Continuous Formulation Approaches of Amorphous Solid Dispersions: Significance of Powder Flow Properties and Feeding Performance

Abstract

:1. Introduction

2. Preparation of Polymer-Based Amorphous Solid Dispersions

3. Continuous Pharmaceutical Manufacturing

3.1. The Current State of Continuous Production

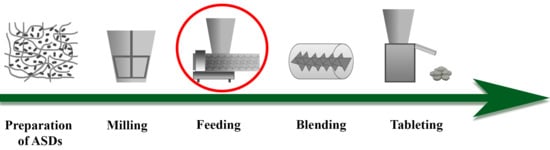

3.2. Continuous Formulation of ASDs

4. Feeding as the Key Step During the Continuous Formulation of Solid Dosage Forms

4.1. Powder Characterization

4.2. Flowability of ASDs

4.3. Improvement of the Flowability of ASDs for Continuous Feeding

4.4. Considerations Related to the Feeders

4.4.1. Feeder Peculiarities

4.4.2. Importance of Feeder Selection

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Lipinski, C.A.; Lombardo, F.; Dominy, B.W.; Feeney, P.J. Experimental and computational approaches to estimate solubility and permeability in drug discovery and development settings. Adv. Drug Deliv. Rev. 2012, 64, 4–17. [Google Scholar] [CrossRef]

- Pouton, C.W. Formulation of poorly water-soluble drugs for oral administration: Physicochemical and physiological issues and the lipid formulation classification system. Eur. J. Pharm. Sci. 2006, 29, 278–287. [Google Scholar] [CrossRef] [PubMed]

- Kawabata, Y.; Wada, K.; Nakatani, M.; Yamada, S.; Onoue, S. Formulation design for poorly water-soluble drugs based on biopharmaceutics classification system: Basic approaches and practical applications. Int. J. Pharm. 2011, 420, 1–10. [Google Scholar] [CrossRef] [PubMed]

- Vasconcelos, T.; Sarmento, B.; Costa, P. Solid dispersions as strategy to improve oral bioavailability of poor water soluble drugs. Drug Discov. Today 2007, 12, 1068–1075. [Google Scholar] [CrossRef]

- Borbás, E.; Sinkó, B.L.; Tsinman, O.; Tsinman, K.; Kiserdei, E.V.; Démuth, B.Z.; Balogh, A.; Bodák, B.; Domokos, A.S.; Dargó, G. Investigation and mathematical description of the real driving force of passive transport of drug molecules from supersaturated solutions. Mol. Pharm. 2016, 13, 3816–3826. [Google Scholar] [CrossRef]

- Hancock, B.C.; Parks, M. What is the true solubility advantage for amorphous pharmaceuticals? Pharm. Res. 2000, 17, 397–404. [Google Scholar] [CrossRef]

- Frank, K.J.; Rosenblatt, K.M.; Westedt, U.; Hölig, P.; Rosenberg, J.; Mägerlein, M.; Fricker, G.; Brandl, M. Amorphous solid dispersion enhances permeation of poorly soluble ABT-102: True supersaturation vs. apparent solubility enhancement. Int. J. Pharm. 2012, 437, 288–293. [Google Scholar] [CrossRef] [Green Version]

- Kalpana, P.; Manish, S.; Dinesh, S.K.; Surendra, J.K. Solid dispersion: Approaches, technology involved, unmet need & challenges. Drug Invent. Today 2010, 2, 349–357. [Google Scholar]

- Qian, F.; Huang, J.; Hussain, M.A. Drug–polymer solubility and miscibility: Stability consideration and practical challenges in amorphous solid dispersion development. J. Pharm. Sci. 2010, 99, 2941–2947. [Google Scholar] [CrossRef]

- Jermain, S.V.; Brough, C.; Williams, R.O., III. Amorphous solid dispersions and nanocrystal technologies for poorly water-soluble drug delivery—An update. Int. J. Pharm. 2018, 535, 379–392. [Google Scholar] [CrossRef]

- Plumb, K. Continuous processing in the pharmaceutical industry: Changing the mind set. Chem. Eng. Res. Des. 2005, 83, 730–738. [Google Scholar] [CrossRef]

- Poechlauer, P.; Manley, J.; Broxterman, R.; Gregertsen, B.R.; Ridemark, M. Continuous processing in the manufacture of active pharmaceutical ingredients and finished dosage forms: An industry perspective. Org. Process. Res. Dev. 2012, 16, 1586–1590. [Google Scholar] [CrossRef]

- Schaber, S.D.; Gerogiorgis, D.I.; Ramachandran, R.; Evans, J.M.; Barton, P.I.; Trout, B.L. Economic analysis of integrated continuous and batch pharmaceutical manufacturing: A case study. Ind. Eng. Chem. Res. 2011, 50, 10083–10092. [Google Scholar] [CrossRef] [Green Version]

- Lee, S.L.; O’Connor, T.F.; Yang, X.; Cruz, C.N.; Chatterjee, S.; Madurawe, R.D.; Moore, C.M.; Lawrence, X.Y.; Woodcock, J. Modernizing pharmaceutical manufacturing: From batch to continuous production. J. Pharm. Innov. 2015, 10, 191–199. [Google Scholar] [CrossRef] [Green Version]

- Mascia, S.; Heider, P.L.; Zhang, H.; Lakerveld, R.; Benyahia, B.; Barton, P.I.; Braatz, R.D.; Cooney, C.L.; Evans, J.; Jamison, T.F.; et al. End-to-end continuous manufacturing of pharmaceuticals: Integrated synthesis, purification, and final dosage formation. Angew. Chem. Int. Ed. 2013, 52, 12359–12363. [Google Scholar] [CrossRef] [PubMed]

- EMA. Assessment Report: Orkambi. 2015. Available online: http://www.ema.europa.eu/docs/en_GB/document_library/EPAR_-_Public_assessment_report/human/003954/WC500197613.pdf (accessed on 31 October 2019).

- Tan, S.; Newton, J. Powder flowability as an indication of capsule filling performance. Int. J. Pharm. 1990, 61, 145–155. [Google Scholar] [CrossRef]

- Démuth, B.; Nagy, Z.K.; Balogh, A.; Vigh, T.; Marosi, G.; Verreck, G.; Van Assche, I.; Brewster, M. Downstream processing of polymer-based amorphous solid dispersions to generate tablet formulations. Int. J. Pharm. 2015, 486, 268–286. [Google Scholar] [CrossRef]

- Blackshields, C.A.; Crean, A.M. Continuous powder feeding for pharmaceutical solid dosage form manufacture: A short review. Pharm. Dev. Technol. 2018, 23, 554–560. [Google Scholar] [CrossRef]

- Démuth, B.; Farkas, A.; Pataki, H.; Balogh, A.; Szabó, B.; Borbás, E.; Sóti, P.L.; Vigh, T.; Kiserdei, É.; Farkas, B.; et al. Detailed stability investigation of amorphous solid dispersions prepared by single-needle and high speed electrospinning. Int. J. Pharm. 2016, 498, 234–244. [Google Scholar]

- Serajuddin, A.T. Solid dispersion of poorly water-soluble drugs: Early promises, subsequent problems, and recent breakthroughs. J. Pharm. Sci. 1999, 88, 1058–1066. [Google Scholar] [CrossRef]

- Baghel, S.; Cathcart, H.; O’Reilly, N.J. Polymeric amorphous solid dispersions: A review of amorphization, crystallization, stabilization, solid-state characterization, and aqueous solubilization of biopharmaceutical classification system class II drugs. J. Pharm. Sci. 2016, 105, 2527–2544. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Vo, C.L.-N.; Park, C.; Lee, B.-J. Current trends and future perspectives of solid dispersions containing poorly water-soluble drugs. Eur. J. Pharm. Biopharm. 2013, 85, 799–813. [Google Scholar] [CrossRef] [PubMed]

- Singh, A.; Van den Mooter, G. Spray drying formulation of amorphous solid dispersions. Adv. Drug Deliv. Rev. 2016, 100, 27–50. [Google Scholar] [CrossRef] [PubMed]

- Walton, D.; Mumford, C. Spray dried products-characterization of particle morphology. Chem. Eng. Res. Des. 1999, 77, 21–38. [Google Scholar] [CrossRef]

- Repka, M.A.; Majumdar, S.; Kumar Battu, S.; Srirangam, R.; Upadhye, S.B. Applications of hot-melt extrusion for drug delivery. Expert Opin. Drug Deliv. 2008, 5, 1357–1376. [Google Scholar] [CrossRef] [PubMed]

- Maniruzzaman, M.; Boateng, J.S.; Snowden, M.J.; Douroumis, D. A review of hot-melt extrusion: Process technology to pharmaceutical products. ISRN Pharm. 2012, 2012, 436763. [Google Scholar] [CrossRef] [Green Version]

- Puri, V.; Brancazio, D.; Desai, P.M.; Jensen, K.D.; Chun, J.-H.; Myerson, A.S.; Trout, B.L. Development of maltodextrin-based immediate-release tablets using an integrated twin-screw hot-melt extrusion and injection-molding continuous manufacturing process. J. Pharm. Sci. 2017, 106, 3328–3336. [Google Scholar] [CrossRef]

- Zhang, J.; Feng, X.; Patil, H.; Tiwari, R.V.; Repka, M.A. Coupling 3D printing with hot-melt extrusion to produce controlled-release tablets. Int. J. Pharm. 2017, 519, 186–197. [Google Scholar] [CrossRef]

- Ahmed, I.; Nafadi, M.; Fatahalla, F. Formulation of a fast-dissolving ketoprofen tablet using freeze-drying in blisters technique. Drug Dev. Ind. Pharm. 2006, 32, 437–442. [Google Scholar] [CrossRef]

- Corveleyn, S.; Remon, J.P. Formulation and production of rapidly disintegrating tablets by lyophilisation using hydrochlorothiazide as a model drug. Int. J. Pharm. 1997, 152, 215–225. [Google Scholar] [CrossRef]

- Sethia, S.; Squillante, E. Solid dispersion of carbamazepine in PVP K30 by conventional solvent evaporation and supercritical methods. Int. J. Pharm. 2004, 272, 1–10. [Google Scholar] [CrossRef] [PubMed]

- Yu, D.-G.; Li, J.-J.; Williams, G.R.; Zhao, M. Electrospun amorphous solid dispersions of poorly water-soluble drugs: A review. J. Control. Release 2018, 292, 91–110. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Wagner, I.; Nagy, Z.K.; Vass, P.; Fehér, C.; Barta, Z.; Vigh, T.; Sóti, P.L.; Harasztos, A.H.; Pataki, H.; Balogh, A.; et al. Stable formulation of protein-type drug in electrospun polymeric fiber followed by tableting and scaling-up experiments. Polym. Adv. Technol. 2015, 26, 1461–1467. [Google Scholar] [CrossRef]

- Hamori, M.; Nagano, K.; Kakimoto, S.; Naruhashi, K.; Kiriyama, A.; Nishimura, A.; Shibata, N. Preparation and pharmaceutical evaluation of acetaminophen nano-fiber tablets: Application of a solvent-based electrospinning method for tableting. Biomed. Pharm. 2016, 78, 14–22. [Google Scholar] [CrossRef] [PubMed]

- Poller, B.; Strachan, C.; Broadbent, R.; Walker, G.F. A minitablet formulation made from electrospun nanofibers. Eur. J. Pharm. Biopharm. 2017, 114, 213–220. [Google Scholar] [CrossRef] [Green Version]

- Démuth, B.; Farkas, A.; Szabó, B.; Balogh, A.; Nagy, B.; Vágó, E.; Vigh, T.; Tinke, A.; Kazsu, Z.; Demeter, Á.; et al. Development and tableting of directly compressible powder from electrospun nanofibrous amorphous solid dispersion. Adv. Powder Technol. 2017, 28, 1554–1563. [Google Scholar] [CrossRef] [Green Version]

- Verreck, G.; Chun, I.; Peeters, J.; Rosenblatt, J.; Brewster, M.E. Preparation and characterization of nanofibers containing amorphous drug dispersions generated by electrostatic spinning. Pharm. Res. 2003, 20, 810–817. [Google Scholar] [CrossRef]

- Radacsi, N.; Giapis, K.P.; Ovari, G.; Szabó-Révész, P.; Ambrus, R. Electrospun nanofiber-based niflumic acid capsules with superior physicochemical properties. J. Pharm. Biomed. Anal. 2019, 166, 371–378. [Google Scholar] [CrossRef] [Green Version]

- Mollan, M.J., Jr.; Lodaya, M. Continuous processing in pharmaceutical manufacturing. Pharm. Manufact Mag. 2004, 11, 1–9. [Google Scholar]

- Burcham, C.L.; Florence, A.J.; Johnson, M.D. Continuous manufacturing in pharmaceutical process development and manufacturing. Annu. Rev. Chem. Biomol. Eng. 2018, 9, 253–281. [Google Scholar] [CrossRef]

- Badman, C.; Trout, B.L. Achieving Continuous Manufacturing May 20–21 2014 Continuous Manufacturing Symposium. J. Pharm. Sci. 2015, 104, 779–780. [Google Scholar] [CrossRef] [PubMed]

- Nasr, M.M.; Krumme, M.; Matsuda, Y.; Trout, B.L.; Badman, C.; Mascia, S.; Cooney, C.L.; Jensen, K.D.; Florence, A.; Johnston, C.; et al. Regulatory Perspectives on Continuous Pharmaceutical Manufacturing: Moving from Theory to Practice: 26–27 September 2016, International Symposium on the Continuous Manufacturing of Pharmaceuticals. J. Pharm. Sci. 2017, 106, 3199–3206. [Google Scholar] [CrossRef] [PubMed]

- FDA. Guidance for Industry: PAT—A Framework for Innovative Pharmaceutical Development, Manufacturing, and Quality Assurance. Available online: http://www.fda.gov/regulatory-information/search-fda-guidance-documents/pat-framework-Innovative-pharmaceutical-development-manufacturing-and-quality-assurance (accessed on 24 October 2019).

- ICH Expert Working Group. ICH Guideline Q10 Pharmaceutical Quality System. International Conference on Harmonisation (ICH). 2008. Available online: http://www.database.ich.org/sites/default/files/Q10_Guideline.pdf (accessed on 31 October 2019).

- ICH Expert Working Group. ICH Guideline Q9 Quality Risk Management. International Conference on Harmonisation. 2005. Available online: http://www.database.ich.org/sites/default/files/Q9_Guideline.pdf (accessed on 31 October 2019).

- ICH Expert Working Group. ICH Guideline Q8(R2), Pharmaceutical Development. International Conference on Harmonisation. 2009. Available online: http://www.database.ich.org/sites/default/files/Q8_R2_Guideline.pdf (accessed on 31 October 2019).

- Teżyk, M.; Milanowski, B.; Ernst, A.; Lulek, J. Recent progress in continuous and semi-continuous processing of solid oral dosage forms: A review. Drug Dev. Ind. Pharm. 2016, 42, 1195–1214. [Google Scholar] [CrossRef] [PubMed]

- Bosch. Bosch Presents New Xelum R&D. Available online: http://www.bosch-presse.de/pressportal/de/en/bosch-presents-new-xelum-randd-158528.html (accessed on 24 October 2019).

- Byrn, S.; Futran, M.; Thomas, H.; Jayjock, E.; Maron, N.; Meyer, R.F.; Myerson, A.S.; Thien, M.P.; Trout, B.L. Achieving continuous manufacturing for final dosage formation: Challenges and how to meet them. May 20–21, 2014 continuous manufacturing symposium. J. Pharm. Sci. 2015, 104, 792–802. [Google Scholar] [CrossRef]

- GEA. Continuous Manufacturing. Available online: http://www.gea.com/en/solutions/continuous-manufacturing.jsp (accessed on 24 October 2019).

- Simonaho, S.-P.; Ketolainen, J.; Ervasti, T.; Toiviainen, M.; Korhonen, O. Continuous manufacturing of tablets with PROMIS-line—Introduction and case studies from continuous feeding, blending and tableting. Eur. J. Pharm. Sci. 2016, 90, 38–46. [Google Scholar] [CrossRef]

- Singh, R.; Román-Ospino, A.D.; Romañach, R.J.; Ierapetritou, M.; Ramachandran, R. Real time monitoring of powder blend bulk density for coupled feed-forward/feed-back control of a continuous direct compaction tablet manufacturing process. Int. J. Pharm. 2015, 495, 612–625. [Google Scholar] [CrossRef]

- Taipale-Kovalainen, K.; Karttunen, A.-P.; Niinikoski, H.; Ketolainen, J.; Korhonen, O. The effects of unintentional and intentional process disturbances on tablet quality during long continuous manufacturing runs. Eur. J. Pharm. Sci. 2019, 129, 10–20. [Google Scholar] [CrossRef]

- Adamo, A.; Beingessner, R.L.; Behnam, M.; Chen, J.; Jamison, T.F.; Jensen, K.F.; Monbaliu, J.-C.M.; Myerson, A.S.; Revalor, E.M.; Snead, D.R.; et al. On-demand continuous-flow production of pharmaceuticals in a compact, reconfigurable system. Science 2016, 352, 61–67. [Google Scholar] [CrossRef] [Green Version]

- Kalivoda, A.; Fischbach, M.; Kleinebudde, P. Application of mixtures of polymeric carriers for dissolution enhancement of fenofibrate using hot-melt extrusion. Int. J. Pharm. 2012, 429, 58–68. [Google Scholar] [CrossRef]

- Gryczke, A.; Schminke, S.; Maniruzzaman, M.; Beck, J.; Douroumis, D. Development and evaluation of orally disInt.egrating tablets (ODTs) containing Ibuprofen granules prepared by hot melt extrusion. Colloids Surf. B Biointerfaces 2011, 86, 275–284. [Google Scholar] [CrossRef]

- Baronsky-Probst, J.; Möltgen, C.-V.; Kessler, W.; Kessler, R. Process design and control of a twin screw hot melt extrusion for continuous pharmaceutical tamper-resistant tablet production. Eur. J. Pharm. Sci. 2016, 87, 14–21. [Google Scholar] [CrossRef] [PubMed]

- Pawar, J.; Narkhede, R.; Amin, P.; Tawde, V. Design and evaluation of topical diclofenac sodium gel using hot melt extrusion Technology as a continuous manufacturing process with Kolliphor® P407. AAPS PharmSciTech 2017, 18, 2303–2315. [Google Scholar] [CrossRef] [PubMed]

- QuInten, T.; De Beer, T.; Vervaet, C.; Remon, J.P. Evaluation of injection moulding as a pharmaceutical Technology to produce matrix tablets. Eur. J. Pharm. Biopharm. 2009, 71, 145–154. [Google Scholar] [CrossRef] [PubMed]

- Ilyés, K.; Balogh, A.; Casian, T.; Igricz, T.; Borbás, E.; Démuth, B.; Vass, P.; Menyhárt, L.; Kovács, N.K.; Marosi, G.; et al. 3D Floating tablets: Appropriate 3D design from the perspective of different in vitro dissolution testing methodologies. Int. J. Pharm. 2019, 15, 118433. [Google Scholar]

- Steckel, H.; Brandes, H.G. A novel spray-drying technique to produce low density particles for pulmonary delivery. Int. J. Pharm. 2004, 278, 187–195. [Google Scholar] [CrossRef]

- Yi, T.; Wan, J.; Xu, H.; Yang, X. A new solid self-microemulsifying formulation prepared by spray-drying to improve the oral bioavailability of poorly water soluble drugs. Eur. J. Pharm. Biopharm. 2008, 70, 439–444. [Google Scholar] [CrossRef]

- Dolenc, A.; Kristl, J.; Baumgartner, S.; Planinšek, O. Advantages of celecoxib nanosuspension formulation and transformation into tablets. Int. J. Pharm. 2009, 376, 204–212. [Google Scholar] [CrossRef]

- Hadida, S.; Van Goor, F.; Dinehart, K.; Looker, A.R.; Mueller, P.; Grootenhuis, P.D. Case history: Kalydeco®(VX-770, Ivacaftor), a CFTR potentiator for the treatment of patients with cystic fibrosis and the G551D-CFTR mutation. In Annual Reports in Medicinal Chemistry; Elsevier: Amsterdam, The Netherlands, 2014; Volume 49, pp. 383–398. [Google Scholar]

- Akdag Cayli, Y.; Sahin, S.; Buttini, F.; Balducci, A.G.; Montanari, S.; Vural, I.; Oner, L. Dry powders for the inhalation of ciprofloxacin or levofloxacin combined with a mucolytic agent for cystic fibrosis patients. Drug Dev. Ind. Pharm. 2017, 43, 1378–1389. [Google Scholar] [CrossRef]

- Örkényi, R.; Éles, J.; Faigl, F.; Vincze, P.; Prechl, A.; Szakács, Z.; Kóti, J.; Greiner, I. Continuous synthesis and purification by coupling a multistep flow reaction with centrifugal partition chromatography. Angew. Chem. Int. Ed. 2017, 56, 8742–8745. [Google Scholar] [CrossRef] [Green Version]

- Balogh, A.; Domokos, A.; Farkas, B.; Farkas, A.; Rapi, Z.; Kiss, D.; Nyiri, Z.; Eke, Z.; Szarka, G.; Örkényi, R.; et al. Continuous end-to-end production of solid drug dosage forms: Coupling flow synthesis and formulation by electrospinning. Chem. Eng. J. 2018, 350, 290–299. [Google Scholar] [CrossRef]

- Bostijn, N.; Van Renterghem, J.; Vanbillemont, B.; Dhondt, W.; Vervaet, C.; De Beer, T. Continuous manufacturing of a pharmaceutical cream: Investigating continuous powder dispersing and residence time distribution (RTD). Eur. J. Pharm. Sci. 2019, 132, 106–117. [Google Scholar] [CrossRef] [PubMed]

- Szabó, E.; Démuth, B.; Nagy, B.; Molnár, K.; Farkas, A.; Szabó, B.; Balogh, A.; Hirsch, E.; Marosi, G.; Nagy, Z. Scaled-up preparation of drug-loaded electrospun polymer fibres and investigation of their continuous processing to tablet form. Express Polym. Lett. 2018, 12, 436–451. [Google Scholar] [CrossRef]

- Clarke, A.J.; Doughty, D.G.; Fiesser, F.H.; Wagner, D.S. Apparatus for Producing a Pharmaceutical Product. US8252234B2, 28 August 2012. [Google Scholar]

- Clarke, A.; Doughty, D. Development of liquid dispensing Technology for the manufacture of low dose drug products. In Continuous Manufacturing of Pharmaceuticals; Kleinebudde, P., Khinast, J., Rantanen, J., Eds.; John Wiley & Sons: Hoboken, NJ, USA, 2017; pp. 551–575. [Google Scholar]

- Savolainen, M.; Heinz, A.; Strachan, C.; Gordon, K.C.; Yliruusi, J.; Rades, T.; Sandler, N. Screening for differences in the amorphous state of indomethacin using multivariate visualization. Eur. J. Pharm. Sci. 2007, 30, 113–123. [Google Scholar] [CrossRef] [PubMed]

- Widjaja, E.; Kanaujia, P.; Lau, G.; Ng, W.K.; Garland, M.; Saal, C.; Hanefeld, A.; Fischbach, M.; Maio, M.; Tan, R.B. Detection of trace crystallinity in an amorphous system using Raman microscopy and chemometric analysis. Eur. J. Pharm. Sci. 2011, 42, 45–54. [Google Scholar] [CrossRef] [PubMed]

- Saerens, L.; Dierickx, L.; Lenain, B.; Vervaet, C.; Remon, J.P.; De Beer, T. Raman spectroscopy for the in-line polymer–drug quantification and solid state characterization during a pharmaceutical hot-melt extrusion process. Eur J. Pharm. Biopharm. 2011, 77, 158–163. [Google Scholar] [CrossRef] [Green Version]

- Vigh, T.; Drávavölgyi, G.; Sóti, P.L.; Pataki, H.; Igricz, T.; Wagner, I.; Vajna, B.; Madarász, J.; Marosi, G.; Nagy, Z.K. Predicting final product properties of melt extruded solid dispersions from process parameters using Raman spectrometry. J. Pharm. Biomed. Anal. 2014, 98, 166–177. [Google Scholar] [CrossRef]

- Nørgaard, L.; Hahn, M.; Knudsen, L.; Farhat, I.; Engelsen, S.B. Multivariate near-infrared and Raman spectroscopic quantifications of the crystallinity of lactose in whey permeate powder. Int. Dairy J. 2005, 15, 1261–1270. [Google Scholar] [CrossRef]

- Tewari, J.; Dixit, V.; Malik, K. On-line monitoring of residual solvent during the pharmaceutical drying process using non-contact infrared sensor: A process analytical Technology (PAT) approach. Sens. Actuators B Chem. 2010, 144, 104–111. [Google Scholar] [CrossRef]

- Fonteyne, M.; Gildemyn, D.; Peeters, E.; Mortier, S.T.F.; Vercruysse, J.; Gernaey, K.V.; Vervaet, C.; Remon, J.P.; Nopens, I.; De Beer, T. Moisture and drug solid-state monitoring during a continuous drying process using empirical and mass balance models. Eur. J. Pharm. Biopharm. 2014, 87, 616–628. [Google Scholar] [CrossRef]

- Chablani, L.; Taylor, M.K.; Mehrotra, A.; Rameas, P.; Stagner, W.C. Inline real-time near-infrared granule moisture measurements of a continuous granulation–drying–milling process. AAPS PharmSciTech 2011, 12, 1050–1055. [Google Scholar] [CrossRef] [Green Version]

- Vercruysse, J.; Peeters, E.; Fonteyne, M.; Cappuyns, P.; Delaet, U.; Van Assche, I.; De Beer, T.; Remon, J.P.; Vervaet, C. Use of a continuous twin screw granulation and drying system during formulation development and process optimization. Eur. J. Pharm. Biopharm. 2015, 89, 239–247. [Google Scholar] [CrossRef] [PubMed]

- Davies, P. Oral solid dosage forms. In Pharmaceutical Preformulation and Formulation, 2nd ed.; CRC Press: Boca Raton, FL, USA, 2015; pp. 391–470. [Google Scholar]

- Nasereddin, J.M.; Wellner, N.; Alhijjaj, M.; Belton, P.; Qi, S. Development of a simple mechanical screening method for predicting the feedability of a pharmaceutical FDM 3D printing filament. Pharm. Res. 2018, 35, 151. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Engisch, W.E.; Muzzio, F.J. Method for characterization of loss-in-weight feeder equipment. Powder Technol. 2012, 228, 395–403. [Google Scholar] [CrossRef]

- Pack, B.W.; Babayan, Y.; Schrad, M.A.; Stroud, P.A.; Sperry, D.C.; White, K.C.; Aburub, A. Development of an in vivo-relevant drug product performance method for an amorphous solid dispersion. J. Pharm. Biomed. Anal. 2017, 142, 307–314. [Google Scholar] [CrossRef]

- Fujimoto, Y.; Hirai, N.; Takatani-Nakase, T.; Takahashi, K. Novel tablet formulation of amorphous indomethacin using wet granulation with a high-speed mixer granulator combined with porous calcium silicate. J. Drug Deliv. Sci. Technol. 2016, 33, 51–57. [Google Scholar] [CrossRef]

- Feng, Z.; Li, M.; Wang, W. Improvement of dissolution and tabletability of carbamazepine solid dispersions with high drug loading prepared by hot-melt extrusion. Pharmazie 2019, 74, 523–528. [Google Scholar]

- Clayton, J. Reviewing current practice in powder testing. Org. Process. Res. Dev. 2014, 19, 102–109. [Google Scholar] [CrossRef]

- Freeman, T. An Introduction to Powders; Freeman Technology: Tewkesbury, UK, 2014. [Google Scholar]

- Hlinak, A.J.; Kuriyan, K.; Morris, K.R.; Reklaitis, G.V.; Basu, P.K. Understanding critical material properties for solid dosage form design. J. Pharm. Innov. 2006, 1, 12–17. [Google Scholar] [CrossRef]

- Cartwright, J.J.; Robertson, J.; D’Haene, D.; Burke, M.D.; Hennenkamp, J.R. Twin screw wet granulation: Loss in weight feeding of a poorly flowing active pharmaceutical ingredient. Powder Technol. 2013, 238, 116–121. [Google Scholar] [CrossRef]

- Engisch, W.E.; Muzzio, F.J. Loss-in-weight feeding trials case study: Pharmaceutical formulation. J. Pharm. Innov. 2015, 10, 56–75. [Google Scholar] [CrossRef]

- Wang, Y.; Li, T.; Muzzio, F.J.; Glasser, B.J. Predicting feeder performance based on material flow properties. Powder Technol. 2017, 308, 135–148. [Google Scholar] [CrossRef] [Green Version]

- Van Snick, B.; Dhondt, J.; Pandelaere, K.; Bertels, J.; Mertens, R.; Klingeleers, D.; Di Pretoro, G.; Remon, J.P.; Vervaet, C.; De Beer, T.; et al. A multivariate raw material property database to facilitate drug product development and enable in-silico design of pharmaceutical dry powder processes. Int. J. Pharm. 2018, 549, 415–435. [Google Scholar] [CrossRef] [PubMed]

- Bostijn, N.; Dhondt, J.; Ryckaert, A.; Szabó, E.; Dhondt, W.; Van Snick, B.; Vanhoorne, V.; Vervaet, C.; De Beer, T. A multivariate approach to predict the volumetric and gravimetric feeding behavior of a low feed rate feeder based on raw material properties. Int. J. Pharm. 2018, 557, 342–353. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Boukouvala, F.; Ierapetritou, M.G. Surrogate-based optimization of expensive flowsheet modeling for continuous pharmaceutical manufacturing. J. Pharm. Innov. 2013, 8, 131–145. [Google Scholar] [CrossRef]

- Fu, X.; Huck, D.; Makein, L.; Armstrong, B.; Willen, U.; Freeman, T. Effect of particle shape and size on flow properties of lactose powders. Particuology 2012, 10, 203–208. [Google Scholar] [CrossRef]

- Liu, L.; Marziano, I.; Bentham, A.; Litster, J.; White, E.; Howes, T. Effect of particle properties on the flowability of ibuprofen powders. Int. J. Pharm. 2008, 362, 109–117. [Google Scholar] [CrossRef]

- Madarász, L.; Nagy, Z.K.; Hoffer, I.; Szabó, B.; Csontos, I.; Pataki, H.; Démuth, B.; Szabó, B.; Csorba, K.; Marosi, G. Real-Time Feedback Control of Twin-Screw Wet Granulation based on Image Analysis. Int. J. Pharm. 2018, 547, 360–367. [Google Scholar] [CrossRef]

- Abdullah, E.; Geldart, D. The use of bulk density measurements as flowability indicators. Powder Technol. 1999, 102, 151–165. [Google Scholar] [CrossRef]

- Shah, R.B.; Tawakkul, M.A.; Khan, M.A. Comparative evaluation of flow for pharmaceutical powders and granules. AAPS PharmSciTech 2008, 9, 250–258. [Google Scholar] [CrossRef] [Green Version]

- Fitzpatrick, J.; Barringer, S.; Iqbal, T. Flow property measurement of food powders and sensitivity of Jenike’s hopper design methodology to the measured values. J. Food Eng. 2004, 61, 399–405. [Google Scholar] [CrossRef]

- Westermarck, S.; Juppo, A.M.; Kervinen, L.; Yliruusi, J. Pore structure and surface area of mannitol powder, granules and tablets determined with mercury porosimetry and nitrogen adsorption. Eur J. Pharm. Biopharm. 1998, 46, 61–68. [Google Scholar] [CrossRef]

- Han, X.; Jallo, L.; To, D.; Ghoroi, C.; Davé, R. Passivation of high-surface-energy sites of milled ibuprofen crystals via dry coating for reduced cohesion and improved flowability. J. Pharm. Sci. 2013, 102, 2282–2296. [Google Scholar] [CrossRef] [PubMed]

- Spillmann, A.; Sonnenfeld, A.; Rudolf von Rohr, P. Effect of surface free energy on the flowability of lactose powder treated by PECVD. Plasma Process. Polym. 2008, 5, 753–758. [Google Scholar] [CrossRef]

- Seppälä, K.; Heinämäki, J.; Hatara, J.; Seppälä, L.; Yliruusi, J. Development of a new method to get a reliable powder flow characteristics using only 1 to 2 g of powder. AAPS PharmSciTech 2010, 11, 402–408. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Boschini, F.; Delaval, V.; Traina, K.; Vandewalle, N.; Lumay, G. Linking flowability and granulometry of lactose powders. Int. J. Pharm. 2015, 494, 312–320. [Google Scholar] [CrossRef] [PubMed]

- De Ryck, A.; Condotta, R.; Dodds, J.A. Shape of a cohesive granular heap. Powder Technol. 2005, 157, 72–78. [Google Scholar] [CrossRef] [Green Version]

- Fitzpatrick, J.; Iqbal, T.; Delaney, C.; Twomey, T.; Keogh, M. Effect of powder properties and storage conditions on the flowability of milk powders with different fat contents. J. Food Eng. 2004, 64, 435–444. [Google Scholar] [CrossRef]

- Søgaard, S.V.; Pedersen, T.; Allesø, M.; Garnaes, J.; Rantanen, J. Evaluation of ring shear testing as a characterization method for powder flow in small-scale powder processing equipment. Int. J. Pharm. 2014, 475, 315–323. [Google Scholar] [CrossRef]

- Taillet, J. Static charge elimination on polymer particulates during their industrial production: Supersonic injection technology. Powder Technol. 2003, 135, 201–208. [Google Scholar] [CrossRef]

- Weick, J.J.; Hagerty, R.O.; Husby, P.K.; Lo, F.Y.-K. Apparatus for Measuring the Static Charge of Flowable Solids. CA2426125A1, 23 May 2002. [Google Scholar]

- Bley, O.; Siepmann, J.; Bodmeier, R. Characterization of moisture-protective polymer coatings using differential scanning calorimetry and dynamic vapor sorption. J. Pharm. Sci. 2009, 98, 651–664. [Google Scholar] [CrossRef]

- Crouter, A.; Briens, L. The effect of moisture on the flowability of pharmaceutical excipients. AAPS PharmSciTech 2014, 15, 65–74. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Gonnissen, Y.; Remon, J.P.; Vervaet, C. Development of directly compressible powders via co-spray drying. Eur. J. Pharm. Biopharm. 2007, 67, 220–226. [Google Scholar] [CrossRef] [PubMed]

- Zhou, D.; Qiu, Y. Understanding material properties in pharmaceutical product development and manufacturing: Powder flow and mechanical properties. JVT 2010, 16, 65. [Google Scholar]

- Davis, M.T.; Potter, C.B.; Walker, G.M. Downstream Processing of a Ternary Amorphous Solid Dispersion: The Impacts of Spray Drying and Hot Melt Extrusion on Powder Flow, Compression and Dissolution. Int. J. Pharm. 2018, 544, 242–253. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Verreck, G.; Heymans, K.; Henrist, D.; Van Assche, I.; Baert, L.; Van den Mooter, G.; Brewster, M. Post-die processing of solid dispersion-based melt extrudates: Milling and tableting. In Proceedings of the AAPS Annual Meeting Exposition, San Antonio, TX, USA, 10–14 November 2013. [Google Scholar]

- Shan-Yang, L.; Yuh-Horng, K. Solid particulates of drug-β-cyclodextrin inclusion complexes directly prepared by a spray-drying technique. Int. J. Pharm. 1989, 56, 249–259. [Google Scholar] [CrossRef]

- Kiekens, F.R.I.; Voorspoels, J.F.M.; Baert, L.E.C. Process for Preparing Spray Dried Formulation of TMC125. CA2651665A1, 13 December 2007. [Google Scholar]

- Vass, P.; Hirsch, E.; Kóczián, R.; Démuth, B.; Farkas, A.; Fehér, C.; Szabó, E.; Németh, Á.; Andersen, S.K.; Vigh, T.; et al. Scaled-up Production and Tableting of Grindable Electrospun Fibers Containing a Protein-Type Drug. Pharmaceutics 2019, 11, 329. [Google Scholar] [CrossRef] [Green Version]

- Hirsch, E.; Vass, P.; Démuth, B.; Pethő, Z.; Bitay, E.; Andersen, S.; Vigh, T.; Verreck, G.; Molnár, K.; Nagy, Z.K.; et al. Electrospinning scale-up and formulation development of PVA nanofibers aiming oral delivery of biopharmaceuticals. Express Polym. Lett. 2019, 13, 590–603. [Google Scholar] [CrossRef]

- Paudel, A.; Worku, Z.A.; Meeus, J.; Guns, S.; Van den Mooter, G. Manufacturing of solid dispersions of poorly water soluble drugs by spray drying: Formulation and process considerations. Int. J. Pharm. 2013, 453, 253–284. [Google Scholar] [CrossRef]

- Vehring, R.; Foss, W.R.; Lechuga-Ballesteros, D. Particle formation in spray drying. J. Aerosol Sci. 2007, 38, 728–746. [Google Scholar] [CrossRef]

- Goddeeris, C.; Van den Mooter, G. Free flowing solid dispersions of the anti-HIV drug UC 781 with Poloxamer 407 and a maximum amount of TPGS 1000: Investigating the relationship between physicochemical characteristics and dissolution behaviour. Eur. J. Pharm. Sci. 2008, 35, 104–113. [Google Scholar] [CrossRef]

- Ramesh, K.; Shekar, B.C.; Khadgapathi, P. Formulation and evaluation of poorly soluble Etravirine by spray drying method. Int. J. Pharm. Pharm. Sci. 2015, 7, 98–103. [Google Scholar]

- Wagner, C.M.; Pein, M.; Breitkreutz, J. Roll compaction of mannitol: Compactability study of crystalline and spray-dried grades. Int. J. Pharm. 2013, 453, 416–422. [Google Scholar] [CrossRef] [PubMed]

- Angi, R.; Solymosi, T.; Erdősi, N.; Jordán, T.; Kárpáti, B.; Basa-Dénes, O.; Ujhelyi, A.; McDermott, J.; Roe, C.; Mair, S. Preparation, Pre-clinical and Clinical Evaluation of a Novel Rapidly Absorbed Celecoxib Formulation. AAPS PharmSciTech 2019, 20, 90. [Google Scholar] [CrossRef] [PubMed]

- Hao, S.; Wang, Y.; Wang, B.; Deng, J.; Zhu, L.; Cao, Y. Formulation of porous poly(lactic-co-glycolic acid) microparticles by electrospray deposition method for controlled drug release. Mat. Sci. Eng. C 2014, 39, 113–119. [Google Scholar] [CrossRef] [PubMed]

- Olusanmi, D.; Jayawickrama, D.; Bu, D.; McGeorge, G.; Sailes, H.; Kelleher, J.; Gamble, J.F.; Shah, U.V.; Tobyn, M. A control strategy for bioavailability enhancement by size reduction: Effect of micronization conditions on the bulk, surface and blending characteristics of an active pharmaceutical ingredient. Powder Technol. 2014, 258, 222–233. [Google Scholar] [CrossRef]

- Han, X.; Ghoroi, C.; Davé, R. Dry coating of micronized API powders for improved dissolution of directly compacted tablets with high drug loading. Int. J. Pharm. 2013, 442, 74–85. [Google Scholar] [CrossRef]

- Mullarney, M.P.; Beach, L.E.; Davé, R.N.; Langdon, B.A.; Polizzi, M.; Blackwood, D.O. Applying dry powder coatings to pharmaceutical powders using a comil for improving powder flow and bulk density. Powder Technol. 2011, 212, 397–402. [Google Scholar] [CrossRef]

- Elversson, J.; Millqvist-Fureby, A. In situ coating—An approach for particle modification and encapsulation of proteins during spray-drying. Int. J. Pharm. 2006, 323, 52–63. [Google Scholar] [CrossRef]

- Vass, P.; Démuth, B.; Farkas, A.; Hirsch, E.; Szabó, E.; Nagy, B.; Andersen, S.K.; Vigh, T.; Verreck, G.; Csontos, I.; et al. Continuous alternative to freeze drying: Manufacturing of cyclodextrin-based reconstitution powder from aqueous solution using scaled-up electrospinning. J. Control. Release 2019, 298, 120–127. [Google Scholar] [CrossRef]

- Jallo, L.J.; Dave, R.N. Explaining electrostatic charging and flow of surface-modified acetaminophen powders as a function of relative humidity through surface energetics. J. Pharm. Sci. 2015, 104, 2225–2232. [Google Scholar] [CrossRef]

- Coperion. Feeders. Available online: http://www.coperion.com/en/products-services/process-equipment/feeders/ (accessed on 8 May 2019).

- Brabender-Technologie. Available online: http://www.brabender-Technologie.com/ (accessed on 8 May 2019).

- Técnicas de Alimentación Dinámica. Available online: http://tad-en.com/ (accessed on 8 May 2019).

- Hopkins, M. Loss in weight feeder systems. Meas. Control. 2006, 39, 237–240. [Google Scholar] [CrossRef] [Green Version]

- Ricciardi, R.J.; Laidlaw, J.S. Materials Feeding System with Level Sensing Probe and Method for Automatic Bulk Density Determination. US5423455A, 13 June 1995. [Google Scholar]

- Bhattachar, S.N.; Hedden, D.B.; Olsofsky, A.M.; Qu, X.; Hsieh, W.-Y.; Canter, K.G. Evaluation of the vibratory feeder method for assessment of powder flow properties. Int. J. Pharm. 2004, 269, 385–392. [Google Scholar] [CrossRef] [PubMed]

- Ola, D.; Popescu, S. Considerations regarding the accuracy of dosing equipments for agro-foods bulk solids that use vibratory feeding systems. Bull. Transilv. Univ. Bras. Wood Ind. Agric. Food Eng. Ser. II 2009, 2, 99. [Google Scholar]

- Al Sayyad, T.; Pershin, V.; Pasko, A.; Pasko, T. Virtual modelling of particles two-Step feeding. J. Phys. Conf. Ser. 2017, 1084, 012005. [Google Scholar] [CrossRef] [Green Version]

- Besenhard, M.; Karkala, S.; Faulhammer, E.; Fathollahi, S.; Ramachandran, R.; Khinast, J. Continuous feeding of low-dose APIs via periodic micro dosing. Int. J. Pharm. 2016, 509, 123–134. [Google Scholar] [CrossRef] [Green Version]

- Engisch, W.E.; Muzzio, F.J. Feedrate deviations caused by hopper refill of loss-in-weight feeders. Powder Technol. 2015, 283, 389–400. [Google Scholar] [CrossRef]

- Hanson, J. Control of a system of loss-in-weight feeders for drug product continuous manufacturing. Powder Technol. 2018, 331, 236–243. [Google Scholar] [CrossRef]

| Property | Impact | Measuring | Ref. |

|---|---|---|---|

| Particle size and shape distribution | Flowability increases with increase in particle size; Spherical shape results in favorable flow properties | Sieve tower; Microscopy and image analysis; Scanning electron microscopy; Laser diffraction | [97,98,99] |

| Bulk density | Hausner ratio and Carr’s index can be determined based on bulk and tapped densities; With increasing Hausner ratio, the flowability decreases; Decreasing Carr’s index means an increase in the flow | Tapping machine; Dynamical tap density tester; Powder rheometer | [100,101] |

| Surface area | With increasing specific surface area, the flowability decreases in general | Pycnometer; | [102,103] |

| Surface energy | Increased surface energy leads to poor flowability | Inverse gas chromatography for separation and mass spectrometry for detection | [104,105] |

| Flow | Higher flow rate indicates higher flowability | Flow through an orifice | [106] |

| Cohesiveness | High cohesiveness allows the powder bed to be compressed easily and the flowability is poor; The cohesive index quantifies the extent of deviation from an ideal conically shaped heap | Powder rheometer; Granular material heap analyzer | [107,108] |

| Internal and wall friction | Effective angle of internal friction influences many aspects related to flow behavior, e.g., risk of arching and risk of segregation due to unwanted flow patterns; The higher the wall friction angle the more difficult it is to move the powder along the wall surface (the worse the flowability) | Shear cells | [109,110] |

| Static charge | Static charge compromises the free-flowing of the powders | Charging device; Faraday cup; Granular material electric charge analyzer | [111,112] |

| Hygroscopicity | Lower hygroscopicity results in better flowability | Dynamic vapor sorption; Loss on drying | [113,114,115] |

| Feeder Type | Powders |

|---|---|

| Loss-in-Weight Belt Feeders | Fragile products; Powders with special characteristics |

| Vibratory Feeders | Fragile ingredients; Fibers; Glass fibers; Rough-grained powders; Granules |

| Bulk Solids Pump Feeders | Free-flowing pellets; Granules; Flakes; Friable products |

| Twin Screw Feeders | Sticky, bridging or flooding powders; Fibers; Glass fibers |

| Single Screw Feeders | Pellets; Other free-flowing bulk materials |

| Smart Weight Belt Feeders | Large volume of powders with different flow characteristics |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Szabó, E.; Démuth, B.; Galata, D.L.; Vass, P.; Hirsch, E.; Csontos, I.; Marosi, G.; Nagy, Z.K. Continuous Formulation Approaches of Amorphous Solid Dispersions: Significance of Powder Flow Properties and Feeding Performance. Pharmaceutics 2019, 11, 654. https://doi.org/10.3390/pharmaceutics11120654

Szabó E, Démuth B, Galata DL, Vass P, Hirsch E, Csontos I, Marosi G, Nagy ZK. Continuous Formulation Approaches of Amorphous Solid Dispersions: Significance of Powder Flow Properties and Feeding Performance. Pharmaceutics. 2019; 11(12):654. https://doi.org/10.3390/pharmaceutics11120654

Chicago/Turabian StyleSzabó, Edina, Balázs Démuth, Dorián László Galata, Panna Vass, Edit Hirsch, István Csontos, György Marosi, and Zsombor K. Nagy. 2019. "Continuous Formulation Approaches of Amorphous Solid Dispersions: Significance of Powder Flow Properties and Feeding Performance" Pharmaceutics 11, no. 12: 654. https://doi.org/10.3390/pharmaceutics11120654

APA StyleSzabó, E., Démuth, B., Galata, D. L., Vass, P., Hirsch, E., Csontos, I., Marosi, G., & Nagy, Z. K. (2019). Continuous Formulation Approaches of Amorphous Solid Dispersions: Significance of Powder Flow Properties and Feeding Performance. Pharmaceutics, 11(12), 654. https://doi.org/10.3390/pharmaceutics11120654