We plan to study this in the future.

Figure 5.

(a) In-plane M-H hysteresis loop for single phase Bi(Fe0.9Co0.1)O3 films measured at 300 K and (b) Expanded view of Figure (a) (c) Different Co concentration dependence of magnetization measured at 30 and 50 kOe at 300 K for various preparation methods.

Figure 5.

(a) In-plane M-H hysteresis loop for single phase Bi(Fe0.9Co0.1)O3 films measured at 300 K and (b) Expanded view of Figure (a) (c) Different Co concentration dependence of magnetization measured at 30 and 50 kOe at 300 K for various preparation methods.