Life Cycle Impact Assessment of Miscanthus Crop for Sustainable Household Heating in Serbia

Abstract

:1. Introduction

2. Materials and Methods

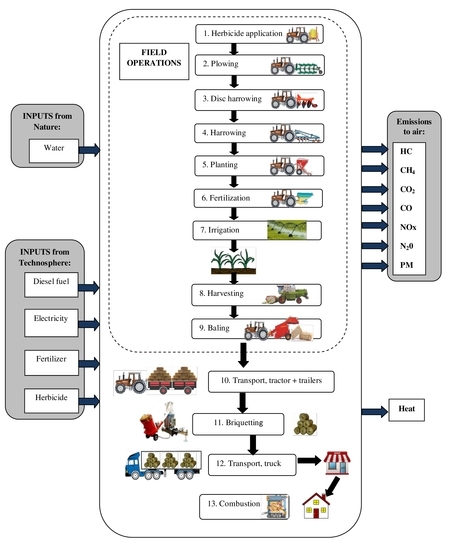

2.1. Goal, Scope, System Boundaries and Functional Unit

2.2. System Description

2.3. Life Cycle Inventory

2.3.1. Inputs: Machinery Used, Fuel Consumption, Productivity

2.3.2. Inputs: Herbicide, Fertilizer, Electricity

2.3.3. Emissions from Machinery Operation

2.4. Inventory for Coal and Wood

2.5. Impact Assessment Method

3. Results and Discussion

3.1. LCIA of Miscanthus Briquettes

3.2. Comparison of Miscanthus with Lignite and Wood Logs

3.3. Sensitivity Analysis

3.4. SOC and Land Use Change

3.4.1. Present Scenario

3.4.2. Future Scenario

3.5. Energy Ratio

4. Summary and Conclusions

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Statistical Office of the Republic of Serbia, Total Energy Balance in 2014. Available online: http://www.stat.gov.rs/en-US/oblasti/energetika (accessed on 20 April 2015).

- Statistical Office of the Republic of Serbia, Dwellings by the Type of Energy Raw Material Used for Heating, Belgrade. 2013. Available online: http://pod2.stat.gov.rs/ObjavljenePublikacije/Popis2011/Knjiga30.pdf (accessed on 22 April 2015).

- R. of S. Ministry of Mining and Energy, Energetski Bilans Republike Srbije za 2015 (Energy Balance of the Republic of Serbia for the Year 2015). 2015. Available online: http://www.mre.gov.rs/doc/efikasnost-izvori/EN BILANS ZA 2015 18 12 2014.doc (accessed on 3 March 2017).

- Faculty of Mining and Geology. Nacrt Strategije Razvoja Energetike Republike Srbije za Period Do 2025. Godine sa Projekcijama Do 2030. Godine (Draft of Energy Sector Development Strategy of the Republic of Serbia for the Period by 2025 with Projections by 2030). 2013. Available online: http://energetskiportal.rs/dokumenta/Strategije/Nacrt strategije razvoja energetike Republike Srbije za period do 2025. godine sa projekcijama do 2030. godine.pdf (accessed on 5 April 2015).

- Perić, M.; Komatina, M.; Bugarski, B.; Antonijević, D. Best Practices of Biomass Energy Life Cycle Assesment and Possible Applications in Serbia-review paper. Croat. J. For. Eng. 2016, 37, 375–390. [Google Scholar]

- Jovanović, B.; Parović, M. Stanje i Razvoj BIOMASE u Srbiji (State and Development of Biomass in Serbia), Belgrade. 2009. Available online: http://www.jeffersoninst.org/sites/default/files/Stanje i razvoj biomase u Srbiji.pdf (accessed on 11 June 2012).

- Lewandowski, I.; Schmidt, U. Nitrogen, energy and land use efficiencies of miscanthus, reed canary grass and triticale as determined by the boundary line approach. Agric. Ecosyst. Environ. 2006, 112, 335–346. [Google Scholar] [CrossRef] [Green Version]

- Smeets, E.M.W.; Lewandowski, I.M.; Faaij, A.P.C. The economical and environmental performance of miscanthus and switchgrass production and supply chains in a European setting. Renew. Sustain. Energy Rev. 2009, 13, 1230–1245. [Google Scholar] [CrossRef]

- Daraban, A.E.; Jurcoane, Ş.; Voicea, I.; Voicu, G. Miscanthus Giganteus Biomass for Sustainable Energy in Small Scale Heating Systems. Agric. Agric. Sci. Procedia 2015, 6, 538–544. [Google Scholar] [CrossRef]

- Murphy, F.; Devlin, G.; Mcdonnell, K. Miscanthus production and processing in Ireland: An analysis of energy requirements and environmental impacts. Renew. Sustain. Energy Rev. 2013, 23, 412–420. [Google Scholar] [CrossRef] [Green Version]

- Daraban, A.E.; Jurcoane, Ş.; Voicea, I. Miscanthus giganteus—An overview about sustainable energy resource for household and small farms heating systems. Rom. Biotechnol. Lett. 2015, 20, 10369–10380. [Google Scholar]

- Morandi, F.; Perrin, A.; Østergård, H. Miscanthus as energy crop: Environmental assessment of a miscanthus biomass production case study in France. J. Clean. Prod. 2016, 137, 313–321. [Google Scholar] [CrossRef]

- Aravindhakshan, S.C.; Epplin, F.M.; Taliaferro, C.M. Economics of switchgrass and miscanthus relative to coal as feedstock for generating electricity. Biomass Bioenergy 2010, 34, 1375–1383. [Google Scholar] [CrossRef]

- Parajuli, R.; Sperling, K.; Dalgaard, T. Environmental performance of Miscanthus as a fuel alternative for district heat production. Biomass Bioenergy 2015, 72, 104–116. [Google Scholar] [CrossRef]

- Bauen, A.W.; Dunnett, A.J.; Richter, G.M.; Dailey, A.G.; Aylott, M.; Casella, E.; Taylor, G. Modelling supply and demand of bioenergy from short rotation coppice and Miscanthus in the UK. Bioresour. Technol. 2010, 101, 8132–8143. [Google Scholar] [CrossRef] [PubMed]

- Dželetović, Ž.; Maksimović, J.; Živanović, I. Prinos Miscanthus × giganteus gajenog na dve lokacije u Srbiji (Yield of Miscanthus × giganteus during crop establishment at two locations in Serbia). J. Process. Energy Agric. 2014, 18, 62–64. [Google Scholar]

- Bilandzija, N.; Jurisic, V.; Voca, N.; Leto, J.; Matin, A.; Sito, S.; Kricka, T. Combustion properties of Miscanthus × giganteus biomass—Optimization of harvest time. J. Energy Inst. 2016, 1–6. [Google Scholar] [CrossRef]

- Burner, D.M.; Hale, A.L.; Carver, P.; Pote, D.H.; Fritschi, F.B. Biomass yield comparisons of giant miscanthus, giant reed, and miscane grown under irrigated and rainfed conditions. Ind. Crop. Prod. 2015, 76, 1025–1032. [Google Scholar] [CrossRef]

- Mantineo, M.; D’Agosta, G.M.; Copani, V.; Patane, C.; Cosentino, S.L. Biomass yield and energy balance of three perennial crops for energy use in the semi-arid Mediterranean environment. Field Crops Res. 2009, 114, 204–213. [Google Scholar] [CrossRef]

- Głowacka, K. A review of the genetic study of the energy crop Miscanthus. Biomass Bioenergy 2011, 35, 2445–2454. [Google Scholar] [CrossRef]

- Dželetović, Ž.; Mihailović, N.; Živanović, I. Prospects of using bioenergy crop Miscanthus × giganteus in Serbia. Mater. Process. Energy Commun. Curr. Res. Technol. Dev. 2013, 360–370. [Google Scholar]

- Lewandowski, I.; Clifton-Brown, J.C.; Scurlock, J.M.O.; Huisman, W. Miscanthus: European experience with a novel energy crop. Biomass Bioenergy 2000, 19, 209–227. [Google Scholar] [CrossRef]

- Dželetović, Ž.S. Miskantus (Miscanthus × giganteus Greef et Deu.)—Proizvodne Odlike i Produktivnost Biomase (Miscanthus—Production Quality and Biomass Productivity); Zadužbina Andrejević: Beograd, Srbija, 2012; p. 104. [Google Scholar]

- Sahoo, K.; Mani, S. GIS based discrete event modeling and simulation of biomass supply chain. In Proceedings of the Winter Simulation Conference (WSC), Huntington Beach, CA, USA, 6–9 December 2015; pp. 967–978. [Google Scholar]

- Lewandowski, I.; Kicherer, A. Combustion quality of biomass: Practical relevance and experiments to modify the biomass quality of Miscanthus × giganteus. Eur. J. Agron. 1997, 6, 163–177. [Google Scholar] [CrossRef]

- Reisinger, K.; Haslinger, C.; Herger, M.; Hofbauer, H. BioBib—A Database for Biofuels. Available online: https://www.vt.tuwien.ac.at/Biobib (accessed on 11 April 2016).

- Huang, Y.; McIlveen-Wright, D.R.; Rezvani, S.; Huang, M.J.; Wang, Y.D.; Roskilly, A.P.; Hewitt, N.J. Comparative techno-economic analysis of biomass fuelled combined heat and power for commercial buildings. Appl. Energy 2013, 112, 518–525. [Google Scholar] [CrossRef]

- Sims, R.E.H.; Hastings, A.; Schlamadinger, B.; Taylor, G.; Smith, P. Energy crops: Current status and future prospects. Glob. Chang. Biol. 2006, 12, 2054–2076. [Google Scholar] [CrossRef]

- Carvalho, L.; Wopienka, E.; Pointner, C.; Lundgren, J.; Verma, V.K.; Haslinger, W.; Schmidl, C. Performance of a pellet boiler fired with agricultural fuels. Appl. Energy 2013, 104, 286–296. [Google Scholar] [CrossRef]

- Sahoo, K. Sustainable design and simulation of multi-feedstock bioenergy supply chain. Ph.D. Thesis, University of Georgia, Athens, GA, USA, 2017. [Google Scholar]

- Técher, D.; Laval-Gilly, P.; Bennasroune, A.; Henry, S.; Martinez-Chois, C.; D’Innocenzo, M.; Falla, J. An appraisal of Miscanthus × giganteus cultivation for fly ash revegetation and soil restoration. Ind. Crops Prod. 2012, 36, 427–433. [Google Scholar] [CrossRef]

- Dželetović, Ž.; Živanović, I.; Pivić, R.; Simić, A.; Lazić, G.; Maksimović, J. Mogućnosti Korišćenja Višegodišnjih Rizomatoznih Trava Za Melioracije Oštećenih Zemljišnjih Površina (Possibilities of Use of Perrenial Rhizomatic Grasses for Melioration of Damaged Land Areas); Melioracije 13; University of Novi Sad, Faculty of Agriculture, Department of Water Management: Novi Sad, Serbia, 2013; pp. 130–137. [Google Scholar]

- Fowler, P.A.; Mclauchlin, A.R.; Hall, L.M. The Potential Industrial Uses of Forage Grasses Including Miscanthus; BioComposites Centre, University of Wales: Bangor, UK, 3 June 2003; Available online: http://www.florento.com/pdf/miscanthus_industrial_use.pdf (accessed on 15 June 2016).

- Acaroglu, M.; Aksoy, A.S. The cultivation and energy balance of Miscanthus  giganteus production in Turkey. Biomass Bioenergy 2005, 29, 42–48. [Google Scholar] [CrossRef]

- Perrin, A.; Wohlfahrt, J.; Morandi, F.; Østergård, H.; Flatberg, T.; De La Rua, C.; Bjørkvoll, T.; Gabrielle, B. Integrated design and sustainable assessment of innovative biomass supply chains: A case-study on miscanthus in France. Appl. Energy 2017, 204, 66–77. [Google Scholar] [CrossRef]

- Xue, S.; Kalinina, O.; Lewandowski, I. Present and future options for Miscanthus propagation and establishment. Renew. Sustain. Energy Rev. 2015, 49, 1233–1246. [Google Scholar] [CrossRef]

- Oljača, S.; Oljača, M.; Kovačević, D.; Glamočlija, Đ. Ekološke posledice upotrebe biljaka za dobijanje energije (Environmental consequences of plant utilization for energy). Agric. Eng. 2007, 32, 91–97. [Google Scholar]

- Ševarlić, M.M. Popis Poljoprivrede 2012–Poljoprivredno Zemljište u Republici Srbiji (Census of Agriculture 2012–Agriculture Land in the Republic of Serbia), Belgrade. 2015. Available online: http://popispoljoprivrede.stat.rs/?page_id=6061 (accessed on 15 June 2016).

- Cherubini, F.; Bird, N.D.; Cowie, A.; Jungmeier, G.; Schlamadinger, B.; Woess-Gallasch, S. Energy-and greenhouse gas-based LCA of biofuel and bioenergy systems: Key issues, ranges and recommendations. Resour. Conserv. Recycl. 2009, 53, 434–447. [Google Scholar] [CrossRef]

- Lewandowski, I.; Kicherer, A.; Vonier, P. CO2-balance for the cultivation and combustion of Miscanthus. Biomass Bioenergy 1995, 8, 81–90. [Google Scholar] [CrossRef]

- Lewandowski, I.; Heinz, A. Delayed harvest of miscanthus—Influences on biomass quantity and quality and environmental impacts of energy production. Eur. J. Agron. 2003, 19, 45–63. [Google Scholar] [CrossRef]

- Styles, D.; Jones, M.B. Energy Crops in Ireland: An Assessment of Their Potential Contribution to Sustainable Agriculture, Electricity and Heat Production; EPA: Wexford, Ireland, 2006. [Google Scholar]

- Felten, D.; Fröba, N.; Fries, J.; Emmerling, C. Energy balances and greenhouse gas-mitigation potentials of bioenergy cropping systems (Miscanthus, rapeseed, and maize) based on farming conditions in Western Germany. Renew. Energy 2013, 55, 160–174. [Google Scholar] [CrossRef]

- Clair, S.S.; Hillier, J.; Smith, P. Estimating the pre-harvest greenhouse gas costs of energy crop production. Biomass Bioenergy 2008, 32, 442–452. [Google Scholar] [CrossRef]

- Styles, D.; Jones, M.B. Energy crops in Ireland: Quantifying the potential life-cycle greenhouse gas reductions of energy-crop electricity. Biomass Bioenergy 2007, 31, 759–772. [Google Scholar] [CrossRef]

- Hamelin, L.; Jørgensen, U.; Petersen, B.M.; Olesen, J.E.; Wenzel, H. Modelling the carbon and nitrogen balances of direct land use changes from energy crops in Denmark: A consequential life cycle inventory. GCB Bioenergy 2012, 4, 889–907. [Google Scholar] [CrossRef]

- Roth, B.; Jones, M.; Burke, J.; Williams, M. The Effects of Land-Use Change from Grassland to Miscanthus × giganteus on Soil N2O Emissions. Land 2013, 2, 437–451. [Google Scholar] [CrossRef]

- Zatta, A.; Clifton-Brown, J.; Robson, P.; Hastings, A.; Monti, A. Land use change from C3 grassland to C4 Miscanthus: Effects on soil carbon content and estimated mitigation benefit after six years. GCB Bioenergy 2014, 6, 360–370. [Google Scholar] [CrossRef] [Green Version]

- Schmidl, C.; Luisser, M.; Padouvas, E.; Lasselsberger, L.; Rzaca, M.; Ramirez-Santa Cruz, C.; Handler, M.; Peng, G.; Bauer, H.; Puxbaum, H. Particulate and gaseous emissions from manually and automatically fired small scale combustion systems. Atmos. Environ. 2011, 45, 7443–7454. [Google Scholar] [CrossRef]

- Dželetović, Ž.S.; Dimitrijević, V.; Stojanović, S.; Pavlović, M. Tehnološki parametri briketiranja biomase Miskantusa (Technological parameters of briquetting of Miscanthus biomass). Agric. Eng. 2012, 631, 81–90. [Google Scholar]

- Moitzi, G.; Schüller, M.; Szalay, T.; Wagentristl, H.; Refenner, K.; Weingartmann, H.; Boxberger, J.; Gronauer, A. Energy consumption and energy efficiency of different tillage systems in the semi-arid region of Austria. Agric. Eng. 2013, 4, 25–33. [Google Scholar]

- Ercegović, Đ.; Pajić, M.; Raičević, D.; Oljača, M.; Gligorijević, K.; Vukić, Đ.; Radojević, R.; Dumanović, Z.; Dragićević, V. Uticaj konzervacijske obrade zemljišta na prinos suncokreta i merkantilnog kukuruza (The influence of conservation tillage of soil on sunflower and maize yield). Agric. Eng. 2009, 2, 69–82. [Google Scholar]

- Ružičić, L.N.; Petrović, P.; Gligorević, K.; Oljča, M.; Ružičić, T. Ekonomsko-tehnološki parametri optimalnog korišćenja traktora (Economic and Technological Parameters for Optimal Use of Tractors). Agro-Knowl. J. 2012, 13, 259–266. [Google Scholar] [CrossRef]

- Radić, P. Cenovnik Mašinskih Usluga u Poljoprivredi (Pricelist of Mechanical Services in Agriculture); Zadružni Savez Vojvodine: Novi Sad, Serbia, 2009; p. 50. [Google Scholar]

- Momirović, N.; Dolijanović, Ž.; Oljača, M.V.; Videnović, Ž. Višegodišnji uticaj različitih sistema obrade zemljišta na energetsku efikasnost i prinos kukuruza (Long term effects of different tillage systems influencing yield and energy efficiency in Maize). Agric. Eng. 2011, 1, 97–104. [Google Scholar]

- Gulati, S.; Singh, M. Energy requirement and management in a potato production system. Potato J. 2011, 38, 61–66. [Google Scholar]

- Miodragović, R.; Đević, M. Rezultati primene mobilnih sistema navodnjavanja kišenjem u biljnoj proizvodnji (Investigation of mobile systems for plant production). Agric. Eng. 2007, 1, 61–69. [Google Scholar]

- Miodragović, R.; Đević, M.; Mileusnić, Z.I. Energetski aspekti navodnjavanja kišenjem (Energy aspects of sprinkler irrigation). Agric. Eng. 2008, 3, 65–71. [Google Scholar]

- Miodragović, R.; Petrović, D.; Mileusnić, Z.; Đević, M. Energetski i distribucioni parametri linearnog sistema navodnjavanja (Energy and distributions parameters of linear irrigation system). Agric. Eng. 2009, 3, 47–55. [Google Scholar]

- Miodragović, R.; Mileusnić, Z.; Dimitrijević, A. Utrošak energije mobilnih irigacijskih sustava (Energy consumption of mobile irrigation systems). In Proceedings of the 41st International Symposium on Agricultural Engineering—Actual Tasks on Agricultural, Opatia, Croatia, 19–22 February 2013; pp. 181–188. [Google Scholar]

- Mathanker, S.K.; Hansen, A.C. Impact of miscanthus yield on harvesting cost and fuel consumption. Biomass Bioenergy 2015, 81, 162–166. [Google Scholar] [CrossRef]

- Johnson, P.C.; Clementson, C.L.; Mathanker, S.K.; Grift, T.E.; Hansen, A.C. Cutting energy characteristics of Miscanthus x giganteus stems with varying oblique angle and cutting speed. Biosyst. Eng. 2012, 112, 42–48. [Google Scholar] [CrossRef]

- Johnson, P.C. Energy Requiremenst and Productivity of Machinery Used to Harvest Herbaceous Energy Crops. Master’s Thesis, University of Illinois at Urbana-Campaign, Urbana and Champaign, IL, USA, 2012. [Google Scholar]

- Tica, N.; Zekić, V.; Milić, D.; Janković, D.; Janić, T. Izveštaj Projekta: Mogućnosti i Ekonomski Aspekti Upotrebe Žetvenih Ostataka za Proizvodnju Toplotne Energije (Project Report: Possibilities and Economic Aspects of Using of Agricultural Residues for Heat Production); University of Novi Sad, Faculty of Agriculture: Novi Sad, Serbia, 2015. [Google Scholar]

- FOEN. Non Road Emissions Database. Available online: http://www.bafu.admin.ch/luft/00596/06906/offroad-daten/index.html?lang=en (accessed on 25 January 2016).

- Dželetović, Ž.; Živanović, I.; Pivić, R.; Maksimović, J. Water supply and biomass production of Miscanthus × giganteus. In Proceedings of the 1st International Congress on Soil Science, XIII National Congress in Soil Science, Belgrade, Serbia, 23–26 September 2013; pp. 435–450. [Google Scholar]

- Miguez, F.E.; Villamil, M.B.; Long, S.P.; Bollero, G.A. Meta-analysis of the effects of management factors on Miscanthus × giganteus growth and biomass production. Agric. For. Meteorol. 2008, 148, 1280–1292. [Google Scholar] [CrossRef]

- Radivojević, D. Popis Poljoprivrede 2012-Poljoprivredna Mehanizacija, Oprema i Objekti (Census of Agriculture 2012-Agricultural Machinery, Equipment and Facilities). Available online: http://pod2.stat.gov.rs/ObjavljenePublikacije/Popis2012/Poljoprivredna%20mehanizacija,%20oprema%20i%20objekti.pdf (accessed on 15 June 2016).

- Fournel, S.; Palacios, J.H.; Morissette, R.; Villeneuve, J.; Godbout, S.; Heitz, M.; Savoie, P. Influence of biomass properties on technical and environmental performance of a multi-fuel boiler during on-farm combustion of energy crops. Appl. Energy 2015, 141, 247–259. [Google Scholar] [CrossRef]

- Venturi, P.; Huisman, W.; Molenaar, J. Mechanization and Costs of Primary Production Chains for Miscanthus × giganteus in The Netherlands. J. Agric. Engng Res. 1998, 69, 209–215. [Google Scholar] [CrossRef]

- Brkić, M.; Janić, T. Upotreba biobriketa za zagrevanje objekata u poljoprivredi (Use of biobriquetes for heating of buildings in agriculture). PTEP J. Process. Energy Agric. 2002, 6, 77–79. [Google Scholar]

- Zekic, V.; Rodic, V.; Jovanovic, M. Potentials and economic viability of small grain residue use as a source of energy in Serbia. Biomass Bioenergy 2010, 34, 1789–1795. [Google Scholar] [CrossRef]

- Jovanović-Popović, M.; Ignjatović, D.; Radivojević, A.; Rajčić, A.; Đukanović, L.; Đuković-Ignjatović, N.; Nedić, M. Nacionalna tipologija stambenih zgrada Srbije (National Typology of Residential Buildings in Serbia). Natl. Typol. Resid. 2013. [Google Scholar] [CrossRef]

- Matthews, R.B.; Grogan, P. Potential C-sequestration rates under short-rotation coppiced willow and Miscanthus biomass crops: A modeling study. Asp. Appl. Biol. 2001, 65, 303–312. [Google Scholar]

- Smith, P. Carbon sequestration in croplands: The potential in Europe and the global context. Eur. J. Agron. 2004, 20, 229–236. [Google Scholar] [CrossRef]

- IPCC. N2O Emissions from Managed Soils, and CO2 Emissions from Lime and Urea Application. 2006. Available online: http://www.ipcc-nggip.iges.or.jp/public/2006gl/pdf/4_Volume4/V4_11_Ch11_N2O&CO2.pdf (accessed on 10 August 2016).

- Lalic, D.; Popovski, K.; Gecevska, V.; Vasilevska, S.P.; Tesic, Z. Analysis of the opportunities and challenges for renewable energy market in the Western Balkan countries. Renew. Sustain. Energy Rev. 2011, 15, 3187–3195. [Google Scholar] [CrossRef]

- Schweinle, J.; Rödl, A.; Börjesson, P.; Neary, D.G.; Langeveld, J.W.; Berndes, G.; Cowie, A.; Ahlgren, S.; Margni, M.; Gaudreault, C.; et al. Assessing the environmental performance of biomass supply chains: methods, results, challenges and limitations. Available online: https://www.fs.fed.us/rm/pubs_journals/2015/rmrs_2015_schweinle_j001.pdf (accessed on 11 March 2016).

- Glavonjic, B.; Jovic, D.; Vasiljevic, A.; Kankaras, R. Forest and Forest Products Country Profile: Serbia and Montenegro-Generva Timber and Forest Discussion Paper 40; UNECE: Geneva, Switzerland, 2005. [Google Scholar]

- Guinée, J.B.; Gorrée, M.; Heijungs, R.; Huppes, G.; Kleijn, R.; de Koning, A.; van Oers, L.; Wegener Sleeswijk, S.; Anneke, S.; de Haes, H.A.U.; et al. Handbook on Life Cycle Assessment—Operational Guide to the ISO Standards. Available online: http://www.springer.com/gp/book/9781402002281 (accessed on 4 April 2015).

- Rebitzer, G.; Ekvall, T.; Frischknecht, R.; Hunkeler, D.; Norris, G.; Rydberg, T.; Schmidt, W.P.; Suh, S.; Weidema, B.P.; Pennington, D.W. Life cycle assessment Part 1: Framework, goal and scope definition, inventory analysis, and applications. Environ. Int. 2004, 30, 701–720. [Google Scholar] [CrossRef] [PubMed]

- Pennington, D.W.; Potting, J.; Finnveden, G.; Lindeijer, E.; Jolliet, O.; Rydberg, T.; Rebitzer, G. Life cycle assessment Part 2: Current impact assessment practice. Environ. Int. 2004, 30, 721–739. [Google Scholar] [CrossRef] [PubMed]

- Bare, J.C. Life cycle impact assessment research developments and needs. Clean Technol. Environ. Policy 2009, 12, 341–351. [Google Scholar] [CrossRef]

- Goedkoop, M.; Heijungs, R.; De Schryver, A.; Struijs, J.; van Zelm, R. ReCiPe 2008. A LCIA Method Which Comprises Harmonised Category Indicators at the Midpoint and the Endpoint Level. Report I: Characterisation. Available online: https://www.leidenuniv.nl/cml/ssp/publications/recipe_characterisation.pdf (accessed on 16 October 2014).

- Muench, S.; Guenther, E. A systematic review of bioenergy life cycle assessments. Appl. Energy 2013, 112, 257–273. [Google Scholar] [CrossRef]

- Pedraza, J.M. Electrical Energy Generation in Europe—The Current Situation and Perspectives in the Use of Renewable Energy Sources and Nuclear Power for Regional Electricity Generation; Springer: Berlin, Germany, 2015. [Google Scholar] [CrossRef]

- Borzêcka-Walker, M.; Faber, A.; Borek, R. Evaluation of carbon sequestration in energetic crops (Miscanthus and coppice willow). Int. Agrophys. 2008, 22, 185–190. [Google Scholar]

- Clifton-Brown, J.; Stampfl, P.S.; Jones, M.B. Miscanthus biomass production for energy in Europe and its potential contribution to decreasing fossil fuel carbon emissions. Glob. Chang. Biol. 2004, 10, 509–518. [Google Scholar] [CrossRef]

- Freibauer, A.; Rounsevell, M.D.A.; Smith, P.; Verhagen, J. Carbon sequestration in the agricultural soils of Europe. Geoderma 2004, 122, 1–23. [Google Scholar] [CrossRef]

- European Climate Change Programme (ECCP). Working Group Sinks Related to Agricultural Soils. Final Report. 2003. Available online: https://ec.europa.eu/clima/sites/clima/files/eccp/second/docs/finalreport_agricsoils_en.pdf (accessed on 18 September 2017).

| Operation: | Machinery Used (References Used) | Energy Consumption (MJ ha−1) | Productivity (h ha−1) | Diesel Consumption (kg ha−1) | Pollutant Emissions (kg ha−1) a |

|---|---|---|---|---|---|

| Herbicide application | Tractor (60 kW) + sprayer, Glyphosate: 3 kg ha−1 [51,52] b | 32 | 0.20 | 1.54 | HC: 0.0066 |

| CO: 0.0233 | |||||

| NOx: 0.2211 | |||||

| PM: 0.0310 | |||||

| CO2: 20.5917 | |||||

| CH4: 0.0017 | |||||

| N2O: 0.0007 | |||||

| Plowing (20–30 cm) | Tractor (103 kW) + plow [53,54] | 217 | 0.9 | 27.46 | HC: 0.0295 |

| CO: 0.1658 | |||||

| NOx: 0.3123 | |||||

| PM: 0.0181 | |||||

| CO2: 20.1638 | |||||

| CH4: 0.0007 | |||||

| N2O: 0.0009 | |||||

| Disc harrowing | Tractor (>100 kW) + disc harrow 450 cm [54,55] | 76 | 0.34 | 8.74 | HC: 0.0112 |

| CO: 0.0626 | |||||

| NOx: 0.1180 | |||||

| PM: 0.0068 | |||||

| CO2: 7.6174 | |||||

| CH4: 0.0003 | |||||

| N2O: 0.0003 | |||||

| Harrowing | Tractor (>100 kW) + harrow 700 cm [54,55] | 60 | 0.33 | 9.57 | HC: 0.0108 |

| CO: 0.0608 | |||||

| NOx: 0.1145 | |||||

| PM: 0.0066 | |||||

| CO2: 7.3934 | |||||

| CH4: 0.0003 | |||||

| N2O: 0.0003 | |||||

| Rhizomes planting | Tractor (35 kW) + semi-automatic potato planter (4 row) [23,56] | 183 | 3.33 | 8.42 | HC: 0.0669 |

| CO: 0.2634 | |||||

| NOx: 0.2211 | |||||

| PM: 0.0035 | |||||

| CO2: 2.5500 | |||||

| CH4: 0.0001 | |||||

| N2O: 0.0001 | |||||

| Fertilization | Tractor (60 kW) + mineral fertilizer spreader Rauch AXIS, 24 m, NPK: 667 kg 15:15:15 ha−1 [52,54,55] | 18 | 0.28 | 1.21 | HC: 0.0092 |

| CO: 0.0326 | |||||

| NOx: 0.0471 | |||||

| PM: 0.0050 | |||||

| CO2: 3.5700 | |||||

| CH4: 0.0002 | |||||

| N2O: 0.0001 | |||||

| Irrigation | Aggregate type “Sever Valmont”—15 kW with diesel engine “TAM” (110.4 kW), Water: 180 m3 ha−1 [57,58,59,60] | 163 | 0.41 | 7.57 | HC: 0.0134 |

| CO: 0.0755 | |||||

| NOx: 0.1423 | |||||

| PM: 0.0082 | |||||

| CO2: 9.1857 | |||||

| CH4: 0.0003 | |||||

| N2O: 0.0004 | |||||

| Harvesting | New Holland H8080, 168 kW, 750 HD Specialty Head with 4.7 m cutting width [61,62,63] | 321 | 0.96 | 27.46 | HC: 0.0887 |

| CO: 0.5159 | |||||

| NOx: 1.0577 | |||||

| PM: 0.0564 | |||||

| CO2: 59.5324 | |||||

| CH4: 0.0021 | |||||

| N2O: 0.0030 | |||||

| Baling and loading | Tractor (26 kW) + Wellger 730press [64] | 216 | 5.22 | 13.46 | HC: 0.1049 |

| CO: 0.4129 | |||||

| NOx: 0.3466 | |||||

| PM: 0.0485 | |||||

| CO2: 32.2789 | |||||

| CH4: 0.0026 | |||||

| N2O: 0.0010 | |||||

| Transport, tractor (t km) | Tractor (60 kW) + 2 trailers Zmaj-470/489 [64] | 23.5 × 120 = 2820 | 6 | 36.74 | HC: 0.1968 |

| CO: 0.6996 | |||||

| NOx: 1.0098 | |||||

| PM: 0.1062 | |||||

| CO2: 76.5 | |||||

| CH4: 0.0036 | |||||

| N2O: 0.0030 | |||||

| Briquetting | BIOMASSER® 2Duo-Set: −Shredder RK7 (7.5 kW) −2x BIOMASSER® Duo BS 207 (12.4 kW) [50] | 5922 | 79 | - | Emissions from electricity (Rep. of Serbia) consumption (Ecoinvent process) |

| Transport, truck (t km) | Truck >20 t | 23.5 × 100 = 2350 | 2 | 32.25 | Agri-footprint process: “Transport, truck >20 t, EURO2, 100%LF, default/GLO Mass” |

| TOTAL | 7208 | 87 | 121.27 | HC: 0.5380; CO: 2.3125; NOx: 3.4031; PM: 0.2905; CO2: 239.3833; CH4: 0.0119; N2O: 0.0099. | |

| Combustion | biomass boiler, 30 kW power, efficiency 0.85, Miscanthus Lower Heating Value (LHV) = 18.3 GJ t−1 | Energy release (MJ ha−1): 365,542 | - | - | HC: 0.3411; CO: 942.8898; NOx: 49.3373; PM: 5.2842. |

| TOTAL | energy output/energy input (EO:EI) = 51:1 | HC: 0.8791; CO: 945.2023; NOx: 52.7404; PM: 5.5747; CO2: 239.3833; CH4: 0.0119; N2O: 0.0099. | |||

| Impact Category: | Units and Receiving Mediums: | Lignite Briquettes (LB) | Wood Logs (WL) | Miscanthus Briquettes (MB) | Future Scenario (FS) | Emissions Reduction: | |||||

|---|---|---|---|---|---|---|---|---|---|---|---|

LB  MB MB | % | WL  MB MB | % | MB  FS FS | % | ||||||

| Climate change (CC) | kg CO2 eq a (to air) | 71,240.30 | 6032.66 | 1181.21 X | 3389.43 | −70,059.09 | −98.34 | −4851.45 | −80.42 | 2208.21 | 65.15% |

| Ozone depletion (OD) | kg CFC−11 b eq (to air) | 0.00066 | 0.00069 | 0.00091 | 0.00061 | +0.00025 | +27.30 | +0.00022 | +24.40 | −0.00029 | −32.81 |

| Terrestrial acidification (TA) | kg SO2 eq (to air) | 246.63 | 60.90 | 38.43 | 36.18 | −208.2 | −84.42 | −22.47 | −36.90 | −2.25 | −5.86 |

| Fresh water eutrophication (FE) | kg P eq (to freshwater) | 175.89 | 4.07 | 1.49 | 1.37 | −174.4 | −99.15 | −2.58 | −63.31 | −0.13 | −8.51 |

| Marine eutrophication (ME) | kg N eq (to freshwater) | 69.06 | 37.15 | 3.33 | 3.10 | −65.73 | −95.18 | −33.82 | −91.04 | −0.23 | −6.89 |

| Human toxicity (HT), Terrestrial ecotoxicity (TET), Freshwater ecotoxicity (FET), Marine ecotoxicity (ME) | kg 1,4-DB c eq (to urban air, urban soil, freshwater, marine water) | 116,557.53 | 4620.55 | 1154.85 | 1061.93 | −115,402.68 | −99.01 | −3465.70 | -75.01 | −92.88 | −8.04 |

| Photochemical oxidant formation (POF) | kg NMVOC d (to air) | 259.25 | 130.33 | 100.96 | 97.32 | −158.28 | −61.06 | −29.37 | −22.54 | −3.64 | −3.61 |

| Particulate matter formation (PMF) | kg PM10 eq (to air) | 120.19 | 47.87 | 20.06 | 19.25 | −100.13 | −83.31 | −27.81 | −58.09 | −0.81 | −4.03 |

| Ionising radiation (IR) | kBq e U235 f eq (to air) | 1714.33 | 443.39 | 74.48 | 24.06 | −1639.84 | −95.66 | −368.91 | −83.20 | −50.42 | −67.69 |

| Water depletion (WD) | Water m3 | −123,981.75 | −14,842.10 | −5640.42 | −5680.60 | +118,341.33 | +95.45 | +9201.68 | +62.00 | −40.18 | 0.71 |

| Fossil depletion (FD) | kg oil eq | 181,28.19 | 1664.98 | 393.93 | 295.06 | −17,734.25 | −97.83 | −1271.05 | −76.34 | −98.87 | −25.10 |

| Residual Biomass | N Content | N Content | N2O-Ndir | N2Odir | N2Ototal | CO2 eq Y | Total C input from Biomass into Soil | Gross Soil C | Gross CO2 eq | CO2 eq (Total) | Net CO2 eq | Net Soil C | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| (t) | (kg) | (kg) | (kg) | (kg) | (kg) | (t) | (t C ha−1 Year−1) | (t CO2 eq ha−1 Year−1) | (t C ha−1 Year−1) | ||||||||||

| Yield (85% dry Matter) t Year−1 | a | b | a | b | a + b | a + b | a + b | a + b | a + b | a | b | b 86% | a + b | a + b 18% | Total | X# + Y | |||

| min: | 18 | 8 | 4.16 | 80 | 20.8 | 100.8 | 2.01 | 3.16 | 3.24 | 0.96 | 3.86 | 2.00 | 1.72 | 5.58 | 1.00 | 3.68 | 2.16 | 1.52 | 0.41 |

| average: | 23.5 | 10.92 | 5.5 | 109.2 | 27.5 | 136.7 | 2.37 | 3.72 | 3.80 | 1.13 | 5.27 | 2.66 | 2.29 | 7.56 | 1.36 | 4.99 | 2.33 | 2.66 | 0.72 |

| max: | 33 | 15.36 | 7.74 | 153.6 | 38.7 | 192.3 | 2.92 | 4.59 | 4.67 | 1.39 | 7.42 | 3.74 | 3.22 | 10.64 | 1.91 | 7.02 | 2.59 | 4.43 | 1.21 |

| Miscanthus Yield | Net C Sequestration Potential for MB | Net C Sequestration Potential for FS | MB: Replacement of Set-Aside | FS: Replacement of Set-Aside |

|---|---|---|---|---|

| (t ha−1 Year−1, 85% Dry Matter) | (t C ha−1 year−1) | |||

| 18 | 1.52 | −0.68 | 0.03 | −0.57 |

| 23.5 | 2.66 | 0.46 | 0.34 | −0.26 |

| 33 | 4.43 | 2.23 | 0.83 | 0.23 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Perić, M.; Komatina, M.; Antonijević, D.; Bugarski, B.; Dželetović, Ž. Life Cycle Impact Assessment of Miscanthus Crop for Sustainable Household Heating in Serbia. Forests 2018, 9, 654. https://doi.org/10.3390/f9100654

Perić M, Komatina M, Antonijević D, Bugarski B, Dželetović Ž. Life Cycle Impact Assessment of Miscanthus Crop for Sustainable Household Heating in Serbia. Forests. 2018; 9(10):654. https://doi.org/10.3390/f9100654

Chicago/Turabian StylePerić, Milica, Mirko Komatina, Dragi Antonijević, Branko Bugarski, and Željko Dželetović. 2018. "Life Cycle Impact Assessment of Miscanthus Crop for Sustainable Household Heating in Serbia" Forests 9, no. 10: 654. https://doi.org/10.3390/f9100654

APA StylePerić, M., Komatina, M., Antonijević, D., Bugarski, B., & Dželetović, Ž. (2018). Life Cycle Impact Assessment of Miscanthus Crop for Sustainable Household Heating in Serbia. Forests, 9(10), 654. https://doi.org/10.3390/f9100654