Properties of Cadmium-(bis)dodecylthiolate and Polymeric Composites Based on It

Abstract

:1. Introduction

2. Experimental Section

2.1. The Synthesis of Cadmium-(bis)dodecylthiolate

2.2. CHNS-Analysis of Cadmium-(bis)dodecylthiolate with General Formula Cd(C12H25S)2 and Molecular Weight of 514 Da

| Characteristics | Value |

|---|---|

| Found content, wt % | 41.1 |

| True content, wt % | 41.8 |

| s, wt % | 1 |

| ±δ, wt % | 0.7 |

| tp, f = n − 1 | 2.3 |

| tfound | 2.2 |

| Element | Theoretically Calculated Content of Elements in the Cadmium bis-(dodecylthiolate), wt % | Experimental Results of Elements Content in the Obtained Cd(SR)2, wt % |

|---|---|---|

| С | 56.03 | 55.9 ± 0.40 |

| H | 9.73 | 10.0 ± 0.40 |

| S | 12.45 | 12.49 ± 0.17 |

| Cd | 21.78 | 21.61 ± 0.40 |

2.3. Differential Scannig Calorymetry (DSC) and Thermogravimetric Analysis (TGA)

2.4. Synthesis of the Bulk Polymeric Samples Containing Cadmium-bis(dodecylthiolate)

2.5. Laser Processing of Samples and Study of Their Luminescent Properties

3. Results and Discussion

3.1. Thermophysical Characteristics of Cadmium-bis(dodecylthiolate)

3.2. Luminescence Properties of the Laser-Irradiated Cadmium-bis(dodecylthiolate)

| Way of Treatment | Description of PL Spectrum |

|---|---|

| Heating at 70 °C | Reversible transformation |

| Heating at 240 °C | Irreversible increase in PL signal with the maximum movement towards the longer wavelengths from 500 to 570 nm |

| Laser irradiation at 266 nm | Increase in PL signal with the maximum wavelength at 600–615 nm |

3.3. DSC and TG Characterizations of the Cd(C12H25S)2/PMMA Samples

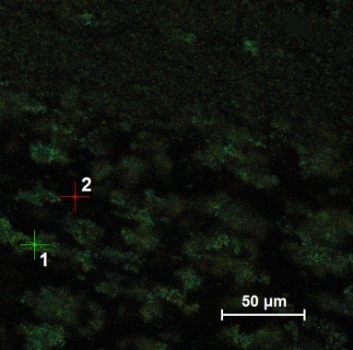

3.4. Luminescence Properties of the Laser-Irradiated Cd(C12H25S)2/PMMA Samples

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Bityurin, N.M. Laser Nanostructuring of Polymers. In Fundamentals of Laser-Assisted Micro- and Nanotechnologies; Veiko, V.P., Konov, V.I., Eds.; Springer International Publishing: Cham, Switzerland, 2014; pp. 293–314. [Google Scholar]

- Talapin, D.V.; Lee, J.-S.; Kovalenko, M.V.; Shevchenko, E.V. Prospects of colloidal nanocrystals for electronic and optoelectronic applications. Chem. Rev. 2010, 110, 389–458. [Google Scholar] [CrossRef] [PubMed]

- Alexandrov, A.; Smirnova, L.; Yakimovich, N.; Sapogova, N.; Soustov, L.; Kirsanov, A.; Bityurin, N. UV initiated growth of gold nanoparticles in PMMA matrix. Appl. Surf. Sci. 2005, 248, 181–184. [Google Scholar] [CrossRef]

- Yakimovich, N.O.; Sapogova, N.V.; Smirnova, L.A.; Aleksandrov, A.P.; Gracheva, T.A.; Kirsanov, A.V.; Bityurin, N.M. Gold-containing nanocomposition materials on the basis of homo- and copolymers of methylmethacrylate. Russ. J. Phys. Chem. B 2006, 2, 128–134. [Google Scholar]

- Bityurin, N.; Alexandrov, A.; Afanasiev, A.; Agareva, N.; Pikulin, A.; Sapogova, N.; Soustov, L.; Salomatina, E.; Gorshkova, E.; Tsverova, N.; et al. Photoinduced nanocomposites—Creation, modification, linear and nonlinear optical properties. Appl. Phys. A 2013, 112, 135–138. [Google Scholar] [CrossRef]

- Malik, M.A.; Afzaal, M.; O’Brien, P. Precursor chemistry for main group elements in semiconducting materials. Chem. Rev. 2010, 110, 4417–4446. [Google Scholar] [CrossRef] [PubMed]

- Brennan, J.G.; Siegrist, T.; Carroll, P.J.; Stuczynski, S.M.; Reynders, P.; Brus, L.E.; Steigerwald, M.L. Bulk and nanostructure group II-VI compounds from molecular organometallic precursors. Chem. Mater. 1990, 2, 403–409. [Google Scholar] [CrossRef]

- Antolini, F.; Di Luccio, T.; Laera, A.M.; Mirenghi, L.; Piscopello, E.; Re, M.; Tapfler, L. Direct synthesis of II-VI compound nanocrystals in polymer matrix. Phys. Stat. Sol. B 2007, 244, 2768–2781. [Google Scholar] [CrossRef]

- Antolini, F.; Burresi, E.; Stroea, L.; Morandi, V.; Ortolani, L.; Accorsi, G.; Blosi, M. Time and temperature dependence of CdS nanoparticles grown in a polystyrene matrix. J. Nanomater. 2012. [Google Scholar] [CrossRef]

- Sun, Z.-B.; Dong, X.-Z.; Chen, W.-Q.; Nakanishi, S.; Duan, X.-M.; Kawata, S. Multicolor polymer nanocomposites: In situ synthesis and fabrication of 3D microstructures. Adv. Mater. 2008, 20, 914–919. [Google Scholar] [CrossRef]

- Antolini, F.; Ghezelbash, A.; Eposito, C.; Trave, E.; Tapfer, L.; Korgel, B.A. Laser-induced nanocomposite formation for printed nanoelectronics. Mater. Lett. 2006, 60, 1095–1098. [Google Scholar] [CrossRef]

- Athanassiou, A.; Cingolani, R.; Tsiranidou, E.; Fotakis, C.; Laera, A.M.; Piscopiello, E.; Tapfer, L. Photon-induced formation of CdS nanocrystals in selected areas of polymer matrices. Appl. Phys. Lett. 2007, 91. [Google Scholar] [CrossRef]

- Fragouli, D.; Laera, A.M.; Caputo, G.; Resta, V.; Pompa, P.P.; Tapfer, L.; Cingolani, R.; Athanassiou, A. The effect of polymer matrices in the in-situ CdS formation under UV irradiation of precursor-polymer films. J. Nanosci. Nanotechnol. 2010, 10, 1267–1272. [Google Scholar] [CrossRef] [PubMed]

- Fragouli, D.; Resta, V.; Pompa, P.P.; Laera, A.M.; Caputo, G.; Tapfer, L.; Cingolani, R.; Athanassiou, A. Patterned structures of in situ size controlled CdS nanocrystals in a polymer matrix under UV irradiation. Nanotechnology 2009, 20. [Google Scholar] [CrossRef] [PubMed]

- Bansal, A.K.; Antolini, F.; Sajjad, M.T.; Stroea, L.; Mazzaro, R.; Ramkumar, S.G.; Kass, K.-J.; Allard, S.; Scherf, U.; Samuel, I.D.W. Photophysical and structural characterization of in situ formed quantum dots. Phys. Chem. Chem. Phys. 2014, 16, 9556–9564. [Google Scholar] [CrossRef] [PubMed]

- Resta, V.; Laera, A.M.; Camposeo, A.; Piscopiello, E.; Persano, L.; Pisignano, D.; Tapfer, L. Spatially confined CdS NCs in situ synthesis through laser irradiation of suitable unimolecular precursor-doped polymer. J. Phys. Chem. C 2012, 116, 25119–25125. [Google Scholar] [CrossRef]

- Onwudiwe, D.C.; Kruger, T.P.J.; Strydom, C.A. Laser assisted solid state reaction for the synthesis of ZnS and CdS nanoparticles from metal xanthate. Mater. Lett. 2014, 116, 154–159. [Google Scholar] [CrossRef]

- Khanna, P.K.; Singh, N. Light emitting CdS quantum dots in PMMA: Synthesis and optical studies. J. Lumin. 2007, 127, 474–482. [Google Scholar] [CrossRef]

- Li, X.; Bullen, C.; Chon, J.W.M.; Evans, R.A.; Gu, M. Two-photon-induced three-dimensional optical data storage in CdS quantum-dot doped photopolymer. Appl. Phys. Lett. 2007, 90. [Google Scholar] [CrossRef]

- Carotenuto, G.; Martorana, B.; Perlo, P.; Nicolais, L. A universal method for the synthesis of metal and metal sulfide clusters embedded in polymer matrices. J. Mater. Chem. 2003, 13, 2927–2930. [Google Scholar] [CrossRef]

- Eurachem/CITAC Guide: Quantifying Uncertainty in Analytical Measurement, 2nd ed.; Ellison, S.L.R.; Roesslein, M.; Williams, A. (Eds.) Eurachem/CITAC: London, UK, 2000.

- Höhne, G.W.H.; Hemminger, W.F.; Flammersheim, H.-J. Differential Scanning Calorimetry, 2nd ed.; Springer: Heidelberg, Germany, 2003. [Google Scholar]

- Drebushchak, V.A. Calibration coefficient of heat-flow DSC. Part II. Optimal calibration procedure. J. Therm. Anal. Cal. 2005, 79, 213–218. [Google Scholar] [CrossRef]

- Fox, D.; Labes, M.M.; Weissberger, A. Physics and Chemistry of Organic Solid State; Wiley: Hoboken, NJ, USA, 1965; Volume 1. [Google Scholar]

- Woggon, U. Optical Properties of Semiconductor Quantum Dots; Springer-Verlag: Berlin, Germany, 1997. [Google Scholar]

- Veamatahau, A.; Jiang, B.; Seifert, T.; Makuta, S.; Latham, K.; Kanehara, M.; Teranishi, T.; Tachibana, Y. Origin of surface trap states in CdS quantum dots: Relationship between size dependent photoluminescence and sulfur vacancy trap states. Phys. Chem. Chem. Phys. 2015, 17, 2850–2858. [Google Scholar] [CrossRef] [PubMed]

© 2015 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons by Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Agareva, N.; Smirnov, A.A.; Afanasiev, A.; Sologubov, S.; Markin, A.; Salomatina, E.; Smirnova, L.; Bityurin, N. Properties of Cadmium-(bis)dodecylthiolate and Polymeric Composites Based on It. Materials 2015, 8, 8691-8700. https://doi.org/10.3390/ma8125487

Agareva N, Smirnov AA, Afanasiev A, Sologubov S, Markin A, Salomatina E, Smirnova L, Bityurin N. Properties of Cadmium-(bis)dodecylthiolate and Polymeric Composites Based on It. Materials. 2015; 8(12):8691-8700. https://doi.org/10.3390/ma8125487

Chicago/Turabian StyleAgareva, Nadezhda, Anton A. Smirnov, Andrey Afanasiev, Semen Sologubov, Alexey Markin, Evgenia Salomatina, Larisa Smirnova, and Nikita Bityurin. 2015. "Properties of Cadmium-(bis)dodecylthiolate and Polymeric Composites Based on It" Materials 8, no. 12: 8691-8700. https://doi.org/10.3390/ma8125487

APA StyleAgareva, N., Smirnov, A. A., Afanasiev, A., Sologubov, S., Markin, A., Salomatina, E., Smirnova, L., & Bityurin, N. (2015). Properties of Cadmium-(bis)dodecylthiolate and Polymeric Composites Based on It. Materials, 8(12), 8691-8700. https://doi.org/10.3390/ma8125487