The Lateral Compressive Buckling Performance of Aluminum Honeycomb Panels for Long-Span Hollow Core Roofs

Abstract

:1. Introduction

2. Results and Discussion

2.1. Lateral Compressive Failure Mode of the Honeycomb Panels

2.1.1. Failure Mode of the Honeycomb Panels in the Lateral Compressive Tests

2.1.2. Stress, Strain and Other Contour Plots of the Finite Element Analysis

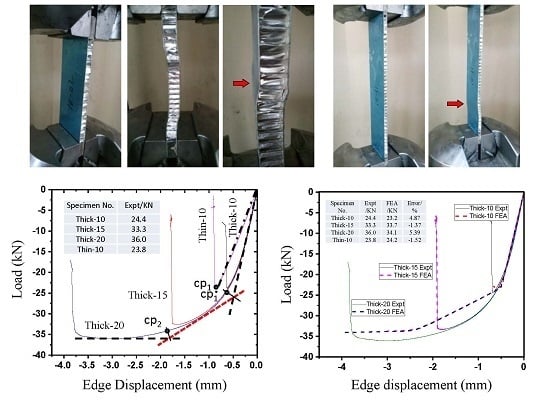

2.2. Lateral Compressive Displacement Curves for the Honeycomb Panels

2.3. Analysis and Discussion

3. Experiment and Finite Element Analysis Method

3.1. Lateral Compressive Tests on Honeycomb Panels

3.2. Finite Element Analysis Method

4. Conclusions

- Face sheet yielding failure occurred in the thick honeycomb panel, which has a lower thickness-to-length ratio. Under the conditions of this experiment, the honeycomb panels with the same planar dimensions but different thicknesses had the same anti-compressive stiffness before buckling, while the lateral compressive buckling load-bearing capacity initially increased rapidly with increasing thickness and eventually approached a limiting value. Under the test conditions in this paper, the increase in load-bearing capacity approached this limit when the thickness of the honeycomb panel exceeded 20 mm. Considering factors such as cost, the honeycomb panels should be 15–20 mm thick.

- The anti-compressive stiffnesses are different in test pieces with different lengths but the same thickness; however, the maximum lateral compressive buckling loads are very similar. In thin honeycomb panels with high length-to-thickness ratios, overall buckling failure occurred due to local buckling that was induced by the collapse of several honeycomb cores or due to the lack of support from the core to the face sheets; that is, the longer the honeycomb panel is, the more flexible the structure is, and the more likely it is that overall instability failure will occur. To prevent failures of this type, the design length-to-thickness ratio should be controlled.

- The error between the results of the nonlinear finite element analysis of honeycomb panel models and the actual test results was less than 6%, and the load–displacement curves that were obtained by the two methods were very similar. These results indicate that the finite element analysis model that was developed in this paper has sufficient calculation accuracy and can provide a theoretical basis for the more rational analysis and design of this new type of spatial structure in the future.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Ma, Y.; Zheng, Y.; Meng, H.; Song, W.; Yao, X.; Lv, H. Heterogeneous PVA hydrogels with micro-cells of both positive and negative Poisson’s ratios. J. Mech. Behav. Biomed. Mater. 2013, 23, 22–31. [Google Scholar] [CrossRef] [PubMed]

- Dirks, J.-H.; Dürr, V. Biomechanics of the stick insect antenna: Damping properties and structural correlates of the cuticle. J. Mech. Behav. Biomed. Mater. 2011, 4, 2031–2042. [Google Scholar] [CrossRef] [PubMed]

- Koester, K.J.; Barth, H.D.; Ritchie, R.O. Effect of aging on the transverse toughness of human cortical bone: Evaluation by R-curves. J. Mech. Behav. Biomed. Mater. 2011, 4, 1504–1513. [Google Scholar] [CrossRef] [PubMed]

- Donius, A.E.; Liu, A.; Berglund, L.A.; Wegst, U.G.K. Superior mechanical performance of highly porous, anisotropic nanocellulose–montmorillonite aerogels prepared by freeze casting. J. Mech. Behav. Biomed. Mater. 2014, 37, 88–99. [Google Scholar] [CrossRef] [PubMed]

- Chen, J.; Gu, C.; Guo, S.; Wan, C.; Wang, X.; Xie, J.; Hu, X. Integrated honeycomb technology motivated by the structure of beetle forewings. Mater. Sci. Eng. C 2012, 32, 1813–1817. [Google Scholar] [CrossRef]

- Chen, J.; Xie, J.; Zhu, H.; Guan, S.; Wu, G.; Noori, M.N.; Guo, S. Integrated honeycomb structure of a beetle forewing and its imitation. Mater. Sci. Eng. C 2012, 32, 613–618. [Google Scholar] [CrossRef]

- Chen, J.; Xie, J.; Wu, Z.; Elbashiry, E.M.A.; Lu, Y. Review of beetle forewing structures and their biomimetic applications in China: (I) On the structural colors and the vertical and horizontal cross-sectional structures. Mater. Sci. Eng. C 2015, 55, 605–619. [Google Scholar] [CrossRef] [PubMed]

- Chen, J.; Zu, Q.; Wu, G.; Xie, J.; Tuo, W. Review of beetle forewing structures and their biomimetic applications in China: (II) On the three-dimensional structure, modeling and imitation. Mater. Sci. Eng. C 2015, 55, 620–633. [Google Scholar] [CrossRef] [PubMed]

- Chen, J.; Wu, G. Beetle forewings: Epitome of the optimal design for lightweight composite materials. Carbohydr. Polym. 2013, 91, 659–665. [Google Scholar] [CrossRef] [PubMed]

- Chen, J.; He, C.; Gu, C.; Liu, J.; Mi, C.; Guo, S. Compressive and flexural properties of biomimetic integrated honeycomb plates. Mater. Des. 2014, 64, 214–220. [Google Scholar] [CrossRef]

- He, C.; Chen, J.; Wu, Z.; Xie, J.; Zu, Q.; Lu, Y. Simulated effect on the compressive and shear mechanical properties of bionic integrated honeycomb plates. Mater. Sci. Eng. C 2015, 50, 286–293. [Google Scholar] [CrossRef] [PubMed]

- Bourada, M.; Tounsi, A.; Houari, M.S.A.; Bedia, E.A.A. A new four-variable refined plate theory for thermal buckling analysis of functionally graded sandwich plates. J. Sandw. Struct. Mater. 2011, 14, 5–33. [Google Scholar] [CrossRef]

- Szyniszewski, S.; Smith, B.H.; Hajjar, J.F.; Arwade, S.R.; Schafer, B.W. Local buckling strength of steel foam sandwich panels. Thin-Walled Struct. 2012, 59, 11–19. [Google Scholar] [CrossRef] [Green Version]

- Boudjemai, A.; Amri, R.; Mankour, A.; Salem, H.; Bouanane, M.H.; Boutchicha, D. Modal analysis and testing of hexagonal honeycomb plates used for satellite structural design. Mater. Des. 2012, 35, 266–275. [Google Scholar] [CrossRef]

- Zhao, C.; Jun, M.; Yin, L.; Zhao, H. Assembled Honeycombed Sheet Light Empty Stomach Building and Roof Structure System. Patent CN101270595A, 24 September 2008. [Google Scholar]

- Zhao, C.; Ma, J.; Tao, J. Experimental study on load capacity of new fabricated honeycomb panel open-web roof structures. J. Southeast Univ. (Nat. Sci. Ed.) 2014, 44, 626–630. [Google Scholar]

- Tao, J. Experimental Study on Lightweighted Roof Structures Based on Honeycomb Panel in High Performance. Master’ Thesis, Southeast University, Nanjing, China, 2012. [Google Scholar]

- Ji, H.-W.; Xu, J.; Li, J.-C.; Shao, W.-Q.; Wang, H.-W. Experimental research on the edgewise compressive strength of honeycomb paperboard. Packag. Eng. 2006, 27, 90–92. [Google Scholar]

- Shao, W.-Q.; Li, Y.-M.; Meng, X.-W.; Ji, H.-W. Influence of the unglued defect on edgewise compressive strength of honeycomb paperboard. Packag. Eng. 2008, 29, 59–62. [Google Scholar]

- Yang, S.; Wu, L.; Sun, Y. End compression failure of honeycomb sandwich panels containing interfacial debonding. Acta Mater. Compos. Sin. 2007, 24, 121–127. [Google Scholar]

- Standardization Administration of China. Test Method for Edgewise Compressive Properties of Sandwich Constructions; GB/T 1454-2005; Standard Press of China: Beijing, China, 2005. (In Chinese) [Google Scholar]

- Standardization Administration of China. The Generals of Test Method for Properties of Adhesive-Bonded Aluminum Honeycomb-Sandwich Structure and Core; GJB130.1-86; Standard Press of China: Beijing, China, 1986. (In Chinese) [Google Scholar]

- Wang, Y.; Shi, Y.; Yuan, H.; Cheng, M. Compressive buckling of aluminum alloy plates. Eng. J. Wuhan Univ. (Eng. Ed.) 2011, 44, 74–78. [Google Scholar]

- Zhang, F.; Huang, B.; Niu, W.; Cui, S. Buckling and postbuckling analysis of nonlinear composite laminates with delamination. J. Northeast. Univ. (Nat. Sci.) 2000, 21, 343–346. [Google Scholar]

- Zhuang, X. The Buckling and Postbuckling Analysis of Flat Composite Stiffened Panels Loaded in Axial Compression. Master’s Thesis, Nanjing University of Aeronautics and Astronautics, Nanjing, China, 2009. [Google Scholar]

- Liu, C. Buckling, Post-Buckling and Load-Carrying Capacity Analysis of Stiffened Composite Panels. Master’s Thesis, Nanjing University of Aeronautics and Astronautics, Nanjing, China, 2009. [Google Scholar]

- Yang, N.; Shen, S. Finite element analysis for nonlinear buckling of plates and shells. J. Harbin Inst. Technol. 2003, 35, 338–341. [Google Scholar]

- Lou, J. Bending, Buckling and Vibration Properties of Composite Lattice Sandwich Structures. Ph.D. Thesis, Harbin Institute of Technology, Harbin, China, 2013. [Google Scholar]

- Zhang, X. Research on the Static and Dynamic Buckling of the Composite Honeycomb Structure in the Out-of-Plane Direction. Master’s Thesis, Huazhong University of Science and Technology, Wuhan, China, 2013. [Google Scholar]

- Yang, Y. Research on Mechanical Properties of Metal Honeycomb Sandwich Plate. Master’s Thesis, Harbin Institute of Technology, Harbin, China, 2013. [Google Scholar]

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhao, C.; Zheng, W.; Ma, J.; Zhao, Y. The Lateral Compressive Buckling Performance of Aluminum Honeycomb Panels for Long-Span Hollow Core Roofs. Materials 2016, 9, 444. https://doi.org/10.3390/ma9060444

Zhao C, Zheng W, Ma J, Zhao Y. The Lateral Compressive Buckling Performance of Aluminum Honeycomb Panels for Long-Span Hollow Core Roofs. Materials. 2016; 9(6):444. https://doi.org/10.3390/ma9060444

Chicago/Turabian StyleZhao, Caiqi, Weidong Zheng, Jun Ma, and Yangjian Zhao. 2016. "The Lateral Compressive Buckling Performance of Aluminum Honeycomb Panels for Long-Span Hollow Core Roofs" Materials 9, no. 6: 444. https://doi.org/10.3390/ma9060444

APA StyleZhao, C., Zheng, W., Ma, J., & Zhao, Y. (2016). The Lateral Compressive Buckling Performance of Aluminum Honeycomb Panels for Long-Span Hollow Core Roofs. Materials, 9(6), 444. https://doi.org/10.3390/ma9060444