Optimization of Injection Molding Parameters for HDPE/TiO2 Nanocomposites Fabrication with Multiple Performance Characteristics Using the Taguchi Method and Grey Relational Analysis

Abstract

:1. Introduction

2. Experimental Method

2.1. Materials

2.2. Experimental Method and Design

2.2.1. Method

Injection Molding Technique

Mechanical Testing

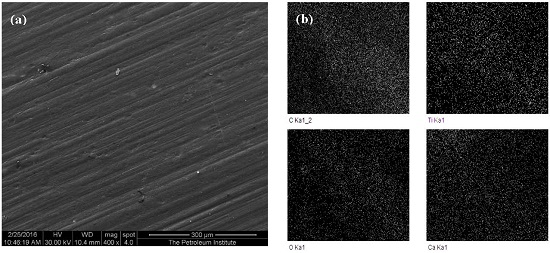

Surface Characterization

2.2.2. Experimental Design

2.2.3. Grey Relational Analysis

3. Analysis and Discussion of the Experimental Results

3.1. Optimal Parameters for Injection Molding Composites

3.2. Analysis of Variance

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Rao, R.V. Advanced Modeling and Optimization of Manufacturing Processes: International Research and Development; Springer Science & Business Media: Berlin, Germany, 2010. [Google Scholar]

- Mozumder, M.; Zhu, J.; Perinpanayagam, H. Nano-TiO 2 Enriched Polymeric Powder Coatings Support Human Mesenchymal Cell Attachment and Growth. J. Biomater. Appl. 2011, 26, 173–193. [Google Scholar] [CrossRef] [PubMed]

- Khaled, S.M.; Sui, R.; Charpentier, P.A.; Rizkalla, A.S. Synthesis of TiO2-PMMA Nanocomposite: Using Methacrylic Acid as a Coupling Agent. Langmuir 2007, 23, 3988–3995. [Google Scholar] [CrossRef] [PubMed]

- Deshpande, S.; Munoli, A. Long-term results of high-density porous polyethylene implants in facial skeletal augmentation: An Indian perspective. Indian J. Plast. Surg. 2010, 43, 34–39. [Google Scholar] [CrossRef] [PubMed]

- Fabian, E.; Landsiedel, R.; Ma-Hock, L.; Wiench, K.; Wohlleben, W.; van Ravenzwaay, B. Tissue distribution and toxicity of intravenously administered titanium dioxide nanoparticles in rats. Arch. Toxicol. 2007, 82, 151–157. [Google Scholar] [CrossRef] [PubMed]

- Dhandapani, V.S.; Subbiah, R.; Thangavel, E.; Arumugam, M.; Park, K.; Gasem, Z.M.; Veeraragavan, V.; Kim, D.-E. Tribological properties, corrosion resistance and biocompatibility of magnetron sputtered titanium-amorphous carbon coatings. Appl. Surf. Sci. 2016, 371, 262–274. [Google Scholar] [CrossRef]

- Zhao, C.; Rehman, F.U.; Jiang, H.; Selke, M.; Wang, X.; Liu, C.-Y. Titanium dioxide-tetra sulphonatophenyl porphyrin nanocomposites for target cellular bio-imaging and treatment of rheumatoid arthritis. Sci. China Chem. 2016, 59, 637–642. [Google Scholar] [CrossRef]

- Bonnefond, A.; González, E.; Asua, J.M.; Leiza, J.R.; Kiwi, J.; Pulgarin, C.; Rtimi, S. New evidence for hybrid acrylic/TiO2 films inducing bacterial inactivation under low intensity simulated sunlight. Colloids Surf. B Biointerfaces 2015, 135, 1–7. [Google Scholar] [CrossRef] [PubMed]

- Rtimi, S.; Sanjines, R.; Andrzejczuk, M.; Pulgarin, C.; Kulik, A.; Kiwi, J. Innovative transparent non-scattering TiO2 bactericide thin films inducing increased E. coli cell wall fluidity. Surf. Coat. Technol. 2014, 254, 333–343. [Google Scholar] [CrossRef]

- Tripathi, G.; Gough, J.E.; Dinda, A.; Basu, B. In vitro cytotoxicity and in vivo osseointergration properties of compression-molded HDPE-HA-Al2O3 hybrid biocomposites. J. Biomed. Mater. Res. A 2013, 101A, 1539–1549. [Google Scholar] [CrossRef]

- Tripathi, G.; Basu, B. In vitro osteogenic cell proliferation, mineralization, and in vivo osseointegration of injection molded high-density polyethylene-based hybrid composites in rabbit animal model. J. Biomater. Appl. 2014, 29, 142–157. [Google Scholar] [CrossRef] [PubMed]

- Duan, Y.; Liu, J.; Ma, L.; Li, N.; Liu, H.; Wang, J.; Zheng, L.; Liu, C.; Wang, X.; Zhao, X.; et al. Toxicological characteristics of nanoparticulate anatase titanium dioxide in mice. Biomaterials 2010, 31, 894–899. [Google Scholar] [CrossRef] [PubMed]

- Shimizu, T.; Fujibayashi, S.; Yamaguchi, S.; Yamamoto, K.; Otsuki, B.; Takemoto, M.; Tsukanaka, M.; Kizuki, T.; Matsushita, T.; Kokubo, T.; et al. Bioactivity of sol-gel-derived TiO2 coating on polyetheretherketone: In vitro and in vivo studies. Acta Biomater. 2016, 35, 305–317. [Google Scholar] [CrossRef] [PubMed]

- Thevenot, P.; Hu, W.; Tang, L. Surface chemistry influences implant biocompatibility. Curr. Top. Med. Chem. 2008, 8, 270–280. [Google Scholar]

- Global Production of Plastics 2014/Statistics. Available online: http://www.statista.com/statistics/282732/global-production-of-plastics-since-1950 (accessed on 22 May 2016).

- Khan, Z.A.; Kamaruddin, S.; Siddiquee, A.N. Feasibility study of use of recycled High Density Polyethylene and multi response optimization of injection moulding parameters using combined grey relational and principal component analyses. Mater. Des. 2010, 31, 2925–2931. [Google Scholar] [CrossRef]

- Davis, C.H.; Mathias, L.J.; Gilman, J.W.; Schiraldi, D.A.; Shields, J.R.; Trulove, P.; Sutto, T.E.; Delong, H.C. Effects of melt-processing conditions on the quality of poly(ethylene terephthalate) montmorillonite clay nanocomposites. J. Polym. Sci. B Polym. Phys. 2002, 40, 2661–2666. [Google Scholar] [CrossRef]

- Wang, J.F.; Liu, X.Y.; Luan, B. Fabrication of Ti/polymer biocomposites for load-bearing implant applications. J. Mater. Process. Technol. 2008, 197, 428–433. [Google Scholar] [CrossRef]

- Tripathi, G.; Basu, B. Injection-molded high-density polyethylene-hydroxyapatite-aluminum oxide hybrid composites for hard-tissue replacement: Mechanical, biological, and protein adsorption behavior. J. Appl. Polym. Sci. 2012, 124, 2133–2143. [Google Scholar] [CrossRef]

- Gungor, A. Mechanical properties of iron powder filled high density polyethylene composites. Mater. Des. 2007, 28, 1027–1030. [Google Scholar] [CrossRef]

- Mourad, A.-H.I. Thermo-mechanical characteristics of thermally aged polyethylene/polypropylene blends. Mater. Des. 2010, 31, 918–929. [Google Scholar] [CrossRef]

- Yang, B.; Deng, Y.-L.; Li, G.-J.; Miao, J.-B.; Xia, R.; Qian, J.-S.; Chen, P.; Liu, J.-W. Solidification behavior of high-density polyethylene (HDPE) during injection molding: Correlation between crystallization kinetics and thermal gradient field. IOP Conf. Ser. Mater. Sci. Eng. 2015, 87, 012020. [Google Scholar] [CrossRef]

- Lin, Y.-H.; Deng, W.-J.; Huang, C.-H.; Yang, Y.-K. Optimization of Injection Molding Process for Tensile and Wear Properties of Polypropylene Components via Taguchi and Design of Experiments Method. Polym. Plast. Technol. Eng. 2007, 47, 96–105. [Google Scholar] [CrossRef]

- Yang, Y.-K. Optimization of Injection Molding Process for Mechanical Properties of Short Glass Fiber and Polytetrafluoroethylene Reinforced Polycarbonate Composites: A Case Study. J. Reinf. Plast. Compos. 2006, 25, 1279–1290. [Google Scholar] [CrossRef]

- Fung, C.-P.; Huang, C.-H.; Doong, J.-L. The Study on the Optimization of Injection Molding Process Parameters with Gray Relational Analysis. J. Reinf. Plast. Compos. 2003, 22, 51–66. [Google Scholar] [CrossRef]

- Xavier, S.F.; Tyagi, D.; Misra, A. Influence of injection-molding parameters on the morphology and mechanical properties of glass fiber-reinforced polypropylene composites. Polym. Compos. 1982, 3, 88–96. [Google Scholar] [CrossRef]

- Delpy, U.; Fischer, G. Effect of mold-filling conditions on fiber distribution in injection-molded disks and on the mechanical properties of such disks. Adv. Polym. Technol. 1985, 5, 19–26. [Google Scholar] [CrossRef]

- Apichartpattanasiri, S.; Hay, J.N.; Kukureka, S.N. A study of the tribological behaviour of polyamide 66 with varying injection-moulding parameters. Wear 2001, 251, 1557–1566. [Google Scholar] [CrossRef]

- Bociaga, E.; Palutkiewicz, P. The influence of injection molding parameters and blowing agent addition on selected properties, surface state, and structure of HDPE parts. Polym. Eng. Sci. 2013, 53, 780–791. [Google Scholar] [CrossRef]

- Zhil’tsova, T.V.; Oliveira, M.S.A.; Ferreira, J.A.F. Relative influence of injection molding processing conditions on HDPE acetabular cups dimensional stability. J. Mater. Process. Technol. 2009, 209, 3894–3904. [Google Scholar] [CrossRef]

- GarcÍa Loera, V.; Castro, J.M.; Mireles Diaz, J.; ChacÓn MondragÓn, Ó.L.; Cabrera-RÍos, M. Setting the Processing Parameters in Injection Molding Through Multiple-Criteria Optimization: A Case Study. IEEE Trans. Syst. Man Cybern. C Appl. Rev. 2008, 38, 710–715. [Google Scholar] [CrossRef]

- Tzeng, C.-J.; Lin, Y.-H.; Yang, Y.-K.; Jeng, M.-C. Optimization of turning operations with multiple performance characteristics using the Taguchi method and Grey relational analysis. J. Mater. Process. Technol. 2009, 209, 2753–2759. [Google Scholar] [CrossRef]

- Dowlatshahi, S. An application of design of experiments for optimization of plastic injection molding processes. J. Manuf. Technol. Manag. 2004, 15, 445–454. [Google Scholar] [CrossRef]

- Seow, L.; Lam, Y. Optimizing flow in plastic injection molding. J. Mater. Process. Technol. 1997, 72, 333–341. [Google Scholar] [CrossRef]

- Liu, S.-J.; Hsu, C.-H.; Chang, C.-Y. Parametric Characterization of the Thin-Wall Injection Molding of Thermoplastic Composites. J. Reinf. Plast. Compos. 2002, 21, 1027–1041. [Google Scholar] [CrossRef]

- Fung, C.-P. Multi-response Optimization of Impact Performances in Fiber-reinforced Poly(butylene terephthalate). J. Thermoplast. Compos. Mater. 2006, 19, 191–205. [Google Scholar] [CrossRef]

- Heim, H.-P. The Statistical Regression Calculation in Plastics Processing—Process Analysis, Optimization and Monitoring. Macromol. Mater. Eng. 2002, 287, 773–783. [Google Scholar] [CrossRef]

- Kuo, Y.; Yang, T.; Huang, G.-W. The use of grey relational analysis in solving multiple attribute decision-making problems. Comput. Ind. Eng. 2008, 55, 80–93. [Google Scholar] [CrossRef]

- Yoon, K.P.; Hwang, C.-L. Multiple Attribute Decision Making: An Introduction; SAGE Publications: New York, NY, USA, 1995. [Google Scholar]

- Yang, T.; Chen, M.-C.; Hung, C.-C. Multiple attribute decision-making methods for the dynamic operator allocation problem. Math. Comput. Simul. 2007, 73, 285–299. [Google Scholar] [CrossRef]

- Yang, T.; Hung, C.-C. Multiple-attribute decision making methods for plant layout design problem. Robot. Comput. Integr. Manuf. 2007, 23, 126–137. [Google Scholar] [CrossRef]

- Deng, J.L. Introduction to Grey system theory. J. Grey Syst. 1989, 1, 1–24. [Google Scholar]

- Parida, A.; Bhuyan, R.; Routara, B. Multiple characteristics optimization in machining of GFRP composites using Grey relational analysis. Int. J. Ind. Eng. Comput. 2014, 5, 511–520. [Google Scholar] [CrossRef] [Green Version]

- Kacker, R.N.; Lagergren, E.S.; Filliben, J.J. Taguchi’s orthogonal arrays are classical designs of experiments. J. Res. Natl. Inst. Stand. Technol. 1991, 96, 577. [Google Scholar] [CrossRef]

- Muhamad, N.; Nor, N.H.M.; Ahmad, S.; Ibrahim, M.H.I.; Harun, M.R. Multiple Performance Optimization for the Best Injection Molding Process of Ti-6Al-4V Green Compact. Appl. Mech. Mater. 2010, 44–47, 2707–2711. [Google Scholar] [CrossRef]

- Jamaludin, K.R.; Muhamad, N.; Rahman, M.N.A.; Ahmad, S.; Ibrahim, M.H.I.; Nor, N.H.M.; Daud, M.Y.M. Application of the Grey-Taguchi Method to the Optimization of Metal Injection Molding (MIM) Process. Key Eng. Mater. 2010, 443, 63–68. [Google Scholar] [CrossRef]

- Mourad, A.-H.I.; Fouad, H.; Elleithy, R. Impact of some environmental conditions on the tensile, creep-recovery, relaxation, melting and crystallinity behaviour of UHMWPE-GUR 410-medical grade. Mater. Des. 2009, 30, 4112–4119. [Google Scholar] [CrossRef]

- Ibrahim, M.H.I.; Muhamad, N.; Sulong, A.B.; Nor, N.H.M.; Jamaludin, K.R.; Harun, M.R.; Chinesta, F.; Chastel, Y.; El Mansori, M. Optimization of Micro Metal Injection Molding By Using Grey Relational Grade. In Proceedings of the International Conference on Advances in Materials and Processing Technologies (Ampt2010), Paris, France, 24–27 October 2010; Volume 1315, pp. 713–718.

- Mishra, P.; Das, D.; Ukamanal, M.; Routara, B.; Sahoo, A. Multi-response optimization of process parameters using Taguchi method and grey relational analysis during turning AA 7075/SiC composite in dry and spray cooling environments. Int. J. Ind. Eng. Comput. 2015, 6, 445–456. [Google Scholar] [CrossRef]

- Hasani, H.; Tabatabaei, G. Somayeh Akhavan Amiri, Grey Relational Analysis to Determine the Optimum Process Parameters for Open-End Spinning Yarns. J. Eng. Fabr. Fibers 2012, 7, 81–86. [Google Scholar]

- Kuo, C.-F.J.; Wei, H.-J.; Huang, C.-C.; Su, T.-L. Processing parameters optimization of multiple quality characteristics of open-end rotor spinning process for Bamboo charcoal and CVC blended fibers. Fibers Polym. 2010, 11, 891–898. [Google Scholar] [CrossRef]

- Sallehuddin, R.; Shamsuddin, S.M.H.; Hashim, S.Z.M. Application of Grey Relational Analysis for Multivariate Time Series. In Proceedings of the 2008 Eighth International Conference on Intelligent Systems Design and Applications, Kaohsiung, Taiwan, 26–28 November 2008; Volume 2, pp. 432–437.

- Ozcelik, B.; Ozbay, A.; Demirbas, E. Influence of injection parameters and mold materials on mechanical properties of ABS in plastic injection molding. Int. Commun. Heat Mass Transf. 2010, 37, 1359–1365. [Google Scholar] [CrossRef]

| Factor Levels | Control Factors | |||

|---|---|---|---|---|

| Concentration of Nano-TiO2 (A, %) | Barrel Temperature (B, °C) | Residence Time (C, min) | Holding Time (D, s) | |

| 1 | 1 | 200 | 30 | 16 |

| 2 | 5 | 225 | 50 | 18 |

| 3 | 10 | 250 | 70 | 20 |

| Run No. | Concentration of Nano-TiO2 (A, %) | Barrel Temperature (B, °C) | Residence Time (C, min) | Holding Time (D, s) |

|---|---|---|---|---|

| 1 | 1 | 1 | 1 | 1 |

| 2 | 1 | 2 | 2 | 2 |

| 3 | 1 | 3 | 3 | 3 |

| 4 | 2 | 1 | 2 | 3 |

| 5 | 2 | 2 | 3 | 1 |

| 6 | 2 | 3 | 1 | 2 |

| 7 | 3 | 1 | 3 | 2 |

| 8 | 3 | 2 | 1 | 3 |

| 9 | 3 | 3 | 2 | 1 |

| Run No. | Yield Strength (σy, MPa) | Young’s Modulus (E, MPa) | Elongation (% δ) |

|---|---|---|---|

| 1 | 20.9 ± 0.2 | 384.3 ± 16.4 | 576.9 ± 31.7 |

| 2 | 20.5 ± 0.5 | 364.6 ± 13.4 | 580.8 ± 29.2 |

| 3 | 19.3 ± 0.7 | 363.2 ± 19.9 | 598.6 ± 41.4 |

| 4 | 22.1 ± 0.6 | 481.8 ± 16.6 | 492.5 ± 30.0 |

| 5 | 22.6 ± 0.3 | 346 ± 23.6 | 646.8 ± 36.6 |

| 6 | 21.3 ± 0.6 | 401.1 ± 12.6 | 622 ± 35.8 |

| 7 | 20.8 ± 0.6 | 438.5 ± 20.6 | 412 ± 35.0 |

| 8 | 21.5 ± 0.7 | 425.9 ± 17.0 | 628.6 ± 42.0 |

| 9 | 19.9 ± 0.2 | 422.9 ± 13.5 | 559.3 ± 31.4 |

| Experimental Run | Orthogonal Array | Comparability Sequence | |||||

|---|---|---|---|---|---|---|---|

| A | B | C | D | Yield Strength (σy, MPa) | Young’s Modulus (E, MPa) | Elongation (% δ) | |

| 1 | 1 | 1 | 1 | 1 | 0.4815 | 0.2820 | 0.7023 |

| 2 | 1 | 2 | 2 | 2 | 0.3704 | 0.1372 | 0.7189 |

| 3 | 1 | 3 | 3 | 3 | 0.0000 | 0.1268 | 0.7947 |

| 4 | 2 | 1 | 2 | 3 | 0.8344 | 1.0000 | 0.3428 |

| 5 | 2 | 2 | 3 | 1 | 1.0000 | 0.0000 | 1.0000 |

| 6 | 2 | 3 | 1 | 2 | 0.5926 | 0.4058 | 0.8944 |

| 7 | 3 | 1 | 3 | 2 | 0.4444 | 0.6813 | 0.0000 |

| 8 | 3 | 2 | 1 | 3 | 0.6667 | 0.5885 | 0.9225 |

| 9 | 3 | 3 | 2 | 1 | 0.1852 | 0.5663 | 0.6273 |

| Experimental Run | Reference Sequence | Grey Coefficients | ||||

|---|---|---|---|---|---|---|

| Yield Strength (σy, MPa) | Young’s Modulus (E, MPa) | Elongation (% δ) | Yield Strength (σy, MPa) | Young’s Modulus (E, MPa) | Elongation (% δ) | |

| 1 | 0.5185 | 0.7180 | 0.2977 | 0.4909 | 0.4105 | 0.6268 |

| 2 | 0.6296 | 0.8628 | 0.2811 | 0.4426 | 0.3669 | 0.6401 |

| 3 | 1.0000 | 0.8732 | 0.2053 | 0.3333 | 0.3641 | 0.7089 |

| 4 | 0.1656 | 0.0000 | 0.6572 | 0.7512 | 1.0000 | 0.4321 |

| 5 | 0.0000 | 1.0000 | 0.0000 | 1.0000 | 0.3333 | 1.0000 |

| 6 | 0.4074 | 0.5942 | 0.1056 | 0.5510 | 0.4569 | 0.8256 |

| 7 | 0.5556 | 0.3187 | 1.0000 | 0.4737 | 0.6107 | 0.3333 |

| 8 | 0.3333 | 0.4115 | 0.0775 | 0.6000 | 0.5486 | 0.8658 |

| 9 | 0.8148 | 0.4337 | 0.3727 | 0.3803 | 0.5355 | 0.5730 |

| Experimental Run | Orthogonal Array | Grey Relational Grades | |||

|---|---|---|---|---|---|

| A | B | C | D | ||

| 1 | 1 | 1 | 1 | 1 | 0.5094 |

| 2 | 1 | 2 | 2 | 2 | 0.4832 |

| 3 | 1 | 3 | 3 | 3 | 0.4688 |

| 4 | 2 | 1 | 2 | 3 | 0.7278 |

| 5 | 2 | 2 | 3 | 1 | 0.7778 |

| 6 | 2 | 3 | 1 | 2 | 0.6112 |

| 7 | 3 | 1 | 3 | 2 | 0.4726 |

| 8 | 3 | 2 | 1 | 3 | 0.6715 |

| 9 | 3 | 3 | 2 | 1 | 0.4963 |

| Control Levels | Response Factors | |||

|---|---|---|---|---|

| A | B | C | D | |

| 1 | 0.4871 | 0.5699 | 0.5973 | 0.5945 |

| 2 | 0.7056 | 0.6441 | 0.5691 | 0.5223 |

| 3 | 0.5468 | 0.5254 | 0.5730 | 0.6227 |

| Control Factors | Level 1 | Level 2 | Level 3 | Degrees of Freedom | Sum of Squares | Mean Square | F | Percentage Contribution (%) |

|---|---|---|---|---|---|---|---|---|

| A | 0.4871 | 0.7056 | 0.5468 | 2 | 0.0765 | 0.0383 | 0.0383 | 66.20 |

| B | 0.5699 | 0.6441 | 0.5254 | 2 | 0.0216 | 0.0108 | 0.0108 | 18.67 |

| C | 0.5973 | 0.5691 | 0.573 | 2 | 0.0014 | 0.0007 | 0.0007 | 1.21 |

| D | 0.5945 | 0.5223 | 0.6227 | 2 | 0.0161 | 0.0080 | 0.0080 | 13.92 |

| Error | 0 | 0.0000 | ||||||

| Total | 8 | 0.1156 | 0.0578 | 0.0578 | 100.00 |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pervez, H.; Mozumder, M.S.; Mourad, A.-H.I. Optimization of Injection Molding Parameters for HDPE/TiO2 Nanocomposites Fabrication with Multiple Performance Characteristics Using the Taguchi Method and Grey Relational Analysis. Materials 2016, 9, 710. https://doi.org/10.3390/ma9080710

Pervez H, Mozumder MS, Mourad A-HI. Optimization of Injection Molding Parameters for HDPE/TiO2 Nanocomposites Fabrication with Multiple Performance Characteristics Using the Taguchi Method and Grey Relational Analysis. Materials. 2016; 9(8):710. https://doi.org/10.3390/ma9080710

Chicago/Turabian StylePervez, Hifsa, Mohammad S. Mozumder, and Abdel-Hamid I. Mourad. 2016. "Optimization of Injection Molding Parameters for HDPE/TiO2 Nanocomposites Fabrication with Multiple Performance Characteristics Using the Taguchi Method and Grey Relational Analysis" Materials 9, no. 8: 710. https://doi.org/10.3390/ma9080710

APA StylePervez, H., Mozumder, M. S., & Mourad, A. -H. I. (2016). Optimization of Injection Molding Parameters for HDPE/TiO2 Nanocomposites Fabrication with Multiple Performance Characteristics Using the Taguchi Method and Grey Relational Analysis. Materials, 9(8), 710. https://doi.org/10.3390/ma9080710