In Vitro Evaluation and Mechanism Analysis of the Fiber Shedding Property of Textile Pile Debridement Materials

Abstract

:1. Introduction

2. Results and Discussion

2.1. Microstructure

2.2. Surface Chemistry Analysis

2.3. Fabric and Pile Weight per Unit Area

2.4. Characterizations of the Ground Fabric

2.4.1. Morphology Observation

2.4.2. Surface Yarn Coverage

2.4.3. Distribution of the Stitch Size

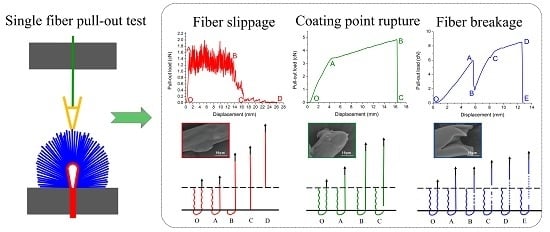

2.5. Single Fiber Pull-Out Test

2.5.1. Influence of Structures on the Single Fiber Pull-Out Force

Pile Density

Number of Ground Yarns

Back-Coating

2.5.2. Mechanism Analysis

Samples without Back-Coating

Samples with Back-Coating

3. Materials and Methods

3.1. Materials

3.2. Design and Fabrication of the Textile Pile Debridement Material

3.3. Microstructure

3.4. Surface Chemistry Analysis

3.5. Fabric and Pile Weight per Unit Area

3.6. Characterizations of the Ground Fabric

3.6.1. Morphology Observation

3.6.2. Surface Yarn Coverage

3.6.3. Distribution of the Stitch Size

3.7. Single Fiber Pull-Out Test

3.8. Statistical Analysis

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Sen, C.K.; Gordillo, G.M.; Roy, S.; Kirsner, R.; Lambert, L.; Hunt, T.K.; Gottrup, F.; Gurtner, G.C.; Longaker, M.T. Human skin wounds: A major and snowballing threat to public health and the economy. Wound Repair Regen. 2009, 17, 763–771. [Google Scholar] [CrossRef] [PubMed]

- Ojeh, N.; Pastar, I.; Tomic-Canic, M.; Stojadinovic, O. Stem cells in skin regeneration, wound healing, and their clinical applications. Int. J. Mol. Sci. 2015, 16, 25476–25501. [Google Scholar] [CrossRef] [PubMed]

- Dill-Muller, D.; Tilgen, W. Established and current procedures in wound healing. Hautarzt 2005, 56, 411–422. [Google Scholar] [PubMed]

- Attinger, C.E.; Janis, J.E.; Steinberg, J.; Schwartz, J.; Al-Attar, A.; Couch, K.A. Clinical approach to wounds: Debridement and wound bed preparation including the use of dressings and wound-healing adjuvants. Plast. Reconstr. Surg. 2006, 117, 72S–109S. [Google Scholar] [CrossRef] [PubMed]

- Moreo, K. Understanding and overcoming the challenges of effective case management for patients with chronic wounds. Case Manag. 2005, 16, 62–67. [Google Scholar] [CrossRef] [PubMed]

- Mustoe, T. Understanding chronic wounds: A unifying hypothesis on their pathogenesis and implications for therapy. Am. J. Surg. 2004, 187, 65S–70S. [Google Scholar] [CrossRef]

- Markova, A.; Mostow, E.N. Us skin disease assessment: Ulcer and wound care. Dermatol. Clin. 2012, 30, 107–111. [Google Scholar] [CrossRef] [PubMed]

- Granick, M.; Boykin, J.; Gamelli, R.; Schultz, G.; Tenenhaus, M. Toward a common language: Surgical wound bed preparation and debridement. Wound Repair Regen. 2006, 14, S1–S10. [Google Scholar] [CrossRef] [PubMed]

- Schultz, G.S.; Sibbald, R.G.; Falanga, V.; Ayello, E.A.; Dowsett, C.; Harding, K.; Romanelli, M.; Stacey, M.C.; Teot, L.; Vanscheidt, W. Wound bed preparation: A systematic approach to wound management. Wound Repair Regen. 2003, 11, S1–S28. [Google Scholar] [CrossRef] [PubMed]

- Doerler, M.; Reich-Schupke, S.; Altmeyer, P.; Stuecker, M. Impact on wound healing and efficacy of various leg ulcer debridement techniques. J. Dtsch. Dermatol. Ges. 2012, 10, 624–631. [Google Scholar] [CrossRef] [PubMed]

- Wolcott, R.D.; Kennedy, J.P.; Dowd, S.E. Regular debridement is the main tool for maintaining a healthy wound bed in most chronic wounds. J. Wound Care 2009, 18, 54–56. [Google Scholar] [CrossRef] [PubMed]

- Schultz, G.S.; Barillo, D.J.; Mozingo, D.W.; Chin, G.A.; Wound Bed Advisory Board Members. Wound bed preparation and a brief history of time. Int. Wound J. 2004, 1, 19–32. [Google Scholar] [CrossRef] [PubMed]

- Klein, S.; Schreml, S.; Dolderer, J.; Gehmert, S.; Niederbichler, A.; Landthaler, M.; Prantl, L. Evidence-based topical management of chronic wounds according to the time principle. J. Dtsch. Dermatol. Ges. 2013, 11, 819–830. [Google Scholar] [PubMed]

- Sibbald, R.G.; Goodman, L.; Woo, K.Y.; Krasner, D.L.; Smart, H.; Tariq, G.; Ayello, E.A.; Burrell, R.E.; Keast, D.H.; Mayer, D.; et al. Special considerations in wound bed preparation 2011: An update. Adv. Skin Wound Care 2011, 24, 415–436. [Google Scholar] [CrossRef] [PubMed]

- Ousey, K.; McIntosh, C. Understanding wound bed preparation and wound debridement. Br. J. Community Nurs. 2010, 15, S22, S24, S26. [Google Scholar] [CrossRef] [PubMed]

- Edwards, J.V.; Yager, D.R.; Cohen, I.K.; Diegelmann, R.F.; Montante, S.; Bertoniere, N.; Bopp, A.F. Modified cotton gauze dressings that selectively absorb neutrophil elastase activity in solution. Wound Repair Regen. 2001, 9, 50–58. [Google Scholar] [CrossRef] [PubMed]

- Emam, H.E.; Saleh, N.H.; Nagy, K.S.; Zahran, M.K. Functionalization of medical cotton by direct incorporation of silver nanoparticles. Int. J. Biol. Macromol. 2015, 78, 249–256. [Google Scholar] [CrossRef] [PubMed]

- McCallon, S.K.; Knight, C.A.; Valiulus, J.P.; Cunningham, M.W.; McCulloch, J.M.; Farinas, L.P. Vacuum-assisted closure versus saline-moistened gauze in the healing of postoperative diabetic foot wounds. Ostomy Wound Manag. 2000, 46, 28–34. [Google Scholar]

- Ponder, R.B.; Krasner, D. Gauzes and related dressings. Ostomy Wound Manag. 1993, 39, 48–49, 52–54, 56–60. [Google Scholar]

- Lagana, G.; Anderson, E.H. Moisture dressings: The new standard in wound care. J. Nurse Prac. 2010, 6, 366–370. [Google Scholar] [CrossRef]

- Cencetti, C.; Bellini, D.; Pavesio, A.; Senigaglia, D.; Passariello, C.; Virga, A.; Matricardi, P. Preparation and characterization of antimicrobial wound dressings based on silver, gellan, pva and borax. Carbohyd. Polym. 2012, 90, 1362–1370. [Google Scholar] [CrossRef] [PubMed]

- Atkin, L. Understanding methods of wound debridement. Br. J. Community Nurs. 2014, 23, S10–S15. [Google Scholar] [CrossRef] [PubMed]

- Bahr, S.; Mustafi, N.; Hattig, P.; Piatkowski, A.; Mosti, G.; Reimann, K.; Abel, M.; Dini, V.; Restelli, J.; Babadagi-Hardt, Z.; et al. Clinical efficacy of a new monofilament fibre-containing wound debridement product. J. Wound Care 2011, 20, 242–248. [Google Scholar] [CrossRef] [PubMed]

- Fu, Y.J.; Wang, L.; Wang, F.J.; Wang, W.Z.; Meng, S.Y. Preparation and mechanical properties of a novel textile pad for wound debridement. J. Donghua Univ. 2014, 31, 621–624. [Google Scholar]

- Fu, Y.; Wang, L.; Wang, F.; Guan, G.; Hu, X.; Xie, Q.; Wang, W.; King, M.W. Influence of structures on the mechanical and absorption properties of a textile pile debridement material and its biological evaluation. RSC Adv. 2015, 5, 87580–87588. [Google Scholar] [CrossRef]

- Mehta, S.; Hersh, S.P.; Tucker, P.A.; Bullerwell, A.C. Evaluating textiles and apparel for controlling contamination in cleanrooms. ASTM 1992, 4, 742–753. [Google Scholar]

- ISO 9073-10:2003. Textiles-Test Methods for Nonwovens-Part 10: Lint and Other Particles Generation in the Dry State. Available online: http://www.iso.org/iso/home/store/catalogue_tc/catalogue_detail.htm?csnumber=30167 (accessed on 21 April 2016).

- EN 1644-2:2000. Test Methods for Nonwovne Compresses for Medical Use-Part 2: Finished Compresses. Available online: http://www.sis.se/en/health-care-technology/pharmaceutics/medical-materials/ss-en-1644-2 (accessed on 21 April 2016).

- Coxon, A.; Grieve, M.; Dunlop, J. A method of assessing the fiber shedding potential of fabrics. J. Forensic Sci. Soc. 1992, 32, 151–158. [Google Scholar] [CrossRef]

- De Wael, K.; Lepot, L.; Lunstroot, K.; Gason, F. Evaluation of the shedding potential of textile materials. Sci. Justice 2010, 50, 192–194. [Google Scholar] [CrossRef] [PubMed]

- Ghosh, P.; Samanta, A.K.; Dev, D. Simultaneous free radical polymerization and acidic polycondensation of acrylamide-formaldehyde resin on jute fabric. J. Appl. Polym. Sci. 1997, 64, 2473–2489. [Google Scholar] [CrossRef]

- Konwar, U.; Mandal, M.; Karak, N. Mesua ferrea l. Seed oil based acrylate-modified thermostable and biodegradable highly branched polyester resin/clay nanocomposites. Prog. Org. Coat. 2011, 72, 676–685. [Google Scholar] [CrossRef]

- Tang, J.; Zhang, Z.; Song, Z.; Chen, L.; Hou, X.; Yao, K. Synthesis and characterization of elastic aliphatic polyesters from sebacic acid, glycol and glycerol. Eur. Polym. J. 2006, 42, 3360–3366. [Google Scholar] [CrossRef]

- Parvinzadeh, M.; Ebrahimi, I. Atmospheric air-plasma treatment of polyester fiber to improve the performance of nanoemulsion silicone. Appl. Surf. Sci. 2011, 257, 4062–4068. [Google Scholar] [CrossRef]

- Cui, X.; Zhong, S.; Wang, H. Emulsifier-free core-shell polyacrylate latex nanoparticles containing fluorine and silicon in shell. Polymer 2007, 48, 7241–7248. [Google Scholar] [CrossRef]

- Huang, J.Q.; Meng, W.D.; Qing, F.L. Synthesis and repellent properties of vinylidene fluoride-containing polyacrylates. J. Fluor. Chem. 2007, 128, 1469–1477. [Google Scholar] [CrossRef]

- Huang, K.; Liu, Y.; Wu, D. Synthesis and characterization of polyacrylate modified by polysiloxane latexes and films. Prog. Org. Coat. 2014, 77, 1774–1779. [Google Scholar] [CrossRef]

- Bao, Y.; Shi, C.; Ma, J.; Wang, B.; Zhang, Y. Double in-situ synthesis of polyacrylate/nano-TiO2 composite latex. Prog. Org. Coat. 2015, 85, 101–108. [Google Scholar] [CrossRef]

- Li, W.; Sakai, T.; Li, Q.; Wang, P. Statistical analysis of fatigue crack growth behavior for grade B cast steel. Mater. Des. 2011, 32, 1262–1272. [Google Scholar] [CrossRef]

- Šeruga, D.; Nagode, M. A method for long-term creep–rupture strength prediction based on a small sample of experimental results, smoothed bootstrapping and time–temperature parameters. Mater. Des. 2015, 67, 180–187. [Google Scholar] [CrossRef]

- Casado, J.A.; Diego, S.; Ferreno, D.; Ruiz, E.; Carrascal, I.; Mendez, D.; Revuelta, J.M.; Ponton, A.; Icardo, J.M.; Gutierrez-Solana, F. Determination of the mechanical properties of normal and calcified human mitral chordae tendineae. J. Mech. Behav. Biomed. 2012, 13, 1–13. [Google Scholar] [CrossRef] [PubMed]

- Xu, D.; Ametov, I.; Grano, S.R. Detachment of coarse particles from oscillating bubbles-the effect of particle contact angle, shape and medium viscosity. Int. J. Miner. Process. 2011, 101, 50–57. [Google Scholar] [CrossRef]

- Yuan, S.J.; Cui, X.L.; Wang, X.S. Investigation into wrinkling behavior of thin-walled 5A02 aluminum alloy tubes under internal and external pressure. Int. J. Mech. Sci. 2015, 92, 245–258. [Google Scholar] [CrossRef]

- Wang, X.; Wang, L.J. Investigation of combing forces—Part v: Fibre tension during top combing. J. Text. Inst. 1998, 89, 155–166. [Google Scholar] [CrossRef]

- Brown, A. Measurement of crimp in single fibers1. Text. Res. J. 1955, 25, 969–976. [Google Scholar] [CrossRef]

- Beglarigale, A.; Yazici, H. Pull-out behavior of steel fiber embedded in flowable rpc and ordinary mortar. Constr. Build. Mater. 2015, 75, 255–265. [Google Scholar] [CrossRef]

- Martinez-Hergueta, F.; Ridruejo, A.; Gonzalez, C.; Llorca, J. Deformation and energy dissipation mechanisms of needle-punched nonwoven fabrics: A multiscale experimental analysis. Int. J. Solids Struct. 2015, 64–65, 120–131. [Google Scholar] [CrossRef]

- Tuyan, M.; Yazici, H. Pull-out behavior of single steel fiber from sifcon matrix. Constr. Build. Mater. 2012, 35, 571–577. [Google Scholar] [CrossRef]

- Ali, M.; Chouw, N. Experimental investigations on coconut-fibre rope tensile strength and pullout from coconut fibre reinforced concrete. Constr. Build. Mater. 2013, 41, 681–690. [Google Scholar] [CrossRef]

- Ray, D.; Sarkar, B.K.; Bose, N.R. Impact fatigue behaviour of vinylester resin matrix composites reinforced with alkali treated jute fibres. Compos. A Appl. Sci. Manuf. 2002, 33, 233–241. [Google Scholar] [CrossRef]

- Ali, M.; Li, X.; Chouw, N. Experimental investigations on bond strength between coconut fibre and concrete. Mater. Des. 2013, 44, 596–605. [Google Scholar] [CrossRef]

- Isla, F.; Ruano, G.; Luccioni, B. Analysis of steel fibers pull-out. Experimental study. Constr. Build. Mater. 2015, 100, 183–193. [Google Scholar] [CrossRef]

- Goh, K.L.; Huq, A.M.A.; Aspden, R.M.; Hukins, D.W.L. Nano-fibre critical length depends on shape. Adv. Compos. Lett. 2008, 17, 131–133. [Google Scholar]

- ISO 139:2005. Textiles-Standard Atmospheres for Conditioning and Testing. Available online: http://www.iso.org/iso/home/store/catalogue_tc/catalogue_detail.htm?csnumber=35179 (accessed on 21 April 2016).

- FZ/T 01033:2012. Test Method of Mass per Unit Area and Pile Percent of Pile Fabric. Available online: http://www.spsp.gov.cn/page/P1388/167.shtml (accessed on 21 April 2016).

- Ng, X.W.; Hukins, D.W.L.; Goh, K.L. Influence of fibre taper on the work of fibre pull-out in short fibre composite fracture. J. Mater. Sci. 2010, 45, 1086–1090. [Google Scholar] [CrossRef]

| Parameters | L2-0 | M2-0 | H2-0 | L3-0 | M3-0 | H3-0 |

|---|---|---|---|---|---|---|

| Ave. (mm2) | 0.23 | 0.24 | 0.26 | 0.09 | 0.10 | 0.12 |

| Min. (mm2) | 0.06 | 0.10 | 0.12 | 0.03 | 0.04 | 0.05 |

| Max. (mm2) | 0.42 | 0.43 | 0.44 | 0.17 | 0.17 | 0.19 |

| PVR (mm2) | 0.36 | 0.33 | 0.31 | 0.14 | 0.13 | 0.13 |

| Parameters | L2-0 | M2-0 | H2-0 | L3-0 | M3-0 | H3-0 | H3-1 | H3-2 |

|---|---|---|---|---|---|---|---|---|

| y0 | 0.69 | 0.26 | 2.60 | 2.57 | −0.27 | 1.30 | 3.23 | 5.20 |

| A | 19.71 | 17.15 | 16.92 | 18.27 | 18.82 | 15.60 | 16.99 | 24.72 |

| xc | 0.99 | 1.27 | 1.39 | 1.06 | 1.40 | 1.57 | 5.73 | 6.79 |

| w | 0.42 | 0.48 | 0.34 | 0.34 | 0.45 | 0.45 | 1.68 | 1.12 |

| R2 | 0.94 | 0.96 | 0.95 | 0.96 | 0.98 | 0.98 | 0.96 | 0.97 |

| Items | Fiber Slippage | Coating Point Rupture | Fiber Breakage |

|---|---|---|---|

| Representative load–displacement curve |  |  |  |

| Fracture morphology |  |  |  |

| Schematic diagram of the single fiber pull-out process |  |  |  |

| Sample No. | Fiber Slippage (%) | Coating Point Rupture (%) | Fiber Breakage (%) |

|---|---|---|---|

| H3-0 | 100 | 0 | 0 |

| H3-1 | 10 | 26 | 64 |

| H3-2 | 0 | 7 | 93 |

| Raw Materials | Linear Density | Number of Filaments per Yarn | Maximum Tensile Force (cN) | Elongation (%) |

|---|---|---|---|---|

| Staple fiber | 3D 1 | - | 8.17 ± 0.59 | 48.05 ± 9.34 |

| Multifilament yarn | 150D 1 | 36 | 533.01 ± 21.13 | 28.29 ± 0.70 |

| Sample No. | Pile Density | Ground Yarn Plies | Back-Coating Time | Pile Height (mm) | Stitch Density (Course × Wale) (/cm2) |

|---|---|---|---|---|---|

| L2-0 | Low | 2 | None | 10 | 9.0 × 6.0 |

| L3-0 | Low | 3 | None | 10 | 9.0 × 6.0 |

| M2-0 | Middle | 2 | None | 10 | 9.0 × 6.0 |

| M3-0 | Middle | 3 | None | 10 | 9.0 × 6.0 |

| H2-0 | High | 2 | None | 10 | 9.0 × 6.0 |

| H3-0 | High | 3 | None | 10 | 9.0 × 6.0 |

| H3-1 | High | 3 | Once | 10 | 9.0 × 6.0 |

| H3-2 | High | 3 | Twice | 10 | 9.0 × 6.0 |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fu, Y.; Xie, Q.; Lao, J.; Wang, L. In Vitro Evaluation and Mechanism Analysis of the Fiber Shedding Property of Textile Pile Debridement Materials. Materials 2016, 9, 302. https://doi.org/10.3390/ma9040302

Fu Y, Xie Q, Lao J, Wang L. In Vitro Evaluation and Mechanism Analysis of the Fiber Shedding Property of Textile Pile Debridement Materials. Materials. 2016; 9(4):302. https://doi.org/10.3390/ma9040302

Chicago/Turabian StyleFu, Yijun, Qixue Xie, Jihong Lao, and Lu Wang. 2016. "In Vitro Evaluation and Mechanism Analysis of the Fiber Shedding Property of Textile Pile Debridement Materials" Materials 9, no. 4: 302. https://doi.org/10.3390/ma9040302

APA StyleFu, Y., Xie, Q., Lao, J., & Wang, L. (2016). In Vitro Evaluation and Mechanism Analysis of the Fiber Shedding Property of Textile Pile Debridement Materials. Materials, 9(4), 302. https://doi.org/10.3390/ma9040302