Microstructural and Mechanical Properties of Alkali Activated Colombian Raw Materials

Abstract

:1. Introduction

2. Experimental

2.1. Materials

2.2. Alkali Activation of the Mixtures

2.3. Techniques

2.4. Compressive Strength, Young's Modulus and Poisson’s Ratio

3. Results and Discussion

3.1. Characterization of the Starting Materials

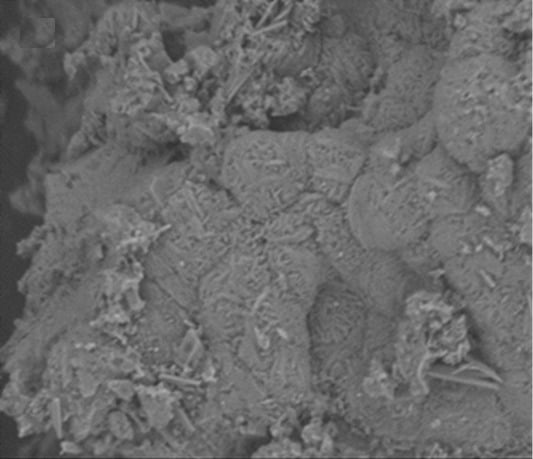

3.2. Mineralogical and Microstructural Characterization of the Alkali-Activated Binders

3.3. Mechanical Characterization of the Alkali-Activated Binders

4. Summary and Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- The Global Cement Report, 11st ed.; International Cement review: London, UK, 2015.

- Gartner, E. Industrially interesting approaches to low CO2 cements. Cem. Concr. Res. 2004, 34, 1489–1498. [Google Scholar] [CrossRef]

- Hendriks, C.A.; Worrel, E.; Price, L.; Martin, N.; Ozawa, M.; Riemer, P. Emission reduction of green house gases from the cement industry. In Proceedings of the 4th International Conference on Green House Gas Control Technologies, Interlaken, Austria, 30 August–2 September 1998.

- Palomo, A.; Grutzeck, M.W.; Blanco, M.T. Alkali-activated fly ashes: A cement for the future. Cem. Concr. Res. 1999, 29, 1323–1329. [Google Scholar] [CrossRef]

- Hardjito, D.; Wallah, S.E.; Sumajouw, D.M.J.; Rangan, B.V. On the development of fly ash-based geopolymer concrete. ACI Mater. J. 2004, 101, 467–472. [Google Scholar]

- Bakharev, T. Geopolymeric materials prepared using class F fly ash and elevated temperature curing. Cem. Concr. Res. 2005, 35, 1224–1232. [Google Scholar] [CrossRef]

- Criado, M.; Fernández-Jiménez, A.; Palomo, A. Alkali activation of fly ash: Effect of the SiO2/Na2O ratio: Part I: FTIR study. Microporous Mesoporous Mater. 2007, 106, 180–191. [Google Scholar] [CrossRef]

- Ma, Y.; Hu, J.; Ye, G. The pore structure and permeability of alkali activated fly ash. Fuel 2013, 104, 771–780. [Google Scholar] [CrossRef]

- Bakharev, T.; Sanjayan, J.G.; Cheng, Y.B. Effect of elevated temperature curing on properties of alkali-activated slag concrete. Cem. Concr. Res. 1999, 29, 1619–1625. [Google Scholar] [CrossRef]

- Puertas, F.; Fernández-Jiménez, A.; Blanco-Varela, M.T. Pore solution in alkali-activated slag cement pastes. Relation to the composition and structure of calcium silicate hydrate. Cem. Concr. Res. 2004, 34, 139–148. [Google Scholar] [CrossRef]

- Palacios, M.; Puertas, F. Effect of carbonation on alkali-activated slag paste. J. Am. Ceram. Soc. 2006, 89, 3211–3221. [Google Scholar] [CrossRef]

- Aydin, S.; Baradan, B. Mechanical and microstructural properties of heat cured alkali-activated slag mortars. Mater. Des. 2012, 35, 374–383. [Google Scholar] [CrossRef]

- Chi, M. Effects of dosage of alkali-activated solution and curing conditions on the properties and durability of alkali-activated slag concrete. Constr. Build. Mater. 2012, 35, 240–245. [Google Scholar] [CrossRef]

- Oh, J.E.; Monteiro, P.J.M.; Jun, S.S.; Choi, S.; Clark, S.M. The evolution of strength and crystalline phases for alkali-activated ground blast furnace slag and fly ash-based geopolymers. Cem. Concr. Res. 2010, 40, 189–196. [Google Scholar] [CrossRef]

- Lee, N.K.; Lee, H.K. Setting and mechanical properties of alkali-activated fly ash/slag concrete manufactured at room temperature. Constr. Build. Mater. 2013, 47, 1201–1209. [Google Scholar] [CrossRef]

- Chithiraputhiran, S.; Neithalath, N. Isothermal reaction kinetics and temperature dependence of alkali activation of slag, fly ash and their blends. Constr. Build. Mater. 2013, 45, 233–242. [Google Scholar] [CrossRef]

- Lee, N.K.; Jang, J.G.; Lee, H.K. Shrinkage characteristics of alkali-activated fly ash/slag paste and mortar at early ages. Cem. Concr. Compos. 2014, 53, 239–248. [Google Scholar] [CrossRef]

- Wang, W.-C.; Wang, H.-Y.; Lo, M.-H. The fresh and engineering properties of alkali activated slag as a function of fly ash replacement and alkali concentration. Construc. Build. Mater. 2015, 84, 224–229. [Google Scholar] [CrossRef]

- Gao, X.; Yu, Q.L.; Brouwers, H.J.H. Reaction kinetics, gel character and strength of ambient temperature cured alkali activated slag-fly ash blends. Construc. Build. Mater. 2015, 80, 105–115. [Google Scholar] [CrossRef]

- Van Jaarsveld, J.G.S.; van Deventer, J.S.J.; Luckey, G.C. The effect of composition and temperature on the properties of fly ash- and kaolinite-based geopolymers. Chem. Eng. J. 2002, 89, 63–73. [Google Scholar] [CrossRef]

- Fernández-Jiménez, A.; Palomo, A. Characterization of fly ashes. Potential reactivity as alkaline cements. Fuel 2003, 82, 2259–2265. [Google Scholar] [CrossRef]

- Kumar, S.; Kumar, R.; Mehrotra, S.P. Influence of granulated blast furnace slag on the reaction, structure and properties of fly ash based geopolymer. Ceram. Int. 2011, 37, 533–541. [Google Scholar] [CrossRef]

- Nath, S.K.; Kumar, S. Influence of iron making slags on strength and microstructure of fly ash geopolymer. Constr. Build. Mater. 2013, 38, 924–930. [Google Scholar] [CrossRef]

- Chi, M.; Huang, R. Binding mechanism and properties of alkali-activated fly ash/slag mortars. Constr. Build. Mater. 2013, 40, 291–298. [Google Scholar] [CrossRef]

- Rashad, A.M. Properties of alkali-activated fly ash concrete blend with slag. Iran J. Mater. Sci. Eng. 2013, 10, 57–64. [Google Scholar]

- Marjanović, N.; Komljenović, M.; Baščarević, Z.; Nikolić, V.; Petrović, R. Physical-mechanical and microstructural properties of alkali-activated fly ash-blast furnace slag blends. Ceram. Inter. 2015, 41, 1421–1435. [Google Scholar] [CrossRef]

- Olivia, M.; Nikraz, H. Properties of fly ash geopolymer concrete designed by Taguchi model. Mater. Des. 2012, 36, 191–198. [Google Scholar] [CrossRef]

- Sofi, M.; van Deventer, J.S.J.; Mendis, P.A.; Luckey, G.C. Engineering properties of inorganic polymeric concretes. Cem. Concr. Res. 2007, 37, 251–257. [Google Scholar] [CrossRef]

- Diaz-Loya, E.I.; Allouche, E.N.; Vaidya, S. Mechanical properties of fly ash-based geopolymer concrete. ACI Mater. J. 2011, 108, 300–306. [Google Scholar]

- Massiot, D.; Fayon, F.; Capron, M.; King, I.; Le Calvé, S.; Alonso, B.; Durand, J.O.; Bujoli, B.; Gan, Z.; Hoatson, G. Modelling one- and two-dimensional solid-state NMR spectra. Magn. Reson. Chem. 2002, 40, 70–76. [Google Scholar] [CrossRef]

- Standard Test Method for Compressive Strength of Cylindrical Concrete Specimens; ASTM C39/C39M-15A; ASTM: West Conshohocken, PA, USA, 2015.

- Standard Test Method for Static Modulus of Elasticity and Poisson’s Ratio of Concrete in Compression; ASTM C469/C469M-14; ASTM: West Conshohocken, PA, USA, 2014.

- Ravikumar, D.; Neithalath, N. Effects of activator characteristics on the reaction product formation in slag binders activated using alkali silicate powder and NaOH. Cem. Concr. Compos. 2012, 34, 809–818. [Google Scholar] [CrossRef]

- Criado, M.; Fernández Jiménez, A.; Sobrados, I.; Palomo, A.; Sanz, J. Effect of relative humidity on the reaction products of alkali activated fly ash. J. Eur. Ceram. Soc. 2012, 32, 2799–2807. [Google Scholar] [CrossRef]

- Gadsden, J.A. Infrared Spectra of Minerals and Related Inorganic Compounds; Butterworths: London, UK, 1975. [Google Scholar]

- Jin, X.-H.; Gao, L.; Guo, J.K. The structural change of diphasic mullite gel studied by XRD and IR spectrum analysis. J. Eur. Ceram. Soc. 2002, 22, 1307–1311. [Google Scholar] [CrossRef]

- Klinowski, J. Nuclear magnetic resonance studies of zeolites. Prog. NMR Spectr. 1984, 16, 237–309. [Google Scholar] [CrossRef]

- Engelhardt, G.; Michel, D. High Resolution Solid State NMR of Silicates and Zeolite; Wiley: London, UK, 1987. [Google Scholar]

- Colomdet, P.; Grimmer, A.R. Application of NMR Spectroscopy to Cement Science; Gordon and Breach Science Publishers: London, UK, 1994. [Google Scholar]

- Puertas, F.; Torres-Carrasco, M. Use of glass waste as an activator in the preparation of alkali-activated slag. Mechanical strength and paste characterization. Cem. Concr. Res. 2014, 57, 95–104. [Google Scholar] [CrossRef]

- Gomes, S.; François, M. Characterization of mullite in silicoaluminous fly ash by XRD, TEM, and 29Si MAS NMR. Cem. Concr. Res. 2000, 30, 175–181. [Google Scholar] [CrossRef]

- He, H.; Guo, J.; Zhu, J.; Yuan, P. 29Si and 27Al MAS NMR spectra of mullites from different kaolinites. Spectrochim. Acta A 2004, 60, 1061–1064. [Google Scholar] [CrossRef]

- Criado, M.; Fernández-Jiménez, A.; de la Torre, A.G.; Aranda, M.A.G.; Palomo, A. An XRD study of the effect of the SiO2/Na2O ratio on the alkali activation of fly ash. Cem. Concr. Res. 2007, 37, 671–679. [Google Scholar] [CrossRef]

- Puertas, F.; Fernández-Jiménez, A. Mineralogical and microstructural characterisation of alkali-activated fly ash/slag pastes. Cem. Concr. Compos. 2003, 25, 287–292. [Google Scholar] [CrossRef]

- Onisei, S.; Pontikes, Y.; Van Gerven, T.; Angelopoulos, G.N.; Velea, T.; Predica, V.; Moldovan, P. Synthesis of inorganic polymers using fly ash and primary lead slag. J. Hazard Mater. 2012, 205–206, 101–110. [Google Scholar] [CrossRef] [PubMed]

- Clayden, N.J.; Esposito, S.; Aronne, A.; Pernice, P. Solid state 27Al NMR and FTIR study of lanthanum aluminosilicate glasses. J. Non Cryst. Solids 1999, 258, 11–19. [Google Scholar] [CrossRef]

- Lee, N.K.; Lee, H.K. Reactivity and reaction products of alkali-activated, fly ash/slag paste. Constr. Build. Mater. 2015, 81, 303–312. [Google Scholar] [CrossRef]

- García-Lodeiro, I.; Fernández-Jiménez, A.; Palomo, A. Variation in hybrid cements over time. Alkaline activation of fly ash-portland cement blends. Cem. Concr. Res. 2013, 52, 112–122. [Google Scholar] [CrossRef]

- Ismail, I.; Bernal, S.A.; Provis, J.L.; San Nicolas, R.; Hamdan, S.; van Deventer, J.S.J. Modification of phase evolution in alkali-activated blast furnace slag by the incorporation of fly ash. Cem. Concr. Compos. 2014, 45, 125–135. [Google Scholar] [CrossRef]

- Bernal, S.A.; Provis, J.L.; Walkley, B.; San Nicolas, R.; Gehman, J.D.; Brice, D.G.; Kilcullen, A.R.; Duxson, P.; van Deventer, J.S.J. Gel nanostructure in alkali-activated binders based on slag and fly ash, and effects of accelerated carbonation. Cem. Concr. Res. 2013, 53, 127–144. [Google Scholar] [CrossRef]

- Criado, M.; Fernández-Jiménez, A.; Palomo, A.; Sobrados, I.; Sanz, J. Effect of the SiO2/Na2O ratio on the alkali activation of fly ash. Part II: 29Si MAS-NMR Survey. Microporous Mesoporous Mater. 2008, 109, 525–534. [Google Scholar] [CrossRef]

- Criado, M.; Fernández-Jiménez, A.; Palomo, A. Alkali activation of fly ash. Part III: Effect of curing conditions on reaction and its graphical description. Fuel 2010, 89, 3185–3192. [Google Scholar] [CrossRef]

- Ruiz-Santaquiteria, C.; Skibsted, J.; Fernández-Jiménez, A.; Palomo, A. Alkaline solution/binder ratio as a determining factor in the alkaline activation of aluminosilicates. Cem. Concr. Res. 2012, 42, 1242–1251. [Google Scholar] [CrossRef]

- Gonzalez-Carreo, T.; Sobrados, I.; Sanz, J. Formation of mullite and spinel phases from SiO2−Al2O3 gels prepared by a spray pyrolysis technique. A 29Si and 27Al MAS NMR study. Chem. Mater. 2007, 19, 3694–3703. [Google Scholar] [CrossRef]

| Material | L.o.I a | SiO2 | Al2O3 | Fe2O3 | CaO | MgO | SO3 | MnO | K2O | P2O5 |

| FA | 4.93 | 60.6 | 22.9 | 6.8 | 1.0 | 0.6 | --- | --- | 1.5 | 0.4 |

| GBFS | 0.95 | 34.8 | 15.5 | 2.4 | 37.4 | 2.3 | 1.4 | 3.8 | 0.4 | 0.2 |

| Material | Cl | TiO2 | V2O5 | Rb2O | SrO | ZrO | Cr2O3 | CuO | ZnO | --- |

| FA | --- | 1.0 | --- | --- | 0.07 | 0.02 | 0.03 | 0.02 | 0.02 | --- |

| GBFS | 0.06 | 0.5 | 0.06 | 0.04 | 0.07 | 0.02 | --- | --- | --- | --- |

| Sample | Binder Material |

|---|---|

| F0S10 | 100% granulated blast-furnace slag |

| F10S0 | 100% fly ash |

| F2S8 | 20% fly ash and 80% slag |

| F4S6 | 40% fly ash and 60% slag |

| F6S4 | 60% fly ash and 40% slag |

| F8S2 | 80% fly ash and 20% slag |

| Blend | Si | Al | Na | Ca | Si/Al | Ca/Si | Al/Ca |

|---|---|---|---|---|---|---|---|

| F0S10 | 13.41 ± 0.32 | 5.27 ± 0.15 | 10.66 ± 0.13 | 10.80 ± 0.17 | 2.55 ± 0.13 | 0.80 ± 0.01 | 0.49 ± 0.02 |

| F10S0 | 22.64 ± 1.14 | 9.50 ± 0.34 | 10.40 ± 0.08 | 0.47 ± 0.13 | 2.39 ± 0.20 | 0.02 ± 0.00 | 20.94 ± 6.64 |

| F2S8 | 15.58 ± 1.12 | 6.93 ± 1.59 | 9.88 ± 0.12 | 6.64 ± 0.29 | 2.25 ± 0.59 | 0.43 ± 0.09 | 1.04 ± 0.68 |

| F4S6 | 15.46 ± 2.87 | 7.52 ± 1.01 | 9.11 ± 2.71 | 5.81 ± 2.09 | 2.05 ± 0.66 | 0.37 ± 0.21 | 1.29 ± 0.31 |

| F6S4 | 16.81 ± 0.08 | 8.50 ± 0.20 | 11.40 ± 1.11 | 5.49 ± 1.89 | 1.98 ± 0.05 | 0.33 ± 0.11 | 1.55 ± 0.61 |

| F8S2 | 16.76 ± 0.90 | 9.37 ± 1.29 | 10.73 ± 0.32 | 4.57 ± 1.20 | 1.79 ± 0.15 | 0.27 ± 0.09 | 2.05 ± 0.85 |

| Mixtures | Raw Slag | End of Chain | C-A-S-H Gel | N-A-S-H Gel | Phases of Silica | |||||||||

| Q0 | Q1 | Q1 | Q1 | Q2(1Al) | Q2(0Al) | Q3(1Al) | Q4(4Al) | Q4(3Al) | Q4(2Al) | Q4(1Al) | Q4(0Al) | Q4(0Al) | ||

| F0S10 | Maximum of the spectrum (ppm) | −70.6 | −75.5 | --- | −79.8 | −82.6 | −87.0 | −91.6 | --- | −104.9 | ||||

| Width | 5.79 | 5.79 | 5.79 | 5.79 | 5.79 | 5.79 | 5.79 | |||||||

| Intermediate (%) | 7.70 | 12.11 | 20.96 | 30.04 | 14.01 | 9.55 | 5.63 | |||||||

| F10S0 | Maximum of the spectrum. (ppm) | --- | −79.8 | --- | −86.9 | −92.4 | −97.3 | −102.4 | −108.4 | −115.6 | ||||

| Width | 6.35 | 6.35 | 6.35 | 6.35 | 6.35 | 6.35 | 6.35 | |||||||

| Intermediate. (%) | 6.70 | 18.66 | 21.36 | 18.20 | 13.72 | 14.67 | 6.69 | |||||||

| F2S8 | Maximum of the spectrum. (ppm) | −72.1 | --- | −76.5 | −80.7 | −85.7 | −90.2 | --- | −93.6 | −99.2 | −104.9 | --- | --- | |

| Width | 5.41 | 5.41 | 5.41 | 5.41 | 5.41 | --- | 5.41 | 5.41 | 5.41 | --- | --- | |||

| Intermediate. (%) | 3.80 | 5.00 | 14.63 | 42.81 | 10.62 | --- | 11.30 | 5.97 | 5.87 | --- | --- | |||

| F4S6 | Maximum of the spectrum. (ppm) | −71.8 | --- | −77.4 | −81.1 | −85.7 | −90.4 | --- | −94.8 | −99.1 | −103.6 | −107.7 | --- | |

| Width | 5.15 | 5.15 | 5.15 | 5.15 | 5.15 | --- | 5.15 | 5.15 | 5.15 | 5.15 | --- | |||

| Intermediate. (%) | 4.59 | 5.45 | 13.59 | 28.49 | 17.62 | --- | 11.32 | 8.37 | 4.70 | 5.86 | --- | |||

| F6S4 | Maximum of the spectrum. (ppm) | −72.1 | --- | −77.2 | −81.9 | −85.9 | --- | −90.3 | −94.1 | −98.9 | −103.9 | −107.4 | −111.5 | |

| Width | 5.22 | 5.22 | 5.22 | 5.22 | --- | 5.22 | 5.22 | 5.22 | 5.22 | 5.22 | 5.22 | |||

| Intermediate. (%) | 5.13 | 7.07 | 12.37 | 20.77 | --- | 13.92 | 11.88 | 12.05 | 5.22 | 6.49 | 5.11 | |||

| F8S2 | Maximum of the spectrum. (ppm) | --- | --- | −77.9 | −83.5 | --- | --- | −88.1 | −93.7 | −98.6 | −103.1 | −108.6 | −115.3 | |

| Width | 5.98 | 5.98 | --- | --- | 5.98 | 5.98 | 5.98 | 5.98 | 5.98 | 5.98 | ||||

| Intermediate. (%) | 4.43 | 10.81 | --- | --- | 19.97 | 19.33 | 11.03 | 11.25 | 14.20 | 8.98 | ||||

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons by Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Criado, M.; Aperador, W.; Sobrados, I. Microstructural and Mechanical Properties of Alkali Activated Colombian Raw Materials. Materials 2016, 9, 158. https://doi.org/10.3390/ma9030158

Criado M, Aperador W, Sobrados I. Microstructural and Mechanical Properties of Alkali Activated Colombian Raw Materials. Materials. 2016; 9(3):158. https://doi.org/10.3390/ma9030158

Chicago/Turabian StyleCriado, Maria, Willian Aperador, and Isabel Sobrados. 2016. "Microstructural and Mechanical Properties of Alkali Activated Colombian Raw Materials" Materials 9, no. 3: 158. https://doi.org/10.3390/ma9030158

APA StyleCriado, M., Aperador, W., & Sobrados, I. (2016). Microstructural and Mechanical Properties of Alkali Activated Colombian Raw Materials. Materials, 9(3), 158. https://doi.org/10.3390/ma9030158